Search results for: 'stop bar'

- Related search terms

- Barmag Wi

- Barmag Win

- Barmag Winder

- barri.com

- Barmag+Winde

-

J-4517 REBUILT/RUNNING CONDITION PELLETIZING LINE, STRAND TYPE, MODEL BCC38 EXTRUDER, 30:1 L/D RATIOJ-4517 REBUILT/RUNNING CONDITION PELLETIZING LINE, STRAND TYPE, MODEL BCC38 EXTRUDER, 30:1 L/D RATIO Learn More

J-4517 REBUILT/RUNNING CONDITION PELLETIZING LINE, STRAND TYPE, MODEL BCC38 EXTRUDER, 30:1 L/D RATIOJ-4517 REBUILT/RUNNING CONDITION PELLETIZING LINE, STRAND TYPE, MODEL BCC38 EXTRUDER, 30:1 L/D RATIO Learn More -

J-4488 GRIBETZ RELIANCE 2 MULTI-NEEDLE QUILTERS, WORKING WIDTH 90”J-4488 GRIBETZ RELIANCE 2 MULTI-NEEDLE QUILTERS, WORKING WIDTH 90” MAKE: GRIBETZ MODEL: RELIANCE 2 WORKING WIDTH: 90” YEAR: 2004 (2 SETS), 2005 (3 SETS), 2006 (1 SET) STATUS: STOPPED QUANTITY: 6 Learn More

J-4488 GRIBETZ RELIANCE 2 MULTI-NEEDLE QUILTERS, WORKING WIDTH 90”J-4488 GRIBETZ RELIANCE 2 MULTI-NEEDLE QUILTERS, WORKING WIDTH 90” MAKE: GRIBETZ MODEL: RELIANCE 2 WORKING WIDTH: 90” YEAR: 2004 (2 SETS), 2005 (3 SETS), 2006 (1 SET) STATUS: STOPPED QUANTITY: 6 Learn More -

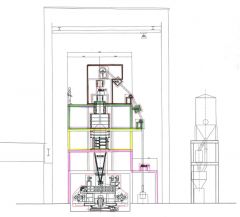

T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008 YEAR 2008, PILOT RUN YEAR 2009, STOPPED PRODUCTION YEAR 2017 FILM MACHINE EXTRUDER: BATTENFELD EXTRUDER DIAMETER 4.5” (115mm) L/D RATIO 24:1 460V 3P 60Hz 125HP AC VECTOR MOTOR RESIN TEMPARETURE: 230°C (446 DEGREEF) OUTPUT: MAX 180KG/H (400 LBS/H) PRESSURE RATINGS ARE: BARREL 20,000PSI BARREL CLAMP 10,000PSI RUPTURED DISC 7,500PSI Learn More

T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008 YEAR 2008, PILOT RUN YEAR 2009, STOPPED PRODUCTION YEAR 2017 FILM MACHINE EXTRUDER: BATTENFELD EXTRUDER DIAMETER 4.5” (115mm) L/D RATIO 24:1 460V 3P 60Hz 125HP AC VECTOR MOTOR RESIN TEMPARETURE: 230°C (446 DEGREEF) OUTPUT: MAX 180KG/H (400 LBS/H) PRESSURE RATINGS ARE: BARREL 20,000PSI BARREL CLAMP 10,000PSI RUPTURED DISC 7,500PSI Learn More -

V-1468 COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTON GAUZE COMPRESSES

V-1468 COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTON GAUZE COMPRESSESREFERENCE NUMBER: V-1468

SURGICAL GAUZE COMPRESSING, FOLDING, AND BAGGING MACHINE

COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTONG GAUZE, COMPRESSES, AND THEN PACKS THEM INDIVIDUALLY OR IN GROUPS INTO SACHETS.

FEATURES

USEFUL WIDTH: 45 CM

NUMBER OF TRACKS: MAXIMUM 2 (VARIES ACCORDING TO THE SIZE OF COMPRESSES)

SIZE:

MINIMUM DIMENSIONS OF COMPRESSES: 5 CM X 5 CM

MAXIMUM DIMENSIONS OF COMPRESSES: 10 CM X 20 CM (16 PLIES)

ALL THE USUAL OR INTERMEDIATE SIZES CAN BE PRODUCED ON THE MACHINE BY SIMPLE ADJUSTMENTS.

NUMBER OF PLIES 8 / 12 / 16 / 20 / 24 / 28 / 32 PLIES (VARIES ACCORDING TO THE SIZE OF COMPRESSES)

FOLDING: THE CONVENTIONAL FOLDING IS THE 5-FOLD "SURGICAL" OR "AMERICAN" TYPE, WITH EDGES AND CORNERS TUCKED-IN, HOWEVER BY OFFSETTING FOLDS OTHER COMBINATIONS ARE POSSIBLE.

STACKING: STACKING IS CARRIED OUT IN THE CHANNELS WHERE THE COMPRESSES ARE COUNTED AND READY TO BE MANUALLY INSERTED INTO PAPER BAGS.

PRODUCTION :

EXAMPLES OF THEORETICAL PRODUCTIONS:

5 CM X5 CM 8 PLIES (2 TRACKS) 13200 COMPRESSES PER HOUR

7.5 CM X 7.5 CM 12 PLIES (2 TRACKS) 13200 COMPRESSES PER HOUR

10 CM X 10 CM 12 PLIES (2 TRACKS) 12000 COMPRESSES PER HOUR

OPTIONS:

BARIUM FIXING TRACK BY TRACK

GAUZE ROLL LOADING BY PNEUMATIC CYLINDERS"

FEATURES LIST:

MATERIAL SUPPORT ADJUSTABLE IN WIDTH,

POSITIVE UNWINDING WITH TENSION CHECK ADJUSTABLE TRACK BY TRACK,

MULTIPLE LENGTH FOLDING DEVICE ADJUSTABLE TRACK BY TRACK,

SPRAY HUMIDIFYING SYSTEM,

SUCTION SYSTEM,

ANTI-STATIC BARS,

ADJUSTABLE FLY CUT MODULE MOTORISED WITH BRUSHLESS MOTOR,

THREE CROSS FOLDING MECHANISMS WITH INDEPENDENT ADJUSTMENT OF EACH FOLD,

TRANSFER BELTS FOR THE COMPRESSES,

MOTORISED LATERAL UNWINDING OF THE PAPER ROLL MODULE,

DEVICE FOR INDIVIDUAL, IN MULTIPLES OR IN SHINGLED FORM PACKAGING - WITH A CHANGEABLE

NUMBER OF COMPRESSES BY SACHET,

CHECK OF FOLLOWING OPERATIONS TRACK BY TRACK:

. END OF FABRIC,

. PRESENCE OF SEAM,

. PRESENCE OF CROSS-FOLDED COMPRESS,

. JAM PREVENTION BEFORE PACKAGING.

COLD SEALING BY PRESSURE AND CUTTING OF SACHETS IN PRINTED AND ZONED PAPER,

POWER SYSTEM OF PACKAGING BY BRUSHLESS MOTOR ALLOWING FOR FLY ADJUSTMENT OF:

. THE COMPRESS POSITION IN THE SACHET,

. THE CROSSWISE KNURLING POSITION,

. THE CROSSWISE CUTTING OF SACHETS.

ACCELERATION RAMP BY FREQUENCY VARIATION,

MACHINE OPERATION BY TOUCH-SENSITIVE SCREEN:

. STORABLE CONFIGURATIONS,

. CLEAR LANGUAGE FAULT DISPLAY,

. COUNTERS : TOTALIZER, PRE-SELECTION, ETC.,

. SOUND AND VISUAL ALARMS,

. "INCIDENT" STATISTICS.

STARTING, STOPPING, STEP BY STEP - BY REMOTE CONTROL.

* CONTINUOUS, TRACK BY TRACK INTEGRATION OF ULTRASONIC BARIUM FIXING.

* PAPER ROLL LOADING BY PNEUMATIC CYLINDERS.

* INK JET MARKING UP TILL 8 LINES.

* SACHETS QUALITY CONTROL DEVICE: EITHER A CHECK BY PHOTO CELLS, OR BY CAMERAS,

* FAULTY SACHET EJECTION DEVICE.

* TABLE WITH CONVERGING BELTS.

Learn More -

M-5297 PICANOL OMNI PLUS 4-P YEAR 2002 WIDTH 2200mm WITH 4 COLORSREFERENCE NUMBER: M-5297 (1313165SC12UC) L PICANOL OMNI PLUS 4-P YEAR 2002 WIDTH 2200mm WITH 4 COLORS BRAND PICANOL OMNI PLUS-4-P-220CM WIDTH 2200mm QUANTITY AVAILABLE: Learn More

M-5297 PICANOL OMNI PLUS 4-P YEAR 2002 WIDTH 2200mm WITH 4 COLORSREFERENCE NUMBER: M-5297 (1313165SC12UC) L PICANOL OMNI PLUS 4-P YEAR 2002 WIDTH 2200mm WITH 4 COLORS BRAND PICANOL OMNI PLUS-4-P-220CM WIDTH 2200mm QUANTITY AVAILABLE: Learn More -

M-5298 PICANOL OMNI PLUS 4-R YEAR 2002 WIDTH 2200mm WITH 4 COLORSREFERENCE NUMBER: M-5298 (1313195MF12UC) L PICANOL OMNI PLUS 4-R YEAR 2002 WIDTH 2200mm WITH 4 COLORS BRAND PICANOL OMNI PLUS-4-R-220CM WIDTH 2200mm TYPE OMNI PLUS 4 COLORS YEAR OCT 2002 QUANTITY AVAILABLE: 4 SETS Learn More

M-5298 PICANOL OMNI PLUS 4-R YEAR 2002 WIDTH 2200mm WITH 4 COLORSREFERENCE NUMBER: M-5298 (1313195MF12UC) L PICANOL OMNI PLUS 4-R YEAR 2002 WIDTH 2200mm WITH 4 COLORS BRAND PICANOL OMNI PLUS-4-R-220CM WIDTH 2200mm TYPE OMNI PLUS 4 COLORS YEAR OCT 2002 QUANTITY AVAILABLE: 4 SETS Learn More -

A-1207 PICANOL OMNI PLUS 800 2P 1900MM STAUBLI 1661REFERENCE NUMBER: A-1207 (0101GHBXX12) A PICANOL OMNI PLUS 800 2P 1900MM STAUBLI 1661 QUANTITY AVAILABLE: 12 Learn More

A-1207 PICANOL OMNI PLUS 800 2P 1900MM STAUBLI 1661REFERENCE NUMBER: A-1207 (0101GHBXX12) A PICANOL OMNI PLUS 800 2P 1900MM STAUBLI 1661 QUANTITY AVAILABLE: 12 Learn More -

M-3365 TOYOTA AIR JET MODEL JAT 610 YEAR 2002 WIDTH 1900mm -STAUBLI CAMREFERENCE NUMBER: M-3365 (88016MKH7UC) K TOYOTA AIR JET MODEL JAT 610 YEAR 2002 WIDTH 1900mm -STAUBLI CAM TOYOTA AIR JET JA2S-190TP-MF-T610 MODEL JAT 610 YEAR 2002 3 SETS WITH ELECTRONIC TAKE-UP AND TOP BEAM ATTACHMENT WITH ORIGINAL TOYOTA LET-OFF WORKING WIDTH 1900mm 2 COLOR 2 ACCUMULATOR STAUBLI POSITIVE CAM 1761A 8 TO 10 LEVERS INSTALLED 6 HEALD FRAMES SUPPLIED FOR EACH MACHINE MECHANICAL TAKE –UP ELECTRONIC LET-OFF 6 BAR WARP STOP BAR 5000 HEALDS AND DROPPERS ROTARY LENO SELVEDGE 4 NOS OF ROTARY LENO BOBBIN 3 BEAMS 1.8 CLOTH ROLLERS QUANTITY AVAILABLE: 42 Learn More

M-3365 TOYOTA AIR JET MODEL JAT 610 YEAR 2002 WIDTH 1900mm -STAUBLI CAMREFERENCE NUMBER: M-3365 (88016MKH7UC) K TOYOTA AIR JET MODEL JAT 610 YEAR 2002 WIDTH 1900mm -STAUBLI CAM TOYOTA AIR JET JA2S-190TP-MF-T610 MODEL JAT 610 YEAR 2002 3 SETS WITH ELECTRONIC TAKE-UP AND TOP BEAM ATTACHMENT WITH ORIGINAL TOYOTA LET-OFF WORKING WIDTH 1900mm 2 COLOR 2 ACCUMULATOR STAUBLI POSITIVE CAM 1761A 8 TO 10 LEVERS INSTALLED 6 HEALD FRAMES SUPPLIED FOR EACH MACHINE MECHANICAL TAKE –UP ELECTRONIC LET-OFF 6 BAR WARP STOP BAR 5000 HEALDS AND DROPPERS ROTARY LENO SELVEDGE 4 NOS OF ROTARY LENO BOBBIN 3 BEAMS 1.8 CLOTH ROLLERS QUANTITY AVAILABLE: 42 Learn More -

M-3366 TOYOTA AIR JET MODEL JAT 610 YEAR 2003 WIDTH 1900mm -STAUBLI CAMREFERENCE NUMBER: M-3366 (88020GYZ7UC) K TOYOTA AIR JET MODEL JAT 610 YEAR 2003 WIDTH 1900mm -STAUBLI CAM TOYOTA AIR JET JA4S-190TP-EF-T610 MODEL JAT 610 YEAR 2003 WORKING WIDTH 1900mm 4 COLOR 4 ACCUMULATOR STAUBLI POSITIVE CAM 1761A 8 TO 10 LEVERS INSTALLED 6 HEALD FRAMES SUPPLIED FOR EACH MACHINE ELECTRONIC TAKE –UP ELECTRONIC LET-OFF 6 BAR WARP STOP BAR 5000 HEALDS AND DROPPERS ROTARY LENO SELVEDGE 4 NOS OF ROTARY LENO BOBBIN 3 BEAMS 1.8 CLOTH ROLLERS QUANTITY AVAILABLE: 18 Learn More

M-3366 TOYOTA AIR JET MODEL JAT 610 YEAR 2003 WIDTH 1900mm -STAUBLI CAMREFERENCE NUMBER: M-3366 (88020GYZ7UC) K TOYOTA AIR JET MODEL JAT 610 YEAR 2003 WIDTH 1900mm -STAUBLI CAM TOYOTA AIR JET JA4S-190TP-EF-T610 MODEL JAT 610 YEAR 2003 WORKING WIDTH 1900mm 4 COLOR 4 ACCUMULATOR STAUBLI POSITIVE CAM 1761A 8 TO 10 LEVERS INSTALLED 6 HEALD FRAMES SUPPLIED FOR EACH MACHINE ELECTRONIC TAKE –UP ELECTRONIC LET-OFF 6 BAR WARP STOP BAR 5000 HEALDS AND DROPPERS ROTARY LENO SELVEDGE 4 NOS OF ROTARY LENO BOBBIN 3 BEAMS 1.8 CLOTH ROLLERS QUANTITY AVAILABLE: 18 Learn More