Search results for: 'heating wi'

- Related search terms

- heating

- heating el

- heating w

- heating+w

- heating+wir

-

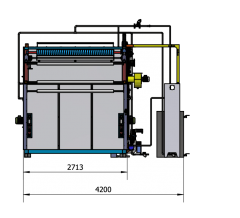

V-1360 SANTEX THERMOBONDING COMPRESSION OVEN FOR NONWOVENS ON ROLL, 80 TO 400 G/M, YEAR 1986

V-1360 SANTEX THERMOBONDING COMPRESSION OVEN FOR NONWOVENS ON ROLL, 80 TO 400 G/M, YEAR 1986V-1360 SANTEX THERMOBONDING COMPRESSION OVEN FOR NONWOVENS ON ROLL, 80 TO 400 G/M, YEAR 1986

WORKING WIDTH: 2500mm

ROLL FACE WIDTH: WORKING WIDTH + 50mm

MATERIAL FIBERS: NONWOVEN WEB OF POLYESTER OR DIFFERENT FIBERS MIXED WITH 10 TO 25% POLYESTER BI-COMPONENT BINDER FIBERS OR DIFFERENT BINDER FIBERS

MACHINE SPEED: 1 TO 20 M/MIN. (OTHERS UPON REQUEST)

COMPOSITION OVEN: 2 HEATING ZONES OF 2 M EACH + 1 COOLING SECTIONQUANTITY: 1

Learn More -

M-0450 GPE1000 AIR BUBBLE FILM MAKING MACHINE

M-0450 GPE1000 AIR BUBBLE FILM MAKING MACHINEDESCRIPTION OF MACHINE THIS MACHINE ADOPTS ONCE-THROUGH SHAPING TECHNIQUE, THUS IT HAS HIGH EFFICIENCY AND EXCELLENT PRODUCT QUALITY. THIS MACHINE SET HAS SUCH FEATURES AS SCIENTIFIC AND REASONABLE STRUCTURE DESIGN, SMOOTH AND RELIABLE RUNNING AND CONVENIENT OPERATION AND MAINTENANCE. AIR BUBBLE SHEET EXTRUSION LINE PRODUCES CONTINUOUS ROLL OF AIR BUBBLE SHEET, AN IDEAL CUSHIONING-PACKAGING AND INSULATING MATERIALS, BY EXTRUDING POLYETHYLENE MELT THROUGH T-DIE OVER A DRIVING VACUUM FORMING ROLL. FEATURE USER-FRIENDLY SYSTEM WITH AC VARIABLE SPEED DRIVES. PID TEMP. CONTROL & DIGITAL TEMP. DISPLAY. 2-LAYERS WIDTH 1000, 1200,1500, 1800, 2000,2500,3000MM CUSTOMIZED. ◆ APPLICATION OF AIR BUBBLE FILM ◆ EXCELLENT SHOCK ABSORBENCY. ◆ VERY LIGHT, TRANSPARENT BUFFER MATERIAL. ◆ HARMLESS AND RESISTANT TO ACID, ALKALI, OIL AND OTHER CHEMICALS. ◆ HIGHLY RESISTANT TO WATER AND MOISTURE. ◆ PRINTING AND LAMINATION WITH OTHER MATERIALS-IN ADDITION TO CUTTING, SLITTING, BAG-MAKING AND PUNCHING-ARE POSSIBLE. ◆ PACKAGE VOLUME REDUCTION PERMITS COST REDUCTION. ◆ EXCELLENT INSULATION EFFECTIVENESS. ◆ VARIED FROM PACKAGING OF FRAGILE ITEMS TO INSULATED COVER FOR SWIMMING POOLS. RAW MATERIAL IS LDPE : YOU CAN USE NEW MATERIAL, OR RECLAIMED MATERIALS. THE COLOR OF FILM MADE BY NEW MATERIAL IS GOOD. THE COLOR OF FILM MADE BY RECLAIMED MATERIALS IS NOT VERY TRANSPARENT, MAYBE A LITTLE GRAY. IF YOU WANT TO PRODUCE COLOR FILM. YOU CAN ADD COLOR MASTER BATCH. TECHNICAL PARAMETERS: ● PRODUCTS PRODUCED: LDPE AIR BUBBLE FILM SHEET IN ROLL ● RAW MATERIAL : LDPE AND LLDPE ● WIDTH OF THE FILM :MAX IS 1000MM ● FILM THICKNESS:0.05MM-0.15MM ● LINEAR SPEED:1000M/H ● OUTPUT:45KG/H ● TOTAL POWER:50KW ● POWER SUPPLY:380V/3PHASE,50HZ (IF THE VOLTAGE IS DIFFERENT PLEASE TELL US, AND THE PRICE MAYBE DIFFERENT) ● MACHINE WEIGHT:3T EQUIPMENT SPECIFICATIONS: 1. EXTRUDER (1) SCREW( ZHOU SHAN) DIAMETER OF SCREW:65MM L/D: 30:1 (2) SCREW AND BARREL MATERIAL: 38 CRMOAL AFTER NITROGEN TREATMENT WITH OPTIMUM HARDNESS, STRONG CORROSION RESISTANCE AND LONG SERVICE LIFETIME. (3) HOPPER SEAT: CENTRAL FEEDING (4) MAIN MOTOR: 15KW, WITH FREQUENCY INVERTER CONTROL (5) HEATING METHOD: ALUMINUM-CASTED HEATER (6) HEATING ZONE : ONE-ZONE DIGITAL TEMPERATURE CONTROL (7) GEAR BOX: HARD TOOTH GEAR BOX 2. FILTER PART: (1) LONG-LIFE NET TYPE MANUAL SCREEN CHANGING ( FAST NET CHANGER$800) (2) FILTER OUTSIDE DIA:160MM (3) FILTER INSIDE DIA: 65MM 3. T-DIE: (1) WIDTH OF T-DIE: LIKE CLOTH-HANGER, ENABLE THE MELTING MATERIAL BE FLOWED EVENLY. WITH ALUMINUM-CASTED HEATER. (2) FILM STRUCTURE: 2LAYERS( FLAT FILM+ AIR BUBBLE FILM) (3) WIDTH:1050MM (4) WIDTH ADJUSTMENT: UT-BLOCK TYPE, SINGLE SIDE IS 200MM (5) HEATING ZONE :THREE ZONE, ALUMINUM-CASTED HEATER 4. TRACTION PART: (1) AIR BUBBLE FORMING ROLLER 1PC:WIDTH 1050MM FORMING WAY: VACUUM SUBPRESSURE MOULD BUBBLE SPEC:10(DIAMETER)X4MM(HEIGHT) AND 8MM*2.5MM ----------IT ALSO CAN BE DESIGNED WITH ACCORDING TO THE CUSTOMERS. (SCOPE: 6MM—32MM) (2) COOLING WAY: WATER COOLING (3) DRIVING WAY: LP MOTOR IN SHANGHAI (4) SPEED-ADJUSTING WAY: INVERTER ADJUSTMENT (5) DRIVING POWER: 1.5KW (6) THREE TRACTION ROLLER: 1050MM 3PCS (7) EQUIPPED WITH CUTTING KNIFES AS CUSTOMER REQUEST. 5. WINDING PART: (1) WITH METER COUNTER, ALARM WARNING (2) TORQUE MOTOR (3) AUTOMATIC COLLECTION. AUTO CHANGER (4) MANUAL CUT FILM (5) WINDING MOTOR POWER:2.2KW 6.ELECTRICAL PARTS AND MOTORS:MADE IN CHINA ● ELECTRICAL PARTS:CHINT BRAND ● MAIN MOTOR:MADE IN SHANGHAI DED0NG BRAND15KW( FREQUENCY INVERTER ADJUST SPEED) ● FREQUENCY INVERTER:MADE IN SHANGHAI NS BRAND ● GEAR BOX : HARD TOOTH GEAR BOX ● ALUMINUM CASTING HEATING 7. COOLING SYSTEM: WATER RECYCLING COOLING SYSTEM. YOU CAN CHOOSE WATER TOWER OR CHILLER. SPARE PARTS AS FREE: 10 INCH WRENCH: 1 PC HEXAGEONIC WRENCH: 1 SET OIL GUN: 1 PC CROSS POINT SCREWDRIVER: 1 PC ELECTRICITY TESTING PEN: 1 PC MAIN SWITCH: 2 PCS TEMPERATURE CONTROLLER: 1 PC ELECTRIC-THERMAL COUPLE: 2 PCS TOOLS AND TOOL BOX: 1 SET SCREW HEATER: 1 PC CURRENT METER: 1 PC CJX1-22A/22V A.C CONTACTOR: 1 PC FILTER: 1 PC GLOVE: 2 PCS DZ47 1P 32A CIRCUITE BREAKER: 1 PC CUTTER: 5 PC OPERATION MANUAL: 1 PC HEAT PLATE: 1 PC

Learn More -

YY-2424 USED NGR REGRANULATION LINE for BOPP FILM, FLUFF, LUMPS, MDO WASTE 900 TO 1000 KG PER HYY-2424 USED NGR REGRANULATION LINE for BOPP FILM, FLUFF, LUMPS, MDO WASTE 900 TO 1000 KG PER H OVERCONSUMPTION: 500 KW OUTPUT: 1000 KGS PER HOUR INTENDED FOR THE FOLLOWING WASTE: OUTPUT; BOPP FILM, FLUFF, LUMPS, MDO WASTE: 900 TO 1000 KG/H; CPP FILM, FLUFF, LUMPS: 900 TO 1000 KG/H; PERFORMANCE IS PROVIDED FOR REFERENCE ONLY. THE CAPACITY OF THE DEVICE DEPENDS ON THE PROPERTIES OF THE MATERIAL, E.G. MOISTURE CONTENT, PRINTING, WEIGHT, MELT INDEX, CONTAMINATION AND DEGREE OF FILTRATION. AVERAGE POWER CONSUMPTION: 500 KW; AVERAGE COOLING WATER DEMAND: 668 L/MIN; AVERAGE FRESH WATER CONSUMPTION: 34 L/H; MAXIMUM COMPRESSED AIR CONSUMPTION: 100 L/MIN. THE VALUES GIVEN ABOVE ARE ONLY REFERENCE VALUES AND MAY DIFFER FROM THE VALUES FINAL VALUES OBTAINED AFTER CALIBRATION OF THE DEVICE. THIS DATA SHOULD NOT BE USED FOR PLANNING. Learn More

YY-2424 USED NGR REGRANULATION LINE for BOPP FILM, FLUFF, LUMPS, MDO WASTE 900 TO 1000 KG PER HYY-2424 USED NGR REGRANULATION LINE for BOPP FILM, FLUFF, LUMPS, MDO WASTE 900 TO 1000 KG PER H OVERCONSUMPTION: 500 KW OUTPUT: 1000 KGS PER HOUR INTENDED FOR THE FOLLOWING WASTE: OUTPUT; BOPP FILM, FLUFF, LUMPS, MDO WASTE: 900 TO 1000 KG/H; CPP FILM, FLUFF, LUMPS: 900 TO 1000 KG/H; PERFORMANCE IS PROVIDED FOR REFERENCE ONLY. THE CAPACITY OF THE DEVICE DEPENDS ON THE PROPERTIES OF THE MATERIAL, E.G. MOISTURE CONTENT, PRINTING, WEIGHT, MELT INDEX, CONTAMINATION AND DEGREE OF FILTRATION. AVERAGE POWER CONSUMPTION: 500 KW; AVERAGE COOLING WATER DEMAND: 668 L/MIN; AVERAGE FRESH WATER CONSUMPTION: 34 L/H; MAXIMUM COMPRESSED AIR CONSUMPTION: 100 L/MIN. THE VALUES GIVEN ABOVE ARE ONLY REFERENCE VALUES AND MAY DIFFER FROM THE VALUES FINAL VALUES OBTAINED AFTER CALIBRATION OF THE DEVICE. THIS DATA SHOULD NOT BE USED FOR PLANNING. Learn More -

YY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINEYY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINE TECHNICAL PARAMETERS: 1. BAG SIZE: BASED ON CUSTOMER'S REQUEST; 2. SPEED: 120 TO 180 BAGS/MIN; 3. PACKING MATERIALS: PAPER + PAPER, PAPER + PLASTIC, 4. PACKAGE MATERIAL DIAMETER Φ≤350mm, WIDTH IS BASED ON CUSTOMER'S REQUEST; 5. VOLTAGE: 3 PHASE 380V 50Hz OR 220V 50/60Hz; 6. MOTORS: a. SERVO MOTOR 1.5KW b. SERVO MOTOR: 1KW c. STEPPING MOTOR 110 d. STEPPING MOTOR VARIABLE FREQUENCY MOTOR 0.37KW 7. TOTAL OF 5 MOTORS IS 4KW 8. USES 28 VOLT FOR THE HEAT CIRCUIT, 2 HEATING PANELS, EACH PANEL WITH 8 HEATING TUBES, EACH TUBE IS 300 W, TOTAL 4.8 KW; 9. MACHINE WEIGHT: 800 KG; 10. MACHINE SIZE: LENGTH 5000 × WIDTH 1300 × HEIGHT 1600mm; 11. CRATE SHIPPING DATA: LENGTH 2600 × WIDTH 1900 × HEIGHT 1800mm. 12. TOTAL OF 5 MOTORS IS: 4KW QUANTITY: 1 Learn More

YY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINEYY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINE TECHNICAL PARAMETERS: 1. BAG SIZE: BASED ON CUSTOMER'S REQUEST; 2. SPEED: 120 TO 180 BAGS/MIN; 3. PACKING MATERIALS: PAPER + PAPER, PAPER + PLASTIC, 4. PACKAGE MATERIAL DIAMETER Φ≤350mm, WIDTH IS BASED ON CUSTOMER'S REQUEST; 5. VOLTAGE: 3 PHASE 380V 50Hz OR 220V 50/60Hz; 6. MOTORS: a. SERVO MOTOR 1.5KW b. SERVO MOTOR: 1KW c. STEPPING MOTOR 110 d. STEPPING MOTOR VARIABLE FREQUENCY MOTOR 0.37KW 7. TOTAL OF 5 MOTORS IS 4KW 8. USES 28 VOLT FOR THE HEAT CIRCUIT, 2 HEATING PANELS, EACH PANEL WITH 8 HEATING TUBES, EACH TUBE IS 300 W, TOTAL 4.8 KW; 9. MACHINE WEIGHT: 800 KG; 10. MACHINE SIZE: LENGTH 5000 × WIDTH 1300 × HEIGHT 1600mm; 11. CRATE SHIPPING DATA: LENGTH 2600 × WIDTH 1900 × HEIGHT 1800mm. 12. TOTAL OF 5 MOTORS IS: 4KW QUANTITY: 1 Learn More -

YY-2846 NEW STEAMER, EFFECTIVE WIDTH 1800mm (ROLL SURFACE 2000mm)YY-2846 NEW STEAMER, EFFECTIVE WIDTH 1800mm (ROLL SURFACE 2000mm) EFFECTIVE WIDTH: 1800mm (ROLL SURFACE 2000mm); CAPACITY: 45M; QUANTITY: 1 Learn More

YY-2846 NEW STEAMER, EFFECTIVE WIDTH 1800mm (ROLL SURFACE 2000mm)YY-2846 NEW STEAMER, EFFECTIVE WIDTH 1800mm (ROLL SURFACE 2000mm) EFFECTIVE WIDTH: 1800mm (ROLL SURFACE 2000mm); CAPACITY: 45M; QUANTITY: 1 Learn More -

L-2532 POLYETHYLENE FOAM PLANK PRODUCTION LINE MODEL 180 1000 TO 2000mm WIDTH 2 TO 18mm THICKNESS

L-2532 POLYETHYLENE FOAM PLANK PRODUCTION LINE MODEL 180 1000 TO 2000mm WIDTH 2 TO 18mm THICKNESSREFERENCE NUMBER: L-2532

Learn More

MODEL: 180

1000 TO 2000mm WIDTH -

M-5175 OLBRICH COATING LINE FOR MANUFACTURING TARPAULIN AND BANNER PVC COATED FABRICS 3300mm

M-5175 OLBRICH COATING LINE FOR MANUFACTURING TARPAULIN AND BANNER PVC COATED FABRICS 3300mmM-5175 OLBRICH COATING LINE FOR MANUFACTURING TARPAULIN AND BANNER PVC COATED FABRICS 3300mm

KNIFE OVER ROLL COATING

LIST OF EQUIPMENT FOR MANUFACTURING OF PVC COATED FABRICS, LINE CAN APPLY ANY TYPE OF COATING INCLUDING WATER BASED OR SOLVENT BASED AND EITHER CLEAR COAT THE FABRIC OR SATURATE COAT ANY WOVEN FABRIC , CAN ALSO DO SUNBRELLA TYPE TECHNICAL TEXTILES

FOR ONE SIDE COATING WITH KISS COATERMANUFACTURED BY OLBRICH GMBH (ERECTED IN 2005) 3400mm (SCRIM CAN BE 3400mm WIDTH)

CAN MAKE 3350mm COATED FABRIC AND AFTER TRIMMED EDGES HAVE A FINISHED PRODUCT OF 3300mm (BEGINNING WITH A 3400mm SCRIM , THERE ARE INBUILT CUTTING BLADES FOR TRIMMING .

MANUFACTURED IN GERMANY BEGINNING 2003 AND 2004COATING LINE

UNWINDER

PENDULUM

WEB CONTROL UNIT

PULLING STATION

PENDULUM

HEATING ROLLER (DIAMETER 570 mm)

PLATFORM

SAWING GAUGE

DOUBLE-KNIFE (DOCTOR) VERTICAL COATING MACHINE

VERTICAL DRIER

COOLING STATION WITH ROLLER LOCK

PENDULUM

SMOOTHING ROLL

MACHINE FRAME

IDLER ROLLER BRIDGE

PULLING STATION

PLATFORM

COATING MACHINE (KNIFE-OVER-ROLL)

HORIZONTAL DRIER

COOLING STATION

IDLER ROLLER BRIDGE

PLATFORM

SMOOTHING CALENDER

SUCTION HOOD

LACQUERING MACHINE (ZIMMER)

TEMPERATURE CONTROL UNIT

DRYER

ACCUMULATOR OF FABRIC

COMPUTER WITH SOFTWARE CONTROL

(SIEMENS)

ELECTRICAL CONTROL PLANT

WEIGHT-PER-UNIT-AREA

MEASURING GAUGE (2 UNITS MAHLO)-ISOTOPE NOT INCLUDED

REWINDER

FREE STANDING SLITTER-REWINDER (SEE PHOTO ATTACHED)

TRIMMING GOUGE

PERIPHERAL EQUIPMENT

LIQUIFIED GAS EQUIPMENT RH80 (RANSOME MANUFACTURING USA)

EVAPORATOR-RANSOME (USA)

CHILLER (ITALY) WITH EXPANSION TANK

BOILER ERENSAN MODEL 2000 (ISI SANAYI A.S. TURKEY) FOR HEATING OIL WITH EXPANSION TANK.

\BOILER FOR HEATING BUILDING, NOT INCLUDED

REGENERATIVE THERMAL OXIDIZER (RTO) ENVIROLOGIC USA

12 STAINLESS STEEL CONTAINERS FOR PLASTISOL VOLUME -1 M3

VACUUM DISSOLVER (SRUGO)-2 UNITS

PIPING, EXHAUST VENT PIPES (NO BUILDING HEATING PIPES )

OVERHEAD CRANE NOT INCLUDEDFLOORSPACE OCCUPIED BY THE LINE:

LENGTH 67,125mm

WIDTH 6200mm

HEIGHT 8100mmSPEED 3 TO 30 M/MIN

HEATING SYSTEM: OIL

QUANTITY: 1 LINE

Learn More -

YY-2703 SLITTER REWINDER FOR PLASTIC FILMS LABEL MATERIAL, ETC., UP TO 1600mm WIDEYY-2703 SLITTER REWINDER FOR PLASTIC FILMS LABEL MATERIAL, ETC., UP TO 1600mm WIDE FEATURES: HOT BLADE CUTTING SYSTEM FOR WOVEN LABELS COLD BLADE CUTTING SYSTEM FOR NON-WOVEN LABELS EASY OPERATION STABLE WORKING AND LONG LIFE QUANTITY: 1 Learn More

YY-2703 SLITTER REWINDER FOR PLASTIC FILMS LABEL MATERIAL, ETC., UP TO 1600mm WIDEYY-2703 SLITTER REWINDER FOR PLASTIC FILMS LABEL MATERIAL, ETC., UP TO 1600mm WIDE FEATURES: HOT BLADE CUTTING SYSTEM FOR WOVEN LABELS COLD BLADE CUTTING SYSTEM FOR NON-WOVEN LABELS EASY OPERATION STABLE WORKING AND LONG LIFE QUANTITY: 1 Learn More -

M-6092 ETHYLENE OXIDE STERILIZER

M-6092 ETHYLENE OXIDE STERILIZERREFERENCE NUMBER: M-6092

ETHYLENE OXIDE STERILIZERSTERILIZING TEMPERATURE: 0~100°C, PID ADJUSTABLE

Learn More

STERILIZING PRESSURE: -95~+80KPA

STERILIZING HUMIDITY: 20~100% RH, ADJUSTABLE

EO CONCENTRATION: 300~1,000 MG/L

STERILIZING TIME: 3~12 HRS -

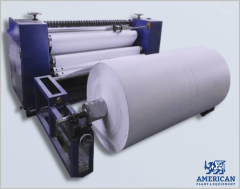

TT-7334 COMPLETE LAMINATING LINE, YEAR 2012 TO 2023TT-7334 COMPLETE LAMINATING LINE, YEAR 2012 TO 2023 Learn More

TT-7334 COMPLETE LAMINATING LINE, YEAR 2012 TO 2023TT-7334 COMPLETE LAMINATING LINE, YEAR 2012 TO 2023 Learn More