Search results for: 'heat+t'

- Related search terms

- heat+tunnel

- heat+tap

- heat+tape

- heat+tap'[0]

-

TT-7630 API SCHMIDT-BRETTEN FLASH PASTEURISER, YEAR 1991TT-7630 API SCHMIDT-BRETTEN FLASH PASTEURISER, YEAR 1991 1. API SCHMIDT-BRETTEN FLASH PASTEURISER 2. BRAND: API SCHMIDT-BRETTEN GMBH CO. KG 3. CONDITION: USED 4. MACHINE TYPE: FLASH PASTEURISER 5. YEAR OF CONSTRUCTION: 1991 6. CONDITION: USED QUANTITY: 1 Learn More

TT-7630 API SCHMIDT-BRETTEN FLASH PASTEURISER, YEAR 1991TT-7630 API SCHMIDT-BRETTEN FLASH PASTEURISER, YEAR 1991 1. API SCHMIDT-BRETTEN FLASH PASTEURISER 2. BRAND: API SCHMIDT-BRETTEN GMBH CO. KG 3. CONDITION: USED 4. MACHINE TYPE: FLASH PASTEURISER 5. YEAR OF CONSTRUCTION: 1991 6. CONDITION: USED QUANTITY: 1 Learn More -

TT-7932 BERGEN B32-46, 5765KW, 60Hz 10000 HOURS, YEAR 2008TT-7932 BERGEN B32-46, 5765KW, 60Hz 10000 HOURS, YEAR 2008 1. BERGEN B32-46 2. 5765KW 3. 60Hz 4. 10000 HOURS QUANTITY: 2 Learn More

TT-7932 BERGEN B32-46, 5765KW, 60Hz 10000 HOURS, YEAR 2008TT-7932 BERGEN B32-46, 5765KW, 60Hz 10000 HOURS, YEAR 2008 1. BERGEN B32-46 2. 5765KW 3. 60Hz 4. 10000 HOURS QUANTITY: 2 Learn More -

TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024 1. MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET 2. 1 UNIT 400 V 3. 2 UNITS 6.3 KV Learn More

TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024 1. MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET 2. 1 UNIT 400 V 3. 2 UNITS 6.3 KV Learn More -

TT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATORTT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATOR QUANTITY: 10 Learn More

TT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATORTT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATOR QUANTITY: 10 Learn More -

TT-5803 COGENERATION PLANT, 3.2 MW, YEAR 2009TT-5803 COGENERATION PLANT, 3.2 MW, YEAR 2009 COGENERATION PLANT 3.2 MW USED QUANTITY: 1 Learn More

TT-5803 COGENERATION PLANT, 3.2 MW, YEAR 2009TT-5803 COGENERATION PLANT, 3.2 MW, YEAR 2009 COGENERATION PLANT 3.2 MW USED QUANTITY: 1 Learn More -

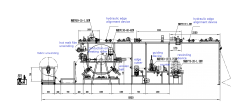

J-3175 HOT MELT FILM LAMINATING MACHINE FOR PLAIN WOVEN FABRICJ-3175 HOT MELT FILM LAMINATING MACHINE FOR PLAIN WOVEN FABRIC MACHINE SPEED: 20 TO 40 METERS PER MINUTE ESTIMATED MACHINE DIMENSIONS: 8850mm x 2450mm x 2200mm (L*W*H) ESTIMATED MACHINE WEIGHT: 6000 KG MOTOR BRAND: SIEMENS ELECTRIC BRAND: SCHNEIDER QUANTITY: 1 Learn More

J-3175 HOT MELT FILM LAMINATING MACHINE FOR PLAIN WOVEN FABRICJ-3175 HOT MELT FILM LAMINATING MACHINE FOR PLAIN WOVEN FABRIC MACHINE SPEED: 20 TO 40 METERS PER MINUTE ESTIMATED MACHINE DIMENSIONS: 8850mm x 2450mm x 2200mm (L*W*H) ESTIMATED MACHINE WEIGHT: 6000 KG MOTOR BRAND: SIEMENS ELECTRIC BRAND: SCHNEIDER QUANTITY: 1 Learn More -

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More -

A-2591 100L/200L HOMOGENIZING AND MIXING TANK (NEW)A-2591 100L/200L HOMOGENIZING AND MIXING TANK (NEW) 100L HOMOGENIZING AND MIXING TANK (BOTTOM HOMOGENIZER & BUTTON CONTROL) • DESIGN CAPACITY: 125 L, WORKING CAPACITY: 100 L • ELECTRIC HEATING • MIXING: FIXED STIRRER + WALL - SCRATCHING AGITATOR + PTFE BLADES POWER: 2.2 KW, SIEMENS JV BRAND • FREQUENCY SPEED ADJUSTABLE, 0 TO 63 RPM, DELTA ORIGINAL BRAND • HOMOGENIZING: BOTTOM CENTER INSERT HIGH SHEAR HOMOGENIZER POWER: 4 KW FREQUENCY SPEED ADJUSTABLE: 0 TO 3000 RPM, DELTA ORIGINAL BRAND • ROTOR AND STATER INCORPORATES WIRE - CUTTING FINISH MACHINING, POLISHING TREATMENT BEFORE ASSEMBLY, AXIS INCORPORATE DYNAMIC BALANCE PROCESSING • BUTTON CONTROL, WATER - PROOF ELECTRICITY CONTROL BOX • ALL MOTOR: EX – PROOF QUANTITY: 1 SET 200L HOMOGENIZING AND MIXING TANK (BOTTOM HOMOGENIZER & BUTTON CONTROL) • DESIGN CAPACITY: 250 L WORKING CAPACITY: 200 L • ELECTRIC HEATING • MIXING: FIXED STIRRER + WALL - SCRATCHING AGITATOR + PTFE BLADES • POWER: 2.2 KW, SIEMENS JV BRAND • FREQUENCY SPEED ADJUSTABLE, 0 TO 63 RPM, DELTA ORIGINAL BRAND • HOMOGENIZING: BOTTOM CENTER INSERT HIGH SHEAR HOMOGENIZER • POWER: 4 KW • FREQUENCY SPEED ADJUSTABLE: 0 TO 3000 RPM, DELTA ORIGINAL BRAND • ROTOR AND STATER INCORPORATES WIRE - CUTTING FINISH MACHINING, POLISHING TREATMENT BEFORE ASSEMBLY, AXIS INCORPORATE DYNAMIC BALANCE PROCESSING • BUTTON CONTROL, WATER - PROOF ELECTRICITY CONTROL BOX • ALL MOTOR:EX-PROOF QUANTITY: 1 SET Learn More

A-2591 100L/200L HOMOGENIZING AND MIXING TANK (NEW)A-2591 100L/200L HOMOGENIZING AND MIXING TANK (NEW) 100L HOMOGENIZING AND MIXING TANK (BOTTOM HOMOGENIZER & BUTTON CONTROL) • DESIGN CAPACITY: 125 L, WORKING CAPACITY: 100 L • ELECTRIC HEATING • MIXING: FIXED STIRRER + WALL - SCRATCHING AGITATOR + PTFE BLADES POWER: 2.2 KW, SIEMENS JV BRAND • FREQUENCY SPEED ADJUSTABLE, 0 TO 63 RPM, DELTA ORIGINAL BRAND • HOMOGENIZING: BOTTOM CENTER INSERT HIGH SHEAR HOMOGENIZER POWER: 4 KW FREQUENCY SPEED ADJUSTABLE: 0 TO 3000 RPM, DELTA ORIGINAL BRAND • ROTOR AND STATER INCORPORATES WIRE - CUTTING FINISH MACHINING, POLISHING TREATMENT BEFORE ASSEMBLY, AXIS INCORPORATE DYNAMIC BALANCE PROCESSING • BUTTON CONTROL, WATER - PROOF ELECTRICITY CONTROL BOX • ALL MOTOR: EX – PROOF QUANTITY: 1 SET 200L HOMOGENIZING AND MIXING TANK (BOTTOM HOMOGENIZER & BUTTON CONTROL) • DESIGN CAPACITY: 250 L WORKING CAPACITY: 200 L • ELECTRIC HEATING • MIXING: FIXED STIRRER + WALL - SCRATCHING AGITATOR + PTFE BLADES • POWER: 2.2 KW, SIEMENS JV BRAND • FREQUENCY SPEED ADJUSTABLE, 0 TO 63 RPM, DELTA ORIGINAL BRAND • HOMOGENIZING: BOTTOM CENTER INSERT HIGH SHEAR HOMOGENIZER • POWER: 4 KW • FREQUENCY SPEED ADJUSTABLE: 0 TO 3000 RPM, DELTA ORIGINAL BRAND • ROTOR AND STATER INCORPORATES WIRE - CUTTING FINISH MACHINING, POLISHING TREATMENT BEFORE ASSEMBLY, AXIS INCORPORATE DYNAMIC BALANCE PROCESSING • BUTTON CONTROL, WATER - PROOF ELECTRICITY CONTROL BOX • ALL MOTOR:EX-PROOF QUANTITY: 1 SET Learn More -

TT-1744 WARTSILA 18V32 HFO GENERATOR, 6MW, 50Hz, 6.6KVTT-1744 WARTSILA 18V32 HFO GENERATOR, 6MW, 50Hz, 6.6KV WARTSILA 18V32 HFO GENERATOR 6MW HOURS: 4175H, 3784H ALTERNATORS: JYOTI LTD, LEROY SOMER 50Hz 6.6KV QUANTITY: 2 Learn More

TT-1744 WARTSILA 18V32 HFO GENERATOR, 6MW, 50Hz, 6.6KVTT-1744 WARTSILA 18V32 HFO GENERATOR, 6MW, 50Hz, 6.6KV WARTSILA 18V32 HFO GENERATOR 6MW HOURS: 4175H, 3784H ALTERNATORS: JYOTI LTD, LEROY SOMER 50Hz 6.6KV QUANTITY: 2 Learn More -

R-6856 FUTURA K AUTOMATIC ROASTING MACHINES

R-6856 FUTURA K AUTOMATIC ROASTING MACHINESR-6856 FUTURA K AUTOMATIC ROASTING MACHINES

AUTOMATIC ROASTING MACHINES RESULT OF LONG STUDIES AND LIVED EXPERIENCE.

THE ROASTING MACHINES SERIES FUTURA K ARE THE RESULT OF LONG STUDIES AND LIVED EXPERIENCE ALONGSIDE OUR CLIENTS COFFEE ROASTERS, FOR THE REALIZATION OF THE MOST ADVANCED MACHINERIES IN THE FIELD OF INDUSTRIAL COFFEE ROASTING.

THE COMPACT DIMENSIONS, RELIABILITY OF THE MATERIALS AND COMPONENTS, THERMAL MANAGEMENT WITH IMMEDIATE RESPONSE, CALIBRATED AND PARTICULARLY FUEL EFFICIENT, HIGH THERMAL AND ACOUSTIC INSULATION AND OTHER POSITIVE FEATURES, MAKE THESE MACHINES REFERENCEGUIDE IN PROFESSIONAL ROASTING FIELD.MAIN COMPONENTS:

FEEDING HOPPER INSULATED WITH PNEUMATIC FILLER DEVICE, MOVABLE INLET, ELECTROPNEUMATIC UNLOADING CONTROL.

ROASTING DRUM MADE BY A FIXED HOUSING WITH DOUBLE INSULATING WALLS FOR THERMAL PROTECTION AND SUPPORTING THE ROTARY CYCLINDER THAT MOVES THE PRODUCT. THE WHOLE CYCLINDER IS MADE OF COMPOUND STEEL TO WITHSTAND THERMAL SHOCKS, ABSOLUTELY ODOURLESS, WITH PERFORATED SHEET FOR PRODUCT CONTAINEMENT, RIGHT AND LEFT BLENDERS SETTLED AT DIFFERENT LEVELS TO OBTAIN PERFECT MIXTURE.

WHEN THE ROASTING PROCESS IS FINISHED, THE COFFEE IS UNLOADED THROUGH A LARGE DOOR WITH ELECTROPNEUMATIC CONTROL OF OPENING AND CLOSING.

THE HEATING GENERATOR IS SPECIFICALLY DESIGNED FOR ROASTING LINE APPLICATIONS. THE PRINCIPLE OF HEATING IS BASED ON HOT AIR FLOWS BY CONVECTION. GAS OR GASOIL BURNER TYPE MODULATING OR MULTI LEVEL- FLAMES ACCORDING THE APPLICATION.

COOLING TANK WITH LARGE STAINLESS STEEL SURFACE, SELF CLEANING, WHERE THE PRODUCT IS MOVED BY MEANS OF 4 CROSSED ARMS. TWO DISCHARGES: ONE IS ELECTROPNEUMATICALLY DRIVEN AND THE OTHER IS MANUAL FOR EMERGENCY. DOOR OF INSPECTION AND EASY CLEANING OF THE LOWER SIDE.

PELLICLES SEPARATOR WITH EXTRACTION, BY WORM CONVEYOR OR INCINERATOR FOR CONSTANT EFFICIENCY OF THE AIR CHAFFS SEPARATION SYSTEM.

SUPPORTING FRAME IN TUBULAR PROFILES, STEEL MADE, TO CONTAIN AND SUPPORT THE OPERATING DEVICES, SO TO OBTAIN A COMPACT MACHINE-LIMITED ENCUMBRANCE, COMPLETE WITH PANELS FOR HEATING AND NOISE CONTAINMENT.

INDEPENDENT ELECTRIC CONTROL BOARD WITH PLC + TOUCH SCREEN AND ALL DEVICES FOR MACHINE CONTROL AND

MANAGEMENT, CAREFULLY WIRED AND EQUIPPED WITH ALL SIGNALS USEFULL FOR ROASTING PROCESS.STANDARD EQUIPMENT:

AUTOMATIC ROASTING SYSTEM MANAGED BY PLC + TOUCH SCREEN WITH RECORDING FOR ROASTING CURVES – PROFILES.

VISUALIZATION BY MONITOR OF TEMPERATURES AND ROASTING FUNTIONS.

FIRE PREVENTION EQUIPMENT ON THE ROASTING DRUM AND COOLING TANK; ON THE CYCLONE-CHAFFS SEPARATOR IF EQUIPPED WITH WORM CONVEYOR FOR CHAFFS EXTRACTION.

ALARM SYSTEM BY BUZZER AND SIGNAL LAMP, UPON INTERVENTION OF THE OVERLOAD PROTECTION DEVICES ON THE ELECTRIC-MOTORS AND ON THE BURNER.

PROTECTING SAFETY SYSTEMS.

CYCLONE FOR COOLING TANK: STANDARD ON MOD. 240-300- 360-480.

OPTIONALS EQUIPMENTCOMPUTERIZED AUTOMATIC ROASTING PROCESS CARP MANAGED BY PC AND MONITOR.

Learn More

HEATING RECOVERY SYSTE

SMOKE BURNER TYPE THERMICAL AND/OR CATALYST

CLEAN AIR ROASTING SYSTEM

CHAFFS COMPACTOR.