Search results for: 'electron 0'

- Related search terms

- Electronic tr

- electron'[0]

- electronic co

- electron d 0

- electronic c

-

TT-1684 SML EXTRUDER, WIDTH 2000mm, YEAR 2016TT-1684 SML EXTRUDER, WIDTH 2000mm, YEAR 2016 QUANTITY: 1 Learn More

TT-1684 SML EXTRUDER, WIDTH 2000mm, YEAR 2016TT-1684 SML EXTRUDER, WIDTH 2000mm, YEAR 2016 QUANTITY: 1 Learn More -

TT-1640 SAVIO GEMINIS TWISTING MACHINE, YEAR 1998 TO 2005TT-1640 SAVIO GEMINIS TWISTING MACHINE, YEAR 1998 TO 2005 SAVIO GEMINIS TWISTING MACHINE YEAR: 1998 TO 2005 380V 50Hz QUANTITY: 16 Learn More

TT-1640 SAVIO GEMINIS TWISTING MACHINE, YEAR 1998 TO 2005TT-1640 SAVIO GEMINIS TWISTING MACHINE, YEAR 1998 TO 2005 SAVIO GEMINIS TWISTING MACHINE YEAR: 1998 TO 2005 380V 50Hz QUANTITY: 16 Learn More -

YY-2227 USED KUSTER PAD BATCH DYEING PLANT, WORKING WIDTH 2000mmYY-2227 USED KUSTER PAD BATCH DYEING PLANT, WORKING WIDTH 2000mm USED CPB-DYEING PLANT ACCORDING TO TYPE 222.11 QUANTITY: 1 CONSISTING OF 2-BOWL DYEING PADDER MAKE: EDUARD KUSTERS TYPE: 222.11 YEAR: COMPL. REFURBISHED BEFORE DELIVERY TECHNICAL DATA: WORKING WIDTH: 2000mm; ROLLER FACE WIDTH: 2200mm; DRIVE SIDE: RIGHT; SERVICE SIDE: LEFT; PRESSURE: 50 KP/CM; TOTAL PRESSURE: 10 TO / 100 NM; SPEED: 60 M/MIN; POWER: 5.5KW; VOLTAGE: 3 X 400 V, 50Hz; AIR CONNECTION: 6 BARS LOCALLY; COLOR OF PAINT: ACCORDING TO AGREEMENT. Learn More

YY-2227 USED KUSTER PAD BATCH DYEING PLANT, WORKING WIDTH 2000mmYY-2227 USED KUSTER PAD BATCH DYEING PLANT, WORKING WIDTH 2000mm USED CPB-DYEING PLANT ACCORDING TO TYPE 222.11 QUANTITY: 1 CONSISTING OF 2-BOWL DYEING PADDER MAKE: EDUARD KUSTERS TYPE: 222.11 YEAR: COMPL. REFURBISHED BEFORE DELIVERY TECHNICAL DATA: WORKING WIDTH: 2000mm; ROLLER FACE WIDTH: 2200mm; DRIVE SIDE: RIGHT; SERVICE SIDE: LEFT; PRESSURE: 50 KP/CM; TOTAL PRESSURE: 10 TO / 100 NM; SPEED: 60 M/MIN; POWER: 5.5KW; VOLTAGE: 3 X 400 V, 50Hz; AIR CONNECTION: 6 BARS LOCALLY; COLOR OF PAINT: ACCORDING TO AGREEMENT. Learn More -

TT-1593 THERMAL OXIDIZERSTT-1593 THERMAL OXIDIZERS THERMAL OXIDIZERS DESIGNED TO INCINERATE TWO SOLVENT LADEN GAS STREAMS USING A SMALL AMOUNT OF NATURAL GAS WITH ELECTRONIC CONTROLS QUANTITY: 1 Learn More

TT-1593 THERMAL OXIDIZERSTT-1593 THERMAL OXIDIZERS THERMAL OXIDIZERS DESIGNED TO INCINERATE TWO SOLVENT LADEN GAS STREAMS USING A SMALL AMOUNT OF NATURAL GAS WITH ELECTRONIC CONTROLS QUANTITY: 1 Learn More -

TT-1552 SML TRI COLOR BCF MACHINE ALONG WITH SUPERBA HEAT SETTING LINE, YEAR 1994 TO 2002TT-1552 SML TRI COLOR BCF MACHINE ALONG WITH SUPERBA HEAT SETTING LINE, YEAR 1994 TO 2002 ITEM 001 COMPLETE BARMAG BCF PLANT TYPE STM 16 PP, YEAR 1994 QUANTITY: 1 ITEM 002 11 BAR BROOMWADE AIR COMPRESSORS (193KW EACH) COMPLETE ELECTRICAL PANEL SETUP QUANTITY: 2 ITEM 003 RIETER CABLING MACHINES (CD/DT 510), YEAR 2002 120 SPINDLES EACH QUANTITY: 2 ITEM 004 SUPERBA HEAT SET PLANT, TYPE TVP2S, YEAR 2000 QUANTITY: 1 ITEM 005 EVILO REWINDERS, YEAR 1999 2 WINDING HEADS PER MACHINE QUANTITY: 2 ITEM 006 KARL MAYER REWINDER, YEAR 1999 2 WINDING HEADS QUANTITY: 1 LAB AND TEST EQUIPMENT STATUS: STOPPED DELIVERY: AT SHORT NOTICE QUANTITY: 1 Learn More

TT-1552 SML TRI COLOR BCF MACHINE ALONG WITH SUPERBA HEAT SETTING LINE, YEAR 1994 TO 2002TT-1552 SML TRI COLOR BCF MACHINE ALONG WITH SUPERBA HEAT SETTING LINE, YEAR 1994 TO 2002 ITEM 001 COMPLETE BARMAG BCF PLANT TYPE STM 16 PP, YEAR 1994 QUANTITY: 1 ITEM 002 11 BAR BROOMWADE AIR COMPRESSORS (193KW EACH) COMPLETE ELECTRICAL PANEL SETUP QUANTITY: 2 ITEM 003 RIETER CABLING MACHINES (CD/DT 510), YEAR 2002 120 SPINDLES EACH QUANTITY: 2 ITEM 004 SUPERBA HEAT SET PLANT, TYPE TVP2S, YEAR 2000 QUANTITY: 1 ITEM 005 EVILO REWINDERS, YEAR 1999 2 WINDING HEADS PER MACHINE QUANTITY: 2 ITEM 006 KARL MAYER REWINDER, YEAR 1999 2 WINDING HEADS QUANTITY: 1 LAB AND TEST EQUIPMENT STATUS: STOPPED DELIVERY: AT SHORT NOTICE QUANTITY: 1 Learn More -

TT-1585 ACRYLIC SPINNING PLANT, YEAR 2001 TO 2007TT-1585 ACRYLIC SPINNING PLANT, YEAR 2001 TO 2007 DISMANTLED, READY FOR SHIPPING REQUIRES 20 TO 22 40 FOOT HIGH CUBE CONTAINERS TO SHIP Learn More

TT-1585 ACRYLIC SPINNING PLANT, YEAR 2001 TO 2007TT-1585 ACRYLIC SPINNING PLANT, YEAR 2001 TO 2007 DISMANTLED, READY FOR SHIPPING REQUIRES 20 TO 22 40 FOOT HIGH CUBE CONTAINERS TO SHIP Learn More -

TT-1560 TRUTZSCHLER MULTIMIXER JUMBO SIZE MPM10, CAPACITY 1 TON PER HOUR, YEAR OVERHAULED 2014TT-1560 TRUTZSCHLER MULTIMIXER JUMBO SIZE MPM10, CAPACITY 1 TON PER HOUR, YEAR OVERHAULED 2014 MACHINE UPDATED ON YEAR 2014 WITH ALL ELECTRIC/ELECTRONIC ELEMENTS NEW, PLC AND TOUCH SCREEN TO SIMPLIFY QUANTITY: 1 Learn More

TT-1560 TRUTZSCHLER MULTIMIXER JUMBO SIZE MPM10, CAPACITY 1 TON PER HOUR, YEAR OVERHAULED 2014TT-1560 TRUTZSCHLER MULTIMIXER JUMBO SIZE MPM10, CAPACITY 1 TON PER HOUR, YEAR OVERHAULED 2014 MACHINE UPDATED ON YEAR 2014 WITH ALL ELECTRIC/ELECTRONIC ELEMENTS NEW, PLC AND TOUCH SCREEN TO SIMPLIFY QUANTITY: 1 Learn More -

TT-1566 SANTEX SANTACOMPACT 240 OPEN WIDTH COMPACTOR, WORKING WIDTH 2400mm, YEAR 2004 RENOVATED 2019TT-1566 SANTEX SANTACOMPACT 240 OPEN WIDTH COMPACTOR, WORKING WIDTH 2400mm, YEAR 2004 RENOVATED 2019 VERY GOOD WORKING CONDITION QUANTITY: 1 Learn More

TT-1566 SANTEX SANTACOMPACT 240 OPEN WIDTH COMPACTOR, WORKING WIDTH 2400mm, YEAR 2004 RENOVATED 2019TT-1566 SANTEX SANTACOMPACT 240 OPEN WIDTH COMPACTOR, WORKING WIDTH 2400mm, YEAR 2004 RENOVATED 2019 VERY GOOD WORKING CONDITION QUANTITY: 1 Learn More -

YY-2215 USED GRANUTECH SATURN MODEL 62-40 HT DUAL SHAFT SHREDDER, CUTTER DIAMETER 20.5" AT HOOKSYY-2215 USED GRANUTECH SATURN MODEL 62-40 HT DUAL SHAFT SHREDDER, CUTTER DIAMETER 20.5" AT HOOKS INLET 55" X 38"; OUTSIDE DIMENSIONS ARE 130" X 61" X 43"; POWER UNIT DIMENSIONS ARE 96" X 86" X 96"; WEIGHT IS 20.000 LBS; POWER UNIT IS 8000 LBS (DRY); CUTTER SHAFT TORQUE: FAST 64.776 FT/LBS, TORQUE: SLOW 78.653 FT/LBS; CUTTER SHAFT SPEED: FAST 22, SPEED: SLOW 18; CUTTER FORCE FAST: 77.732 LBS, SLOW: 94.383 LBS; CUTTER DIAMETER 20.5" AT HOOKS; POWER UNIT OPEN LOOP, SKID MOUNTED; ELECTRICAL POWER 200 HP (2 X 100) (OPTIONAL 150-300HP); HYDRAULIC FLOW 156 GPM; QUANTITY: 1 Learn More

YY-2215 USED GRANUTECH SATURN MODEL 62-40 HT DUAL SHAFT SHREDDER, CUTTER DIAMETER 20.5" AT HOOKSYY-2215 USED GRANUTECH SATURN MODEL 62-40 HT DUAL SHAFT SHREDDER, CUTTER DIAMETER 20.5" AT HOOKS INLET 55" X 38"; OUTSIDE DIMENSIONS ARE 130" X 61" X 43"; POWER UNIT DIMENSIONS ARE 96" X 86" X 96"; WEIGHT IS 20.000 LBS; POWER UNIT IS 8000 LBS (DRY); CUTTER SHAFT TORQUE: FAST 64.776 FT/LBS, TORQUE: SLOW 78.653 FT/LBS; CUTTER SHAFT SPEED: FAST 22, SPEED: SLOW 18; CUTTER FORCE FAST: 77.732 LBS, SLOW: 94.383 LBS; CUTTER DIAMETER 20.5" AT HOOKS; POWER UNIT OPEN LOOP, SKID MOUNTED; ELECTRICAL POWER 200 HP (2 X 100) (OPTIONAL 150-300HP); HYDRAULIC FLOW 156 GPM; QUANTITY: 1 Learn More -

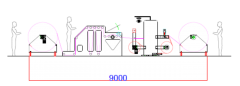

YY-2212 PERFORATING LINE, USEFUL WORKING WIDTH 1800mmYY-2212 PERFORATING LINE, USEFUL WORKING WIDTH 1800mm GENERAL TECHNICAL FEATURES: USEFUL WORKING WIDTH: 1800mm; MAXIMUM DIAMETER OF THE ROLL TO BE UNWOUND: mm. 1550 (FOAM) / 1550 (FABRIC); MAXIMUM ROLL WEIGHT: 200KG; ADJUSTABLE MECHANICAL SPEED: 400 STROKES PER MINUTE; APPROXIMATE PRODUCTION SPEED (DEPENDING ON THE TYPE OF MATERIAL AND DRILLING): M/MIN 3/6; POWER DISCHARGED ON CM: TON 120000; THREE-PHASE PRIMARY VOLTAGE + EARTH: V/Hz 380/400+E/50 Hz; INSTALLED POWER OF THE MOTORS: 26KW; AC MOTORS, ELECTRIC DRIVES, ELECTRIC CABLES AND WIRING, ARE ACCORDING TO CEI STANDARDS; EPOXY PAINTING; THE MACHINES ARE AUTOMATICALLY SYNCHRONIZED BY MEANS OF ELECTRONIC DRIVES "INVERTER" A.C. MOTORS, PNEUMATIC DANCER ROLLERS (COMPENSATORS) AND LOAD CELLS. QUANTITY: 1 Learn More

YY-2212 PERFORATING LINE, USEFUL WORKING WIDTH 1800mmYY-2212 PERFORATING LINE, USEFUL WORKING WIDTH 1800mm GENERAL TECHNICAL FEATURES: USEFUL WORKING WIDTH: 1800mm; MAXIMUM DIAMETER OF THE ROLL TO BE UNWOUND: mm. 1550 (FOAM) / 1550 (FABRIC); MAXIMUM ROLL WEIGHT: 200KG; ADJUSTABLE MECHANICAL SPEED: 400 STROKES PER MINUTE; APPROXIMATE PRODUCTION SPEED (DEPENDING ON THE TYPE OF MATERIAL AND DRILLING): M/MIN 3/6; POWER DISCHARGED ON CM: TON 120000; THREE-PHASE PRIMARY VOLTAGE + EARTH: V/Hz 380/400+E/50 Hz; INSTALLED POWER OF THE MOTORS: 26KW; AC MOTORS, ELECTRIC DRIVES, ELECTRIC CABLES AND WIRING, ARE ACCORDING TO CEI STANDARDS; EPOXY PAINTING; THE MACHINES ARE AUTOMATICALLY SYNCHRONIZED BY MEANS OF ELECTRONIC DRIVES "INVERTER" A.C. MOTORS, PNEUMATIC DANCER ROLLERS (COMPENSATORS) AND LOAD CELLS. QUANTITY: 1 Learn More