Search results for: 'Complete+aut'

-

TT-3948 SULZER PROJECTILE LOOMS P7100 & PU FOR TERRY FABRICS, WIDTH 3300 TO 3900mm, YEAR 1985 TO 1999, CAM AND DOBBYTT-3948 SULZER PROJECTILE LOOMS P7100 & PU FOR TERRY FABRICS, WIDTH 3300 TO 3900mm, YEAR 1985 TO 1999, CAM AND DOBBY ITEM 001 SULZER PROJECTILE LOOMS, P7100 TYPE P7100 B360 N4 EP R Q D1 QUANTITY: 8 SETS ITEM 002 SULZER PROJECTILE LOOMS, TYPE PU 130 VSD KR FOR TERRY FABRICS TYPE PU 130 VSD120 KR D1 G QUANTITY: 12 SETS ITEM 003 SULZER PROJECTILE LOOMS, TYPE PU 153 VSD KR FOR TERRY FABRICS TYPE PU 153 VSD 110 KR D1 G YEAR 1985 QUANTITY: 4 SETS Learn More

TT-3948 SULZER PROJECTILE LOOMS P7100 & PU FOR TERRY FABRICS, WIDTH 3300 TO 3900mm, YEAR 1985 TO 1999, CAM AND DOBBYTT-3948 SULZER PROJECTILE LOOMS P7100 & PU FOR TERRY FABRICS, WIDTH 3300 TO 3900mm, YEAR 1985 TO 1999, CAM AND DOBBY ITEM 001 SULZER PROJECTILE LOOMS, P7100 TYPE P7100 B360 N4 EP R Q D1 QUANTITY: 8 SETS ITEM 002 SULZER PROJECTILE LOOMS, TYPE PU 130 VSD KR FOR TERRY FABRICS TYPE PU 130 VSD120 KR D1 G QUANTITY: 12 SETS ITEM 003 SULZER PROJECTILE LOOMS, TYPE PU 153 VSD KR FOR TERRY FABRICS TYPE PU 153 VSD 110 KR D1 G YEAR 1985 QUANTITY: 4 SETS Learn More -

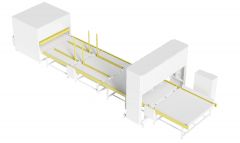

TT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXITTT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXIT AUTOMATIC GLUE SPRAY MACHINE APPLICATION: THE AUTOMATIC GLUE SPRAY MACHINE IS HIGHLY AUTOMATED. THROUGH INFRARED MEASUREMENT, IT CAN AUTOMATICALLY IDENTIFY THE HEIGHT AND WIDTH OF THE MATERIAL, AND AUTOMATICALLY ADJUST THE POSITION OF THE GLUE NOZZLE FOR SPRAYING ACCORDING TO THE DETECTION HEIGHT. AUTOMATIC GLUE SPRAY MACHINE CAN COMPLETE SUCH PROCESSES AS AUTOMATICALLY GLUE SPRAYING, PNEUMATIC TURNING OVER OF THE UNIT AND AUTOMATICALLY PRESSING. WITH PLC CONTROL, HIGH PRODUCTION EFFICIENCY, SINGLE SPRAYING IS ABOUT 30 SECONDS PER SHEET. IT IS SUITABLE FOR SHEETS WITH WIDTH OF 850 TO 2200mm AND HEIGHT OF 5 TO 400mm THE GLUE SPRAYING MACHINE IS SUITABLE FOR FOAM, LATEX, MATTRESS AND HOME TEXTILE INDUSTRIES. Learn More

TT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXITTT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXIT AUTOMATIC GLUE SPRAY MACHINE APPLICATION: THE AUTOMATIC GLUE SPRAY MACHINE IS HIGHLY AUTOMATED. THROUGH INFRARED MEASUREMENT, IT CAN AUTOMATICALLY IDENTIFY THE HEIGHT AND WIDTH OF THE MATERIAL, AND AUTOMATICALLY ADJUST THE POSITION OF THE GLUE NOZZLE FOR SPRAYING ACCORDING TO THE DETECTION HEIGHT. AUTOMATIC GLUE SPRAY MACHINE CAN COMPLETE SUCH PROCESSES AS AUTOMATICALLY GLUE SPRAYING, PNEUMATIC TURNING OVER OF THE UNIT AND AUTOMATICALLY PRESSING. WITH PLC CONTROL, HIGH PRODUCTION EFFICIENCY, SINGLE SPRAYING IS ABOUT 30 SECONDS PER SHEET. IT IS SUITABLE FOR SHEETS WITH WIDTH OF 850 TO 2200mm AND HEIGHT OF 5 TO 400mm THE GLUE SPRAYING MACHINE IS SUITABLE FOR FOAM, LATEX, MATTRESS AND HOME TEXTILE INDUSTRIES. Learn More -

YY-2101 MASTER INDIGO DYEING LINE, WIDTH 1800mm, YEAR 2004YY-2101 MASTER INDIGO DYEING LINE, WIDTH 1800mm, YEAR 2004 YEAR: 2004 WIDTH: 1800mm QUANTITY: 1 Learn More

YY-2101 MASTER INDIGO DYEING LINE, WIDTH 1800mm, YEAR 2004YY-2101 MASTER INDIGO DYEING LINE, WIDTH 1800mm, YEAR 2004 YEAR: 2004 WIDTH: 1800mm QUANTITY: 1 Learn More -

P-4950 COMPLETE SPINNING PLANT – ZINSER – RIETER – FOR FIREPROOF THREAD

P-4950 COMPLETE SPINNING PLANT – ZINSER – RIETER – FOR FIREPROOF THREADP-4950 COMPLETE SPINNING PLANT – ZINSER – RIETER – FOR FIREPROOF THREAD

THIS SPINNING PLANT WAS COMPLETELY MODERNIZED IN 2008

PREPARED TO WORK FIREPROOF THREAD

THIS PLANT IS COMPLETED WITH ALL ITS MECHANISMS TO OPERATE AT THE TIME

HAS A MOISTURE CONDITIONER FOR THE ENTIRE FACTORY WITH WATER FILTERS AND DIFFERENT COMPARTMENTS WITH APPROXIMATELY 20M LONG AND 4M WIDE

IT ALSO HAS 2 CHAMBERS FOR DRYING THE YARN

THE PRODUCTION THICK YARNS TYPES AND TYPES OF MATERIAL THAT CAN WORK THIS SPINNING.

THE RELATIONSHIPS OF THE MACHINES:

1 BOILER VYC 12 BAR.

1 AUTOCLAVE TAINOX

1 ELECTRIC INDUSTRIAL SCALES

1 OPENING (RIETER)

1 CARDING RIETER

1 CARDING RIETER

1 DRAWING FRAME (24)

1 ROVING FRAME (24)

5 SPINNING FRAME G/01, ZINSER. (118X2 UNIT)

1 SPINNING FRAME G/01, RIETER (108X2 UNIT)

1 AUTOMATIC SCHLAFHORST AUTOCONER. ( 40 )

1 CENTRAL TEMPERATURE / HUMIDITY OF APPROX 20 M X 4 M.

2 CABINS DRYING.

1 FULL LAVORATORIO

2 COMPRESSORS (25 AND 30 HP)

1 DRYER

1 DEPOSIT OF AIR,

*ALL ACCESSORIES IN THE FACTORY.

STOCK ALSO NO THREAD IN LYCRA, ALSO MATERIALS IN BALES

Learn More

QUANTITY: 1 COMPLETE PLANT -

M-4089 COMPLETE RIETER RING SPINNING & YARN DYE FACTORY – 37,056 SPINDLES - Will Sell Individually

M-4089 COMPLETE RIETER RING SPINNING & YARN DYE FACTORY – 37,056 SPINDLES - Will Sell IndividuallyREFERENCE NUMBER: M-4089 (990DJSKXX8) L

COMPLETE RIETER RING SPINNING & YARN DYE FACTORY – 37,056 SPINDLES- will sell individually

FACTORY WAS PRODUCING VARIOUS SPECIALTY YARNS FOR USE IN APPAREL AND TECHNICAL TEXTILES

ALL RING FRAMES SHORT STAPLE FOR FIBERS UP TO 40mm, 220mm TUBES, APPROXIMATELY HALF OF THE RING FRAMES ARE WITH PINTER CORE DEVICE OR AMSLER SLUBBING DEVICE. AMSLER AND PINTER AVAILABLE TO SELL SEPARATELY.

COMPLETE YARN DYE HOUSE & DYE LAB

QUANTITY AVAILABLE: 1

Learn More -

TT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATORTT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATOR QUANTITY: 10 Learn More

TT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATORTT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATOR QUANTITY: 10 Learn More -

AUTOMATEX, SPINNBAU NEEDLE PUNCH LINEREFERENCE NUMBER: T-6840 AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE BRAND: AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE CONSISTING OF: BLEND LINE, 60” WIDE, 4 HOPPERS WITH 12 HEAVY DUTY EXTENDED APRONS & NEW ELECTRONIC WEIGHING SYSTEM (2016). ALL MACHINES COMPLETELY RECONDITIONED IN 2016. OMMI STACK RESERVE, AUTOMATIC COMBO 332, YEAR 2000 SPINNBAU CARD, 2500mm, DOUBLE DOFFER, YEAR 1995, REPORTED ~1500 TO 1800 PPH CAPACITY DEPENDING UPON PRODUCT. AUTOMATEX FA/3000 TC CROSSLAPPER, YEAR 1997, AC DRIVES. BATT DRAFTER, 12 ROLLS. AUTOMATEX PR-100/T PRE-NEEDLER, 60mm STROKE, YEAR 1997 DRAFTER, 5 ROLLS. AUTOMATEX AG 154/TB NEEDLE LOOM, QUAD PUNCH, 50mm STROKE, YEAR 1997 FOUR ROLL STRETCH. METAL DETECTOR. ENTEX TENTER WITH VERTICAL IR HEAT BANKS, YEAR 1997 WINDER, YEAR 1997 PERKINS 4 ROLL CALENDER, NO STEEL ROLLS OR HEAT SYSTEM INCLUDED BUT MIGHT BE NEGOTIATED. EHHARDT+LEIMER GUIDER MODEL SE 11062, YEAR 2013 ENTEC WINDER, YEAR 1997 FINISHED WIDTH REPORTED OF 210" BUT COULD GO WIDER. LINE RAN PRIMARILY GEOTEXTILE & BEDDING PRODUCTS FROM 4.5 TO 10 OZ/YD. QUANTITY: 1 Learn More

AUTOMATEX, SPINNBAU NEEDLE PUNCH LINEREFERENCE NUMBER: T-6840 AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE BRAND: AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE CONSISTING OF: BLEND LINE, 60” WIDE, 4 HOPPERS WITH 12 HEAVY DUTY EXTENDED APRONS & NEW ELECTRONIC WEIGHING SYSTEM (2016). ALL MACHINES COMPLETELY RECONDITIONED IN 2016. OMMI STACK RESERVE, AUTOMATIC COMBO 332, YEAR 2000 SPINNBAU CARD, 2500mm, DOUBLE DOFFER, YEAR 1995, REPORTED ~1500 TO 1800 PPH CAPACITY DEPENDING UPON PRODUCT. AUTOMATEX FA/3000 TC CROSSLAPPER, YEAR 1997, AC DRIVES. BATT DRAFTER, 12 ROLLS. AUTOMATEX PR-100/T PRE-NEEDLER, 60mm STROKE, YEAR 1997 DRAFTER, 5 ROLLS. AUTOMATEX AG 154/TB NEEDLE LOOM, QUAD PUNCH, 50mm STROKE, YEAR 1997 FOUR ROLL STRETCH. METAL DETECTOR. ENTEX TENTER WITH VERTICAL IR HEAT BANKS, YEAR 1997 WINDER, YEAR 1997 PERKINS 4 ROLL CALENDER, NO STEEL ROLLS OR HEAT SYSTEM INCLUDED BUT MIGHT BE NEGOTIATED. EHHARDT+LEIMER GUIDER MODEL SE 11062, YEAR 2013 ENTEC WINDER, YEAR 1997 FINISHED WIDTH REPORTED OF 210" BUT COULD GO WIDER. LINE RAN PRIMARILY GEOTEXTILE & BEDDING PRODUCTS FROM 4.5 TO 10 OZ/YD. QUANTITY: 1 Learn More -

YY-3533 SHUTTLE LOOMS WITH AUTOMATIC CHANGE SPOOL DEVICE FOR TECHNICAL FABRICS, DENIM, AND OTHER FABRICS, WORKING WIDTH 2140mmYY-3533 SHUTTLE LOOMS WITH AUTOMATIC CHANGE SPOOL DEVICE FOR TECHNICAL FABRICS, DENIM, AND OTHER FABRICS, WORKING WIDTH 2140mm SHUTTLE LOOMS WITH AUTOMATIC CHANGE SPOOL DEVICE FOR TECHNICAL FABRICS, DENIM, AND OTHER FABRICS TECHNICAL FEATURE OF THE LOOM: 1. MAXIMUM WEAVING WIDTH: 2140mm – MIN. 1000mm (ON REQUEST BE POSSIBLE ALL WEAVING WIDTH); 2. THE LOOM IS SUITABLE FOR WEAVING TUBULAR FABRICS AND FLATS; 3. ADJUSTABLE WIRE/CM. MAX. 200 – MIN. 5; 4. MAX SPEED FROM 150 RPM; 5. MAXIMUM WARP TENSION: DAN/M 1500. QUANTITY: 1 Learn More

YY-3533 SHUTTLE LOOMS WITH AUTOMATIC CHANGE SPOOL DEVICE FOR TECHNICAL FABRICS, DENIM, AND OTHER FABRICS, WORKING WIDTH 2140mmYY-3533 SHUTTLE LOOMS WITH AUTOMATIC CHANGE SPOOL DEVICE FOR TECHNICAL FABRICS, DENIM, AND OTHER FABRICS, WORKING WIDTH 2140mm SHUTTLE LOOMS WITH AUTOMATIC CHANGE SPOOL DEVICE FOR TECHNICAL FABRICS, DENIM, AND OTHER FABRICS TECHNICAL FEATURE OF THE LOOM: 1. MAXIMUM WEAVING WIDTH: 2140mm – MIN. 1000mm (ON REQUEST BE POSSIBLE ALL WEAVING WIDTH); 2. THE LOOM IS SUITABLE FOR WEAVING TUBULAR FABRICS AND FLATS; 3. ADJUSTABLE WIRE/CM. MAX. 200 – MIN. 5; 4. MAX SPEED FROM 150 RPM; 5. MAXIMUM WARP TENSION: DAN/M 1500. QUANTITY: 1 Learn More -

TT-7117 RIETER COMPLETE OPEN END PLANT, 6,000 ROTORS, YEAR 2008 TO 2016, 50HzTT-7117 RIETER COMPLETE OPEN END PLANT, 6,000 ROTORS, YEAR 2008 TO 2016, 50Hz ITEM 001 1. BLOW ROOM LINE 2. YEAR: 2015 ITEM 002 1. CARDING MACHINE 2. YEAR: 2014 TO 2015 3. MODEL: C70 ITEM 003 1. RIETER DRAWING MACHINE 2. YEAR: 2008 ITEM 004 1. FULLY AUTOMATIC OE MACHINE 2. BRAND: RIETER 3. YEAR: 2016 Learn More

TT-7117 RIETER COMPLETE OPEN END PLANT, 6,000 ROTORS, YEAR 2008 TO 2016, 50HzTT-7117 RIETER COMPLETE OPEN END PLANT, 6,000 ROTORS, YEAR 2008 TO 2016, 50Hz ITEM 001 1. BLOW ROOM LINE 2. YEAR: 2015 ITEM 002 1. CARDING MACHINE 2. YEAR: 2014 TO 2015 3. MODEL: C70 ITEM 003 1. RIETER DRAWING MACHINE 2. YEAR: 2008 ITEM 004 1. FULLY AUTOMATIC OE MACHINE 2. BRAND: RIETER 3. YEAR: 2016 Learn More -

TT-4823 TRUETZSCHLER AUTOMATEX NONWOVEN NEEDLELOOMS, WORKING WIDTH 7000mm, YEAR 2002TT-4823 TRUETZSCHLER AUTOMATEX NONWOVEN NEEDLELOOMS, WORKING WIDTH 7000mm, YEAR 2002 ITEM 001 TANDEM NEEDLELOOM BRAND: AUTOMATEX MODEL AG 80 T/BA QUANTITY: 1 ITEM 002 PRENEEDLER BRAND: AUTOMATEX MODEL PR 50/T QUANTITY: 1 Learn More

TT-4823 TRUETZSCHLER AUTOMATEX NONWOVEN NEEDLELOOMS, WORKING WIDTH 7000mm, YEAR 2002TT-4823 TRUETZSCHLER AUTOMATEX NONWOVEN NEEDLELOOMS, WORKING WIDTH 7000mm, YEAR 2002 ITEM 001 TANDEM NEEDLELOOM BRAND: AUTOMATEX MODEL AG 80 T/BA QUANTITY: 1 ITEM 002 PRENEEDLER BRAND: AUTOMATEX MODEL PR 50/T QUANTITY: 1 Learn More