Search results for: 'fiber open m'

-

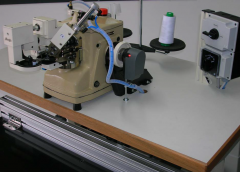

M-1004 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSFOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDED CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBRES, ALL KIND OF CUSHIONS, EVEN BIG SHAPED SIZES. THE RANGE OF SEWING MACHINE HAS BEEN STUDIED AND BUILT FOLLOWING THE MOST MODERN CONCEPT OF TECHNOLOGY; THEIR COMPONENTS ARE THE MOST ADVANCED AND THE MATERIALS ARE HIGHLY SELECTED: THIS MAKES THE MACHINES STRONG, SAFE, SILENT AND EASY TO BE USED. OPERATIONS FEATURES: THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS. WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA, AND NOT ONLY. VERSATILITY AND PERFORMANCE: KITS AND ACCESSORIES ARE AVAILABLE TO MEET THE MOST DIFFERENT REQUIREMENTS. IT IS POSSIBLE TO SEW (NEVER MIND THE SIZE, THE SHAPE AND THE WEIGHT): - LIGHT COTTON, NONWOVEN, FABRICS COUPLED WITH SYNTHETIC FIBRES, POLYESTER, CARDED AND SIMILAR. - FEATHER PILLOWS - HEAVY MATERIAL SUCH AS CUSHIONS IN SYNTHETIC FIBRES OR DACRON COUPLED WITH FOAM, CUSHIONS WITH SPRINGS ETC. COMPLETE WITH: - EXTENDED SEWING GROUP WITH DOUBLE MOTORIZED TOOTHED PLATES. - SEWING HEAD (OVERLOCK – 1 YARN) STITCH LENGTH: 1 TO 5mm - YARN CUTTING (TRIMMER), CUPS OPENING AND PNEUMATIC OIL PUMP - ELECTRONIC EFKA MOTOR 220V/240V SINGLE PHASE - SPEED: 1900 RPM - PERFORMANCE: 6 SECONDS PER CUSHION (SEWING 15 TO 20 CENTIMETERS) - ELECTRONIC MOBILE FOOTBOARD ALSO INCLUDES 1 SET OF NEEDLES, 1 INSTRUCTION BOOK, 1 CE CONFORMITYPRODUCTIVITY: 10/12 CUSHIONS PER MINUTE (CONSIDERED A OPEN SIDE OF 6/8”) Learn More

M-1004 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSFOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDED CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBRES, ALL KIND OF CUSHIONS, EVEN BIG SHAPED SIZES. THE RANGE OF SEWING MACHINE HAS BEEN STUDIED AND BUILT FOLLOWING THE MOST MODERN CONCEPT OF TECHNOLOGY; THEIR COMPONENTS ARE THE MOST ADVANCED AND THE MATERIALS ARE HIGHLY SELECTED: THIS MAKES THE MACHINES STRONG, SAFE, SILENT AND EASY TO BE USED. OPERATIONS FEATURES: THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS. WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA, AND NOT ONLY. VERSATILITY AND PERFORMANCE: KITS AND ACCESSORIES ARE AVAILABLE TO MEET THE MOST DIFFERENT REQUIREMENTS. IT IS POSSIBLE TO SEW (NEVER MIND THE SIZE, THE SHAPE AND THE WEIGHT): - LIGHT COTTON, NONWOVEN, FABRICS COUPLED WITH SYNTHETIC FIBRES, POLYESTER, CARDED AND SIMILAR. - FEATHER PILLOWS - HEAVY MATERIAL SUCH AS CUSHIONS IN SYNTHETIC FIBRES OR DACRON COUPLED WITH FOAM, CUSHIONS WITH SPRINGS ETC. COMPLETE WITH: - EXTENDED SEWING GROUP WITH DOUBLE MOTORIZED TOOTHED PLATES. - SEWING HEAD (OVERLOCK – 1 YARN) STITCH LENGTH: 1 TO 5mm - YARN CUTTING (TRIMMER), CUPS OPENING AND PNEUMATIC OIL PUMP - ELECTRONIC EFKA MOTOR 220V/240V SINGLE PHASE - SPEED: 1900 RPM - PERFORMANCE: 6 SECONDS PER CUSHION (SEWING 15 TO 20 CENTIMETERS) - ELECTRONIC MOBILE FOOTBOARD ALSO INCLUDES 1 SET OF NEEDLES, 1 INSTRUCTION BOOK, 1 CE CONFORMITYPRODUCTIVITY: 10/12 CUSHIONS PER MINUTE (CONSIDERED A OPEN SIDE OF 6/8”) Learn More -

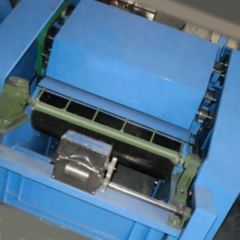

P-4286 MARIO CROSTA SPT/6 CARBON FIBER GRINDER YEAR 2001 WIDTH 2300mm

P-4286 MARIO CROSTA SPT/6 CARBON FIBER GRINDER YEAR 2001 WIDTH 2300mmP-4286 MARIO CROSTA SPT/6 CARBON FIBER GRINDER YEAR 2001 WIDTH 2300mm

MARIO CROSTA

TYPE: SPT/6

CARBON FIBER GRINDER

YEAR: 2001

TABLE WIDTH: 2300mm

TO OPEN AND TUBULAR

FOLD OUTPUT

COMPLETE WITH SUCTION UNITQUANTITY: 1

Learn More -

TT-4057 PILLOW/BOLSTER PILLOW/CUSHION FILLING, 14KW, WITH TWO FILLING FANSTT-4057 PILLOW/BOLSTER PILLOW/CUSHION FILLING, 14KW, WITH TWO FILLING FANS PILLOW/BOLSTER PILLOW/CUSHION FILLING POWER SUPPLY: 3-PHASE 4-WIRE 380V POWER: 14KW QUANTITY: 1 Learn More

TT-4057 PILLOW/BOLSTER PILLOW/CUSHION FILLING, 14KW, WITH TWO FILLING FANSTT-4057 PILLOW/BOLSTER PILLOW/CUSHION FILLING, 14KW, WITH TWO FILLING FANS PILLOW/BOLSTER PILLOW/CUSHION FILLING POWER SUPPLY: 3-PHASE 4-WIRE 380V POWER: 14KW QUANTITY: 1 Learn More -

TT-4359 NEEDLE PUNCHING LINE, YEAR 1993 TO 2023TT-4359 NEEDLE PUNCHING LINE, YEAR 1993 TO 2023 CARDING + LAPPING + DILO NEEDLE LOOM OUG II-S40 BRAND: TRUTZSCHLER, REISKY & SCHLESE, DILO, MESUTRONIC, TEMAFA FIBER: SYNTHETIC & VISCOS FIBER FINENESS: 1.7 TO 6.7 DTEX Learn More

TT-4359 NEEDLE PUNCHING LINE, YEAR 1993 TO 2023TT-4359 NEEDLE PUNCHING LINE, YEAR 1993 TO 2023 CARDING + LAPPING + DILO NEEDLE LOOM OUG II-S40 BRAND: TRUTZSCHLER, REISKY & SCHLESE, DILO, MESUTRONIC, TEMAFA FIBER: SYNTHETIC & VISCOS FIBER FINENESS: 1.7 TO 6.7 DTEX Learn More -

M-2057 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mmREFERENCE NUMBER: M-2057 (77011229TGUX) NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mm Learn More

M-2057 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mmREFERENCE NUMBER: M-2057 (77011229TGUX) NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mm Learn More -

F-1225 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mmREFERENCE NUMBER: F-1225 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mm Learn More

F-1225 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mmREFERENCE NUMBER: F-1225 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mm Learn More -

TT-2155 RIETER COMPLETE SPINNING PLANT WITH 16,128 SPINDLES, YEAR 1991 TO 1995TT-2155 RIETER COMPLETE SPINNING PLANT WITH 16,128 SPINDLES, YEAR 1991 TO 1995 RIETER COMPLETE SPINNING PLANT 16,128 SPINDLES YEAR 1991 TO 1995 QUANTITY: 1 PLANT Learn More

TT-2155 RIETER COMPLETE SPINNING PLANT WITH 16,128 SPINDLES, YEAR 1991 TO 1995TT-2155 RIETER COMPLETE SPINNING PLANT WITH 16,128 SPINDLES, YEAR 1991 TO 1995 RIETER COMPLETE SPINNING PLANT 16,128 SPINDLES YEAR 1991 TO 1995 QUANTITY: 1 PLANT Learn More -

TT-5050 FIBERS CARDING MACHINE/INDUSTRIAL BLENDING MACHINE/NONWOVEN CARDING MACHINERY SHEEP WOOL MACHINE CASHMERE CARDING MACHINE FOR NONWOVEN, 50HzTT-5050 FIBERS CARDING MACHINE/INDUSTRIAL BLENDING MACHINE/NONWOVEN CARDING MACHINERY SHEEP WOOL MACHINE CASHMERE CARDING MACHINE FOR NONWOVEN, 50Hz CONDITION: NEW FIBERS CARDING MACHINE/BLENDING MACHINE VOLTAGE: 380V/50Hz 3 PHASE CAN BE CUSTOMIZED QUANTITY: 1 Learn More

TT-5050 FIBERS CARDING MACHINE/INDUSTRIAL BLENDING MACHINE/NONWOVEN CARDING MACHINERY SHEEP WOOL MACHINE CASHMERE CARDING MACHINE FOR NONWOVEN, 50HzTT-5050 FIBERS CARDING MACHINE/INDUSTRIAL BLENDING MACHINE/NONWOVEN CARDING MACHINERY SHEEP WOOL MACHINE CASHMERE CARDING MACHINE FOR NONWOVEN, 50Hz CONDITION: NEW FIBERS CARDING MACHINE/BLENDING MACHINE VOLTAGE: 380V/50Hz 3 PHASE CAN BE CUSTOMIZED QUANTITY: 1 Learn More -

TT-4132 PROFESSIONAL ALPACA WOOL TOP MAKING SPINNING MACHINE, CAPACITY 40 TO 70 KG PER HOURTT-4132 PROFESSIONAL ALPACA WOOL TOP MAKING SPINNING MACHINE, CAPACITY 40 TO 70 KG PER HOUR BRAND: PASEN CARDING MACHINES CONDITION: NEW QUANTITY: 1 Learn More

TT-4132 PROFESSIONAL ALPACA WOOL TOP MAKING SPINNING MACHINE, CAPACITY 40 TO 70 KG PER HOURTT-4132 PROFESSIONAL ALPACA WOOL TOP MAKING SPINNING MACHINE, CAPACITY 40 TO 70 KG PER HOUR BRAND: PASEN CARDING MACHINES CONDITION: NEW QUANTITY: 1 Learn More -

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More