Search results for: 'pillow press'

- Related search terms

- Pillow+v

- pillow co

- PILLOW+PA

- pressure tank

- press table

-

V-1710 FOAM (LATEX) MATTRESS PUNCHING 2200mm wide and 200 mm thick – 100 punches per minute (MAX)V-1710 FOAM (LATEX) MATTRESS PUNCHING 2200mm wide and 200 mm thick – 100 punches per minute (MAX) THIS MACHINE IS SPECIALLY DESIGNED FOR LARGE-FORMAT MATTRESSES WITH SPONGE, FOAM AND LATEX PUNCHING. THE THICKNESS OF PUNCHING MATERIAL CAN REACH 200mm THE MATERIAL AFTER PUNCHING CAN BETTER IMPROVE THE BREATHABILITY. THE EXCELLENT MATERIAL FOR MODERN HEALTHY SLEEP PRODUCTS IS THE FIRST PUNCHING EQUIPMENT FOR THE MAJORITY OF MATTRESS AND PILLOW MANUFACTURERS. QUANTITY: 1 Learn More

V-1710 FOAM (LATEX) MATTRESS PUNCHING 2200mm wide and 200 mm thick – 100 punches per minute (MAX)V-1710 FOAM (LATEX) MATTRESS PUNCHING 2200mm wide and 200 mm thick – 100 punches per minute (MAX) THIS MACHINE IS SPECIALLY DESIGNED FOR LARGE-FORMAT MATTRESSES WITH SPONGE, FOAM AND LATEX PUNCHING. THE THICKNESS OF PUNCHING MATERIAL CAN REACH 200mm THE MATERIAL AFTER PUNCHING CAN BETTER IMPROVE THE BREATHABILITY. THE EXCELLENT MATERIAL FOR MODERN HEALTHY SLEEP PRODUCTS IS THE FIRST PUNCHING EQUIPMENT FOR THE MAJORITY OF MATTRESS AND PILLOW MANUFACTURERS. QUANTITY: 1 Learn More -

J-2210 DRILLING MACHINE, 2100mm MAX DRILLING WIDTH, 6 TO 28mm HOLE DIAMETERJ-2210 DRILLING MACHINE, 2100mm MAX DRILLING WIDTH, 6 TO 28mm HOLE DIAMETER DRILLING MACHINE VERTICAL DRILLING OF MATTRESSES AND PILLOWS BY MEANS OF SPECIAL INTERCHANGEABLE DRILLS WITH DIFFERENT DIAMETERS MATERIALS: EXPANDED PU FOAM, PE FOAM, VISCO, BONDED FOAM AND SIMILAR, LATEX EXCLUDED VERTICAL AND LATERAL MOVEMENTS OF THE THRUST YOKE ALLOW STRAIGHT AND CROSSED DRILLING, POSSIBLE TO OBTAIN 9 TYPES OF DRAWINGS FOR EACH MATTRESS COMPRESSED AIR JET TAKES FOAM SCRAPS OUT LEAVING HOLES FREE, WASTE EVACUATED WITH SMALL CONVEYOR AND SUCKED AND CONVEYED TO PROPER COLLECTOR STATION FOR RECYCLING CONTROLLED LUBRICATION DEVICE FOR DRILLS PNEUMATIC COMPRESSED DEVICE KEEPS MATTRESS FIRM DURING PERFORATION AND GUARANTEES BETTER PERFORMANCE EASY AND FAST REMOVING AND REPLACING OF DRILLS FEEDING AND UNLOADING CONVEYORS ARE CONTROLLED BY INVERTERS CONTROL CONSOLE COMPLETE WITH MULTIFUNCTION DEVICE (NEXUS) DRILLING SIMULATION AND PRODUCTION TIME AND COST COMPUTATION SOFTWARE INTERCONNECTION (INDUSTRY 4.0) QUANTITY: 1 Learn More

J-2210 DRILLING MACHINE, 2100mm MAX DRILLING WIDTH, 6 TO 28mm HOLE DIAMETERJ-2210 DRILLING MACHINE, 2100mm MAX DRILLING WIDTH, 6 TO 28mm HOLE DIAMETER DRILLING MACHINE VERTICAL DRILLING OF MATTRESSES AND PILLOWS BY MEANS OF SPECIAL INTERCHANGEABLE DRILLS WITH DIFFERENT DIAMETERS MATERIALS: EXPANDED PU FOAM, PE FOAM, VISCO, BONDED FOAM AND SIMILAR, LATEX EXCLUDED VERTICAL AND LATERAL MOVEMENTS OF THE THRUST YOKE ALLOW STRAIGHT AND CROSSED DRILLING, POSSIBLE TO OBTAIN 9 TYPES OF DRAWINGS FOR EACH MATTRESS COMPRESSED AIR JET TAKES FOAM SCRAPS OUT LEAVING HOLES FREE, WASTE EVACUATED WITH SMALL CONVEYOR AND SUCKED AND CONVEYED TO PROPER COLLECTOR STATION FOR RECYCLING CONTROLLED LUBRICATION DEVICE FOR DRILLS PNEUMATIC COMPRESSED DEVICE KEEPS MATTRESS FIRM DURING PERFORATION AND GUARANTEES BETTER PERFORMANCE EASY AND FAST REMOVING AND REPLACING OF DRILLS FEEDING AND UNLOADING CONVEYORS ARE CONTROLLED BY INVERTERS CONTROL CONSOLE COMPLETE WITH MULTIFUNCTION DEVICE (NEXUS) DRILLING SIMULATION AND PRODUCTION TIME AND COST COMPUTATION SOFTWARE INTERCONNECTION (INDUSTRY 4.0) QUANTITY: 1 Learn More -

J-3489 PILLOW FILLING MACHINE FOR FEATHER AND FIBER MIX, TWO NOZZLES -FOR FEATHER/DOWN & FIBER COTTON MIXJ-3489 PILLOW FILLING MACHINE FOR FEATHER AND FIBER MIX, TWO NOZZLES -FOR FEATHER/DOWN & FIBER COTTON MIX POWER SUPPLY: 380 VOLTS, 60 OR 50 Hz (or as per clients need) TOTAL POWER: 12 KW AIR COMPRESSOR POWER REQUIRED: >/= 15 KW WORKING PRESSURE: 0.6 TO 0.8 Mpa MAIN MIXING BOX DIMENSIONS: 2200mm LENGTH x 900mm WIDTH x 2250mm HEIGHT WEIGHING BOX DIMENSIONS: 2200mm LENGTH x 900mm WIDTH x 1600mm HEIGHT TOTAL FLOORSPACE: >12 SQUARE METERS MIXING BOX WEIGHT: 412 KG WEIGHING BOX WEIGHT: 364 KG QUANTITY: 1 Learn More

J-3489 PILLOW FILLING MACHINE FOR FEATHER AND FIBER MIX, TWO NOZZLES -FOR FEATHER/DOWN & FIBER COTTON MIXJ-3489 PILLOW FILLING MACHINE FOR FEATHER AND FIBER MIX, TWO NOZZLES -FOR FEATHER/DOWN & FIBER COTTON MIX POWER SUPPLY: 380 VOLTS, 60 OR 50 Hz (or as per clients need) TOTAL POWER: 12 KW AIR COMPRESSOR POWER REQUIRED: >/= 15 KW WORKING PRESSURE: 0.6 TO 0.8 Mpa MAIN MIXING BOX DIMENSIONS: 2200mm LENGTH x 900mm WIDTH x 2250mm HEIGHT WEIGHING BOX DIMENSIONS: 2200mm LENGTH x 900mm WIDTH x 1600mm HEIGHT TOTAL FLOORSPACE: >12 SQUARE METERS MIXING BOX WEIGHT: 412 KG WEIGHING BOX WEIGHT: 364 KG QUANTITY: 1 Learn More -

J-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHERJ-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHER SILO CAPACITY: 4.4m3 AUTOMATIC PRE-WEIGHING UNIT: 1, 300 LITER CAPACITY FILLING NOZZLES: 1 OUTPUT CAPACITY: UP TO 400 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (UP TO 2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 3 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 5.2 KW – 16 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db QUANTITY: 1 Learn More

J-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHERJ-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHER SILO CAPACITY: 4.4m3 AUTOMATIC PRE-WEIGHING UNIT: 1, 300 LITER CAPACITY FILLING NOZZLES: 1 OUTPUT CAPACITY: UP TO 400 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (UP TO 2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 3 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 5.2 KW – 16 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db QUANTITY: 1 Learn More -

J-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHERJ-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHER SILO VOLUME: 6.0m3 AUTOMATIC PRE-WEIGHING UNITS: 2 UNITS WITH 210 LITER CAPACITY FILLING NOZZLE: 1 OUTPUT CAPACITY: UP TO 700 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 6 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 7.4 KW – 32 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db Learn More

J-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHERJ-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHER SILO VOLUME: 6.0m3 AUTOMATIC PRE-WEIGHING UNITS: 2 UNITS WITH 210 LITER CAPACITY FILLING NOZZLE: 1 OUTPUT CAPACITY: UP TO 700 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 6 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 7.4 KW – 32 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db Learn More -

FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60HzREFERENCE NUMBER: T-6869 FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60Hz FEED HOPPER WITH LONG EXTENDED APRON 1500mm FEED HOPPER MODEL: OP-B POWER: 3.6KW FILLING CAPACITY: 800KG/H LAYOUT: 5940 X 1600 X 2200mm WEIGHT: 3200KG WORKING WIDTH: 1500mm VOLTAGE: 440V 60Hz 3 PHASES (AS PER ORDER) AIR PRESSURE: 0.6 TO 0.8MPA MAIN STRUCTURE: MADE BY COMPUTERIZED LASER CUTTING MACHINE ELECTRICITY: KEY PARTS ARE WORLD FAMOUS BRAND, OMRON, SCHNEIDER. BEARING: SKF SPRAY: RUST-PROOF PRETREATMENT AND ELECTROSTATIC COATING. ROLLERS: WITH DYNAMIC BALANCE PROCESSING. DESCRIPTION: • MACHINE IS MAINLY USED TO LOAD A BALE OF FIBER AND SEND IT TO NEXT PROGRAM AUTOMATICALLY. • THE SUITABLE MATERIAL CAN BE CONJUGATE SILICON POLYESTER FIBER THAT SHORTER THAN 100mm. POLYESTER FIBER: RECYCLE AND VIRGIN POLYESTER STAPLE FIBER. 0.6 TO 15D, 32mm TO 64mm, MICROFIBER ALSO POSSIBLE. • ANTI-DEVIATION DEVICE, CONVEYOR BELT TRACK PROTECTION, TO ENSURE THAT BELT ALWAYS RUNNING STRAIGHT. • ONE OPERATOR • WORKING PROCESS: 1. USE FORKLIFT TO PUT BALE OF FIBER ON THE CONVEYOR. 2. THE FIRST CONVEYOR WILL SEND FIBER TO THE SECOND CONVEYOR 3. THEN THE SPIKED INCLINE BELT LIFTS THE FIBER, THE EVENING ROLLER TAKES THE EXCESSIVE FIBER OFF AND THE STRIPPING ROLLER STRIP THE FIBER OFF AND FIBER FALLS DOWN TO NEXT PROCESS. 4. THERE ARE PHOTO CELLS TO CONTROL THE MATERIAL FIBER LEVEL, FEEDING AND SUPPLY SPEED. • ELECTRICAL KEY PARTS ARE WORLD FAMOUS BRANDS, SUCH AS SCHNEIDER ETC. AVAILABLE WORLDWIDE. • ELECTRICAL WITH OVERLOAD PROTECTION. Learn More

FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60HzREFERENCE NUMBER: T-6869 FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60Hz FEED HOPPER WITH LONG EXTENDED APRON 1500mm FEED HOPPER MODEL: OP-B POWER: 3.6KW FILLING CAPACITY: 800KG/H LAYOUT: 5940 X 1600 X 2200mm WEIGHT: 3200KG WORKING WIDTH: 1500mm VOLTAGE: 440V 60Hz 3 PHASES (AS PER ORDER) AIR PRESSURE: 0.6 TO 0.8MPA MAIN STRUCTURE: MADE BY COMPUTERIZED LASER CUTTING MACHINE ELECTRICITY: KEY PARTS ARE WORLD FAMOUS BRAND, OMRON, SCHNEIDER. BEARING: SKF SPRAY: RUST-PROOF PRETREATMENT AND ELECTROSTATIC COATING. ROLLERS: WITH DYNAMIC BALANCE PROCESSING. DESCRIPTION: • MACHINE IS MAINLY USED TO LOAD A BALE OF FIBER AND SEND IT TO NEXT PROGRAM AUTOMATICALLY. • THE SUITABLE MATERIAL CAN BE CONJUGATE SILICON POLYESTER FIBER THAT SHORTER THAN 100mm. POLYESTER FIBER: RECYCLE AND VIRGIN POLYESTER STAPLE FIBER. 0.6 TO 15D, 32mm TO 64mm, MICROFIBER ALSO POSSIBLE. • ANTI-DEVIATION DEVICE, CONVEYOR BELT TRACK PROTECTION, TO ENSURE THAT BELT ALWAYS RUNNING STRAIGHT. • ONE OPERATOR • WORKING PROCESS: 1. USE FORKLIFT TO PUT BALE OF FIBER ON THE CONVEYOR. 2. THE FIRST CONVEYOR WILL SEND FIBER TO THE SECOND CONVEYOR 3. THEN THE SPIKED INCLINE BELT LIFTS THE FIBER, THE EVENING ROLLER TAKES THE EXCESSIVE FIBER OFF AND THE STRIPPING ROLLER STRIP THE FIBER OFF AND FIBER FALLS DOWN TO NEXT PROCESS. 4. THERE ARE PHOTO CELLS TO CONTROL THE MATERIAL FIBER LEVEL, FEEDING AND SUPPLY SPEED. • ELECTRICAL KEY PARTS ARE WORLD FAMOUS BRANDS, SUCH AS SCHNEIDER ETC. AVAILABLE WORLDWIDE. • ELECTRICAL WITH OVERLOAD PROTECTION. Learn More -

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINE

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINEI. FUNCTION

Learn More

THIS MACHINE IS USED TO PACK DISPOSABLE SURGICAL FACE MASK WITH THE SIZE OF 190 X 65mm. IT CAN ALSO BE USED TO PACK OTHER PRODUCTS SUCH AS WET TISSUE.

II. FEATURES:

1. ONE SET OF INK TO INJECT PRINTER IS INCLUDED; IT CAN BE USED TO PRINT THE DATA AND OTHER INFORMATION.

2. THE AIR COMPRESSOR EQUIPMENT IS OPTIONAL.

3. PACKING MATERIAL: SINGLE TO SIDE HEAT TO SEALING PACKAGING FILM MATERIALS, SUCH AS OPP, CPP, OPP COMPOSITE PE, PET COMPOSITE PE, SINGLE TO LAYER OR COMPOSITE PACKAGING FILM MATERIALS.

4. BAG FORM: BACK TO SEALED PACKING, CAN BE CUSTOMIZED.

5. VERTICAL/HORIZONTAL SEAL: RETICULATED PACKAGING/VERTICAL AND RETICULATED PACKAGING.

III. SPECIFICATION:

NAME: PILLOW PACKING MACHINE

TYPE KD TO 350

APPLICATION: FOR ALL KINDS OF OPP HEAT TO SEALING FILM, COMPOSITE FILM, SPRAY FILM PAPER, ALUMINUM FOIL FILM, ALUMINUM PLASTIC COMPOSITE FILM

MACHINE SIZE: 4600 X 850 X 1500

PACKING SPEED: 60 TO 220 BAG/MIN

MAX. PACKING SIZE: 330mm, 150mm, 80mm. LENGTH: 330mm, WIDTH: 150mm, HEIGHT: 80mm

MIN. PACKING SIZE: 50mm, 10mm, 5mm. LENGTH: 50mm, WIDTH: 10mm, HEIGHT: 5mm

ELECTRICAL: AC220V, 2.7KW

AIR PRESSURE 0.5 TO 0.7 MPA

AIR CONSUMPTION: >0.36 (M3/H)

(DB) NOISE: 60 TO 70DB

MACHINE WEIGHT: 550KG

MOTOR FREQUENCY ADJUST: 0 TO 50HZ

AUTOMATIC CONTROL

AUTOMATIC PRINTING

STANDARD: GMP STANDARD, PACKAGING MACHINE ENTERPRISE STANDARD

APPROVAL: ISO9001:2000, CE ISO:2000 -

J-3800 AUTOMATIC ROLL PACKING MACHINE FOR PILLOWS – 960 PILLOWS PER 8 HOUR SHIFT

J-3800 AUTOMATIC ROLL PACKING MACHINE FOR PILLOWS – 960 PILLOWS PER 8 HOUR SHIFTPILLOW DIMENSIONS (MAXIMUM): 800 x 600 x 200mm (ONCE COMPRESSED, HEIGHT IS 30mm)

Learn More

CAPACITY: 2 PILLOWS PER MINUTE (960 PILLOWS PER 8 HOUR SHIFT)

EXIT DIAMETER: 80 TO 200mm (CUSTOMIZED PER CUSTOMER, PLEASE SPECIFY WHEN ORDERING)

PRESSURE: 1.2 TONS

POWER: 6.37 KW

WEIGHT: 400 KGS

DIMENSIONS: 1850 x 2940 x 2100mm -

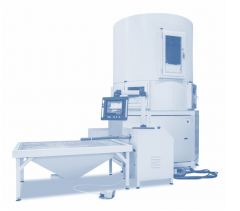

F-1429 DOWN FILLING MACHINE MODEL SR-3

F-1429 DOWN FILLING MACHINE MODEL SR-3REFERENCE NUMBER: F-1429

down FILLING MACHINE MODEL SR-3

PRODUCT FEATURES

• FULLY ENCLOSED DESIGN TO KEEP SURROUNDINGS CLEAN AND TO SAVE MATERIAL

• AUTOMATIC WEIGHING WITH ACCURATE LOAD CELL TO ENSURE PRODUCTION QUALITY

• FILLING TIME IS 2 TO 5 SECONDS

• NICE DESIGN SUITABLE FOR ALL KINDS OF FABRIC

• CE CERTIFICATE

• TYPE : SR-3

• DIMENSION: 3000 x 2500 x 2000MM

• VOLTAGE: 200/380/415V 50/60HZ 3PHASE

• POWER: 3.8 KW

• FILLING RANGE: 2-100 G, DEPENDING ON THE MATERIAL

• ACCURACY: ±0.2G

• AIR PRESSURE: 0.5 TO 0.8MPA

• THE DEVELOPED COMPUTERIZED DOWN & FEATHER WEIGHING FILLING MACHINE IS MAINLY USED TO FILL JACKETS, SLEEPING BAGS, CUSHIONS, PILLOWS, PADS, COMFORTERS ETC THAT ARE MADE WITH DOWN & FEATHER AND CONTROLLED BY A COMPUTERIZED WEIGHING SYSTEM.

• THREE HOPPER-SYSTEM FOR CONSTANT SUPPLY

• THE VACUUM FILLING FUNCTION THAT DOES NOT HURT THE MATERIAL AND KEEPS THE ORIGINAL ELASTICITY AND SOFT-HAND FEELING.

• ACCURATE WEIGHING RESULTS; THE TOLERANCE IS WITHIN 0.2 GRAM. IT CAN BE ADJUSTED ACCORDING TO THE PRODUCTION REQUIREMENT BY CHOOSING GROUP ERROR OR SINGLE PIECE ERROR FROM THE CONTROL PANEL, SO THAT THE PRODUCTION QUALITY IS ASSURED AND MATERIAL WASTE IS CONTROLLED

• THE WHOLE LINE CAN BE HANDLED BY ONE OPERATOR WITH VERY SIMPLE

OPERATION

• ALL THE MATERIALS ARE INSIDE THE HOPPERS WITHOUT PRODUCING ANY DUST THAT AFFECTS THE WORKING AREA

• KEY ELECTRICAL COMPONENTS ARE IMPORTED

• THE WHOLE LINE OPERATION IS CONTROLLED BY PLC SYSTEM

• ACCORDING TO DIFFERENT QUANTITY AND QUALITY PRODUCTION REQUIREMENTS THE MACHINE CONTROL PANEL CAN BE SET UP FOR 100 GROUPS OF RECIPES AND EACH RECIPE CAN BE 50 SETS OF DIFFERENT WEIGHT VALUE FOR FILLING OPTIONS, WHICH IS ENOUGH TO FILL DIFFERENT PARTS OF THE SAME PRODUCTION.

• THE AVERAGE FILLING TIME CAN BE 4 TO 10 SECONDS (DEPENDING ON THE ACCURACY) AND THE FILLING TIME CAN BE ADJUSTED

• THE CUSTOMER’S DIFFERENT REQUIREMENTS ARE CONSIDERED BY OUR PROFESSIONAL ENGINEERS SO THAT THE MACHINES ARE SUITABLE FOR YOUR PARTICULAR NEEDS

• MATERIAL HOPPER: DIA.1200 x 2000MM 1PCS

• WEIGHING SYSTEM: 1200 x 1000 x 1000MM 1PCS(3SETS)

• FILLING TABLE :1200 x 550 x 1500 1PCS

• PLC CONTROL SYSTEM AND CONTROL PANEL: 1SETS

• BLOWER: 3PCS

• PIPE SYSTEM

Learn More