Search results for: 'fabric cutting machine'

- Related search terms

- Machine+c'

- machine f'

- Machine c''

- machine de'

- machine'''''

-

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mmM-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

OFFER 001

SPUNBOND PRODUCTION LINE

WORKING WIDTH: 4040mm

WEIGHT: 130 TO 250 G/M2OFFER 002

POLYMER CLEANING GROUPOFFER 003

CRYSTALLIZING GROUPOFFER 004

DRYING GROUPOFFER 005

PNEUMATIC CONVEYING SYSTEMOFFER 006

EXTRUDER HOPPEROFFER 007

EXTRUDEROFFER 008

FILTERING UNITOFFER 009

MELT TRANSFER LINEOFFER 010

SPINNING BEAMOFFER 011

SPINNING PACKSOFFER 012

FILAMENTS QUENCHING SYSTEMOFFER 013

FILAMENTS DRAWING AND DISTRIBUTION SYSTEMOFFER 014

WEB FORMING CONVEYOR BELTOFFER 015

CREEL FOR APPLICATION OF REINFORCING FILAMENTSOFFER 016

PRE-NEEDLING MACHINEOFFER 017

NEEDLING MACHINEOFFER 018

THERMOSETTING UNITOFFER 019

OUTLET CALENDEROFFER 020

FOULARDOFFER 021

BINDER PREPARATION SYSTEMOFFER 022

DRYEROFFER 023

OUTLET CALENDEROFFER 024

AUTOMATIC WINDEROFFER 025

AIR COMPRESSORS (FOR FILAMENTS STRETCHING EJECTORS)OFFER 026

DIATHERMIC OIL HEATING SYSTEMOFFER 027

CHILLED WATER CIRCULATION AND GENERATION SYSTEMOFFER 028

EQUIPMENT FOR CLEANING CYCLE, SPECIAL TOOLSOFFER 029

FIBRE DUST RECOVERY SYSTEMOFFER 030

EDGES RECOVERY SYSTEMOFFER 031

SPINNING SECTION STEEL STRUCTUREOFFER 032

DISTRIBUTION ELECTRIC CABINETSOFFER 033

PROCESS ELECTRIC SYSTEM OF EXISTING MACHINES ACCORDING TO THE ACTUAL LAYOUTOFFER 034

CABLES AND CABLING MATERIALSQUANTITY: 1 LINE

Learn More -

C-4357 FULL-AUTO SINGLE AND DOUBLE SHEETS WET TISSUE MACHINE WITH AUTO ELIMINATION FUNCTION Y-200, WIDTH 900mm

C-4357 FULL-AUTO SINGLE AND DOUBLE SHEETS WET TISSUE MACHINE WITH AUTO ELIMINATION FUNCTION Y-200, WIDTH 900mmC-4357 FULL-AUTO SINGLE AND DOUBLE SHEETS WET TISSUE MACHINE WITH AUTO ELIMINATION FUNCTION Y-200, WIDTH 900mm

Y-200 FULL-AUTO SINGLE AND DOUBLE SHEETS WET TISSUE MACHINE WITH AUTO

ELIMINATION FUNCTION

MAIN TECHNICAL PARAMETER (SUITABLE FOR 1 OR 2 PIECE /BAG)

PRODUCTION FLOW: UNROLLING — FOLDING — WETTING — CUTTING — STACKING — PACKING — DELIVERING

(1) MAIN TECHNICAL PARAMETER:

POWER SUPPLY: 380V 50HZ

POWER: 6KW

SUITABLE RAW MATERIAL: AIR LAID PAPER, SPUNLACE/HOT-ROLLING NONWOVEN FABRIC

SIZE OF RAW MATERIAL: (150 TO 250) × 1000 (mm, W*DIA)

WEIGHT OF RAW MATERIAL: 40 TO 80G/㎡

WET TISSUE UNFOLDED SIZE: (140 TO 280) × (150 TO 250) (mm, L×W)

WET TISSUE FOLDED SIZE: (70 TO 140) × (45 TO 85) (mm, L×W)

PACKING FILM: OPP/PE, PET/PE

PRODUCTION SPEED: 150 TO 240 PCS/MIN

NET WEIGHT: 1850 KG

SIZE OF MACHINE: 7200*900*1650 (mm, L×W ×H)QUANTITY: 1

Learn More -

V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”)V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”) THIS LINE INCLUDES PREFOLDING MACHINE, BANDAGE DRYING MACHINE, FOLDING MACHINE, AND WINDING MACHINE. FINAL PRODUCT IS 6 PLY USES 4 OUTPUT LINES, OUTPUT IS APPROXIMATELY 48 PIECES PER MINUTE FINAL WIDTH OF FABRIC: USUALLY CUSTOMERS USE 780mm WIDTH, MACHINE CAN BE MADE ACCORDING TO DIFFERENT REQUESTS MACHINE TOTAL LENGTH: 19 METERS (62.3 FEET) TOTAL QUANTITY: 1 COMPLETE PRODUCTION LINE Learn More

V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”)V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”) THIS LINE INCLUDES PREFOLDING MACHINE, BANDAGE DRYING MACHINE, FOLDING MACHINE, AND WINDING MACHINE. FINAL PRODUCT IS 6 PLY USES 4 OUTPUT LINES, OUTPUT IS APPROXIMATELY 48 PIECES PER MINUTE FINAL WIDTH OF FABRIC: USUALLY CUSTOMERS USE 780mm WIDTH, MACHINE CAN BE MADE ACCORDING TO DIFFERENT REQUESTS MACHINE TOTAL LENGTH: 19 METERS (62.3 FEET) TOTAL QUANTITY: 1 COMPLETE PRODUCTION LINE Learn More -

J-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mmJ-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mm QUILTING MACHINE QUILTING WIDTH: 2450mm QUANTITY: 1 PANEL CUTTER SPEED: 10 METERS PER MINUTE POWER: 3.2 KW AIR PRESSURE: 0.4 TO 0.8 Mpa VOLTAGE: 380 V / 50 Hz, 220 V / 60 Hz, 3-PHASE DIMENSIONS: 3500 x 1150 x 2300 (L x W x H mm) WEIGHT: 1150 KG QUANTITY: 1 Learn More

J-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mmJ-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mm QUILTING MACHINE QUILTING WIDTH: 2450mm QUANTITY: 1 PANEL CUTTER SPEED: 10 METERS PER MINUTE POWER: 3.2 KW AIR PRESSURE: 0.4 TO 0.8 Mpa VOLTAGE: 380 V / 50 Hz, 220 V / 60 Hz, 3-PHASE DIMENSIONS: 3500 x 1150 x 2300 (L x W x H mm) WEIGHT: 1150 KG QUANTITY: 1 Learn More -

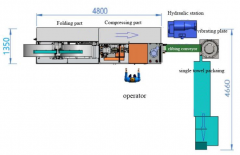

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More -

C-4355 FULL-AUTO WET TISSUE FOLDING MACHINE Y-12 AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGE

C-4355 FULL-AUTO WET TISSUE FOLDING MACHINE Y-12 AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGEC-4355 FULL-AUTO WET TISSUE FOLDING MACHINE Y-12 AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGE

OFFER 001

Y-360 FULL AUTOMATIC RECIPROCATING TYPE PACKING MACHINE

PRODUCTION TYPE: BABY WET TISSUE

PRODUCTION PROCESS: CONNECT TO Y-2700 FOLDING MACHINE (OR Y-12 FOLDING MACHINE) → FEEDING WIPE AUTOMATIC →CONVEYING TO PACKING MACHINE → SETTING PACKING FILM → SETTING WINDOW HOLE LABEL → CENTRAL SEALING →END SEALING AND RECIPROCATING CUT → OUTPUT FINISHED PRODUCTS.

MAINTECHNICAL PARAMETER: (SUITABLE TO PACK: 5 TO 120PCS/BAG)

PRODUCT SPEED: 55 TO 60 BAG/MIN

DIAMETER OF RAW FILM ROLL: ≤380mm

WIDTH OF RAW FILM ROLL: ≤420mm

WRAPPING MATERIAL: PP, OPP, PET, PE, AND ALL SUITABLE FILMS

SHAPES OF PACKING: PILLOW TYPE PACKAGING

PACKING LENGTH: 110 TO 300mm (TOUCH SCREEN SETABLE)

PACKING WIDTH: 80 TO 150mm (ADJUSTABLE)

HEIGHT OF PACKING: 10 TO 100mm (ADJUSTABLE)

HORIZONTAL SEALING PATTERN: RECIPROCATION HEAT SEALING

DRIVE MOTOR PATTERN: ALL SERVO DRIVE

CONTROL PATTERN: YASKAWA SIMOTION CONTROL SYSTEM

OPERATION INTERFACE: 7 INCH LCD

FILM SUPPLY SYSTEM: SERVO DRIVE

HORIZONTAL SYSTEM: SERVO DRIVE

FEEDING SYSTEM: SERVO DRIVE

LABELING SYSTEM: SERVO DRIVE

PUNCHING SYSTEM: SERVO DRIVE

HORIZONTAL PROTECTION: TORQUE OVERLOAD PROTECTION

AIR REQUIREMENTS: 0.5 TO 0.8 MPA 0.01 M3/MIN

ELECTRIC POWER REQUIREMENTS: 380VAC 50/60HZ

GENERAL POWER: 7.6KW

DIMENSION OF MACHINE: 3610 × 1150 × 1900mm

STANDARD EQUIPMENT: DATE PRINTING UNIT, PUNCHING UNIT, LABELLING UNIT, INSERTING CORNER UNIT, ELECTRICAL EYE TRACKING AUTOMATICALLY

(2) SYSTEM CHARACTER

1. THE PACKING FILM ADOPTS MECHNICAL TENSION CONTROL

2. TWO LABEL MACHINE, ONE SUB-LABELING, THE OTHER IS ANTI-COUNTERFEITING LABEL

3. PUNCHING AT THE PACKING FILM AUTOMATICALLY

4. HEATING PRINTING (DATE) DEVICE

5. FOUR BACK AND FORTH TRANSVERSE SEALING DEVICE WITHINSERT CORNER BY CYLINDER FORM

6. EIGHT SERVO MOTORS, CONTROLLING FEEDING PACKING FILM, TRANSVERSE SEALING, FEEDING TISSUE RESPECTIVELY

7. LENGTHWAYS SEALING DEVICE, CONTROL THEOPEN-CLOSEBY CYLINDER. THE SEALING WHEEL ARE APART AUTOMATICALLY WHEN THE MACHINE STOPS

8. PUNCHING, LABELING AND THE EYE MARK’S RELATIVED POSITION CAN BE SET IN THE TOUCH SCREEN.

9. AUTOMATIC FEEDING RAW MATERIAL DEVICE

10. COLOUR TOUCH SCREEN, MOTION SYSTEM CONTROL

11. MAIN MOTOR ADOPTS FAMOUS BRAND

12. MAIN MACHINE ADOPTS FRAMES FORMOFFER 002

Y-360 FULL AUTOMATIC RECIPROCATING TYPE PACKING MACHINE

YASKAWA ELECTRICITY FROM JAPAN

ITEM NUMBER: 1

MOTION CONTROLLER

JEPMC-MP2300S-E

YASKAWA

QUANTITY: 1

ITEM NUMBER: 2

EXTENDED MODULE

R7K4FML-6-DCA32A

YASKAWA

QUANTITY: 1

ITEM NUMBER: 3

SERVO MOTOR/SERVO UNIT

SGMJV-08ADE6S /SGDV-5R5A11A

YASKAWA 750W

QUANTITY: 5

ITEM NUMBER: 4

SERVO MOTOR/SERVO UNIT

SGMGV-13ADC61 /SGDV-120A11A

YASKAWA 1.3KW

QUANTITY: 1

ITEM NUMBER: 5

SERVO MOTOR/SERVO UNIT

SGMGV-20ADA61/SGDV-180A11A

YASKAWA 1.8KW

QUANTITY: 1

ITEM NUMBER: 6

SERVO MOTOR/SERVO UNIT

SGMGV-09ADC61/SGDV-7R6A11A

YASKAWA 0.85 KW

QUANTITY: 1

ITEM NUMBER: 7

POWER CABLE + ENCODER CABLE

JZZP-CVM09/JZSP-CVP02-05

YASKAWA 850W

QUANTITY: 1

ITEM NUMBER: 8

POWER CABLE + ENCODER CABLE

JZSP-CMM00-05 JZSP-CMP00-05

YASKAWA 750W

QUANTITY: 7

ITEM NUMBER: 9

POWER CABLE + ENCODER CABLE

JZSP-CVM30-05 JZSP-CVP02-5

YASKAWA 1.3KW, 1.8KW

QUANTITY: 2

ITEM NUMBER: 10

COMMUNICATION CABLE

JEPMC-W6002-05

QUANTITY: 12

ITEM NUMBER: 11

TERMINAL RESISTANCE

JEPMC-W6022-E

QUANTITY: 2

ITEM NUMBER: 12

TOUCH PANEL

WEINVIEW

7 INCH

QUANTITY: 1

ITEM NUMBER: 13

AIR BREAK SWITCH

LG

QUANTITY: 12

ITEM NUMBER: 14

RESIDUAL CURRENT CIRCUIT BREAKER

CHINT

QUANTITY: 1

ITEM NUMBER: 15

CONTACTOR (SWITCH)

SCHNEIDER

QUANTITY: 1

ITEM NUMBER: 16

POWER SWITCH

M&W

350W

QUANTITY: 1

ITEM NUMBER: 17

SOLID STATE RELAY (SSR)

ANV

QUANTITY: 6

ITEM NUMBER: 18

TEMPERATURE CONTROLLER

DTE10P

QUANTITY: 1

ITEM NUMBER: 19

RELAY

OMRON

QUANTITY: 4OFFER 003

Y-12 BABY WIPES FOLDING MACHINE

PRODUCTION FLOW: UNROLLING - SLITTING FABRIC INTO LANES - FOLDING - WETTING - CUTTING – PILE & COUNTING - DELIVERING

MAIN TECHNICAL PARAMETER (SUITABLE TO WET TISSUE FOR LARGE SIZE PACKING)

PRODUCT TYPE: BABY WIPES (NON CROSS FOLDING)

PRODUCT SPEED: 200 TO 270 CUTS/MIN (SET ON PLC)

SUITABLE RAW MATERIAL: AIR LAID PAPER, SPUNLACE/HOT-ROLLING NONWOVEN FABRIC

WEIGHT OF RAW MATERIAL: 40-80G/㎡

FOLDING WAY: “Z” SHAPE (POP UP AND NON-POP UP)

CUTTING UNITE:

A. DOUBLE PAPER SHELVES

B. 10 LANES OR 12 LANES, 2 ROLLS

C. RAW MATERIAL ROLL WIDTH: 900 TO 1200mm

LENGTH OF WET TISSUE: 140 TO 185mm (SET ON PLC)

FREQUENCY OF RECEIVING PAPER: 14 TO 20 TIMES/MIN (SET ON PLC)

SIZE OF RAW MATERIAL: (1000 TO 1250) × Ø1000 (mm, W×DIA)

WET TISSUE UNFOLDED SIZE: (140 TO 185) × (150 TO 200) (mm, L×W)

WET TISSUE FOLDED SIZE: (140 TO 185) × (80 TO 110) (mm, L×W)

MATERIAL SUPPLY SYSTEM: SERVO MOTOR

CUTTING SYSTEM: CONVERTER MOTOR

PILING SYSTEM: SERVO MOTOR

POWER SUPPLY: 380V 50HZOFFER 004

Learn More

Y-12 WET TISSUE FOLDING MACHINE

MAIN PARTS

ITEM NUMBER: 1

PLC

FX3U-32T

MITSUBISHI (JAPAN)

QUANTITY: 1

ITEM NUMBER: 2

SERVO MOTOR (CONTROL THE DISTANCE OF TISSUE

ASD-B2-2023-B, ECMA-E21320RS

3.0KW DELTA (TAIWAN)

QUANTITY: 1

ITEM NUMBER: 3

SERVO MOTOR (RECEIVING TISSUE)

ASD-B2-0721-B, ECMA-C20807RS

750W DELTA (TAIWAN)

QUANTITY: 1

ITEM NUMBER: 4

TURBINE WORM REDUCER MOTOR

WPDA120-1:10-Y100L2-4

3KW NANJING UTTON (CHINA)

QUANTITY: 1

ITEM NUMBER: 5

INVERTER

SB70G4

4KW SENLON

QUANTITY: 1

ITEM NUMBER: 6

TOUCH SCREEN

7INCH

WECON

QUANTITY: 1

ITEM NUMBER: 7

AIR SWITCH

LG

QUANTITY: 1

ITEM NUMBER: 8

SWITCHING POWER SUPPLY

S-100-24

SHANGHAI MINGWEI (CHINA)

QUANTITY: 1

ITEM NUMBER: 9

INDICATOR LIGHT

SCHNEIDER

SCHNEIDER (GERMAN)

QUANTITY: 1

ITEM NUMBER: 10

EMERGENCY STOP SWITCH

SCHNEIDER

SCHNEIDER (GERMAN)

QUANTITY: 1

ITEM NUMBER: 11

POTENTIOMETER

5KΩ

QUANTITY: 1

ITEM NUMBER: 12

ROTARY ENCODER

INCREMENTAL POLE OUTPUT

KOYO (JAPAN)

QUANTITY: 1

ITEM NUMBER: 13

RELAY

OMRON

OMRON (JAPAN)

QUANTITY: 5

ITEM NUMBER: 14

PROXIMITY SWITCH

AUTONICS

AUTONICS (KOREA)

QUANTITY: 2 -

A-2523 MELTBLOWN FABRIC PRODUCTION MACHINE 600 mmA-2523 MELTBLOWN FABRIC PRODUCTION MACHINE 600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 600mm PRODUCTION SPEED: 13 TO 17 M/min EXTRUDER DIAMETER IN mm: 65mm EXTRUDER MOTOR IN KW: 22KW PRODUCT WEIGHT RANGE: 5000 TO 6000 KGS MELTBLOWN FABRIC THICKNESS: 25 TO 30 GSM MAX OUTPUT: 300 TO 400 KG / 24 HOURS DIMENSION: 15000 X 3000 X 3000 mm WEIGHT: 5000 TO 6000 KGS POWER (TOTAL KW): 96 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 PRODUCTION TIME: 15 DAYS Learn More

A-2523 MELTBLOWN FABRIC PRODUCTION MACHINE 600 mmA-2523 MELTBLOWN FABRIC PRODUCTION MACHINE 600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 600mm PRODUCTION SPEED: 13 TO 17 M/min EXTRUDER DIAMETER IN mm: 65mm EXTRUDER MOTOR IN KW: 22KW PRODUCT WEIGHT RANGE: 5000 TO 6000 KGS MELTBLOWN FABRIC THICKNESS: 25 TO 30 GSM MAX OUTPUT: 300 TO 400 KG / 24 HOURS DIMENSION: 15000 X 3000 X 3000 mm WEIGHT: 5000 TO 6000 KGS POWER (TOTAL KW): 96 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 PRODUCTION TIME: 15 DAYS Learn More -

A-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mmA-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 1600mm PRODUCTION SPEED: 24 TO 30 M/min EXTRUDER DIAMETER IN mm: 90mm EXTRUDER MOTOR IN KW: 45 KW PRODUCT WEIGHT RANGE: 8000 TO 1000 KGS MELTBLOWN FABRIC THICKNESS: 25 TO 30 GSM MAX OUTPUT: 1500 TO 1800 KG / 24 HOURS DIMENSION: 20000 X 8000 X 9000 mm WEIGHT: 8000 TO 1000 KGS POWER (TOTAL KW): 575 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 + 1 X 20 PRODUCTION TIME: 45 DAYS Learn More

A-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mmA-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 1600mm PRODUCTION SPEED: 24 TO 30 M/min EXTRUDER DIAMETER IN mm: 90mm EXTRUDER MOTOR IN KW: 45 KW PRODUCT WEIGHT RANGE: 8000 TO 1000 KGS MELTBLOWN FABRIC THICKNESS: 25 TO 30 GSM MAX OUTPUT: 1500 TO 1800 KG / 24 HOURS DIMENSION: 20000 X 8000 X 9000 mm WEIGHT: 8000 TO 1000 KGS POWER (TOTAL KW): 575 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 + 1 X 20 PRODUCTION TIME: 45 DAYS Learn More -

J-4810 FUNG CHANG INDUSTRIAL RASCHEL KNITTING LINES FOR PLASTIC BAGS, YEAR 2020J-4810 FUNG CHANG INDUSTRIAL RASCHEL KNITTING LINES FOR PLASTIC BAGS, YEAR 2020 MAKE: FUNG CHANG INDUSTRIAL CO, LTD YEAR: 2020 CONSISTING OF 2 RASCHEL KNITTING LINES: ITEM 001 RASCHEL KNITTING LINE WITH AUTO-CUTTING DEVICE (COMPLETE LINE FOR ONION / POTATOES / FIRE LOG NETS), YEAR 2020 QUANTITY: 1 LINE ITEM 002 RASCHEL KNITTING LINE WITH AUTO-CUTTING DEVICE (COMPLETE LINE FOR ONION / POTATOES / FIRE LOG NETS), YEAR 2020 QUANTITY: 1 LINE Learn More

J-4810 FUNG CHANG INDUSTRIAL RASCHEL KNITTING LINES FOR PLASTIC BAGS, YEAR 2020J-4810 FUNG CHANG INDUSTRIAL RASCHEL KNITTING LINES FOR PLASTIC BAGS, YEAR 2020 MAKE: FUNG CHANG INDUSTRIAL CO, LTD YEAR: 2020 CONSISTING OF 2 RASCHEL KNITTING LINES: ITEM 001 RASCHEL KNITTING LINE WITH AUTO-CUTTING DEVICE (COMPLETE LINE FOR ONION / POTATOES / FIRE LOG NETS), YEAR 2020 QUANTITY: 1 LINE ITEM 002 RASCHEL KNITTING LINE WITH AUTO-CUTTING DEVICE (COMPLETE LINE FOR ONION / POTATOES / FIRE LOG NETS), YEAR 2020 QUANTITY: 1 LINE Learn More -

A-1553 HAEMMERLE-XETMA FAM CUTTING YEAR 1984 W.1800mm

A-1553 HAEMMERLE-XETMA FAM CUTTING YEAR 1984 W.1800mmREFERENCE NUMBER: A-1553

Learn More

HAEMMERLE / XETMA FAM CUTTING MACHINE YEAR 1984 WIDTH 1800mm – TO CUT BACK WARP YARN OF WOVEN FABRICS

HAEMMERLE / XETMA FAM CUTTING MACHINE

MODEL: FAM

YEAR: 1984

WORKING WIDTH: 1800mm

QUANTITY: 1