Search results for: 'Cutting+machine'

- Related search terms

- cutting+machines

- Cutting+machine ed

- Cutting+machine edg

- Cutting+machine edge sw

- Cutting+machine+ed

-

TT-5005 ALBRECHT BAUMER BSL-D ROTARY TABLE HORIZONTAL SPLITTING MACHINE, YEAR 1990, CAROUSELTT-5005 ALBRECHT BAUMER BSL-D ROTARY TABLE HORIZONTAL SPLITTING MACHINE, YEAR 1990, CAROUSEL ALBRECHT BAUMER BSL-D YEAR OF CONSTRUCTION 1990 CONDITION USED QUANTITY: 1 Learn More

TT-5005 ALBRECHT BAUMER BSL-D ROTARY TABLE HORIZONTAL SPLITTING MACHINE, YEAR 1990, CAROUSELTT-5005 ALBRECHT BAUMER BSL-D ROTARY TABLE HORIZONTAL SPLITTING MACHINE, YEAR 1990, CAROUSEL ALBRECHT BAUMER BSL-D YEAR OF CONSTRUCTION 1990 CONDITION USED QUANTITY: 1 Learn More -

TT-4591 METEX LOOMS FOR WEAVING CUTED VELVETS (PLUSH), WIDTH 1400mm, YEAR 1997 TO 2003, JACQUARDTT-4591 METEX LOOMS FOR WEAVING CUTED VELVETS (PLUSH), WIDTH 1400mm, YEAR 1997 TO 2003, JACQUARD QUANTITY: 2 Learn More

TT-4591 METEX LOOMS FOR WEAVING CUTED VELVETS (PLUSH), WIDTH 1400mm, YEAR 1997 TO 2003, JACQUARDTT-4591 METEX LOOMS FOR WEAVING CUTED VELVETS (PLUSH), WIDTH 1400mm, YEAR 1997 TO 2003, JACQUARD QUANTITY: 2 Learn More -

YY-2964 USED DELTA ADULT DIAPER PRODUCTION MACHINE, YEAR 2003YY-2964 USED DELTA ADULT DIAPER PRODUCTION MACHINE, YEAR 2003 BRAND NAME: DELTA YEAR OF MANUFACTURING: 2003 PRODUCE 3 SIZES LENGTH SMALL 670, MEDIUM 780 AND LARGE 940 mm Learn More

YY-2964 USED DELTA ADULT DIAPER PRODUCTION MACHINE, YEAR 2003YY-2964 USED DELTA ADULT DIAPER PRODUCTION MACHINE, YEAR 2003 BRAND NAME: DELTA YEAR OF MANUFACTURING: 2003 PRODUCE 3 SIZES LENGTH SMALL 670, MEDIUM 780 AND LARGE 940 mm Learn More -

YY-2691 CROSS PERFORATION MACHINE WITH SLITTER - 1600mm (64 INCHES)YY-2691 CROSS PERFORATION MACHINE WITH SLITTER - 1600mm (64 INCHES) ASK FOR MORE DETAILS! QUANTITY: 1 Learn More

YY-2691 CROSS PERFORATION MACHINE WITH SLITTER - 1600mm (64 INCHES)YY-2691 CROSS PERFORATION MACHINE WITH SLITTER - 1600mm (64 INCHES) ASK FOR MORE DETAILS! QUANTITY: 1 Learn More -

TT-2331 SSI DUAL-SHEAR SHREDDER, 31” CHAMBER, NOMINAL CUTTER THICKNESS 50mmTT-2331 SSI DUAL-SHEAR SHREDDER, 31” CHAMBER, NOMINAL CUTTER THICKNESS 50mm SSI DUAL-SHEAR SHREDDER USED MODEL M100E(63) QUANTITY: 1 Learn More

TT-2331 SSI DUAL-SHEAR SHREDDER, 31” CHAMBER, NOMINAL CUTTER THICKNESS 50mmTT-2331 SSI DUAL-SHEAR SHREDDER, 31” CHAMBER, NOMINAL CUTTER THICKNESS 50mm SSI DUAL-SHEAR SHREDDER USED MODEL M100E(63) QUANTITY: 1 Learn More -

TT-2330 SSI DUAL-SHEAR SHREDDER, CHAMBER 31", NOMINAL CUTTER THICKNESS 50mmTT-2330 SSI DUAL-SHEAR SHREDDER, CHAMBER 31", NOMINAL CUTTER THICKNESS 50mm SSI DUAL-SHEAR SHREDDER UNUSED MODEL M100E(63) QUANTITY: 1 Learn More

TT-2330 SSI DUAL-SHEAR SHREDDER, CHAMBER 31", NOMINAL CUTTER THICKNESS 50mmTT-2330 SSI DUAL-SHEAR SHREDDER, CHAMBER 31", NOMINAL CUTTER THICKNESS 50mm SSI DUAL-SHEAR SHREDDER UNUSED MODEL M100E(63) QUANTITY: 1 Learn More -

YY-2315 TOTAL AUTOMATIC MACHINE LINE FOR MANUFACTURING HYGIENIC, COSMETIC AND MEDICAL PADS PACKED IN THERMAL SEALED FOIL BAGSYY-2315 TOTAL AUTOMATIC MACHINE LINE FOR MANUFACTURING HYGIENIC, COSMETIC AND MEDICAL PADS PACKED IN THERMAL SEALED FOIL BAGS QUANTITY: 1 Learn More

YY-2315 TOTAL AUTOMATIC MACHINE LINE FOR MANUFACTURING HYGIENIC, COSMETIC AND MEDICAL PADS PACKED IN THERMAL SEALED FOIL BAGSYY-2315 TOTAL AUTOMATIC MACHINE LINE FOR MANUFACTURING HYGIENIC, COSMETIC AND MEDICAL PADS PACKED IN THERMAL SEALED FOIL BAGS QUANTITY: 1 Learn More -

YY-1895 SEMI-AUTOMATIC REWINDING MACHINE WITH WEB GUIDE, SLITTING UNIT, PERFORATION – 2500mmYY-1895 SEMI-AUTOMATIC REWINDING MACHINE WITH WEB GUIDE, SLITTING UNIT, PERFORATION – 2500mm PRODUCT USAGE: THIS MACHINE IS MAINLY USED FOR RE-WINDING AND TRIMMING OF VARIOUS PAPERS, PAPER-PLASTIC COMPOSITES, FILM AND OTHER DECORATIVE MATERIALS AS WELL AS PACKAGING MATERIALS. FEATURES: 1. THIS MACHINE INCORPORATES SERVO FIXED LENGTH FEEDING TO MAINTAIN HIGH PRECISION DURING HIGH SPEED REWINDING. 2. PLC TOUCH SCREEN AUTOMATICALLY COUNTS METERS, METER LENGTH CAN BE AUTOMATICALLY SET. 3. ROUND BLADE / RAZOR KNIFE SLITTING. 4. PNEUMATIC AUTOMATIC FEEDING, FEEDING AND DISCHARGING STATIONS WITH AIR EXPANSION SHAFT. 5. AUTOMATIC CUTTING, LENGTH SETTING, PRE-FEEDING (REWINDING) TO REWIND. QUANTITY: 1 Learn More

YY-1895 SEMI-AUTOMATIC REWINDING MACHINE WITH WEB GUIDE, SLITTING UNIT, PERFORATION – 2500mmYY-1895 SEMI-AUTOMATIC REWINDING MACHINE WITH WEB GUIDE, SLITTING UNIT, PERFORATION – 2500mm PRODUCT USAGE: THIS MACHINE IS MAINLY USED FOR RE-WINDING AND TRIMMING OF VARIOUS PAPERS, PAPER-PLASTIC COMPOSITES, FILM AND OTHER DECORATIVE MATERIALS AS WELL AS PACKAGING MATERIALS. FEATURES: 1. THIS MACHINE INCORPORATES SERVO FIXED LENGTH FEEDING TO MAINTAIN HIGH PRECISION DURING HIGH SPEED REWINDING. 2. PLC TOUCH SCREEN AUTOMATICALLY COUNTS METERS, METER LENGTH CAN BE AUTOMATICALLY SET. 3. ROUND BLADE / RAZOR KNIFE SLITTING. 4. PNEUMATIC AUTOMATIC FEEDING, FEEDING AND DISCHARGING STATIONS WITH AIR EXPANSION SHAFT. 5. AUTOMATIC CUTTING, LENGTH SETTING, PRE-FEEDING (REWINDING) TO REWIND. QUANTITY: 1 Learn More -

FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60HzREFERENCE NUMBER: T-6869 FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60Hz FEED HOPPER WITH LONG EXTENDED APRON 1500mm FEED HOPPER MODEL: OP-B POWER: 3.6KW FILLING CAPACITY: 800KG/H LAYOUT: 5940 X 1600 X 2200mm WEIGHT: 3200KG WORKING WIDTH: 1500mm VOLTAGE: 440V 60Hz 3 PHASES (AS PER ORDER) AIR PRESSURE: 0.6 TO 0.8MPA MAIN STRUCTURE: MADE BY COMPUTERIZED LASER CUTTING MACHINE ELECTRICITY: KEY PARTS ARE WORLD FAMOUS BRAND, OMRON, SCHNEIDER. BEARING: SKF SPRAY: RUST-PROOF PRETREATMENT AND ELECTROSTATIC COATING. ROLLERS: WITH DYNAMIC BALANCE PROCESSING. DESCRIPTION: • MACHINE IS MAINLY USED TO LOAD A BALE OF FIBER AND SEND IT TO NEXT PROGRAM AUTOMATICALLY. • THE SUITABLE MATERIAL CAN BE CONJUGATE SILICON POLYESTER FIBER THAT SHORTER THAN 100mm. POLYESTER FIBER: RECYCLE AND VIRGIN POLYESTER STAPLE FIBER. 0.6 TO 15D, 32mm TO 64mm, MICROFIBER ALSO POSSIBLE. • ANTI-DEVIATION DEVICE, CONVEYOR BELT TRACK PROTECTION, TO ENSURE THAT BELT ALWAYS RUNNING STRAIGHT. • ONE OPERATOR • WORKING PROCESS: 1. USE FORKLIFT TO PUT BALE OF FIBER ON THE CONVEYOR. 2. THE FIRST CONVEYOR WILL SEND FIBER TO THE SECOND CONVEYOR 3. THEN THE SPIKED INCLINE BELT LIFTS THE FIBER, THE EVENING ROLLER TAKES THE EXCESSIVE FIBER OFF AND THE STRIPPING ROLLER STRIP THE FIBER OFF AND FIBER FALLS DOWN TO NEXT PROCESS. 4. THERE ARE PHOTO CELLS TO CONTROL THE MATERIAL FIBER LEVEL, FEEDING AND SUPPLY SPEED. • ELECTRICAL KEY PARTS ARE WORLD FAMOUS BRANDS, SUCH AS SCHNEIDER ETC. AVAILABLE WORLDWIDE. • ELECTRICAL WITH OVERLOAD PROTECTION. Learn More

FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60HzREFERENCE NUMBER: T-6869 FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60Hz FEED HOPPER WITH LONG EXTENDED APRON 1500mm FEED HOPPER MODEL: OP-B POWER: 3.6KW FILLING CAPACITY: 800KG/H LAYOUT: 5940 X 1600 X 2200mm WEIGHT: 3200KG WORKING WIDTH: 1500mm VOLTAGE: 440V 60Hz 3 PHASES (AS PER ORDER) AIR PRESSURE: 0.6 TO 0.8MPA MAIN STRUCTURE: MADE BY COMPUTERIZED LASER CUTTING MACHINE ELECTRICITY: KEY PARTS ARE WORLD FAMOUS BRAND, OMRON, SCHNEIDER. BEARING: SKF SPRAY: RUST-PROOF PRETREATMENT AND ELECTROSTATIC COATING. ROLLERS: WITH DYNAMIC BALANCE PROCESSING. DESCRIPTION: • MACHINE IS MAINLY USED TO LOAD A BALE OF FIBER AND SEND IT TO NEXT PROGRAM AUTOMATICALLY. • THE SUITABLE MATERIAL CAN BE CONJUGATE SILICON POLYESTER FIBER THAT SHORTER THAN 100mm. POLYESTER FIBER: RECYCLE AND VIRGIN POLYESTER STAPLE FIBER. 0.6 TO 15D, 32mm TO 64mm, MICROFIBER ALSO POSSIBLE. • ANTI-DEVIATION DEVICE, CONVEYOR BELT TRACK PROTECTION, TO ENSURE THAT BELT ALWAYS RUNNING STRAIGHT. • ONE OPERATOR • WORKING PROCESS: 1. USE FORKLIFT TO PUT BALE OF FIBER ON THE CONVEYOR. 2. THE FIRST CONVEYOR WILL SEND FIBER TO THE SECOND CONVEYOR 3. THEN THE SPIKED INCLINE BELT LIFTS THE FIBER, THE EVENING ROLLER TAKES THE EXCESSIVE FIBER OFF AND THE STRIPPING ROLLER STRIP THE FIBER OFF AND FIBER FALLS DOWN TO NEXT PROCESS. 4. THERE ARE PHOTO CELLS TO CONTROL THE MATERIAL FIBER LEVEL, FEEDING AND SUPPLY SPEED. • ELECTRICAL KEY PARTS ARE WORLD FAMOUS BRANDS, SUCH AS SCHNEIDER ETC. AVAILABLE WORLDWIDE. • ELECTRICAL WITH OVERLOAD PROTECTION. Learn More -

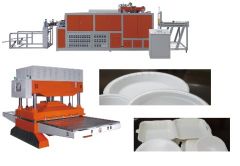

L-5818 POLYSTYRENE FOAM PLATE FORMING MACHINE

L-5818 POLYSTYRENE FOAM PLATE FORMING MACHINEREFERENCE NUMBER: L-5818

POLYSTYRENE FOAM PLATE FORMING MACHINE

RATED POWER: 90 KW

SHEET WIDTH: 800 TO 1080mm

MAX FORMING AREA: 1000 X 1300mm

WORKING SPEED: 17 TO 22 TIMES PER MINUTE

This machine is semi-automatic.

After forming, hydraulic cutting machine will be needed to cut out each product.

QUANTITY: 1

Learn More