Search results for: 'compo''

-

G-6734-B F-3 FEATHER FILLING MACHINE•TYPE : F-3 •DIMENSION: 3000 x 2500 x 2000MM •VOLTAGE: PER CUSTOMER REQUEST •POWER: 3.8 KW •FILLING RANGE: 2 TO 100 G, DEPENDING ON THE MATERIAL •ACCURACY: ±0.2 GRAMS •AIR PRESSURE: 0.5 TO 0.8MPA Learn More

G-6734-B F-3 FEATHER FILLING MACHINE•TYPE : F-3 •DIMENSION: 3000 x 2500 x 2000MM •VOLTAGE: PER CUSTOMER REQUEST •POWER: 3.8 KW •FILLING RANGE: 2 TO 100 G, DEPENDING ON THE MATERIAL •ACCURACY: ±0.2 GRAMS •AIR PRESSURE: 0.5 TO 0.8MPA Learn More -

G-6734-A F-2 FEATHER FILLING MACHINE•ITEM NO.: F-2 •DIMENSION: APPROX. 11000*2500*3000MM •VOLTAGE: 380V 50HZ 3PHASE •POWER: 11KW •FILLING RANGE: 2-100 G, DEPENDING ON THE MATERIAL •ACCURACY: ±1G •AIR PRESSURE: 0.5-0.8MPA •THERE ARE 4 WEIGHING SYSTEM AND 2 WORKING TABLE ASSEMBLED TO THE DOWN FEATHER FILLING LINE •IT IS MAINLY USED TO MAKE DOWN FEATHER QUILTING Learn More

G-6734-A F-2 FEATHER FILLING MACHINE•ITEM NO.: F-2 •DIMENSION: APPROX. 11000*2500*3000MM •VOLTAGE: 380V 50HZ 3PHASE •POWER: 11KW •FILLING RANGE: 2-100 G, DEPENDING ON THE MATERIAL •ACCURACY: ±1G •AIR PRESSURE: 0.5-0.8MPA •THERE ARE 4 WEIGHING SYSTEM AND 2 WORKING TABLE ASSEMBLED TO THE DOWN FEATHER FILLING LINE •IT IS MAINLY USED TO MAKE DOWN FEATHER QUILTING Learn More -

G-6734 F-1 FEATHER FILLING MACHINE•PRODUCT NAME: WEIGHING DOWN & FEATHER FILLING MACHINE •TYPE: EF-1 •DIMENSION: 7500*2500*3500MM •VOLTAGE: 380V 50HZ 3PHASE •POWER: 11KW •FILLING RANGE: 2-100 G, DEPENDING ON THE MATERIAL •ACCURACY: ±0.2G,±1G,±1.5G,DEPENDING ON THE FILLING WEIGHT •AIR SUPPLY: 0.5-0.8MPA •WEIGHT: APPROX. 800KG Learn More

G-6734 F-1 FEATHER FILLING MACHINE•PRODUCT NAME: WEIGHING DOWN & FEATHER FILLING MACHINE •TYPE: EF-1 •DIMENSION: 7500*2500*3500MM •VOLTAGE: 380V 50HZ 3PHASE •POWER: 11KW •FILLING RANGE: 2-100 G, DEPENDING ON THE MATERIAL •ACCURACY: ±0.2G,±1G,±1.5G,DEPENDING ON THE FILLING WEIGHT •AIR SUPPLY: 0.5-0.8MPA •WEIGHT: APPROX. 800KG Learn More -

J-0032 BRUCKNER DRYING AND THERMO-FIXING LINE YEAR 1982 WIDTH 1800mmREFERENCE NUMBER: J-0032 (1313NBMJKXX12) BRUCKNER DRYING AND THERMO-FIXING LINE YEAR 1982 WIDTH 1800mm QUANTITY AVAILABLE:1 Learn More

J-0032 BRUCKNER DRYING AND THERMO-FIXING LINE YEAR 1982 WIDTH 1800mmREFERENCE NUMBER: J-0032 (1313NBMJKXX12) BRUCKNER DRYING AND THERMO-FIXING LINE YEAR 1982 WIDTH 1800mm QUANTITY AVAILABLE:1 Learn More -

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More -

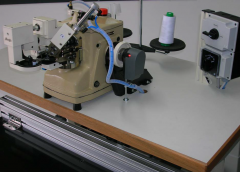

M-1004 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSFOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDED CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBRES, ALL KIND OF CUSHIONS, EVEN BIG SHAPED SIZES. THE RANGE OF SEWING MACHINE HAS BEEN STUDIED AND BUILT FOLLOWING THE MOST MODERN CONCEPT OF TECHNOLOGY; THEIR COMPONENTS ARE THE MOST ADVANCED AND THE MATERIALS ARE HIGHLY SELECTED: THIS MAKES THE MACHINES STRONG, SAFE, SILENT AND EASY TO BE USED. OPERATIONS FEATURES: THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS. WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA, AND NOT ONLY. VERSATILITY AND PERFORMANCE: KITS AND ACCESSORIES ARE AVAILABLE TO MEET THE MOST DIFFERENT REQUIREMENTS. IT IS POSSIBLE TO SEW (NEVER MIND THE SIZE, THE SHAPE AND THE WEIGHT): - LIGHT COTTON, NONWOVEN, FABRICS COUPLED WITH SYNTHETIC FIBRES, POLYESTER, CARDED AND SIMILAR. - FEATHER PILLOWS - HEAVY MATERIAL SUCH AS CUSHIONS IN SYNTHETIC FIBRES OR DACRON COUPLED WITH FOAM, CUSHIONS WITH SPRINGS ETC. COMPLETE WITH: - EXTENDED SEWING GROUP WITH DOUBLE MOTORIZED TOOTHED PLATES. - SEWING HEAD (OVERLOCK – 1 YARN) STITCH LENGTH: 1 TO 5mm - YARN CUTTING (TRIMMER), CUPS OPENING AND PNEUMATIC OIL PUMP - ELECTRONIC EFKA MOTOR 220V/240V SINGLE PHASE - SPEED: 1900 RPM - PERFORMANCE: 6 SECONDS PER CUSHION (SEWING 15 TO 20 CENTIMETERS) - ELECTRONIC MOBILE FOOTBOARD ALSO INCLUDES 1 SET OF NEEDLES, 1 INSTRUCTION BOOK, 1 CE CONFORMITYPRODUCTIVITY: 10/12 CUSHIONS PER MINUTE (CONSIDERED A OPEN SIDE OF 6/8”) Learn More

M-1004 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSFOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDED CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBRES, ALL KIND OF CUSHIONS, EVEN BIG SHAPED SIZES. THE RANGE OF SEWING MACHINE HAS BEEN STUDIED AND BUILT FOLLOWING THE MOST MODERN CONCEPT OF TECHNOLOGY; THEIR COMPONENTS ARE THE MOST ADVANCED AND THE MATERIALS ARE HIGHLY SELECTED: THIS MAKES THE MACHINES STRONG, SAFE, SILENT AND EASY TO BE USED. OPERATIONS FEATURES: THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS. WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA, AND NOT ONLY. VERSATILITY AND PERFORMANCE: KITS AND ACCESSORIES ARE AVAILABLE TO MEET THE MOST DIFFERENT REQUIREMENTS. IT IS POSSIBLE TO SEW (NEVER MIND THE SIZE, THE SHAPE AND THE WEIGHT): - LIGHT COTTON, NONWOVEN, FABRICS COUPLED WITH SYNTHETIC FIBRES, POLYESTER, CARDED AND SIMILAR. - FEATHER PILLOWS - HEAVY MATERIAL SUCH AS CUSHIONS IN SYNTHETIC FIBRES OR DACRON COUPLED WITH FOAM, CUSHIONS WITH SPRINGS ETC. COMPLETE WITH: - EXTENDED SEWING GROUP WITH DOUBLE MOTORIZED TOOTHED PLATES. - SEWING HEAD (OVERLOCK – 1 YARN) STITCH LENGTH: 1 TO 5mm - YARN CUTTING (TRIMMER), CUPS OPENING AND PNEUMATIC OIL PUMP - ELECTRONIC EFKA MOTOR 220V/240V SINGLE PHASE - SPEED: 1900 RPM - PERFORMANCE: 6 SECONDS PER CUSHION (SEWING 15 TO 20 CENTIMETERS) - ELECTRONIC MOBILE FOOTBOARD ALSO INCLUDES 1 SET OF NEEDLES, 1 INSTRUCTION BOOK, 1 CE CONFORMITYPRODUCTIVITY: 10/12 CUSHIONS PER MINUTE (CONSIDERED A OPEN SIDE OF 6/8”) Learn More -

M-1487 CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC YEAR 2000 WIDTH 3600mmREFERENCE NUMBER: M-1487 (660125KJH5RXM) CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC YEAR 2000 WIDTH 3600mm CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC MEZZERA BIANCO ROLLERS WIDTH: 3800 mm WORKING WIDTH: 3600 mm YEAR OF CONSTRUCTION: 2000 COMPOSED OF: - DOUBLE INTRODUCTION, FRAME MANUFACTURED IN PAINTED FE PROFILES , SLINGING BY ADJUSTABLE FLYWHEELS, 2 GROUPS OF WIDENING-CENTRING ROLLERS E+L KF20, FABRIC GUIDING ROLLERS IN AISI 316, DRAGGING CALANDER WITH 3 ROLLERS. - BY-PASS AND SYNCHRONIZATION BRIDGE COMPOSED OF : FRAME IN CARBON STEEL FE37, GROUP OF GUIDING ROLLERS IN STAINLESS STEEL COMPLETE WITH SELF-ALIGNED BEARINGS TO GUIDE THE FABRIC TO THE FOLLOWING SECTION . - ROLLER WASHING UNIT IN OPEN WIDTH , MOD. ACTIVA 30, WITH DOUBLE FABRIC DWELLING. - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - SQUEEZING SYSTEM WITH : 2 ROLLERS COATED RUBBER/EBONITE, RUBBER HARDNESS 75-80 SHA, WORKING PRESSURE 3000 KG, A.C. MOTOR GEARBOX, INVERTER, PNEUMATIC DRIVE. - ROLLER WASHING UNIT IN OPEN WIDTH , MOD. ACTIVA 30, WITH DOUBLE FABRIC DWELLING. - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - SQUEEZING SYSTEM WITH : 2 ROLLERS COATED RUBBER/EBONITE, RUBBER HARDNESS 75-80 SHA, WORKING PRESSURE 3000 KG, A.C. MOTOR GEARBOX, INVERTER, PNEUMATIC DRIVE. - ROLLER WASHING UNIT IN OPEN WIDTH, MOD. ACTIVA 20, WITH SIMPLE FABRIC DWELLING - INTERMEDIATE SEPARATOR FOR TANK SPLITTING - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - DELIVERY GROUP WITH PNEUMATIC FOULARD OF 10 TON RUBBER/EBONITE, COMPLETE WITH BEARING FRAME AND PROTECTION CASING. RUBBER ROLLER WITH HIGH SQUEEZING EFFECT ROLLIN - SECOND DISCHARGING STACK - PUMP FOR THE BATH RECYCLING IN THE NEUTRALIZATION PART - PH-METER WITH DOSING PUMP TO NEUTRALIZE IN THE FIRST SECTION OF THE LAST TANK - BIG BATCHER, ADHERING TYPE, DRIVEN BY MOTOR WITH VARIABLE SPEED. - SLAT WIDENING UNIT FOR DOUBLE ROW - 2 DUCTING FOR THE WATER RECOVERY BETWEEN THE 2 WASHING UNITS IN OPEN WIDTH - 3 TEMPERATURE AUTOMATIC CONTROLS PER EACH WASHING UNIT - 4 SETS OF PROPORTIONAL VALVES WITH LITER COUNTER - COMPLETE MOTORIZATION OF THE LINE WITH MOTORS GROUP, ELECTRIC CONTROL CABINET AND SYNOPTICAL PANEL. - VERTICAL DRYER RAMALLUMIN COMPOSED OF 2 COLUMNS WITH 8 ROLLERS, IN ORDER TO DRY BOTH FACES OF THE FABRIC, FOR A TOTAL OF 16 DRYING ROLLERS. O MAX. WORKING WIDTH: 3600 mm. O MAX. MECHANICAL SPEED: 80 MT./MIN. O MAX. WEIGHT OF THE FABRIC, IN WIDTH 3400 mm 900 GR./LINEAR METER O FORESEEN WORKING SPEED WITH FABRIC W=3400mm W=850 GR. 40/45 MT./MIN. O FORESEEN WORKING SPEED WITH FABRIC W=3400 W=425 GR. 80 MT./MIN. O MODIFIED, AS FOLLOWS, WITH ADDITIONS OF : 2 COOLING ROLLERS, 1 SET OF ACCESSORIES FOR THE FEEDING AND RETURN OF THE COOLING WATER, SET OF COMPONENTS FOR THE CONTROL, 4 RETURN CYLINDERS, COMPENSATING GROUP ON THE INTRODUCTION SIDE, 3 SUCTIONING HOODS, 1 EXHAUSTER. Learn More

M-1487 CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC YEAR 2000 WIDTH 3600mmREFERENCE NUMBER: M-1487 (660125KJH5RXM) CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC YEAR 2000 WIDTH 3600mm CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC MEZZERA BIANCO ROLLERS WIDTH: 3800 mm WORKING WIDTH: 3600 mm YEAR OF CONSTRUCTION: 2000 COMPOSED OF: - DOUBLE INTRODUCTION, FRAME MANUFACTURED IN PAINTED FE PROFILES , SLINGING BY ADJUSTABLE FLYWHEELS, 2 GROUPS OF WIDENING-CENTRING ROLLERS E+L KF20, FABRIC GUIDING ROLLERS IN AISI 316, DRAGGING CALANDER WITH 3 ROLLERS. - BY-PASS AND SYNCHRONIZATION BRIDGE COMPOSED OF : FRAME IN CARBON STEEL FE37, GROUP OF GUIDING ROLLERS IN STAINLESS STEEL COMPLETE WITH SELF-ALIGNED BEARINGS TO GUIDE THE FABRIC TO THE FOLLOWING SECTION . - ROLLER WASHING UNIT IN OPEN WIDTH , MOD. ACTIVA 30, WITH DOUBLE FABRIC DWELLING. - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - SQUEEZING SYSTEM WITH : 2 ROLLERS COATED RUBBER/EBONITE, RUBBER HARDNESS 75-80 SHA, WORKING PRESSURE 3000 KG, A.C. MOTOR GEARBOX, INVERTER, PNEUMATIC DRIVE. - ROLLER WASHING UNIT IN OPEN WIDTH , MOD. ACTIVA 30, WITH DOUBLE FABRIC DWELLING. - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - SQUEEZING SYSTEM WITH : 2 ROLLERS COATED RUBBER/EBONITE, RUBBER HARDNESS 75-80 SHA, WORKING PRESSURE 3000 KG, A.C. MOTOR GEARBOX, INVERTER, PNEUMATIC DRIVE. - ROLLER WASHING UNIT IN OPEN WIDTH, MOD. ACTIVA 20, WITH SIMPLE FABRIC DWELLING - INTERMEDIATE SEPARATOR FOR TANK SPLITTING - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - DELIVERY GROUP WITH PNEUMATIC FOULARD OF 10 TON RUBBER/EBONITE, COMPLETE WITH BEARING FRAME AND PROTECTION CASING. RUBBER ROLLER WITH HIGH SQUEEZING EFFECT ROLLIN - SECOND DISCHARGING STACK - PUMP FOR THE BATH RECYCLING IN THE NEUTRALIZATION PART - PH-METER WITH DOSING PUMP TO NEUTRALIZE IN THE FIRST SECTION OF THE LAST TANK - BIG BATCHER, ADHERING TYPE, DRIVEN BY MOTOR WITH VARIABLE SPEED. - SLAT WIDENING UNIT FOR DOUBLE ROW - 2 DUCTING FOR THE WATER RECOVERY BETWEEN THE 2 WASHING UNITS IN OPEN WIDTH - 3 TEMPERATURE AUTOMATIC CONTROLS PER EACH WASHING UNIT - 4 SETS OF PROPORTIONAL VALVES WITH LITER COUNTER - COMPLETE MOTORIZATION OF THE LINE WITH MOTORS GROUP, ELECTRIC CONTROL CABINET AND SYNOPTICAL PANEL. - VERTICAL DRYER RAMALLUMIN COMPOSED OF 2 COLUMNS WITH 8 ROLLERS, IN ORDER TO DRY BOTH FACES OF THE FABRIC, FOR A TOTAL OF 16 DRYING ROLLERS. O MAX. WORKING WIDTH: 3600 mm. O MAX. MECHANICAL SPEED: 80 MT./MIN. O MAX. WEIGHT OF THE FABRIC, IN WIDTH 3400 mm 900 GR./LINEAR METER O FORESEEN WORKING SPEED WITH FABRIC W=3400mm W=850 GR. 40/45 MT./MIN. O FORESEEN WORKING SPEED WITH FABRIC W=3400 W=425 GR. 80 MT./MIN. O MODIFIED, AS FOLLOWS, WITH ADDITIONS OF : 2 COOLING ROLLERS, 1 SET OF ACCESSORIES FOR THE FEEDING AND RETURN OF THE COOLING WATER, SET OF COMPONENTS FOR THE CONTROL, 4 RETURN CYLINDERS, COMPENSATING GROUP ON THE INTRODUCTION SIDE, 3 SUCTIONING HOODS, 1 EXHAUSTER. Learn More -

M-1526 THERMOBONDING LINE YEAR 1999-2000 WIDTH 3200mmWORKING WIDTH: 3.200 mm WEIGHT: 100 – 1000 G/M² CAPACITY: 600 KG/H COMPOSED OF: CARDING MACHINE CROSSLAPPER QUILT MACHINE THERMOSETTING OVEN 4X BURNER FOR AIR HEATING AND CIRCULATION SYSTEM 4X FAN WINDER ELECTRIC SYSTEM PIPING Learn More

M-1526 THERMOBONDING LINE YEAR 1999-2000 WIDTH 3200mmWORKING WIDTH: 3.200 mm WEIGHT: 100 – 1000 G/M² CAPACITY: 600 KG/H COMPOSED OF: CARDING MACHINE CROSSLAPPER QUILT MACHINE THERMOSETTING OVEN 4X BURNER FOR AIR HEATING AND CIRCULATION SYSTEM 4X FAN WINDER ELECTRIC SYSTEM PIPING Learn More -

M-5162 BRUCKNER STENTER YEAR 2000 WIDTH 3600mmREFERENCE NUMBER: M-5162 (12122ZTQBK11RX) L BRUCKNER STENTER YEAR 2000 WIDTH 3600mm BRUCKNER STENTER YEAR 2000 WIDTH 3600mm QUANTITY AVAILABLE: 1 Learn More

M-5162 BRUCKNER STENTER YEAR 2000 WIDTH 3600mmREFERENCE NUMBER: M-5162 (12122ZTQBK11RX) L BRUCKNER STENTER YEAR 2000 WIDTH 3600mm BRUCKNER STENTER YEAR 2000 WIDTH 3600mm QUANTITY AVAILABLE: 1 Learn More -

J-0026 PREPARATION LINE SCHLUMBERGER GN6, YEAR 1990, WIDTH 2000mm TO 7350mmREFERENCE NUMBER: J-0026 (1111GMNRBXX10UX) PREPARATION LINE SCHLUMBERGER GN6, YEAR 1990, WIDTH 2000mm TO 7350mm COMPOSED OF: - 1 SET WITH SINGLE DELIVERY ON TO CAN SIZE: 1000X1200, WITH MECHANICAL ATL - 1 SET WITH TWO DELIVERY ON TO CAN SIZE: 700X1000 - 1 SET WITH FOUR DELIVERY ON TO 2 CANS SIZE: 500X1000 1 SET DELIVERY INTO ROPE, YOC 1990, WIDTH 2000mm TO 7350mm WITH MECHANICAL ATL QUANTITY AVAILABLE: 1 Learn More

J-0026 PREPARATION LINE SCHLUMBERGER GN6, YEAR 1990, WIDTH 2000mm TO 7350mmREFERENCE NUMBER: J-0026 (1111GMNRBXX10UX) PREPARATION LINE SCHLUMBERGER GN6, YEAR 1990, WIDTH 2000mm TO 7350mm COMPOSED OF: - 1 SET WITH SINGLE DELIVERY ON TO CAN SIZE: 1000X1200, WITH MECHANICAL ATL - 1 SET WITH TWO DELIVERY ON TO CAN SIZE: 700X1000 - 1 SET WITH FOUR DELIVERY ON TO 2 CANS SIZE: 500X1000 1 SET DELIVERY INTO ROPE, YOC 1990, WIDTH 2000mm TO 7350mm WITH MECHANICAL ATL QUANTITY AVAILABLE: 1 Learn More