Search results for: 'drawing-i'

- Related search terms

- drawing-in

- Drawing-in machine

-

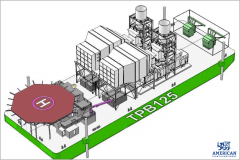

TT-3411 REVERSE OSMOSIS PLANT, PRODUCTION 20 MILLION US GALLONS PER DAY – SEA WATER DESALINATION PLANTTT-3411 REVERSE OSMOSIS PLANT, PRODUCTION 20 MILLION US GALLONS PER DAY – SEA WATER DESALINATION PLANT 173 MWE POWER BARGE SGT SERIES 5 2000E TURBINE AMOUNTED ON BARGE BRAND NEW UNIT TWIN INSTALLATION. 300MW 2856 RPM 60Hz - CAN OPERATE ON EITHER LIQUID FUEL OR GAS; - TRANSPORTABLE BY TOWING OR ON HEAVY LIFT VESSELS; - CAN BE MOORED AT BERTH OR POSITIONED IN PROTECTED WATERS USING SPUDS; - FUEL SUPPLY BY STORAGE BARGE OR PIPED FROM LAND-BASED STORAGE; - ENVIRONMENTALLY FRIENDLY; - BARGE & SYSTEMS ABS CLASSED; - APPROVED BY LLOYDS OF LONDON. Learn More

TT-3411 REVERSE OSMOSIS PLANT, PRODUCTION 20 MILLION US GALLONS PER DAY – SEA WATER DESALINATION PLANTTT-3411 REVERSE OSMOSIS PLANT, PRODUCTION 20 MILLION US GALLONS PER DAY – SEA WATER DESALINATION PLANT 173 MWE POWER BARGE SGT SERIES 5 2000E TURBINE AMOUNTED ON BARGE BRAND NEW UNIT TWIN INSTALLATION. 300MW 2856 RPM 60Hz - CAN OPERATE ON EITHER LIQUID FUEL OR GAS; - TRANSPORTABLE BY TOWING OR ON HEAVY LIFT VESSELS; - CAN BE MOORED AT BERTH OR POSITIONED IN PROTECTED WATERS USING SPUDS; - FUEL SUPPLY BY STORAGE BARGE OR PIPED FROM LAND-BASED STORAGE; - ENVIRONMENTALLY FRIENDLY; - BARGE & SYSTEMS ABS CLASSED; - APPROVED BY LLOYDS OF LONDON. Learn More -

TT-3063 CARD TC-03, YEAR 2005, CAN DIAMETER 1000mmTT-3063 CARD TC-03, YEAR 2005, CAN DIAMETER 1000mm QUANTITY: 2 Learn More

TT-3063 CARD TC-03, YEAR 2005, CAN DIAMETER 1000mmTT-3063 CARD TC-03, YEAR 2005, CAN DIAMETER 1000mm QUANTITY: 2 Learn More -

YY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOURYY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOUR THE MACHINE IS COMPOSED OF MOTOR, HYDRAULIC SYSTEM, DRAG HOOK, PULL MOUTH, BODY, ETC. THE BASIC PRINCIPLE IS: THE MOTOR DRIVES THE HYDRAULIC SYSTEM AND HYDRAULIC CYLINDER, AND THE DRAG HOOK IS CONNECTED TO THE PULL ROD OF THE OIL CYLINDER. THE ACTION OF THE OIL PUMP AND OIL CYLINDER MAKES THE DRAG HOOK RECIPROCATE. QUANTITY: 1 Learn More

YY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOURYY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOUR THE MACHINE IS COMPOSED OF MOTOR, HYDRAULIC SYSTEM, DRAG HOOK, PULL MOUTH, BODY, ETC. THE BASIC PRINCIPLE IS: THE MOTOR DRIVES THE HYDRAULIC SYSTEM AND HYDRAULIC CYLINDER, AND THE DRAG HOOK IS CONNECTED TO THE PULL ROD OF THE OIL CYLINDER. THE ACTION OF THE OIL PUMP AND OIL CYLINDER MAKES THE DRAG HOOK RECIPROCATE. QUANTITY: 1 Learn More -

TT-2972 SOLAR TAURUS 70 CTG TURBINE PLANT, 7.43 MW, 60Hz, YEAR 2011TT-2972 SOLAR TAURUS 70 CTG TURBINE PLANT, 7.43 MW, 60Hz, YEAR 2011 SOLAR TURBINE PLANT, 7.43 MW 60Hz VINTAGE YEAR 2011 QUANTITY: 1 Learn More

TT-2972 SOLAR TAURUS 70 CTG TURBINE PLANT, 7.43 MW, 60Hz, YEAR 2011TT-2972 SOLAR TAURUS 70 CTG TURBINE PLANT, 7.43 MW, 60Hz, YEAR 2011 SOLAR TURBINE PLANT, 7.43 MW 60Hz VINTAGE YEAR 2011 QUANTITY: 1 Learn More -

YY-2554 CHOCOLATE BUNCH WRAPPERS FOR SALEYY-2554 CHOCOLATE BUNCH WRAPPERS FOR SALE ITEM 001 CHOCOLATE BUNCH FOIL WRAPPERS (AVAILABLE SEPARATELY) MANUFACTURED BY ACMA-GD QUANTITY: 2 ITEM 002 CHOCOLATE BUNCH WRAPPER MANUFACTURED BY RASCH QUANTITY: 1 Learn More

YY-2554 CHOCOLATE BUNCH WRAPPERS FOR SALEYY-2554 CHOCOLATE BUNCH WRAPPERS FOR SALE ITEM 001 CHOCOLATE BUNCH FOIL WRAPPERS (AVAILABLE SEPARATELY) MANUFACTURED BY ACMA-GD QUANTITY: 2 ITEM 002 CHOCOLATE BUNCH WRAPPER MANUFACTURED BY RASCH QUANTITY: 1 Learn More -

YY-2286 UNUSED 8.7MW 60Hz STX-MAN 1 X 18V32/40 POWER PLANT ENGINE, YEAR 2011, GENERATOR’S VOLTAGE 13800 VYY-2286 UNUSED 8.7MW 60Hz STX-MAN 1 X 18V32/40 POWER PLANT ENGINE, YEAR 2011, GENERATOR’S VOLTAGE 13800 V MAIN SPECIFICATIONS: - ENGINE MODEL: 18V32/40 X 1 SET; - MAKER: STX-MAN; - CONTINUOUS OUTPUT: 8,730KWE X 720 RPM; - FREQUENCY & VOLTAGE: 60Hz & 13,800V; - YEAR OF PRODUCTION: 2011; - FUEL OIL: HEAVY FUEL OIL HFO (700CST/50°C); QUANTITY: 1 Learn More

YY-2286 UNUSED 8.7MW 60Hz STX-MAN 1 X 18V32/40 POWER PLANT ENGINE, YEAR 2011, GENERATOR’S VOLTAGE 13800 VYY-2286 UNUSED 8.7MW 60Hz STX-MAN 1 X 18V32/40 POWER PLANT ENGINE, YEAR 2011, GENERATOR’S VOLTAGE 13800 V MAIN SPECIFICATIONS: - ENGINE MODEL: 18V32/40 X 1 SET; - MAKER: STX-MAN; - CONTINUOUS OUTPUT: 8,730KWE X 720 RPM; - FREQUENCY & VOLTAGE: 60Hz & 13,800V; - YEAR OF PRODUCTION: 2011; - FUEL OIL: HEAVY FUEL OIL HFO (700CST/50°C); QUANTITY: 1 Learn More -

J-3914 CONTINUOUS HORIZONTAL FOAM CUTTING MACHINE, BUN SIZE 2500 x 2500 x 1300mmJ-3914 CONTINUOUS HORIZONTAL FOAM CUTTING MACHINE, BUN SIZE 2500 x 2500 x 1300mm MAXIMUM BUN SIZE: 2500 x 2500 x 1300mm MAXIMUM CUTTING SPEED: 40 METERS PER MINUTE SYSTEM: WINDOWS 7, LICENSED SOLENOID VALVE: FESTO SOFTWARE FOR DRAWING: ZW CAD, LICENSED CUTTING SOFTWARE: PROPRIETARY QUANTITY: 1 Learn More

J-3914 CONTINUOUS HORIZONTAL FOAM CUTTING MACHINE, BUN SIZE 2500 x 2500 x 1300mmJ-3914 CONTINUOUS HORIZONTAL FOAM CUTTING MACHINE, BUN SIZE 2500 x 2500 x 1300mm MAXIMUM BUN SIZE: 2500 x 2500 x 1300mm MAXIMUM CUTTING SPEED: 40 METERS PER MINUTE SYSTEM: WINDOWS 7, LICENSED SOLENOID VALVE: FESTO SOFTWARE FOR DRAWING: ZW CAD, LICENSED CUTTING SOFTWARE: PROPRIETARY QUANTITY: 1 Learn More -

T-6550 MEDICAL PROTECTIVE CLOTHING BLOOD SYNTHETIC PENETRABILITY TESTER

T-6550 MEDICAL PROTECTIVE CLOTHING BLOOD SYNTHETIC PENETRABILITY TESTERREFERENCE NUMBER: T-6550

MEDICAL PROTECTIVE CLOTHING BLOOD SYNTHETIC PENETRABILITY TESTER

TECHNICAL SPECIFICATIONS AND CONFIGURATION:

1. THE INSTRUMENT ADOPTS AN AIR SOURCE THAT CAN PROVIDE (0.5 ~ 30±0.1) KPA PRESSURE TO CONTINUOUSLY PRESSURIZED THE SAMPLE, WHICH IS NOT RESTRICTED BY THE SPACE OF THE TEST SITE;

2. THE AIR PRESSURE RANGE CAN BE ADJUSTED FREELY, AND THE ADJUSTMENT RANGE (0.5 ~ 30) KPA;

3. COLOR TOUCH SCREEN DISPLAY AND OPERATION;

4. THE SAMPLE CLAMPING PAD IS PROCESSED WITH IMPORTED SPECIAL ALUMINUM PROFILES, WHICH IS LIGHT IN MATERIAL, CLEAN IN SURFACE AND NEVER RUSTS.

5. THE INSTRUMENT ADOPTS IMPORTED SPECIAL ALUMINUM WIRE DRAWING PANEL, EQUIPPED WITH METAL KEYS, SENSITIVE OPERATION, NOT EASY TO DAMAGE;

6. CLAMPING DEVICE FOR INSTRUMENT SAMPLES, EQUIPPED WITH LOCKING PROTECTION, TO PREVENT THE SYNTHETIC BLOOD FROM SPLASHING AROUND;

7. CLAMPING FORCE IS ACCURATE AND RELIABLE;

8. THE TEST TANK IS EQUIPPED WITH A SPECIAL PLACEMENT DEVICE, WHICH IS CONVENIENT FOR CUSTOMERS TO OPERATE;

9. THE TEST TANK IS PROCESSED WITH SPECIAL 316 STAINLESS STEEL, AND THE TOP IS EQUIPPED WITH A SPECIAL COVER FOR HIGH TRANSPARENT PROTECTION;

10. THE WASHER BELOW THE SAMPLE IS MADE OF HIGH-QUALITY PTFE MATERIAL AFTER SPECIAL PROCESSING;

11. SQUARE METAL BLOCK NET: OPEN SPACE ≥50°%; BENDING ≤5mm AT 30KPA;

12. INSTRUMENT TIME CONTROL ACCURACY ≤01 SECONDS;

13. THE SHELL OF THE INSTRUMENT IS MADE OF HIGH-QUALITY METAL BAKING PAINT, WHICH IS BEAUTIFUL AND GENEROUS.

14. EQUIPPED WITH PRINTER INTERFACE, CONNECTED TO THE PRINTER CAN DIRECTLY PRINT DATA REPORTS.

TECHNICAL PARAMETERS:

1. SAMPLE SIZE: 75mm X 75mm

2. TEST AREA: 28.26 SQUARE CENTIMETERS

3. AIR PRESSURE ADJUSTMENT RANGE (0.5 ~ 30) KPA

4. EXTERNAL SIZE: 500mm X 500mm X 500mm (L X W X H)

5. WEIGHT OF THE INSTRUMENT: 40 KG

6. POWER SUPPLY: AC220V, 50HZ,SCOPE OF SUPPLY: 1. ONE MAIN MACHINE; 2. TWO PTFE GASKETS; 3. TWO ORDINARY WASHERS; 4. ONE METAL BLOCKING NET; 5. A SET OF SPECIAL LOCKING TOOLS; 6. ONE HIGH-QUALITY SILENT AIR PUMP, [NOTE: SAFETY PRODUCTION LICENSE IS NOT INCLUDED]. 7. EQUIPPED WITH PRINTER INTERFACE; 8. ONE SAMPLE TEMPLATE; 9. ONE PRODUCT CERTIFICATE; 10. ONE COPY OF PRODUCT OPERATION MANUAL.

OPERATION INSTRUCTION:

INSERT THE AIR PUMP OUTPUT PIPE INTO THE OIL AND WATER SEPARATOR OF THE INSTRUMENT AS REQUIRED (PRESSURE 0.1-0.3MPA).

AFTER SWITCHING ON THE POWER, THE STARTUP INTERFACE (NAME OF THE DEVICE) IS DISPLAYED.

PRESS THE "ENTER" BUTTON TO ENTER THE TEST INTERFACE, AS SHOWN IN THE FOLLOWING FIGURE:

CLICK "SETTING” BUTTON, GET INTO PARAMETER SETTING SCREEN, AS BELOW THIS SCREEN CAN SET THE SYSTEM TIME, DATE AND TESTING TIME, AFTER SETTING, CLICK "SAVE” BUTTON TO KEEP THE SETTING DATA. (NOTE: IT REQUIRES 5 MINUTES IN THE STANDARD)

QUANTITY: 1

Learn More -

P-5096 STA ROASTING SYSTEM MILLENIUM 3 240 KILOS

P-5096 STA ROASTING SYSTEM MILLENIUM 3 240 KILOSP-5096 STA ROASTING SYSTEM MILLENIUM 3 240 KILOS

ABSOLUTE RESPECT OF THE COFFEE, BIG PERFORMANCE IN REDUCED SPACES WITH MOST HOT AIR THROUGH THE BEANS OF A DRUM BATCHING SYSTEM. 10 YEARS OF VERY EXCITING RESEARCH HAS GONE INTO THIS LINE OF MACHINES. MILLENNIUM CONCENTRATES TECNOLOGY INNOVATION IN THE RESPECT OF THE PRODUCT QUALITY WHICH HAS NEVER BEEN REALISED BEFORE. WE GIVE VALUE TO YOUR PRODUCT WHILE MAKING YOUR JOB SIMPLER.

TECHNICAL DATA:

CONTROL BOARD WITH PARTIAL OR FULL AUTOMATIC DRIVE.

COMPUTERIZED AUTOMATIC ROASTING PROCESS WITH RECORDING SYSTEM.

CONTROL THROUGH PLC. FITTING FOR PC

ALARM SYSTEM BY BUZZER AND SIGNAL LAMP WITH DISPLAY ANOMALIES

PRE-HEATING SYSTEM FOR RAW COFFEE IN STAND-BY

TEMPERATURE COFFEE CONTROL BOTH DURING ROASTING AND COOLING CYCLE

HOT AIR GENERATOR (STA IMPIANTI PATENTED SYSTEM).

"LOW INERTIA" DEVICE FOR IMMEDIATE STARTING OF PRODUCTION.

INDUSTRIAL BURNER WITH 3 LEVELS (VARIABLES) AT IMMEDIATE ANSWER

PROCESS AIR ADMITTANCE CONTROL SYSTEM.

FITTING FOR CLEANED AIR TO AIR EXCHANGER

CONTROL BOARD COMPLETE WITH LIGHTING DEVICE.

SCREENER WITH AUTOMATIC DRAWING.

WATER PUMP COMPLETE WITH TANK AND SAFETY “BY PASS” DEVICE.

PRE-COOLING SYSTEM CONNECTED TO THE ROASTING DRUM.

PRE-COOLING SYSTEM CONNECTED TO THE COOLER.

FIRE PREVENTION SYSTEM LINKED TO THE CHAFF COLLECTOR.

CYCLON FOR COOLER AND DESTONER.

SELF-CLEANING COOLING CONTAINER.

ADDITIONAL EMERGENCY DISCHARGE FOR COOLER.

INTEGRATED DESTONER.

SERVOCONTROL DEVICE FOR REMOTE ADJUSTMENT OF DESTONER.

SOUND PROOFING SYSTEM

GLOBAL SAFETY PROTECTIONQUANTITY: 1

Learn More -

E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINEINVENTORY NUMBER: E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINE OVEN LENGTH: 16.9 M. FOAMING HEIGHT: 1.0 TO 1.3 M. FOAMING WIDTH: 1.15 TO 2.3 M. FOAMING DENSITY: 10 TO 50KG/M3. CONVEYOR BELT LENGTH: 16.9 M. SIDE BOARD WIDTH ADJUSTMENT: 0.98 TO 2.4M. CONVEYOR BELT SPEED: 2.0 TO 7.0M/MIN. MIXING-HEAD POWER: 37KW. WITH BLOCK CUTTING MACHINE. TOTAL POWER: 130KW. TOTAL OUTPUT: 200 TO 350KG/MIN. MACHINE EXTERNAL SIZE: L34000 X W4550 X H4200mm. CE CERTIFICATE GUARANTEE FOR ONE YEAR. QUANTITY AVAILABLE: 1 Learn More

E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINEINVENTORY NUMBER: E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINE OVEN LENGTH: 16.9 M. FOAMING HEIGHT: 1.0 TO 1.3 M. FOAMING WIDTH: 1.15 TO 2.3 M. FOAMING DENSITY: 10 TO 50KG/M3. CONVEYOR BELT LENGTH: 16.9 M. SIDE BOARD WIDTH ADJUSTMENT: 0.98 TO 2.4M. CONVEYOR BELT SPEED: 2.0 TO 7.0M/MIN. MIXING-HEAD POWER: 37KW. WITH BLOCK CUTTING MACHINE. TOTAL POWER: 130KW. TOTAL OUTPUT: 200 TO 350KG/MIN. MACHINE EXTERNAL SIZE: L34000 X W4550 X H4200mm. CE CERTIFICATE GUARANTEE FOR ONE YEAR. QUANTITY AVAILABLE: 1 Learn More