Search results for: 'Panel+c''

-

INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNITREFERENCE NUMBER: A-2472 INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT MACHINE HAS A HIGH PRODUCTION CAPACITY. IT ALSO ENABLES EASY MONITORING AND MANAGEMENT OF ALL PARAMETERS THAT ARE EFFECTIVE IN THE PRODUCTION OF NANOFIBERS. FOR THE COMMERCIAL PRODUCTION, REPEATABLE PRODUCTION OF MATERIALS IN UNIFORM AND SPECIFIC STANDARDS HAS THE HIGHEST IMPORTANCE. MACHINE IS EQUIPPED WITH 132 ELECTROSPINNING NEEDLES AND A HOMOGENIZATION SYSTEM, ALLOWING THE SURFACE TO BE UNIFORMLY AND CONTINUOUSLY AT A WIDTH OF 1 METER. BECAUSE OF ITS ADVANCED AUTOMATION SYSTEM AND THE AIR CONDITIONING EQUIPMENT, IT ENABLES CONTINUOUS PRODUCTION AT THE HIGHEST SET QUALITY EVEN UNDER CHANGING ENVIRONMENTAL CONDITIONS. SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATIC PAINTED SHEET METAL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX. 600 KGS DIMENSIONS: 3650 x 1950 X 1940 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: IN THE SPINNERET 0-(+)60 KV VOLTAGE PRECISION: 0.1 KV MAXIMUM CURRENT: 3 MA PUMP SYSTEM FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML CONTINUES FEEDING PUMP SYSTEM FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 33 PCS NUMBER OF FEEDING PIPE SETS: 4 PCS NUMBER OF NOZZLES: 132 PCS SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: STANDARD NOZZLE: 0.8 mm (DIFFERENT DIAMETERS CAN BE USED) MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 3 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 25 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 150 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 50 mm TO 350 mm DISTANCE ADJUSTMENT PRECISION: 1 mm COLLECTOR ROLL TO ROLL COLLECTOR FIBER DEPOSITION WIDTH: 1000 mm SUBSTRATE WINDING SPEED: MAX. 0,1 M/ min TO MIN. 10 M/ min COATING HOMOGENEITY SYSTEM: X-AXIS STROKE OF COATING HOMOGENEITY SYSTEM: 30 mm TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm/SEC UNIQUE USER INTERFACE 12” TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 Hz @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 5000 X 3000 mm Learn More

INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNITREFERENCE NUMBER: A-2472 INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT MACHINE HAS A HIGH PRODUCTION CAPACITY. IT ALSO ENABLES EASY MONITORING AND MANAGEMENT OF ALL PARAMETERS THAT ARE EFFECTIVE IN THE PRODUCTION OF NANOFIBERS. FOR THE COMMERCIAL PRODUCTION, REPEATABLE PRODUCTION OF MATERIALS IN UNIFORM AND SPECIFIC STANDARDS HAS THE HIGHEST IMPORTANCE. MACHINE IS EQUIPPED WITH 132 ELECTROSPINNING NEEDLES AND A HOMOGENIZATION SYSTEM, ALLOWING THE SURFACE TO BE UNIFORMLY AND CONTINUOUSLY AT A WIDTH OF 1 METER. BECAUSE OF ITS ADVANCED AUTOMATION SYSTEM AND THE AIR CONDITIONING EQUIPMENT, IT ENABLES CONTINUOUS PRODUCTION AT THE HIGHEST SET QUALITY EVEN UNDER CHANGING ENVIRONMENTAL CONDITIONS. SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATIC PAINTED SHEET METAL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX. 600 KGS DIMENSIONS: 3650 x 1950 X 1940 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: IN THE SPINNERET 0-(+)60 KV VOLTAGE PRECISION: 0.1 KV MAXIMUM CURRENT: 3 MA PUMP SYSTEM FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML CONTINUES FEEDING PUMP SYSTEM FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 33 PCS NUMBER OF FEEDING PIPE SETS: 4 PCS NUMBER OF NOZZLES: 132 PCS SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: STANDARD NOZZLE: 0.8 mm (DIFFERENT DIAMETERS CAN BE USED) MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 3 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 25 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 150 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 50 mm TO 350 mm DISTANCE ADJUSTMENT PRECISION: 1 mm COLLECTOR ROLL TO ROLL COLLECTOR FIBER DEPOSITION WIDTH: 1000 mm SUBSTRATE WINDING SPEED: MAX. 0,1 M/ min TO MIN. 10 M/ min COATING HOMOGENEITY SYSTEM: X-AXIS STROKE OF COATING HOMOGENEITY SYSTEM: 30 mm TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm/SEC UNIQUE USER INTERFACE 12” TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 Hz @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 5000 X 3000 mm Learn More -

AUTEFA, DILO, SPINNBAU COMPLETE NONWOVEN LINEREFERENCE NUMBER: T-6855 AUTEFA, DILO, SPINNBAU COMPLETE NONWOVEN LINE BRAND: AUTEFA, DILO, SPINNBAU SHORT DESCRIPTION: COMPLETE NONWOVEN LINE ITEM 001 SINGLE DOFFER CARD BY “BESSI” - ITALY YEAR 1966 - WORKING WIDTH 2500mm - HOPPER-FEEDER WITH SCALE (WEIGHPAN) AND TOP SILO - INLET UNIT WITH ROLLERS - BREAST UNIT DIAMETER 1500mm WITH 3 PAIRS WORKERS/ STRIPPER (ORIGINALLY EQUIPPED WITH 5 PAIRS, UNUSED 2 PAIRS STILL AVAILABLE) - FANCY ROLL - TRANSPORT ROLL DIAMETER 1200mm - SWIFT DIAMETER 1500mm WITH 3 PAIRS WORKERS/ STRIPPER (ORIGINALLY EQUIPPED WITH 5 PAIRS, UNUSED 2 PAIRS STILL AVAILABLE) - DOFFER DIAMETER 1500mm WITH FLY-COMB - FLEXIBLE AND RIGID METALLIC WIRES IN EXCELLENT CONDITIONS QUANTITY: 1 ITEM 002 CROSS-LAPPER BY “MAK-AUTEFA” - GERMANY MODEL 101-42 YEAR 1965 - INLET WORKING WIDTH 2500mm - EXIT WORKING WIDTH 3000mm QUANTITY: 1 ITEM 003 PRE-NEEDLER BY “DILO” - GERMANY MODEL NFZ 3000 YEAR 1967 - WORKING WIDTH 3000mm - 2 NEEDLE BOARDS WITH TOTALLY 3000 NEEDLES / LIN MT - WITH BATT INLET UNIT QUANTITY: 1 ITEM 004 FINISH NEEDLERS BY “DILO” MODEL OD II 25 YEAR 1979 EACH - WORKING WIDTH 2500mm EACH - EACH ONE WITH 2 NEEDLE BOARDS WITH TOTALLY 5000 NEEDLES / LIN MT QUANTITY: 2 ITEM 005 TRANSVERSAL CUTTER BY “SPINNBAU-AUTEFA” - GERMANY. YEAR 1973 - WORKING WIDTH 2500mm QUANTITY: 1 ITEM 006 LONGITUDINAL CUTTER ITALIAN MAKE + ROLL WINDER ITALIAN MAKE ON ELECTRONIC WEIGHTING CELLS. WORKING WIDTH 2500mm QUANTITY: 1 ITEM 007 ROLLS LIFTING CRANE QUANTITY: 1 ALL ELECTRIC MOTORS AND CONTROL PANELS 400 V / 50 Hz Learn More

AUTEFA, DILO, SPINNBAU COMPLETE NONWOVEN LINEREFERENCE NUMBER: T-6855 AUTEFA, DILO, SPINNBAU COMPLETE NONWOVEN LINE BRAND: AUTEFA, DILO, SPINNBAU SHORT DESCRIPTION: COMPLETE NONWOVEN LINE ITEM 001 SINGLE DOFFER CARD BY “BESSI” - ITALY YEAR 1966 - WORKING WIDTH 2500mm - HOPPER-FEEDER WITH SCALE (WEIGHPAN) AND TOP SILO - INLET UNIT WITH ROLLERS - BREAST UNIT DIAMETER 1500mm WITH 3 PAIRS WORKERS/ STRIPPER (ORIGINALLY EQUIPPED WITH 5 PAIRS, UNUSED 2 PAIRS STILL AVAILABLE) - FANCY ROLL - TRANSPORT ROLL DIAMETER 1200mm - SWIFT DIAMETER 1500mm WITH 3 PAIRS WORKERS/ STRIPPER (ORIGINALLY EQUIPPED WITH 5 PAIRS, UNUSED 2 PAIRS STILL AVAILABLE) - DOFFER DIAMETER 1500mm WITH FLY-COMB - FLEXIBLE AND RIGID METALLIC WIRES IN EXCELLENT CONDITIONS QUANTITY: 1 ITEM 002 CROSS-LAPPER BY “MAK-AUTEFA” - GERMANY MODEL 101-42 YEAR 1965 - INLET WORKING WIDTH 2500mm - EXIT WORKING WIDTH 3000mm QUANTITY: 1 ITEM 003 PRE-NEEDLER BY “DILO” - GERMANY MODEL NFZ 3000 YEAR 1967 - WORKING WIDTH 3000mm - 2 NEEDLE BOARDS WITH TOTALLY 3000 NEEDLES / LIN MT - WITH BATT INLET UNIT QUANTITY: 1 ITEM 004 FINISH NEEDLERS BY “DILO” MODEL OD II 25 YEAR 1979 EACH - WORKING WIDTH 2500mm EACH - EACH ONE WITH 2 NEEDLE BOARDS WITH TOTALLY 5000 NEEDLES / LIN MT QUANTITY: 2 ITEM 005 TRANSVERSAL CUTTER BY “SPINNBAU-AUTEFA” - GERMANY. YEAR 1973 - WORKING WIDTH 2500mm QUANTITY: 1 ITEM 006 LONGITUDINAL CUTTER ITALIAN MAKE + ROLL WINDER ITALIAN MAKE ON ELECTRONIC WEIGHTING CELLS. WORKING WIDTH 2500mm QUANTITY: 1 ITEM 007 ROLLS LIFTING CRANE QUANTITY: 1 ALL ELECTRIC MOTORS AND CONTROL PANELS 400 V / 50 Hz Learn More -

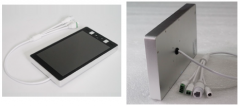

H-2414 8” FACIAL RECOGNITION WITH TEMPERATURE DETECTION PANEL PC

H-2414 8” FACIAL RECOGNITION WITH TEMPERATURE DETECTION PANEL PCPC MAIN SPECS:

CPU: HISILICON HI3516D V300 DUAL CORE, CORTEX-A7, 1.0 TOPS

RAM: 4GB

STORAGE: 16GB (CAN SAVE 50,000 FACE DATABASE)

LINUX OS

WORKING TEMPERATURE: -20°C TO 60°C

SUPPORT LIVE DETECTION

SUPPORT FACE RECOGNITION, RECOGNITION DISTANCE: ≤500mm, TIME: ≤ 0.2S

SUPPORT AUTOMATIC TEMPERATURE DETECTION, RECOGNITION DISTANCE: ≤ 500mm, TIME: ≤0.3S

SUPPORT THE SECONDARY DEVELOPMENT OF DEVICE-SIDE APPLICATION

SOFTWARELCD PANEL MAIN SPECS:

Learn More

RESOLUTION: 800 X 1280 (10:16)

BRIGHTNESS: 500CD/M2 (TYP)

CONTRAST: 800:1

INTERFACES: 1 X LAN/ 1 X WIGEN OUTPUT/1 X RELAY OUTPUT/ 1 X DC INPUT

SUPPORT DISPLAY OUTPUT TO LAPTOP PC OR DESKTOP PC VIA LAN PORT

SENSOR:

1 X FAR INFRARED TEMPERATURE SENSOR

1 X 2MP FRONT CAMERA -

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWN

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWNEFFECTIVE WIDTH: 1600mm

DAILY OUTPUT: 10,000 KGS PER DAY

WEIGHT RANGE: 10 TO 150 GSM

FILAMENT DIAMETER: 1.6 TO 2.0 DENIER

SPEED: 350 TO 400 METERS PER MINUTE

RAW MATERIAL: POLYPROPYLENE (PP)

DIMENSIONS: 35,000 X 15,000 X 11,000mm

VOLTAGE: 380 VOLTS, 3 PHASECONSISTING OF:

SPUNBOND EQUIPMENT

PP VACUUM SUCTION MACHINE (2)

7800 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS PER HOUR

POWER: 7.5 KWMASTER BATCH DOSING UNIT (2)

ACCURACY: 0.01%EXTRUDER (2)

DIAMETER: 130mm

SINGLE SCREW (2)

HEATING SYSTEM: ELECTRICITY

MOTOR: 75 KWMELT FILTRATION MACHINE (2)

PIPE SIZE: 50mm

FILTER AREA: 3.5 SQUARE METERS

MELT FLOW: 650 KGS PER HOUR

DOUBLE FILTRATION CHAMBERMELTING PUMP (2)

40 RPM

FLOW CAPACITY: 400 KGS PER HOUR

POWER: 7.5 KWSPINNING BEAM (2)

DIMENSIONS: 1900 X 256mm

HANGER TYPE MELT DISTRIBUTION

HEATING SYSTEM: OIL

WORKING TEMPERATURE: 200 TO 260 CELSIUSSPINNERET (4)

HARDNESS: 30

SIZE: 1900mm LONG X 256mm WIDE

HOLE DIAMETER 0.45mm

HOLE QUANTITY: 6500 HOLE PER METERQUENCHING UNIT (2)

WORKING TEMP: 20 CELSIUS

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

AIR PRESSURE: 6500

FILTER SIZE: 80#FILAMENT DRAFT UNITS (2)

AIR PRESSURE: 5020PA

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

INSIDE TEMP: 10 TO 25 CELSIUS

FILAMENT FINENESS: 1.6 TO 2.0 DENIERMELT BLOWN EQUIPMENT

VACUUM SUCTION MACHINE (2)

LOAD CAPACITY: 700 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS/H

POWER: 7.5 KWMASTER BATCH DOSING UNIT (2)

4 HOPPERS

200 KGS HOPPER LOADEXTRUDER

DIAMETER: 105mm

SINGLE SCREW

MOTOR: 18.5 KWMELT FILTER

DOUBLE CYLINDER

HYDRAULIC

MELT FLOW CAPACITY: 450 KGS/HR

FILTER SIZE: 150mm DIAMETER

ELECTRIC HEATINGMELTING PUMP

SPEED: 40 RPM

MELT FLOW CAPACITY: 450 KGS PER HOUR

POWER: 7.5 KWMELT BLOWN DIE SPINNARET

SPINNERET HOLE SIZE: 0.32 TO 0.35mm

HOLE DISTANCE: 40 TO 42 PER INCH

FABRIC WEIGHT: 2 TO 200 GSMHIGH PRESSURE AIR BLOWER

AIR FLOW CAPACITY: 70 TO 100 CUBIC METERS PER MINUTE

AIR PRESSURE: 100 KPA

POWER: 200 KWWEB FORMING MACHINE

SPEED: 100 METERS PER MINUTEELECTRIC TREATMENT

VOLTAGE: 220 VOLTS, 50 Hz

INPUT CURRENT: 3A

OUTPUT VOLTAGE: 60 KV

TREAT WEB WIDTH: 1.6 METERSHOT AIR HEATING MACHINE

WORKING TEMP: 350 CELSIUS

PRESSURE: 0.8 KPA

HEATING: ELECTRIC

POWER: 200 KWTHERMAL CALENDER

PROCESSING SPEED: 400 METERS PER MINUTE

ROLLER SIZE: 2000mm LONG, 520mm DIAMETER

EMBOSSING ROLLER: 1

LINEAR PRESSURE: 30 TO 125 N/mm

HEATING SYSTEM: OILHYDROPHILIC MACHINE

SPEED: 400 METERS PER MINUTE

FEEDING SYSTEM: DOUBLE KISSING ROLLER

KISS ROLLER DIAMETER: 215mm

LIQUID TANK: 200 KGS WITH HEAT/WARM AND MIXDRYING SYSTEM:

INFRARED + HOT AIR

DRIVE ROLL SIZE: 150mm

HEATING EQUIPMENT: QUARTZ HEATER, HOT AIR BLOWER, EXHAUST AIR BLOWERINSPECTION MACHINE

EFFECTIVE WIDTH: 1600mm

INSPECTION SPEED: 400 METERS PER MINUTE

INSPECT GSM: 10 TO 40 GSMAUTOMATIC WINDING MACHINE

SPEED: 400 METERS PER MINUTE

ROLLER DIAMETER: 2000mm

ROLLER EXCHANGE SYSTEM: AUTOMATIC

FABRIC INSPECTOR: ONLINE

POWER: 15 KWHIGH SPEED SLITTING MACHINE

PROCESS SPEED: 800 METERS PER MIN

ROLL DIAMETER: MAX 1500mm

SLITTING WIDTH: 80mm

PAPER TUBE SIZE: 76mm DIAMETER

AUTO TENSILE CONTROL: AVAILABLE ONLINE

METER COUNTING: AVAILABLE ONLINEOIL HEATER (4)

HEATING POWER: 60 KW

MOTOR POWER: 7.5 KW

OIL PUMP FLOW: 30 CUBIC METERS PER SECOND

PRESSURE: 0.4 KPAWATER CHILLER

DRIVE SYSTEM: SCREW

COOLING CAPACITY: 300,000 CALORIES

TEMP: 0 TO 20 CELSIUS

POWER: 110 KWAIR BLOWER

SPEED: 1450 RPM

AIR BLOW CAPACITY: 12,000 CUBIC METERS PER HOUR

PRESSURE: 5200 PA

POWER: 30 KW x 3, 45 KW x 1AIR COMPRESSOR

DRIVE SYSTEM: SCREW

PRESSURE: 0.8 KPA

POWER: 15 KWHEATING SYSTEM: ELECTRIC

TEMP: 350 CELSIUS

HEATING TIME: 6 TO 8 HOURS

POWER: 4 KWULTRASONIC CLEANING MACHINE

3mm THICK

SIZE: 2000 X 500mm

FREQUENCY VIBRATION: 100 KHZ

TEMP: 40 CELSIUSELECTRONIC PANEL BOARD

PLATFORM

Learn More -

PP-1138 FABRIC LIST WITH YARDS

PP-1138 FABRIC LIST WITH YARDS1. 5 ROLLS – CK6658 – RELIC – 115 YARDS

2. 13 ROLLS – CK6270 – 210 YARDS

3. 3 ROLLS – QUARUM LAMPE GREY – 92374 – 192.47 YARDS

4. 5 ROLLS – ORELAND BLACK STEELE – 344.80 YARDS

5. 8 ROLLS – CK5259 + 3 ROLLS – 125 YARDS

6. 2 ROLLS – WORLD LUX – CK7149 – 50 YARDS

7. 12 ROLLS – WORLD LUX – CK7150 – 250 YARDS ??

8. 6 ROLLS – VICTOR ELAS STEEL/NAT/BLK – D370942 – 186 YARDS

9. 2 ROLLS – EVA BAS/NAT/BLK – D370916 – 107.8 YARDS

10. 2 ROLLS – BLUE – PNL – CK5970 – 45 YARDS

11. 4 ROLLS – GREY – 10028 – 65 YARDS

12.

13. 3 ROLLS – QUARUM LAMPE BLUE – 92331 – 224.53 YARDS

14. 3 ROLLS – W272 EGGSHELL – 945094 – 300 YARDS

15. 6 ROLLS – W272 SILVER – 945100 – 150 YARDS

16.

17. 5 ROLLS – CREATIVE CT 15118 – 50 YARDS

18. 4 ROLLS – CREATIVE NAT/BLK/BET SILVER- CT0481 – 85 YARDS

19.

20.

21.

22.

23. 6 ROLLS – LORI WHITE – DUNCAN – DT002 – 270 YARDS

24. 5 ROLLS – ‘YC’ CK6054 – 25 YARDS

25. 2 ROLLS – POTTSTOWN GOLD – 120.4 YARDS

26. 3 ROLLS- MOET SOFT PLATINUM W7461 – 30 YARDS

27.

28.

29. 5 ROLLS – BORDEUX BE PORT – W5087 – 50 YARDS

30. 4 ROLLS – NATURAL NEW COOL THERAPY – CK 7240 – 127.30 YARDS

31. 2 ROLLS – NATURES DREAM – CK7247 – 65.7 YARDS

32.

33.

34. 3 ROLLS – YASMINE DIAMOND/NATURAL – M3929 – 49 YARDS

35.

36.

37. 3 ROLLS – KENDALL SILVERY – BLUE/ NATURAL BAMBOO – M3961- 50 YARDS

38. 5 ROLLS – LEGACY BLUE – CK6162 – 178.5 YARDS

39.

40. 21 ROLLS – CK7592 – 177 YARDS

41. 11 ROLLS – NEW WORLD LUXURY – CK7453 – 1 – 102.2 YARDS

42. 2 ROLLS- MAVIME STORM/NAT/SLATE FACE – M4148 – 57 YARDS

43. 4 ROLLS – LEGACY ETTA/FLEX PANEL – CK7595 – 80 YARDS

44. 8 ROLLS – LEGACY JB/CRADLE – CK7593 – 263.7 YARDS

45.

46. 1 ROLL – LAMERO RD ‘LA COLLECTION’ - TN43175 – L4189 – 48 YARDS

47. 1 ROLL – BLUE NEW – BLUE HOSTESS – CK7141 – 30 YARDS

48. 26 ROLLS – IRON SWART ACCTIK – MT 100252 – 726.40 YARDS

49. 26 ROLLS – EE SPAMDEX – MT 100095 – 727.20 YARDS

50.

51.

52. 10 ROLLS – CAROLYN 500 GR/M2 LAMPE – 353.05 YARDS

53. 3 ROLLS – JUDY CHARCOAL GREY – LAMPE – 100.52 YARDS

54. 3 ROLLS – CK7385 – 92 YARDS

55.

TOTAL: 6,173.57NOT ON LIST

1. MO6317 EXCALIBUR – 564.10 YARDS

2. RED HILL – DAYBREAK – 597.30 YARDS

3. SURYA M4234 – STORM-MANGO SLATE – 450 YARDS ??

4. SO526CI – DIAMOND NATURAL – EXCEPTIONAL – 105 YARDS

5. M3781 – NORMAND

6. DK961T NATIO1048 CULP ‘WORLD’

7. CT1710 – TT3 – DIAMOND DREAMZZ

TOTAL: 1,716.40PUT RED TAGS ON UNKNOWN ROLLS

GRAND TOTAL : 7,889.97 YARDAGE

Learn More -

J-1937 LAMINATING MACHINE FOR FOAM TO FABRIC – CONTINUOUS WITH SLITTING, NEW

J-1937 LAMINATING MACHINE FOR FOAM TO FABRIC – CONTINUOUS WITH SLITTING, NEWSILICON COATED NOMEX FELT (ITB BRAND – ITALIAN)

BLANKET THICKNESS: 8mm

PNEUMATICALLY ADJUSTABLE FELT PRESSURE

MAXIMUM WORKING WIDTH: 2100mm (82.6”)

EVA HOT MELT FILM, FILM ROLL MIMIMUM 500 METERS, MAXIMUM 1000 METERS

36 KW HEATER RESISTANCE

MAIN DRUM DIAMETER: 500mm

TEFLON COATED MAIN CYLINDER

PNEUMATIC BLANKET EDGE CONTROL BY PHOTOCELL

WORKING SPEED: 5 TO 10 METERS PER MINUTE, DEPENDING ON FABRIC THICKNESS (THICK FABRIC IS SLOWER, NORMAL FABRIC IS FASTER)

PLC CONTROLLER WITH TOUCH SCREEN OPERATOR PANEL

PROGRAMMABLE HEATING UP AND COOLING DOWN

ROLL TO ROLL WORKING SYSTEM

SLITTING UNIT WITH 3 PIECE PNEUMATIC CUTTER AND DUAL CENTER REWINDING UNIT (OPTIONAL)

440 V 3-PHASE, 60 Hz, 55 AMPLEAD TIME: 6 TO 8 WEEKS AFTER RECEIPT OF DEPOSIT

Learn More -

L-6683 DOUBLE BELT COMPRESSION THERMOBONDING OVEN

L-6683 DOUBLE BELT COMPRESSION THERMOBONDING OVENL-6683 DOUBLE BELT COMPRESSION THERMOBONDING OVEN SYSTEM 6000mm X 3300mm WIDE

INCLUDING:

THERMOBONDING OVEN

- DOUBLE COMPRESSION CONVEYORS SYSTEM SINGLE PASS

- DOUBLE BELT SOFT & HARD WADDING OVEN (6000mm LONG)

WORKING WIDTH: 3300mm

LENGTH OF HEATING CHAMBER: 6000mm

PANELS ARE 100mm THICK

TEMPERATURE INSIDE: UP TO 220 C

GAS BURNER 25 CUBIC METER PER HOUR DEPENDING ON MATERIAL THICKNESS

TWO GAS BURNERS ONE ON EACH SIDE 80 START AND 25 RUN CBM/H WITH MAINLINE 2 INCH

REDUCED TO 1” AT BURNER, PRESSURE 10 TO 15 KPascal

TWO HOT AIR FANS 22 KW EACH

ONE EXHAUST FAN 5.5 KW

WORKING SPEED: 1 TO 8 METERS PER MINUTE

DOUBLE TEFLON BELT WITH SINGLE PASS, WEAVE IS 2mm X 2mm

SUCTION HOOD AT THE ENTRANCE

THICKNESS OF FINAL PRODUCT 20 TO 150mm DEPENDINGCOOLING UNIT

- FOUR COOLING PRESS ROLLERS 200mm diameter , 10mm shell thickness, with chiller

12,000 watt output power , input power 5700 watt , capacity 65 liter per minute

WORKING WIDTH: 3300mm

- LENGTHWISE CUTTER – 7 KNIVES ,pneumatically activated , BLADE DIAMETER 650mm

-SINGLE MOTOR

- MOVABLE SIDEWAYS

- CROSS CUTTER 2.2 KW MOTOR . UP TO 4 CUTS PER MINUTE

MAXIMUM LENGTH 2000mm

WORKING WIDTH: 2800mm

PVC CONVEYOR AT THE EXITELECTRICAL CONTROL SYSTEM

-ELECTRICAL CABINET UL COMPONENTSQUANTITY: 1

Learn More -

L-6069 EASTMAN STATIC TABLE CUTTING MACHINE MODEL M9000, 20’ X 72’, YEAR 2009

L-6069 EASTMAN STATIC TABLE CUTTING MACHINE MODEL M9000, 20’ X 72’, YEAR 2009REFERENCE NUMBER: L-6069

EASTMAN STATIC TABLE CUTTING MACHINE MODEL M9000, 20’ X 72’, YEAR 2009

STATIC TABLE CUTTING MACHINE

MAKE: EASTMAN

MODEL: M9000

20 FEET LONG X 72 FEET WIDE

PURCHASED IN YEAR 2009

220 VOLT, 1 PHASE

QUANTITY: 1

Learn More -

P-5392 FEHRER NL28 PRE NEEDLE LOOM WIDTH 2600mm

P-5392 FEHRER NL28 PRE NEEDLE LOOM WIDTH 2600mmREFERENCE NUMBER: P-5392

FEHRER NL28 PRE NEEDLE LOOM WIDTH 2600mm

FEHRER

TYPE: NL28

PRE NEEDLE LOOM

WORKING WIDTH: 2600mm

SINGLE BOARD

QUANTITY: 1

Learn More -

L-4034 LONG SHEET FOAM PEELING MACHINE- 2300 mm X 60 METERS LONG – NEW

L-4034 LONG SHEET FOAM PEELING MACHINE- 2300 mm X 60 METERS LONG – NEWREFERENCE NUMBER: L-4034

LONG SHEET FOAM PEELING MACHINE- 2300 mm X 60 METERS LONG – NEW

CUTTING WIDTH: 2300mm

CUTTING HEIGHT: 1300mm (51 inches) (beginning bun height)

CUTTING SPEED: 0 TO 60 METERS PER MINUTE

CUTTING THICKNESS: 2 TO 60mm

Learn More