Search results for: 'process'[0]'

-

TT-7540 LAEM-IMS-GOEBEL SLITTER-REWINDER, 1400mm, YEAR 2007TT-7540 LAEM-IMS-GOEBEL SLITTER-REWINDER, 1400mm, YEAR 2007 1. BRAND: LAEM/IMS/GOEBEL 2. SLITTER REWINDER FOR CONVERTERS 3. DUAL SHAFT CENTRE WINDER WITH SEPARATE SHAFTLESS UNWINDER 4. TR 115-1400 Learn More

TT-7540 LAEM-IMS-GOEBEL SLITTER-REWINDER, 1400mm, YEAR 2007TT-7540 LAEM-IMS-GOEBEL SLITTER-REWINDER, 1400mm, YEAR 2007 1. BRAND: LAEM/IMS/GOEBEL 2. SLITTER REWINDER FOR CONVERTERS 3. DUAL SHAFT CENTRE WINDER WITH SEPARATE SHAFTLESS UNWINDER 4. TR 115-1400 Learn More -

TT-6700 COMPLETE BOTTLING LINE PROCOMAC FOR STILL AND SPARKLING WATER, UP TO 12000 BPH, YEAR 2018 TO 2000TT-6700 COMPLETE BOTTLING LINE PROCOMAC FOR STILL AND SPARKLING WATER, UP TO 12000 BPH, YEAR 2018 TO 2000 1. USED 2. IN PRODUCTION 3. SPEED: 12000 BPH 4. CONTAINERS: PET 5. FORMATS: 0.50 L, 1.0 L, 1.5 L, 2 L 6. PRODUCT: WATER (SPARKLING), WATER (STILL) 7. FILL TYPE: ISOBARIC 8. NECK TYPE: 28 QUANTITY: 1 Learn More

TT-6700 COMPLETE BOTTLING LINE PROCOMAC FOR STILL AND SPARKLING WATER, UP TO 12000 BPH, YEAR 2018 TO 2000TT-6700 COMPLETE BOTTLING LINE PROCOMAC FOR STILL AND SPARKLING WATER, UP TO 12000 BPH, YEAR 2018 TO 2000 1. USED 2. IN PRODUCTION 3. SPEED: 12000 BPH 4. CONTAINERS: PET 5. FORMATS: 0.50 L, 1.0 L, 1.5 L, 2 L 6. PRODUCT: WATER (SPARKLING), WATER (STILL) 7. FILL TYPE: ISOBARIC 8. NECK TYPE: 28 QUANTITY: 1 Learn More -

TT-6478 SSI MODEL M85-H DUAL SHAFT SHREDDER WITH CLEATED REM CONVEYOR - TRUCK TIRES, 100 HPTT-6478 SSI MODEL M85-H DUAL SHAFT SHREDDER WITH CLEATED REM CONVEYOR - TRUCK TIRES, 100 HP 1. SSI MODEL M85-H DUAL SHEAR SHREDDER 2. LOW SPEED, HIGH TORQUE, TWO SHAFT, ROTARY SHEAR SHREDDER DESIGNED TO EFFICIENTLY PROCESS A VARIETY OF DIFFICULT MATERIALS. QUANTITY: 1 Learn More

TT-6478 SSI MODEL M85-H DUAL SHAFT SHREDDER WITH CLEATED REM CONVEYOR - TRUCK TIRES, 100 HPTT-6478 SSI MODEL M85-H DUAL SHAFT SHREDDER WITH CLEATED REM CONVEYOR - TRUCK TIRES, 100 HP 1. SSI MODEL M85-H DUAL SHEAR SHREDDER 2. LOW SPEED, HIGH TORQUE, TWO SHAFT, ROTARY SHEAR SHREDDER DESIGNED TO EFFICIENTLY PROCESS A VARIETY OF DIFFICULT MATERIALS. QUANTITY: 1 Learn More -

YY-3265 COMPLETE LINE TO BLOW, FILL, BUNDLE, AND PALLETIZE BEVERAGES IN PET BOTTLESYY-3265 COMPLETE LINE TO BLOW, FILL, BUNDLE, AND PALLETIZE BEVERAGES IN PET BOTTLES COMPLETE LINE TO BLOW, FILL, BUNDLE, AND PALLETIZE BEVERAGES IN PET BOTTLES BLOW MOLDING LABELING HIGH PRESSURE AIR COMPRESSOR DESCON AIRVEYOR- APPROXIMATELY 400′ CROWN FILLING MACHINE AND CAPPING MACHINE ACMI BOTTLE AND CASE CONVEYOR, SHRINK WRAPPER, PALLETIZER, STRETCH WRAPPING MACHINE WATER PROCESSING EQUIPMENT QUANTITY: 1 Learn More

YY-3265 COMPLETE LINE TO BLOW, FILL, BUNDLE, AND PALLETIZE BEVERAGES IN PET BOTTLESYY-3265 COMPLETE LINE TO BLOW, FILL, BUNDLE, AND PALLETIZE BEVERAGES IN PET BOTTLES COMPLETE LINE TO BLOW, FILL, BUNDLE, AND PALLETIZE BEVERAGES IN PET BOTTLES BLOW MOLDING LABELING HIGH PRESSURE AIR COMPRESSOR DESCON AIRVEYOR- APPROXIMATELY 400′ CROWN FILLING MACHINE AND CAPPING MACHINE ACMI BOTTLE AND CASE CONVEYOR, SHRINK WRAPPER, PALLETIZER, STRETCH WRAPPING MACHINE WATER PROCESSING EQUIPMENT QUANTITY: 1 Learn More -

Y-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mmYY-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mm WLS ROLLING & SCORING THE RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS: 2000 TO 3800 KG/HR. FEATURES: - CONDITION: REFURBISHED - MANUFACTURER: WLS - USAGE: CHEWING GUM FORMING LINE - CAPACITY: 2.000 KG/HR. - WORKING WIDTH: 460mm - PIECES’ DIMENSIONS: ACCORDING TO THE CUSTOMERS NEED Learn More

Y-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mmYY-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mm WLS ROLLING & SCORING THE RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS: 2000 TO 3800 KG/HR. FEATURES: - CONDITION: REFURBISHED - MANUFACTURER: WLS - USAGE: CHEWING GUM FORMING LINE - CAPACITY: 2.000 KG/HR. - WORKING WIDTH: 460mm - PIECES’ DIMENSIONS: ACCORDING TO THE CUSTOMERS NEED Learn More -

TT-3888 MURATA PROCESS CONER 21C, YEAR 2004 TO 2009TT-3888 MURATA PROCESS CONER 21C, YEAR 2004 TO 2009 MURATA PROCESS CONER 21C SPINDLES PER SET 60 YARN CLEANER: QUANTUM 2 / ZENIT WAX DEVICE: YES SPLICER NOZZLE G2Z MAGAZINE TYPE Learn More

TT-3888 MURATA PROCESS CONER 21C, YEAR 2004 TO 2009TT-3888 MURATA PROCESS CONER 21C, YEAR 2004 TO 2009 MURATA PROCESS CONER 21C SPINDLES PER SET 60 YARN CLEANER: QUANTUM 2 / ZENIT WAX DEVICE: YES SPLICER NOZZLE G2Z MAGAZINE TYPE Learn More -

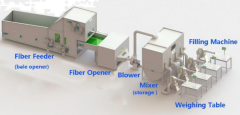

YY-2309 CUSHION & PILLOW PRODUCTION LINE, 4 FANSYY-2309 CUSHION & PILLOW PRODUCTION LINE, 4 FANS DETAILS: POWER: 30.3KW; THIS SYSTEM SUITABLE FOR MAKING CUSHIONS AND PILLOWS FILLED WITH FIBER FOAM . HIGH PRODUCTIVITY, EASY TO OPERATE. SMOOTH PROCESS FROM FIBER OPENING, TO THE FILLING PROCESS WITHOUT JAMMING. QUANTITY: 1 Learn More

YY-2309 CUSHION & PILLOW PRODUCTION LINE, 4 FANSYY-2309 CUSHION & PILLOW PRODUCTION LINE, 4 FANS DETAILS: POWER: 30.3KW; THIS SYSTEM SUITABLE FOR MAKING CUSHIONS AND PILLOWS FILLED WITH FIBER FOAM . HIGH PRODUCTIVITY, EASY TO OPERATE. SMOOTH PROCESS FROM FIBER OPENING, TO THE FILLING PROCESS WITHOUT JAMMING. QUANTITY: 1 Learn More -

YY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mmYY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mm ITEM 001 BALE OPENER (2 SETS) AND SEALED BALE OPENER (1 SET) ITEM 002 FIBER OPENING MACHINE (FOR LOW MELT FIBER OR PP) - 1 SET ITEM 003 PRE-OPENER – 1 SET ITEM 004 BIG CHAMBER BLENDER – 1 SET ITEM 005 MAIN-OPENER – 1 SET ITEM 006 VIBRATING FEEDER – 1 SET ITEM 007 CONDENSER – 2 SETS ITEM 008 AUTO-LEVER - 1 SET ITEM 009 AIR LAID MACHINE – 1 SET ITEM 010 AUTO-LEVER – 1 SET ITEM 011 BATT FEEDER – 1 SET ITEM 012 HIGH SPEED SINGLE SHAFT SINGLE BOARD PRE NEEDLE LOOM – 1 SET ITEM 013 HIGH SPEED SINGLE SHAFT SINGLE BOARD MAIN NEEDLE LOOM – 1 SET ITEM 014 DOUBLE BELT THERMAL-BONDED OVEN – 1 SET ITEM 015 DOUBLE-ROLLER CALENDER MACHINE – 1 SET ITEM 016 COOLING UNIT – 1 SET Learn More

YY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mmYY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mm ITEM 001 BALE OPENER (2 SETS) AND SEALED BALE OPENER (1 SET) ITEM 002 FIBER OPENING MACHINE (FOR LOW MELT FIBER OR PP) - 1 SET ITEM 003 PRE-OPENER – 1 SET ITEM 004 BIG CHAMBER BLENDER – 1 SET ITEM 005 MAIN-OPENER – 1 SET ITEM 006 VIBRATING FEEDER – 1 SET ITEM 007 CONDENSER – 2 SETS ITEM 008 AUTO-LEVER - 1 SET ITEM 009 AIR LAID MACHINE – 1 SET ITEM 010 AUTO-LEVER – 1 SET ITEM 011 BATT FEEDER – 1 SET ITEM 012 HIGH SPEED SINGLE SHAFT SINGLE BOARD PRE NEEDLE LOOM – 1 SET ITEM 013 HIGH SPEED SINGLE SHAFT SINGLE BOARD MAIN NEEDLE LOOM – 1 SET ITEM 014 DOUBLE BELT THERMAL-BONDED OVEN – 1 SET ITEM 015 DOUBLE-ROLLER CALENDER MACHINE – 1 SET ITEM 016 COOLING UNIT – 1 SET Learn More -

V-2042 WATER RECIRCULATION SYSTEM FOR WATERJETSV-2042 WATER RECIRCULATION SYSTEM FOR WATERJETS 6 LITERS PER MINUTE MAXIMUM JET HEAD USES 1 TO 2 LITERS PER MINUTE FILTRATION: FROM 5 TO 10 MICRONS Learn More

V-2042 WATER RECIRCULATION SYSTEM FOR WATERJETSV-2042 WATER RECIRCULATION SYSTEM FOR WATERJETS 6 LITERS PER MINUTE MAXIMUM JET HEAD USES 1 TO 2 LITERS PER MINUTE FILTRATION: FROM 5 TO 10 MICRONS Learn More -

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More