Search results for: 'one piece'

- Related search terms

- Piece

- one

- one drive setup

- one off thing

- ONE BLADE

-

TT-1678 ROUND CLEANING PAD MAKING MACHINE WITH EMBOSSING, WIDTH 380mmTT-1678 ROUND CLEANING PAD MAKING MACHINE WITH EMBOSSING, WIDTH 380mm MOTHER ROLL WIDTH: 380mm OUTPUT LINE: 6 LINES MOTHER ROLL QUANTITY: 4 PIECES FINISHED PAD DIAMETER: 57mm MOTHER ROLL MATERIAL: SPUNLACE NON-WOVEN FABRIC PRODUCTION SPEED: 2500 TO 3000 PIECES/MINUTE RATED VOLTAGE: 380 VOLTS (OR 220 VOLTS) RATED FREQUENCY: 50Hz (OR 60 Hz) TOTAL POWER: 3.5 KW DIMENSIONS: LENGTH 5500mm × WIDTH 1200mm × HEIGHT 2000mm WEIGHT: 2500 KG QUANTITY: 1 Learn More

TT-1678 ROUND CLEANING PAD MAKING MACHINE WITH EMBOSSING, WIDTH 380mmTT-1678 ROUND CLEANING PAD MAKING MACHINE WITH EMBOSSING, WIDTH 380mm MOTHER ROLL WIDTH: 380mm OUTPUT LINE: 6 LINES MOTHER ROLL QUANTITY: 4 PIECES FINISHED PAD DIAMETER: 57mm MOTHER ROLL MATERIAL: SPUNLACE NON-WOVEN FABRIC PRODUCTION SPEED: 2500 TO 3000 PIECES/MINUTE RATED VOLTAGE: 380 VOLTS (OR 220 VOLTS) RATED FREQUENCY: 50Hz (OR 60 Hz) TOTAL POWER: 3.5 KW DIMENSIONS: LENGTH 5500mm × WIDTH 1200mm × HEIGHT 2000mm WEIGHT: 2500 KG QUANTITY: 1 Learn More -

J-4026 FLAT PILLOW ROLLER, FLATTENING AND ROLLING MACHINE – 6 PIECES PER MINUTEJ-4026 FLAT PILLOW ROLLER, FLATTENING AND ROLLING MACHINE – 6 PIECES PER MINUTE POWER: 11.2 KW WEIGHT: 1000 KG AIR PRESSURE: 0.4 TO 0.8 Mpa FRONT BELT CONVEYOR: 750 x 1430 x 700mm PRESSING PLATE BELT: 650 x 1100mm PRESSING PLATE: 750 x 950mm STROKE HEIGHT: 300mm MIDDLE BELT CONVEYOR: 800 x 1800 x 750mm WRAPPING MACHINE: 620 x 2800 x 1200mm ELECTRIC CABINET: 450 x 800 x 1000mm OVERALL DIMENSIONS: 2800 x 5100 x 2050mm OVERALL VOLUME: 13 CUBIC METERS QUANTITY: 1 Learn More

J-4026 FLAT PILLOW ROLLER, FLATTENING AND ROLLING MACHINE – 6 PIECES PER MINUTEJ-4026 FLAT PILLOW ROLLER, FLATTENING AND ROLLING MACHINE – 6 PIECES PER MINUTE POWER: 11.2 KW WEIGHT: 1000 KG AIR PRESSURE: 0.4 TO 0.8 Mpa FRONT BELT CONVEYOR: 750 x 1430 x 700mm PRESSING PLATE BELT: 650 x 1100mm PRESSING PLATE: 750 x 950mm STROKE HEIGHT: 300mm MIDDLE BELT CONVEYOR: 800 x 1800 x 750mm WRAPPING MACHINE: 620 x 2800 x 1200mm ELECTRIC CABINET: 450 x 800 x 1000mm OVERALL DIMENSIONS: 2800 x 5100 x 2050mm OVERALL VOLUME: 13 CUBIC METERS QUANTITY: 1 Learn More -

J-3688 HAUSER SNA 3300 QUILTING MACHINES, YEAR 1998J-3688 HAUSER SNA 3300 QUILTING MACHINES, YEAR 1998 EACH MACHINE REQUIRES 33 SQUARE METERS OF FLOOR SPACE DIMENSIONS: 5500mm LENGTH x 6000mm WIDTH STATUS: 4 MACHINES ASSEMBLED ON MILL FLOOR AND ONE MACHINE STORED INSIDE CONTAINER QUANTITY: 5 Learn More

J-3688 HAUSER SNA 3300 QUILTING MACHINES, YEAR 1998J-3688 HAUSER SNA 3300 QUILTING MACHINES, YEAR 1998 EACH MACHINE REQUIRES 33 SQUARE METERS OF FLOOR SPACE DIMENSIONS: 5500mm LENGTH x 6000mm WIDTH STATUS: 4 MACHINES ASSEMBLED ON MILL FLOOR AND ONE MACHINE STORED INSIDE CONTAINER QUANTITY: 5 Learn More -

T-6586 ISOLATION PROTECTIVE CLOTHING MT-B001-XL, 70G COMPOSITE NON-WOVEN FABRIC

T-6586 ISOLATION PROTECTIVE CLOTHING MT-B001-XL, 70G COMPOSITE NON-WOVEN FABRICREFERENCE NUMBER: T-6586

ISOLATION PROTECTIVE CLOTHING MT-B001-XL, 70G COMPOSITE NON-WOVEN FABRIC

ISOLATION PROTECTIVE CLOTHING

MODEL: MT-B001-XL

MATERIAL: 70G COMPOSITE NON-WOVEN FABRIC

SURFACE: WITH BLUE SEALING STRIPS

WEIGHT: 230G/PIECE

SIZE: XL (170-180CM)

DESIGN: ONE-PIECE TYPE FRONT OPENING, COLLARLESS HOOD, ELASTIC BRIM, ELASTIC CUFFS AND LEG OPENINGS.

FEATURE: ISOLATE BACTERIA, WATERPROOF, MICRO BREATHABLE, TEXTURE SOFT, THE HIGHEST GRADE MEDICAL PROTECTIVE CLOTHING MATERIAL.

USAGE: USED FOR VIRUS PROTECTION IN HOSPITAL GENERAL SICKROOM, AIRPORT, BUS STATION, RAILWAY STATION, FACTORY ETC.

CERTIFICATE: CE

ITEM 001

QUANTITY: ≥ 30,000 PIECES

ITEM 002

QUANTITY: ≥ 10,000 PIECES

ITEM 003

QUANTITY: ≥ 1,000 PIECES

MARKS: THIS PROTECTIVE CLOTHING/ISOLATION CLOTHING NOT INCLUDED SHOES COVER, NOT USED IN ICU.

Learn More -

V-1807 AUTOMATIC FACE MASK WITH OUTER EAR LOOP MACHINE, 120 MASKS PER MINUTE, FLAT TYPE

V-1807 AUTOMATIC FACE MASK WITH OUTER EAR LOOP MACHINE, 120 MASKS PER MINUTE, FLAT TYPEI. FUNCTION

Learn More

THE MACHINE IS FULLY AUTOMATIC EAR TO LOOP MASK MAKING MACHINE. THIS MACHINE INCLUDES ONE SET OF CS-175 AND 2 SETS CS-WD175 AND BY A UNIT OF AUTOMATED DISPENSER. MASK BODIES PRODUCED ON THE MASK MACHINE CAN BE ALLOCATED ONTO 2 SETS OF SUBSEQUENT MACHINES CONTROLLED BY PLC AT THE SPEED OF 0 TO 120 PIECES PER MINUTE. ALL OF OPERATIONS OF THE MACHINE ARE CONTROLLED THROUGH TOUCH SCREEN OR PLCS.

II. PROCESS

AFTER THE MACHINE MAKES THE MASK BODY, THE CONVEYOR BELT STRUCTURE TRANSPORTS THE MASK BODY PIECE TO THE CONNECTING CONVEYOR. THROUGH THE CONNECTION CONVEYOR MASK PLATE TO THE CONVEYOR BELT, AGAIN THROUGH THE CONVEYOR BELT THE MASK IS TRANSPORTED TO THE EAR PIECE SECTION TO THE FRONT OF THE MACHINE ABOVE THE FIRST MASK PLATE, FINALLY THROUGH THE CYLINDER DOWN THE MASK ONTO MASK EAR MACHINE DISC, FOLLOWED UP BY EAR MASKS FOR THE EARS OF THE BELT WELDING MACHINE AND THEN IT’S COMPLETE.

III. FEATURES:

1. MACHINE FRAME IS MADE OF ALUMINUM ALLOY, PREVENTED FROM RUST;

2. THE MACHINE CAN MAKE 1 TO 3 TYPES OF MASK BLANKS ACCORDING TO WHAT THE CUSTOMER REQUIRES.

3. THE SIZE OF THE MASK BLANK AND THE FOLDING LOCATION CAN BE ADJUSTED;

4. THE DIRECTION OF THE EAR LOOP IS OUTSIDE;

5. A COMPUTER PROGRAM CONTROL AND PHOTOELECTRIC DETECTION ACHIEVES A HIGH RELIABILITY AND LOW FAILURE RATE. -

G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINEREFERENCE NUMBER: G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINE FOR SALE: (5 PILLOWS PER MINUTE) FIBER OPENING, ACCURATE WEIGHING BY WEIGH PAN WITH LOAD CELL AND HIGH SPEED FILLING SYSTEM TOUCH SCREEN PANEL, FULLY AUTOMATED AND ACCURATE HANDLES WEIGHTS OF PILLOWS: FROM 150g TO 1500g PRODUCTION RATE: 5 PIECES PER MIN, 2400 PIECES PER 8 HOURS METAL DETECTOR AND OVERLOAD ALARM INCLUDES FIBER OPENING MACHINE ONE PERSON CAN RUN WHOLE LINE TWO HEAD FILLING MACHINE WITH PATTING DEVICES OPTIONAL: VACUUM FILLING TABLE QUANTITY AVAILABLE: 1 Learn More

G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINEREFERENCE NUMBER: G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINE FOR SALE: (5 PILLOWS PER MINUTE) FIBER OPENING, ACCURATE WEIGHING BY WEIGH PAN WITH LOAD CELL AND HIGH SPEED FILLING SYSTEM TOUCH SCREEN PANEL, FULLY AUTOMATED AND ACCURATE HANDLES WEIGHTS OF PILLOWS: FROM 150g TO 1500g PRODUCTION RATE: 5 PIECES PER MIN, 2400 PIECES PER 8 HOURS METAL DETECTOR AND OVERLOAD ALARM INCLUDES FIBER OPENING MACHINE ONE PERSON CAN RUN WHOLE LINE TWO HEAD FILLING MACHINE WITH PATTING DEVICES OPTIONAL: VACUUM FILLING TABLE QUANTITY AVAILABLE: 1 Learn More -

TT-8573 SAURER AUTOCORO 480 WITH 240 SPINDLES, YEAR 2011TT-8573 SAURER AUTOCORO 480 WITH 240 SPINDLES, YEAR 2011 1. SAURER AUTOCORO 480 2. E-SAVE TYPE 3. COROBOX SE12 4. YEAR 2011 QUANTITY: 1 Learn More

TT-8573 SAURER AUTOCORO 480 WITH 240 SPINDLES, YEAR 2011TT-8573 SAURER AUTOCORO 480 WITH 240 SPINDLES, YEAR 2011 1. SAURER AUTOCORO 480 2. E-SAVE TYPE 3. COROBOX SE12 4. YEAR 2011 QUANTITY: 1 Learn More -

TT-8496 EPE FOAM BONDING MACHINE, 66KW, WIDTH 2000mmTT-8496 EPE FOAM BONDING MACHINE, 66KW, WIDTH 2000mm 1. MAIN MOTOR (4KW/380V) 1 SET 2. ONE MAIN INVERTER (4KW/380V) 3. ENERGY-SAVING HIGH-PRESSURE FAN: 4KW 2 SETS 4. HEAT GUNS (16 KW) 4 SETS QUANTITY: 1 Learn More

TT-8496 EPE FOAM BONDING MACHINE, 66KW, WIDTH 2000mmTT-8496 EPE FOAM BONDING MACHINE, 66KW, WIDTH 2000mm 1. MAIN MOTOR (4KW/380V) 1 SET 2. ONE MAIN INVERTER (4KW/380V) 3. ENERGY-SAVING HIGH-PRESSURE FAN: 4KW 2 SETS 4. HEAT GUNS (16 KW) 4 SETS QUANTITY: 1 Learn More -

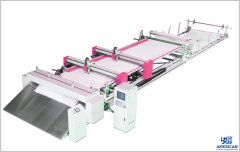

YY-2261 COMPUTERIZED DOUBLE SADDLES QUILTING MACHINE WITH SUPPORT BELT, MAXIMUM SPEED 3000 RPM PER MINUTE, MAXIMUM QUILTING THICKNESS 50mmYY-2261 COMPUTERIZED DOUBLE SADDLES QUILTING MACHINE WITH SUPPORT BELT, MAXIMUM SPEED 3000 RPM PER MINUTE, MAXIMUM QUILTING THICKNESS 50mm APPLICATION: SUITABLE FOR THE SINGLE HEAD QUILTING PATTERNS OF MATTRESS, DUVET, BLANKET, MATTRESS PROTECTOR. QUANTITY: 1 Learn More

YY-2261 COMPUTERIZED DOUBLE SADDLES QUILTING MACHINE WITH SUPPORT BELT, MAXIMUM SPEED 3000 RPM PER MINUTE, MAXIMUM QUILTING THICKNESS 50mmYY-2261 COMPUTERIZED DOUBLE SADDLES QUILTING MACHINE WITH SUPPORT BELT, MAXIMUM SPEED 3000 RPM PER MINUTE, MAXIMUM QUILTING THICKNESS 50mm APPLICATION: SUITABLE FOR THE SINGLE HEAD QUILTING PATTERNS OF MATTRESS, DUVET, BLANKET, MATTRESS PROTECTOR. QUANTITY: 1 Learn More -

YY-2003 PET PAD MAKING MACHINE, 100 PADS PER MINUTEYY-2003 PET PAD MAKING MACHINE, 100 PADS PER MINUTE TECHNICAL PARAMETERS: 1. POWER SUPPLY: 380V/50Hz OR 220V 50/60Hz 2. POWER: 80KW (INCLUDE A HOT MELT GLUE MACHINE) 3. STABLE SPEED: 0 TO 50 METERS PER MINUTE(5 LAYERS) 4. DIMENSION: LENGTH 20000 X WIDTH 5000 X HEIGHT 3500mm 5. WEIGHT: 13T 6. YUNG PRESS: ≥0.6MPA 1.2M³/MIN 7. PRODUCTS’ SPECIFICATIONS: WIDTH(300 TO 600mm), LENGTH(400 TO 1000mm) 8. THE CORE SIZE: WIDTH(300 TO 500MM), LENGTH(400 TO 800mm) 9. SAP WEIGHT: 10 TO 50G/㎡ 10. WOODEN PULP WEIGHT: 40 TO 110G/㎡ 11. AUTOMATIC TENSION CONTROL 12. SINGLE SAP APPLICATOR 13. ABSORBENT CORE PREPARATION UNIT 14. ABSORBENT LAYER CROSS CUTTING UNIT 15. BACK SHEET APPLICATION AND EDGE FOLDING UNIT 16. HOT MELT GLUING UNIT 17. FINISHED PRODUCTS EMBOSSING UNIT 18. WIDTH FOLDING UNIT 19. FINISHED PRODUCTS CUTTING UNIT 20. LENGTH FOLDING UNIT DELIVERY TIME: 100 DAYS QUANTITY: 1 Learn More

YY-2003 PET PAD MAKING MACHINE, 100 PADS PER MINUTEYY-2003 PET PAD MAKING MACHINE, 100 PADS PER MINUTE TECHNICAL PARAMETERS: 1. POWER SUPPLY: 380V/50Hz OR 220V 50/60Hz 2. POWER: 80KW (INCLUDE A HOT MELT GLUE MACHINE) 3. STABLE SPEED: 0 TO 50 METERS PER MINUTE(5 LAYERS) 4. DIMENSION: LENGTH 20000 X WIDTH 5000 X HEIGHT 3500mm 5. WEIGHT: 13T 6. YUNG PRESS: ≥0.6MPA 1.2M³/MIN 7. PRODUCTS’ SPECIFICATIONS: WIDTH(300 TO 600mm), LENGTH(400 TO 1000mm) 8. THE CORE SIZE: WIDTH(300 TO 500MM), LENGTH(400 TO 800mm) 9. SAP WEIGHT: 10 TO 50G/㎡ 10. WOODEN PULP WEIGHT: 40 TO 110G/㎡ 11. AUTOMATIC TENSION CONTROL 12. SINGLE SAP APPLICATOR 13. ABSORBENT CORE PREPARATION UNIT 14. ABSORBENT LAYER CROSS CUTTING UNIT 15. BACK SHEET APPLICATION AND EDGE FOLDING UNIT 16. HOT MELT GLUING UNIT 17. FINISHED PRODUCTS EMBOSSING UNIT 18. WIDTH FOLDING UNIT 19. FINISHED PRODUCTS CUTTING UNIT 20. LENGTH FOLDING UNIT DELIVERY TIME: 100 DAYS QUANTITY: 1 Learn More