Search results for: 'polye'

- Related search terms

- polyester machine

- polyester STAPLE FIBER LINE

- POLYES

- polyester FIBER'

- Polyester processing

-

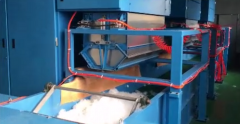

FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60HzREFERENCE NUMBER: T-6869 FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60Hz FEED HOPPER WITH LONG EXTENDED APRON 1500mm FEED HOPPER MODEL: OP-B POWER: 3.6KW FILLING CAPACITY: 800KG/H LAYOUT: 5940 X 1600 X 2200mm WEIGHT: 3200KG WORKING WIDTH: 1500mm VOLTAGE: 440V 60Hz 3 PHASES (AS PER ORDER) AIR PRESSURE: 0.6 TO 0.8MPA MAIN STRUCTURE: MADE BY COMPUTERIZED LASER CUTTING MACHINE ELECTRICITY: KEY PARTS ARE WORLD FAMOUS BRAND, OMRON, SCHNEIDER. BEARING: SKF SPRAY: RUST-PROOF PRETREATMENT AND ELECTROSTATIC COATING. ROLLERS: WITH DYNAMIC BALANCE PROCESSING. DESCRIPTION: • MACHINE IS MAINLY USED TO LOAD A BALE OF FIBER AND SEND IT TO NEXT PROGRAM AUTOMATICALLY. • THE SUITABLE MATERIAL CAN BE CONJUGATE SILICON POLYESTER FIBER THAT SHORTER THAN 100mm. POLYESTER FIBER: RECYCLE AND VIRGIN POLYESTER STAPLE FIBER. 0.6 TO 15D, 32mm TO 64mm, MICROFIBER ALSO POSSIBLE. • ANTI-DEVIATION DEVICE, CONVEYOR BELT TRACK PROTECTION, TO ENSURE THAT BELT ALWAYS RUNNING STRAIGHT. • ONE OPERATOR • WORKING PROCESS: 1. USE FORKLIFT TO PUT BALE OF FIBER ON THE CONVEYOR. 2. THE FIRST CONVEYOR WILL SEND FIBER TO THE SECOND CONVEYOR 3. THEN THE SPIKED INCLINE BELT LIFTS THE FIBER, THE EVENING ROLLER TAKES THE EXCESSIVE FIBER OFF AND THE STRIPPING ROLLER STRIP THE FIBER OFF AND FIBER FALLS DOWN TO NEXT PROCESS. 4. THERE ARE PHOTO CELLS TO CONTROL THE MATERIAL FIBER LEVEL, FEEDING AND SUPPLY SPEED. • ELECTRICAL KEY PARTS ARE WORLD FAMOUS BRANDS, SUCH AS SCHNEIDER ETC. AVAILABLE WORLDWIDE. • ELECTRICAL WITH OVERLOAD PROTECTION. Learn More

FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60HzREFERENCE NUMBER: T-6869 FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60Hz FEED HOPPER WITH LONG EXTENDED APRON 1500mm FEED HOPPER MODEL: OP-B POWER: 3.6KW FILLING CAPACITY: 800KG/H LAYOUT: 5940 X 1600 X 2200mm WEIGHT: 3200KG WORKING WIDTH: 1500mm VOLTAGE: 440V 60Hz 3 PHASES (AS PER ORDER) AIR PRESSURE: 0.6 TO 0.8MPA MAIN STRUCTURE: MADE BY COMPUTERIZED LASER CUTTING MACHINE ELECTRICITY: KEY PARTS ARE WORLD FAMOUS BRAND, OMRON, SCHNEIDER. BEARING: SKF SPRAY: RUST-PROOF PRETREATMENT AND ELECTROSTATIC COATING. ROLLERS: WITH DYNAMIC BALANCE PROCESSING. DESCRIPTION: • MACHINE IS MAINLY USED TO LOAD A BALE OF FIBER AND SEND IT TO NEXT PROGRAM AUTOMATICALLY. • THE SUITABLE MATERIAL CAN BE CONJUGATE SILICON POLYESTER FIBER THAT SHORTER THAN 100mm. POLYESTER FIBER: RECYCLE AND VIRGIN POLYESTER STAPLE FIBER. 0.6 TO 15D, 32mm TO 64mm, MICROFIBER ALSO POSSIBLE. • ANTI-DEVIATION DEVICE, CONVEYOR BELT TRACK PROTECTION, TO ENSURE THAT BELT ALWAYS RUNNING STRAIGHT. • ONE OPERATOR • WORKING PROCESS: 1. USE FORKLIFT TO PUT BALE OF FIBER ON THE CONVEYOR. 2. THE FIRST CONVEYOR WILL SEND FIBER TO THE SECOND CONVEYOR 3. THEN THE SPIKED INCLINE BELT LIFTS THE FIBER, THE EVENING ROLLER TAKES THE EXCESSIVE FIBER OFF AND THE STRIPPING ROLLER STRIP THE FIBER OFF AND FIBER FALLS DOWN TO NEXT PROCESS. 4. THERE ARE PHOTO CELLS TO CONTROL THE MATERIAL FIBER LEVEL, FEEDING AND SUPPLY SPEED. • ELECTRICAL KEY PARTS ARE WORLD FAMOUS BRANDS, SUCH AS SCHNEIDER ETC. AVAILABLE WORLDWIDE. • ELECTRICAL WITH OVERLOAD PROTECTION. Learn More -

L-4682 BALE BREAKER SYSTEM FOR MICRO FIBER MIXING, WIDTH 1200mm

L-4682 BALE BREAKER SYSTEM FOR MICRO FIBER MIXING, WIDTH 1200mmREFERENCE NUMBER: L-4682

Learn More

WIDTH: 1200mm

CAPACITY: 200-600KG/H

QUANTITY: 1 -

V-1288 MERELLO ME-305 PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009

V-1288 MERELLO ME-305 PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009REFERENCE NUMBER: V-1288

MERELLO ME-305PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009

WRAPS PILLOWS AND CUSHIONS BETWEEN 35X35 AND 150X70cm IN POLYETHYLENE TUBE, WITHOUT LATERAL SEALS

HIGH QUALITY BAGS, MORE ESTHETICAL AND VERY WELL ADJUSTED. INCLUDES OPTIONAL PRINTER FOR LABELS DIRECTLY ON THE BAG, PUNCHES HANDLES AND DETECTS CENTERED LOGOS. MINIMUM WASTE, ENERGY SAVINGS.

AUTOMATIC CYCLE: IN-FEED, WRAPPING, COMPRESSION AND SEALING. EASY AND FAST CHANGE OF THE ROLL, MÁX. ROLL: 500 mm.. CYCLE CONTROLLED BY PLC WITH TOUCH SCREEN. SURFACE OCCUPATION: 4.5X2M (EXTRA BIG DIMENSIONS AVAILABLE AS OPTION).

HIGH PRODUCTIVITY: 10/12 UNITS PER MINUTE

WELL-ENGINEERED MACHINE FOR FLATTENING AND WRAPPING CUSHIONS FOR “FLAT PACK” OPERATIONS

THIS IS IDEAL FOR STORING AND SHIPPING PILLOWS AND CUSHIONS IN A MINIMAL AMOUNT OF SPACE

AUTOMATICALLY WRAPS EVERY TYPE OF PILLOW BETWEEN 40CM x 40CM (16”x16”) TO 110CM x 80CM (42”x32”)

CYCLES UP TO 8 PER MINUTE

AUTOMATICALLY ADJUSTS TO VARYING SIZES

PLASTIC ROLLS ARE EASILY CHANGES

THE MACHINE FORMS A TUBE STYLE BAG FROM A POLYETHYLENE ROLL, WITH PERFECT SIZE ADJUSTMENT AND REQUIRES NO LATERAL SEALING. CHANGING THE POLYETHYLENE ROLL IS FAST AND EASY, AND DIFFERENT SIZES CAN BE USED WITHOUT ADJUSTMENT

CUTS ARE MADE BY A MAINTENANCE-FREE, SMOKELESS COLD BLADE

A TOUCH SCREEN PLC CONTROL DISPLAYS INPUT PARAMETERS AND CYCLE INFORMATION

ELECTRONIC INVERTER ENABLES SMOOTH MOTORIZED MOVEMENTS

OPTIONAL VIDEO JET THERMAL PRINTER CAN PRINT PRODUCT DATA AND BAR CODES DIRECTLY ON FINISHED PACKAGE

MACHINE DIMENSIONS ARE: 4.5M x 2M (14.75’ x 6.5’)

SAVES SPACE AND MATERIAL EXPENSE BY EXTRACTING AIR FROM THE BAG DURING PACKAGING PROCESS

QUANTITY: 1

Learn More -

P-2121 RIETER D30 DRAW FRAMES YEAR 2001REFERENCE NUMBER: P-2121 RIETER D30 DRAW FRAMES YEAR 2001 RIETER TYPE: D30 DRAW FRAMES YEAR: 2001 SUITABLE FOR COTTON, POLYESTER OR MIXED UP TO 80mm SPEED 250 to 1000 M/MIN DRAFTING 3 OVER 3 PRESSION BAR REGULATION – ELECTRONIC INTEGRATED DUST ASPIRATION AUTOMATIC CAN CHANGER 18 INCHES x 42 INCHES CAN SIZE CREEL WITH SENSORS RIETER QUALITY MONITORS VOLTAGE: 220 VOLTS, 60 HERTZ 11.6 KILOWATTS POWER PNEUMATIC DRAFTING SYSTEM RSB D30 YEAR 2001 CARDS: C 1/2 – 1976 - COTTON C 1/3 – 1984 – POLYESTER C 1/3 – 1982 – POLYESTER ADDITIONAL DRAW FRAMES: 2 DO/2 YEAR: 1985 QUANTITY AVAILABLE: 2 Learn More

P-2121 RIETER D30 DRAW FRAMES YEAR 2001REFERENCE NUMBER: P-2121 RIETER D30 DRAW FRAMES YEAR 2001 RIETER TYPE: D30 DRAW FRAMES YEAR: 2001 SUITABLE FOR COTTON, POLYESTER OR MIXED UP TO 80mm SPEED 250 to 1000 M/MIN DRAFTING 3 OVER 3 PRESSION BAR REGULATION – ELECTRONIC INTEGRATED DUST ASPIRATION AUTOMATIC CAN CHANGER 18 INCHES x 42 INCHES CAN SIZE CREEL WITH SENSORS RIETER QUALITY MONITORS VOLTAGE: 220 VOLTS, 60 HERTZ 11.6 KILOWATTS POWER PNEUMATIC DRAFTING SYSTEM RSB D30 YEAR 2001 CARDS: C 1/2 – 1976 - COTTON C 1/3 – 1984 – POLYESTER C 1/3 – 1982 – POLYESTER ADDITIONAL DRAW FRAMES: 2 DO/2 YEAR: 1985 QUANTITY AVAILABLE: 2 Learn More -

F-1422 BALE BREAKER/FIBER MIXING SYSTEM 03E (NEW)REFERENCE NUMBER: F-1422 BALE BREAKER/FIBER MIXING SYSTEM 03E (NEW) MACHINE IS USED TO MIX FIBERS (SILICONIZED, NON-SILICONIZED POLYESTER, LOW MELT POLYESTER, CONJUGATE, HOLLOW POLYESTER FIBER) IN DIFFERENT RATIO AND SEND TO THE CARDING MACHINE. TECHNIQUE DATA: CAPACITY: 400 TO 600KG/H TOTAL POWER: 4.45KW PRE-OPENING MACHINE POWER: 7KW MACHINE WORKING WIDTH: 1200mm PRE-OPENER WORKING WIDTH: 1000mm WEIGHING CAPACITY: 1500GM WEIGHING TOLERANCE: 6% VOLUME OF WEIGHING HOPPER: 0.3M³ WEIGHING SPEED: 3 TO 5 TIMES/MIN OVERALL MACHINE DIMENSIONS: 6300mm × 3360mm × 1300mm QUANTITY AVAILABLE: 1 Learn More

F-1422 BALE BREAKER/FIBER MIXING SYSTEM 03E (NEW)REFERENCE NUMBER: F-1422 BALE BREAKER/FIBER MIXING SYSTEM 03E (NEW) MACHINE IS USED TO MIX FIBERS (SILICONIZED, NON-SILICONIZED POLYESTER, LOW MELT POLYESTER, CONJUGATE, HOLLOW POLYESTER FIBER) IN DIFFERENT RATIO AND SEND TO THE CARDING MACHINE. TECHNIQUE DATA: CAPACITY: 400 TO 600KG/H TOTAL POWER: 4.45KW PRE-OPENING MACHINE POWER: 7KW MACHINE WORKING WIDTH: 1200mm PRE-OPENER WORKING WIDTH: 1000mm WEIGHING CAPACITY: 1500GM WEIGHING TOLERANCE: 6% VOLUME OF WEIGHING HOPPER: 0.3M³ WEIGHING SPEED: 3 TO 5 TIMES/MIN OVERALL MACHINE DIMENSIONS: 6300mm × 3360mm × 1300mm QUANTITY AVAILABLE: 1 Learn More -

A-1180 MURATA JET SPINNER MVS 810 14 SET X 72 SPINDLES SETREFERENCE NUMBER: A-1180 (1212GHBXX11) A MURATA JET SPINNER MVS 810 14 set x 72 SPINDLES set MURATA JET SPINNER 1. Type: MVS 810 2. Q'nty: 14 set x 72 SPINDLES / set 3. Year: 1) 2001: 1 set 2) 2002: 1 set 3) 2003: 2 set 4) 2004: 10 set 4. Working Yarn count :( Ne16-100/1) 5. Knotting: Fisherman Knot 6. Cone angle: 0 and 2 deg’ 7. With Auto doffer per each set 8. RPM: 380 and 400 9. Max package diaMETER: 300 mm diaMETER 10. Production Yarn: Polyester /cotton, Polyester/rayon, 100% rayon, Acryl / Polyester, 100% cotton, Acryl/Cotton etc 11. Production: 740 kg/day/set (21,600 Kg/month/set) QUANTITY AVAILABLE: 1 Learn More

A-1180 MURATA JET SPINNER MVS 810 14 SET X 72 SPINDLES SETREFERENCE NUMBER: A-1180 (1212GHBXX11) A MURATA JET SPINNER MVS 810 14 set x 72 SPINDLES set MURATA JET SPINNER 1. Type: MVS 810 2. Q'nty: 14 set x 72 SPINDLES / set 3. Year: 1) 2001: 1 set 2) 2002: 1 set 3) 2003: 2 set 4) 2004: 10 set 4. Working Yarn count :( Ne16-100/1) 5. Knotting: Fisherman Knot 6. Cone angle: 0 and 2 deg’ 7. With Auto doffer per each set 8. RPM: 380 and 400 9. Max package diaMETER: 300 mm diaMETER 10. Production Yarn: Polyester /cotton, Polyester/rayon, 100% rayon, Acryl / Polyester, 100% cotton, Acryl/Cotton etc 11. Production: 740 kg/day/set (21,600 Kg/month/set) QUANTITY AVAILABLE: 1 Learn More -

YY-2098 NONWOVEN ROLL PRESSING MACHINE, MAXIMUM WORKING WIDTH 2500mmYY-2098 NONWOVEN ROLL PRESSING MACHINE, MAXIMUM WORKING WIDTH 2500mm MAXIMUM WORKING WIDTH: 2500mm POWER: 1.5KW WEIGHT: 600KG QUANTITY: 1 Learn More

YY-2098 NONWOVEN ROLL PRESSING MACHINE, MAXIMUM WORKING WIDTH 2500mmYY-2098 NONWOVEN ROLL PRESSING MACHINE, MAXIMUM WORKING WIDTH 2500mm MAXIMUM WORKING WIDTH: 2500mm POWER: 1.5KW WEIGHT: 600KG QUANTITY: 1 Learn More -

R-1192 CUSHION ROLL BAG MAKING MACHINE OC668, MACHINE SIZE 3200 × 1250 × 1800mm

R-1192 CUSHION ROLL BAG MAKING MACHINE OC668, MACHINE SIZE 3200 × 1250 × 1800mmREFERENCE NUMBER: R-1192

CUSHION ROLL BAG MAKING MACHINE OC668, MACHINE SIZE 3200 × 1250 × 1800mm

CUSHION ROLL BAG MAKING MACHINEOC668

THIS MACHINE IS SUITABLE FOR HIGH-DENSITY POLYETHYLENE LONGEVITY ETHYLENE (HDPE)

LOW DENSITY POLYETHYLENE (LDPE) AND POLYPROPYLENE (PP) SEALING

MODEL: 500mm

BAG LAYER: SINGLE LAYER

BAG WIDTH: 100 TO 400mm

BAG LENGTH: 100 TO 1000mm

BAG SPEED: 50 TO 120PCS/MIN

Learn More -

V-1360 SANTEX THERMOBONDING COMPRESSION OVEN FOR NONWOVENS ON ROLL, 80 TO 400 G/M, YEAR 1986

V-1360 SANTEX THERMOBONDING COMPRESSION OVEN FOR NONWOVENS ON ROLL, 80 TO 400 G/M, YEAR 1986V-1360 SANTEX THERMOBONDING COMPRESSION OVEN FOR NONWOVENS ON ROLL, 80 TO 400 G/M, YEAR 1986

WORKING WIDTH: 2500mm

ROLL FACE WIDTH: WORKING WIDTH + 50mm

MATERIAL FIBERS: NONWOVEN WEB OF POLYESTER OR DIFFERENT FIBERS MIXED WITH 10 TO 25% POLYESTER BI-COMPONENT BINDER FIBERS OR DIFFERENT BINDER FIBERS

MACHINE SPEED: 1 TO 20 M/MIN. (OTHERS UPON REQUEST)

COMPOSITION OVEN: 2 HEATING ZONES OF 2 M EACH + 1 COOLING SECTIONQUANTITY: 1

Learn More -

K-4728 ELECTRONIC CUTTING MACHINE FOR STRETCH FABRIC FOR MATTRESSESREFERENCE NUMBER: K-4728 ELECTRONIC CUTTING MACHINE FOR STRETCH FABRIC FOR MATTRESSES HIGH PRECISION CAPABLE OF DOING THE JOB OF CUTTING PADDED QUILTED FABRICS WITH EASE AND PRECISION. QUANTITY AVAILABLE: 1 Learn More

K-4728 ELECTRONIC CUTTING MACHINE FOR STRETCH FABRIC FOR MATTRESSESREFERENCE NUMBER: K-4728 ELECTRONIC CUTTING MACHINE FOR STRETCH FABRIC FOR MATTRESSES HIGH PRECISION CAPABLE OF DOING THE JOB OF CUTTING PADDED QUILTED FABRICS WITH EASE AND PRECISION. QUANTITY AVAILABLE: 1 Learn More