Search results for: 'Continuous+fo'

- Related search terms

- Continuous+foa

- Continuous+foam

- Continuous+fo'[0]

- continuous+foaming

- CONTINUOUS+FOAMING+MACHINE

-

J-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEETJ-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEET SUITABLE FOR FOAM ROLL WRAP FOAM DENSITY: 25 KGS/m3 TO 45 KGS/m3 CAPACITY: 15 SECONDS PER SHEET, CONTINUOUS OPERATION MAXIMUM MATTRESS SIZE: 2200 x 1500 x 150mm ROLL DIAMETER: 50 TO 300mm VOLTAGE: 380 VOLTS, 50 Hz OR 220 VOLTS, 60 Hz TOTAL POWER: 25 KW WEIGHT: 6.5 TONS QUANTITY: 1 Learn More

J-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEETJ-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEET SUITABLE FOR FOAM ROLL WRAP FOAM DENSITY: 25 KGS/m3 TO 45 KGS/m3 CAPACITY: 15 SECONDS PER SHEET, CONTINUOUS OPERATION MAXIMUM MATTRESS SIZE: 2200 x 1500 x 150mm ROLL DIAMETER: 50 TO 300mm VOLTAGE: 380 VOLTS, 50 Hz OR 220 VOLTS, 60 Hz TOTAL POWER: 25 KW WEIGHT: 6.5 TONS QUANTITY: 1 Learn More -

TT-3155 SITOLA SCC-W HORIZONTAL CNC CONTOUR CUTTING MACHINE, YEAR 2021TT-3155 SITOLA SCC-W HORIZONTAL CNC CONTOUR CUTTING MACHINE, YEAR 2021 AVAILABILITY SHORT DELIVERY TIMES UPON AGREEMENT. Learn More

TT-3155 SITOLA SCC-W HORIZONTAL CNC CONTOUR CUTTING MACHINE, YEAR 2021TT-3155 SITOLA SCC-W HORIZONTAL CNC CONTOUR CUTTING MACHINE, YEAR 2021 AVAILABILITY SHORT DELIVERY TIMES UPON AGREEMENT. Learn More -

K-8157 COAL FIRED POWER PLANT (2 X 50MW)

K-8157 COAL FIRED POWER PLANT (2 X 50MW)K-8157 COAL FIRED POWER PLANT (2 X 50MW)

ENERGY BOILERS (CAE)

TURBINE SYSTEMS

STEAM TURBINES (TA) - DSL ARE 50 - 1

-CONDENSING TURBINE WITH TWO ADJUSTABLE OUTLETS, SUCH AS "ACTING" ON A SINGLE LINE OF TREES, DESIGNED TO DRIVE THE AC GENERATOR DIRECT-TYPE TH 60-2

-IS COMPOSED OF TWO BODIES: THE BODY OF HIGH PRESSURE (CIP) AND MEDIUM AND LOW PRESSURE BODY (CMP + CJP)

-HAS TWO ADJUSTABLE OUTLETS (PLUG SOCKETS AND PLUG HEATING) AND FIVE FIXED DOSES REGENERATIVE CIRCUIT FEEDSQUARES OF 600 CARS OVER T/H (WITH BUCKET WHEEL AND ARM LENGTH 12 M) - 4 PCS

-TIP HAMMER CRUSHERS CCA - 160 TO 2 PIECES

- RUBBER BANDS COAL TRANSPORTTHE MAIN EQUIPMENT IS ADDED TO ENSURE PROPER OPERATION FOLLOWING:

- SOLID FUEL STORAGE

- INSTALLATIONS AND INDUSTRIAL WATER SUPPLIES AND WASTEWATER DISCHARGE

- INSTALLATION OF EXHAUST HYDRAULIC SLAG

- WATER TREATMENT STATION

TO USE COAL, WEIGHT 88%, 12% NATURAL GASQUANTITY: 1

Learn More -

G-1535 FOAM DRILLING MACHINE (FOAM PERFORATING MACHINE)G-1535 FOAM DRILLING MACHINE (FOAM PERFORATING MACHINE) MODEL: NOVA 26 TECHNICAL DATA: LOADING CONVEYOR: 2100 X 2100mm (82" X 82") UNLOADING CONVEYOR: 2100 X 2100mm (82" X 82") MAXIMUM DRILLING WIDTH: 2100mm (82") MAXIMUM DRILLING HEIGHT: 180mm (7") HOLE DIAMETER: 6 TO 30mm (1/4" TO 1.18") MAXIMUM CONTEMPORANEOUS HOLES NUMBER: 26 MINIMUM DISTANCE BETWEEN THE CHUCKS: 80mm POWER: 11 KW VOLTAGE: AS PER CUSTOMER WORKING PRESSURE BAR: 6 (90 PSI) NET WEIGHT: 2293 KGS (5000 LBS) FLOOR SPACE: 4375 X 3780 H 2204mm Learn More

G-1535 FOAM DRILLING MACHINE (FOAM PERFORATING MACHINE)G-1535 FOAM DRILLING MACHINE (FOAM PERFORATING MACHINE) MODEL: NOVA 26 TECHNICAL DATA: LOADING CONVEYOR: 2100 X 2100mm (82" X 82") UNLOADING CONVEYOR: 2100 X 2100mm (82" X 82") MAXIMUM DRILLING WIDTH: 2100mm (82") MAXIMUM DRILLING HEIGHT: 180mm (7") HOLE DIAMETER: 6 TO 30mm (1/4" TO 1.18") MAXIMUM CONTEMPORANEOUS HOLES NUMBER: 26 MINIMUM DISTANCE BETWEEN THE CHUCKS: 80mm POWER: 11 KW VOLTAGE: AS PER CUSTOMER WORKING PRESSURE BAR: 6 (90 PSI) NET WEIGHT: 2293 KGS (5000 LBS) FLOOR SPACE: 4375 X 3780 H 2204mm Learn More -

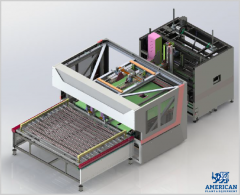

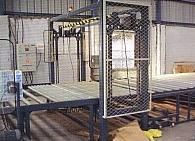

E-4174 FOAM PROCESSING MACHINES FOR SALEINVENTORY NUMBER: E-4174 FOAM PROCESSING MACHINES FOR SALE MODEL SL-KC FOAM GRINDER MODEL SL-BC BLOCK CUTTER FOR CONTINUOUS FOAMING MACHINE MODEL SL-PC FOAM PEELER QUANTITY AVAILABLE: 3 Learn More

E-4174 FOAM PROCESSING MACHINES FOR SALEINVENTORY NUMBER: E-4174 FOAM PROCESSING MACHINES FOR SALE MODEL SL-KC FOAM GRINDER MODEL SL-BC BLOCK CUTTER FOR CONTINUOUS FOAMING MACHINE MODEL SL-PC FOAM PEELER QUANTITY AVAILABLE: 3 Learn More -

M-0450 GPE1000 AIR BUBBLE FILM MAKING MACHINE

M-0450 GPE1000 AIR BUBBLE FILM MAKING MACHINEDESCRIPTION OF MACHINE THIS MACHINE ADOPTS ONCE-THROUGH SHAPING TECHNIQUE, THUS IT HAS HIGH EFFICIENCY AND EXCELLENT PRODUCT QUALITY. THIS MACHINE SET HAS SUCH FEATURES AS SCIENTIFIC AND REASONABLE STRUCTURE DESIGN, SMOOTH AND RELIABLE RUNNING AND CONVENIENT OPERATION AND MAINTENANCE. AIR BUBBLE SHEET EXTRUSION LINE PRODUCES CONTINUOUS ROLL OF AIR BUBBLE SHEET, AN IDEAL CUSHIONING-PACKAGING AND INSULATING MATERIALS, BY EXTRUDING POLYETHYLENE MELT THROUGH T-DIE OVER A DRIVING VACUUM FORMING ROLL. FEATURE USER-FRIENDLY SYSTEM WITH AC VARIABLE SPEED DRIVES. PID TEMP. CONTROL & DIGITAL TEMP. DISPLAY. 2-LAYERS WIDTH 1000, 1200,1500, 1800, 2000,2500,3000MM CUSTOMIZED. ◆ APPLICATION OF AIR BUBBLE FILM ◆ EXCELLENT SHOCK ABSORBENCY. ◆ VERY LIGHT, TRANSPARENT BUFFER MATERIAL. ◆ HARMLESS AND RESISTANT TO ACID, ALKALI, OIL AND OTHER CHEMICALS. ◆ HIGHLY RESISTANT TO WATER AND MOISTURE. ◆ PRINTING AND LAMINATION WITH OTHER MATERIALS-IN ADDITION TO CUTTING, SLITTING, BAG-MAKING AND PUNCHING-ARE POSSIBLE. ◆ PACKAGE VOLUME REDUCTION PERMITS COST REDUCTION. ◆ EXCELLENT INSULATION EFFECTIVENESS. ◆ VARIED FROM PACKAGING OF FRAGILE ITEMS TO INSULATED COVER FOR SWIMMING POOLS. RAW MATERIAL IS LDPE : YOU CAN USE NEW MATERIAL, OR RECLAIMED MATERIALS. THE COLOR OF FILM MADE BY NEW MATERIAL IS GOOD. THE COLOR OF FILM MADE BY RECLAIMED MATERIALS IS NOT VERY TRANSPARENT, MAYBE A LITTLE GRAY. IF YOU WANT TO PRODUCE COLOR FILM. YOU CAN ADD COLOR MASTER BATCH. TECHNICAL PARAMETERS: ● PRODUCTS PRODUCED: LDPE AIR BUBBLE FILM SHEET IN ROLL ● RAW MATERIAL : LDPE AND LLDPE ● WIDTH OF THE FILM :MAX IS 1000MM ● FILM THICKNESS:0.05MM-0.15MM ● LINEAR SPEED:1000M/H ● OUTPUT:45KG/H ● TOTAL POWER:50KW ● POWER SUPPLY:380V/3PHASE,50HZ (IF THE VOLTAGE IS DIFFERENT PLEASE TELL US, AND THE PRICE MAYBE DIFFERENT) ● MACHINE WEIGHT:3T EQUIPMENT SPECIFICATIONS: 1. EXTRUDER (1) SCREW( ZHOU SHAN) DIAMETER OF SCREW:65MM L/D: 30:1 (2) SCREW AND BARREL MATERIAL: 38 CRMOAL AFTER NITROGEN TREATMENT WITH OPTIMUM HARDNESS, STRONG CORROSION RESISTANCE AND LONG SERVICE LIFETIME. (3) HOPPER SEAT: CENTRAL FEEDING (4) MAIN MOTOR: 15KW, WITH FREQUENCY INVERTER CONTROL (5) HEATING METHOD: ALUMINUM-CASTED HEATER (6) HEATING ZONE : ONE-ZONE DIGITAL TEMPERATURE CONTROL (7) GEAR BOX: HARD TOOTH GEAR BOX 2. FILTER PART: (1) LONG-LIFE NET TYPE MANUAL SCREEN CHANGING ( FAST NET CHANGER$800) (2) FILTER OUTSIDE DIA:160MM (3) FILTER INSIDE DIA: 65MM 3. T-DIE: (1) WIDTH OF T-DIE: LIKE CLOTH-HANGER, ENABLE THE MELTING MATERIAL BE FLOWED EVENLY. WITH ALUMINUM-CASTED HEATER. (2) FILM STRUCTURE: 2LAYERS( FLAT FILM+ AIR BUBBLE FILM) (3) WIDTH:1050MM (4) WIDTH ADJUSTMENT: UT-BLOCK TYPE, SINGLE SIDE IS 200MM (5) HEATING ZONE :THREE ZONE, ALUMINUM-CASTED HEATER 4. TRACTION PART: (1) AIR BUBBLE FORMING ROLLER 1PC:WIDTH 1050MM FORMING WAY: VACUUM SUBPRESSURE MOULD BUBBLE SPEC:10(DIAMETER)X4MM(HEIGHT) AND 8MM*2.5MM ----------IT ALSO CAN BE DESIGNED WITH ACCORDING TO THE CUSTOMERS. (SCOPE: 6MM—32MM) (2) COOLING WAY: WATER COOLING (3) DRIVING WAY: LP MOTOR IN SHANGHAI (4) SPEED-ADJUSTING WAY: INVERTER ADJUSTMENT (5) DRIVING POWER: 1.5KW (6) THREE TRACTION ROLLER: 1050MM 3PCS (7) EQUIPPED WITH CUTTING KNIFES AS CUSTOMER REQUEST. 5. WINDING PART: (1) WITH METER COUNTER, ALARM WARNING (2) TORQUE MOTOR (3) AUTOMATIC COLLECTION. AUTO CHANGER (4) MANUAL CUT FILM (5) WINDING MOTOR POWER:2.2KW 6.ELECTRICAL PARTS AND MOTORS:MADE IN CHINA ● ELECTRICAL PARTS:CHINT BRAND ● MAIN MOTOR:MADE IN SHANGHAI DED0NG BRAND15KW( FREQUENCY INVERTER ADJUST SPEED) ● FREQUENCY INVERTER:MADE IN SHANGHAI NS BRAND ● GEAR BOX : HARD TOOTH GEAR BOX ● ALUMINUM CASTING HEATING 7. COOLING SYSTEM: WATER RECYCLING COOLING SYSTEM. YOU CAN CHOOSE WATER TOWER OR CHILLER. SPARE PARTS AS FREE: 10 INCH WRENCH: 1 PC HEXAGEONIC WRENCH: 1 SET OIL GUN: 1 PC CROSS POINT SCREWDRIVER: 1 PC ELECTRICITY TESTING PEN: 1 PC MAIN SWITCH: 2 PCS TEMPERATURE CONTROLLER: 1 PC ELECTRIC-THERMAL COUPLE: 2 PCS TOOLS AND TOOL BOX: 1 SET SCREW HEATER: 1 PC CURRENT METER: 1 PC CJX1-22A/22V A.C CONTACTOR: 1 PC FILTER: 1 PC GLOVE: 2 PCS DZ47 1P 32A CIRCUITE BREAKER: 1 PC CUTTER: 5 PC OPERATION MANUAL: 1 PC HEAT PLATE: 1 PC

Learn More -

GPE1500 PE AIR BUBBLE FILM MAKING MACHINEDESCRIPTION OF MACHINE THIS MACHINE ADOPTS ONCE-THROUGH SHAPING TECHNIQUE, THUS IT HAS HIGH EFFICIENCY AND EXCELLENT PRODUCT QUALITY. THIS MACHINE SET HAS SUCH FEATURES AS SCIENTIFIC AND REASONABLE STRUCTURE DESIGN, SMOOTH AND RELIABLE RUNNING AND CONVENIENT OPERATION AND MAINTENANCE. AIR BUBBLE SHEET EXTRUSION LINE PRODUCES CONTINUOUS ROLL OF AIR BUBBLE SHEET, AN IDEAL CUSHIONING-PACKAGING AND INSULATING MATERIALS, BY EXTRUDING POLYETHYLENE MELT THROUGH T-DIE OVER A DRIVING VACUUM FORMING ROLL. FEATURE USER-FRIENDLY SYSTEM WITH AC VARIABLE SPEED DRIVES. PID TEMP. CONTROL & DIGITAL TEMP. DISPLAY. 2-LAYERS WIDTH 1000, 1200,1500, 1800, 2000,2500,3000MM CUSTOMIZED. ◆ APPLICATION OF AIR BUBBLE FILM ◆ EXCELLENT SHOCK ABSORBENCY. ◆ VERY LIGHT, TRANSPARENT BUFFER MATERIAL. ◆ HARMLESS AND RESISTANT TO ACID, ALKALI, OIL AND OTHER CHEMICALS. ◆ HIGHLY RESISTANT TO WATER AND MOISTURE. ◆ PRINTING AND LAMINATION WITH OTHER MATERIALS-IN ADDITION TO CUTTING, SLITTING, BAG-MAKING AND PUNCHING-ARE POSSIBLE. ◆ PACKAGE VOLUME REDUCTION PERMITS COST REDUCTION. ◆ EXCELLENT INSULATION EFFECTIVENESS. ◆ VARIED FROM PACKAGING OF FRAGILE ITEMS TO INSULATED COVER FOR SWIMMING POOLS. RAW MATERIAL IS LDPE : YOU CAN USE NEW MATERIAL, OR RECLAIMED MATERIALS. THE COLOR OF FILM MADE BY NEW MATERIAL IS GOOD. THE COLOR OF FILM MADE BY RECLAIMED MATERIALS IS NOT VERY TRANSPARENT, MAYBE A LITTLE GRAY. IF YOU WANT TO PRODUCE COLOR FILM. YOU CAN ADD COLOR MASTER BATCH. TECHNICAL PARAMETERS: ● PRODUCTS PRODUCED: LDPE AIR BUBBLE FILM SHEET IN ROLL ● RAW MATERIAL : LDPE AND LLDPE ● WIDTH OF THE FILM :MAX IS 1500MM ● FILM THICKNESS:0.05MM-0.15MM ● LINEAR SPEED:800M/H ● OUTPUT:75KG/H ● TOTAL POWER:70KW ● POWER SUPPLY:380V/3PHASE,50HZ (IF THE VOLTAGE IS DIFFERENT PLEASE TELL US, AND THE PRICE MAYBE DIFFERENT) ● MACHINE WEIGHT:3T ● NEED ONE 20’ CONTAINER: EQUIPMENT SPECIFICATIONS: 1. EXTRUDER (1) SCREW( ZHOU SHAN) DIAMETER OF SCREW:75MM L/D: 30:1 (2) SCREW AND BARREL MATERIAL: 38 CRMOAL AFTER NITROGEN TREATMENT WITH OPTIMUM HARDNESS, STRONG CORROSION RESISTANCE AND LONG SERVICE LIFETIME. (3) HOPPER SEAT: CENTRAL FEEDING (4) MAIN MOTOR: 18.5KW, WITH FREQUENCY INVERTER CONTROL (5) HEATING METHOD: ALUMINUM-CASTED HEATER (6) HEATING ZONE : FOUR-ZONE DIGITAL TEMPERATURE CONTROL (7) GEAR BOX: HARD TOOTH GEAR BOX 2. FILTER PART: (1) LONG-LIFE NET TYPE MANUAL SCREEN CHANGING ( FAST NET CHANGER$800) (2) FILTER OUTSIDE DIA:180MM (3) FILTER INSIDE DIA:75MM 3. T-DIE: (1) WIDTH OF T-DIE: LIKE CLOTH-HANGER, ENABLE THE MELTING MATERIAL BE FLOWED EVENLY. WITH ALUMINUM-CASTED HEATER. (2) FILM STRUCTURE: 2LAYERS( FLAT FILM+ AIR BUBBLE FILM) (3) WIDTH:1550MM (4) WIDTH ADJUSTMENT: OUT-BLOCK TYPE, SINGLE SIDE IS 250MM (5) HEATING ZONE :THREE ZONE, ALUMINUM-CASTED HEATER (6) HEATING POWER: 13KW 4. TRACTION PART: (1) AIR BUBBLE FORMING ROLLER 1PC:WIDTH 1550MM FORMING WAY: VACUUM SUBPRESSURE MOULD BUBBLE SPEC:10(DIAMETER)X4MM(HEIGHT),8MM*2.5MM ----------IT ALSO CAN BE DESIGNED WITH ACCORDING TO THE CUSTOMERS. (SCOPE: 6MM—32MM) (2) COOLING WAY: WATER COOLING (3) DRIVING WAY: LP MOTOR IN SHANGHAI (4) SPEED-ADJUSTING WAY: INVERTER ADJUSTMENT (5) DRIVING POWER: 3KW (6) THREE TRACTION ROLLER: 1550MM 3PCS (7) EQUIPPED WITH CUTTING KNIFES AS CUSTOMER REQUEST. 5. WINDING PART: (1) WITH METER COUNTER, ALARM WARNING (2) TORQUE MOTOR (3) AUTOMATIC COLLECTION. AUTO CHANGER (4) MANUAL CUT FILM (5) WINDING MOTOR POWER:2.2KW 6.ELECTRICAL PARTS AND MOTORS:MADE IN CHINA ● ELECTRICAL PARTS:CHINT BRAND ● MAIN MOTOR:MADE IN SHANGHAI DED0NG BRAND 18.5KW( FREQUENCY INVERTER ADJUST SPEED) ● FREQUENCY INVERTER:MADE IN SHANGHAI NS BRAND ● GEAR BOX : HARD TOOTH GEAR BOX ● ALUMINUM CASTING HEATING 7. COOLING SYSTEM: WATER RECYCLING COOLING SYSTEM. YOU CAN CHOOSE WATER TOWER OR CHILLER SPARE PARTS AS FREE: 10 INCH WRENCH: 1 PC HEXAGEONIC WRENCH: 1 SET OIL GUN: 1 PC CROSS POINT SCREWDRIVER: 1 PC ELECTRICITY TESTING PEN: 1 PC MAIN SWITCH: 2 PCS TEMPERATURE CONTROLLER: 1 PC ELECTRIC-THERMAL COUPLE: 2 PCS TOOLS AND TOOL BOX: 1 SET SCREW HEATER: 1 PC CURRENT METER: 1 PC CJX1-22A/22V A.C CONTACTOR: 1 PC FILTER: 1 PC GLOVE: 2 PCS DZ47 1P 32A CIRCUITE BREAKER: 1 PC CUTTER: 5 PC OPERATION MANUAL: 1 PC HEAT PLATE: 1 PC Learn More

GPE1500 PE AIR BUBBLE FILM MAKING MACHINEDESCRIPTION OF MACHINE THIS MACHINE ADOPTS ONCE-THROUGH SHAPING TECHNIQUE, THUS IT HAS HIGH EFFICIENCY AND EXCELLENT PRODUCT QUALITY. THIS MACHINE SET HAS SUCH FEATURES AS SCIENTIFIC AND REASONABLE STRUCTURE DESIGN, SMOOTH AND RELIABLE RUNNING AND CONVENIENT OPERATION AND MAINTENANCE. AIR BUBBLE SHEET EXTRUSION LINE PRODUCES CONTINUOUS ROLL OF AIR BUBBLE SHEET, AN IDEAL CUSHIONING-PACKAGING AND INSULATING MATERIALS, BY EXTRUDING POLYETHYLENE MELT THROUGH T-DIE OVER A DRIVING VACUUM FORMING ROLL. FEATURE USER-FRIENDLY SYSTEM WITH AC VARIABLE SPEED DRIVES. PID TEMP. CONTROL & DIGITAL TEMP. DISPLAY. 2-LAYERS WIDTH 1000, 1200,1500, 1800, 2000,2500,3000MM CUSTOMIZED. ◆ APPLICATION OF AIR BUBBLE FILM ◆ EXCELLENT SHOCK ABSORBENCY. ◆ VERY LIGHT, TRANSPARENT BUFFER MATERIAL. ◆ HARMLESS AND RESISTANT TO ACID, ALKALI, OIL AND OTHER CHEMICALS. ◆ HIGHLY RESISTANT TO WATER AND MOISTURE. ◆ PRINTING AND LAMINATION WITH OTHER MATERIALS-IN ADDITION TO CUTTING, SLITTING, BAG-MAKING AND PUNCHING-ARE POSSIBLE. ◆ PACKAGE VOLUME REDUCTION PERMITS COST REDUCTION. ◆ EXCELLENT INSULATION EFFECTIVENESS. ◆ VARIED FROM PACKAGING OF FRAGILE ITEMS TO INSULATED COVER FOR SWIMMING POOLS. RAW MATERIAL IS LDPE : YOU CAN USE NEW MATERIAL, OR RECLAIMED MATERIALS. THE COLOR OF FILM MADE BY NEW MATERIAL IS GOOD. THE COLOR OF FILM MADE BY RECLAIMED MATERIALS IS NOT VERY TRANSPARENT, MAYBE A LITTLE GRAY. IF YOU WANT TO PRODUCE COLOR FILM. YOU CAN ADD COLOR MASTER BATCH. TECHNICAL PARAMETERS: ● PRODUCTS PRODUCED: LDPE AIR BUBBLE FILM SHEET IN ROLL ● RAW MATERIAL : LDPE AND LLDPE ● WIDTH OF THE FILM :MAX IS 1500MM ● FILM THICKNESS:0.05MM-0.15MM ● LINEAR SPEED:800M/H ● OUTPUT:75KG/H ● TOTAL POWER:70KW ● POWER SUPPLY:380V/3PHASE,50HZ (IF THE VOLTAGE IS DIFFERENT PLEASE TELL US, AND THE PRICE MAYBE DIFFERENT) ● MACHINE WEIGHT:3T ● NEED ONE 20’ CONTAINER: EQUIPMENT SPECIFICATIONS: 1. EXTRUDER (1) SCREW( ZHOU SHAN) DIAMETER OF SCREW:75MM L/D: 30:1 (2) SCREW AND BARREL MATERIAL: 38 CRMOAL AFTER NITROGEN TREATMENT WITH OPTIMUM HARDNESS, STRONG CORROSION RESISTANCE AND LONG SERVICE LIFETIME. (3) HOPPER SEAT: CENTRAL FEEDING (4) MAIN MOTOR: 18.5KW, WITH FREQUENCY INVERTER CONTROL (5) HEATING METHOD: ALUMINUM-CASTED HEATER (6) HEATING ZONE : FOUR-ZONE DIGITAL TEMPERATURE CONTROL (7) GEAR BOX: HARD TOOTH GEAR BOX 2. FILTER PART: (1) LONG-LIFE NET TYPE MANUAL SCREEN CHANGING ( FAST NET CHANGER$800) (2) FILTER OUTSIDE DIA:180MM (3) FILTER INSIDE DIA:75MM 3. T-DIE: (1) WIDTH OF T-DIE: LIKE CLOTH-HANGER, ENABLE THE MELTING MATERIAL BE FLOWED EVENLY. WITH ALUMINUM-CASTED HEATER. (2) FILM STRUCTURE: 2LAYERS( FLAT FILM+ AIR BUBBLE FILM) (3) WIDTH:1550MM (4) WIDTH ADJUSTMENT: OUT-BLOCK TYPE, SINGLE SIDE IS 250MM (5) HEATING ZONE :THREE ZONE, ALUMINUM-CASTED HEATER (6) HEATING POWER: 13KW 4. TRACTION PART: (1) AIR BUBBLE FORMING ROLLER 1PC:WIDTH 1550MM FORMING WAY: VACUUM SUBPRESSURE MOULD BUBBLE SPEC:10(DIAMETER)X4MM(HEIGHT),8MM*2.5MM ----------IT ALSO CAN BE DESIGNED WITH ACCORDING TO THE CUSTOMERS. (SCOPE: 6MM—32MM) (2) COOLING WAY: WATER COOLING (3) DRIVING WAY: LP MOTOR IN SHANGHAI (4) SPEED-ADJUSTING WAY: INVERTER ADJUSTMENT (5) DRIVING POWER: 3KW (6) THREE TRACTION ROLLER: 1550MM 3PCS (7) EQUIPPED WITH CUTTING KNIFES AS CUSTOMER REQUEST. 5. WINDING PART: (1) WITH METER COUNTER, ALARM WARNING (2) TORQUE MOTOR (3) AUTOMATIC COLLECTION. AUTO CHANGER (4) MANUAL CUT FILM (5) WINDING MOTOR POWER:2.2KW 6.ELECTRICAL PARTS AND MOTORS:MADE IN CHINA ● ELECTRICAL PARTS:CHINT BRAND ● MAIN MOTOR:MADE IN SHANGHAI DED0NG BRAND 18.5KW( FREQUENCY INVERTER ADJUST SPEED) ● FREQUENCY INVERTER:MADE IN SHANGHAI NS BRAND ● GEAR BOX : HARD TOOTH GEAR BOX ● ALUMINUM CASTING HEATING 7. COOLING SYSTEM: WATER RECYCLING COOLING SYSTEM. YOU CAN CHOOSE WATER TOWER OR CHILLER SPARE PARTS AS FREE: 10 INCH WRENCH: 1 PC HEXAGEONIC WRENCH: 1 SET OIL GUN: 1 PC CROSS POINT SCREWDRIVER: 1 PC ELECTRICITY TESTING PEN: 1 PC MAIN SWITCH: 2 PCS TEMPERATURE CONTROLLER: 1 PC ELECTRIC-THERMAL COUPLE: 2 PCS TOOLS AND TOOL BOX: 1 SET SCREW HEATER: 1 PC CURRENT METER: 1 PC CJX1-22A/22V A.C CONTACTOR: 1 PC FILTER: 1 PC GLOVE: 2 PCS DZ47 1P 32A CIRCUITE BREAKER: 1 PC CUTTER: 5 PC OPERATION MANUAL: 1 PC HEAT PLATE: 1 PC Learn More -

PE1800 AIR BUBBLE FILM MAKING MACHINEDESCRIPTION OF MACHINE THIS MACHINE INCLUDES ONCE-THROUGH SHAPING TECHNIQUE, THUS IT HAS HIGH EFFICIENCY AND EXCELLENT PRODUCT QUALITY. AIR BUBBLE SHEET EXTRUSION LINE PRODUCES CONTINUOUS ROLL OF AIR BUBBLE SHEET, AN IDEAL CUSHIONING-PACKAGING AND INSULATING MATERIALS, BY EXTRUDING POLYETHYLENE MELT THROUGH T-DIE OVER A DRIVEN VACUUM FORMING ROLL. FEATURES USER-FRIENDLY SYSTEM WITH AC VARIABLE SPEED DRIVES. PID TEMP. CONTROL & DIGITAL TEMP. DISPLAY. 2-LAYERS WIDTH 1000, 1200,1500, 1800, 2000,2500,3000MM AND CUSTOMIZE WIDTHS. APPLICATIONS OF AIR BUBBLE FILMS: ◆ EXCELLENT SHOCK ABSORBENCY. ◆ VERY LIGHT, TRANSPARENT BUFFER MATERIAL. ◆ HARMLESS AND RESISTANT TO ACID, ALKALI, OIL AND OTHER CHEMICALS. ◆ HIGHLY RESISTANT TO WATER AND MOISTURE. ◆ PRINTING AND LAMINATION WITH OTHER MATERIALS-IN ADDITION TO CUTTING, SLITTING, BAG-MAKING AND PUNCHING-ARE POSSIBLE. ◆ PACKAGE VOLUME REDUCTION PERMITS COST REDUCTION. ◆ EXCELLENT INSULATION EFFECTIVENESS. ◆ VARIED FROM PACKAGING OF FRAGILE ITEMS TO INSULATED COVER FOR SWIMMING POOLS. RAW MATERIAL IS LDPE : YOU CAN USE VIRGIN POZYMER, OR RECLAIMED POLYMERS. CAN BE COLORED FILM WITH NEW POLYMER ( BY RECLAIMED MATERIALS IS NOT VERY TRANSPARENT, MAYBE A LITTLE GRAY. IF YOU WANT TO PRODUCE COLOR FILM. YOU CAN ADD COLOR MASTER BATCH. TECHNICAL PARAMETERS: PRODUCTS PRODUCED: LDPE AIR BUBBLE FILM SHEET IN ROLL RAW MATERIAL : LDPE AND LLDPE WIDTH OF THE FILM :MAX IS 1800MM FILM THICKNESS:0.05MM-0.15MM LINEAR SPEED:800M/H OUTPUT:90KG/H TOTAL POWER:86KW POWER SUPPLY:380V/3PHASE,50HZ (IF THE VOLTAGE IS DIFFERENT PLEASE TELL US, AND THE PRICE MAYBE DIFFERENT) MACHINE WEIGHT:3.5T NEED ONE 40’ CONTAINER EQUIPMENT SPECIFICATIONS: 1. EXTRUDER (1) SCREW( ZHOU SHAN) DIAMETER OF SCREW:90MM L/D: 30:1 (2) SCREW AND BARREL MATERIAL: 38 CRMOAL AFTER NITROGEN TREATMENT WITH OPTIMUM HARDNESS, STRONG CORROSION RESISTANCE AND LONG SERVICE LIFE TIME. (3) HOPPER: CENTRAL FEEDING (4) MAIN MOTOR: 30KW, WITH FREQUENCY INVERTER CONTROL (5) HEATING METHOD: ALUMINUM-CASTED HEATER (6) HEATING ZONE : FOUR-ZONE DIGITAL TEMPERATURE CONTROL (7) GEAR BOX: HARD TOOTH GEAR BOX 2. FILTER PART: (1) LONG-LIFE NET TYPE MANUAL SCREEN CHANGING ( FAST NET CHANGER$800) (2) FILTER OUTSIDE DIA:200MM (3) FILTER INSIDE DIA:105MM 3. T-DIE: (1) WIDTH OF T-DIE: LIKE CLOTH-HANGER, ENABLE THE MELTING MATERIAL BE FLOWED EVENLY. WITH ALUMINUM-CASTED HEATER. (2) FILM STRUCTURE: 2LAYERS( FLAT FILM+ AIR BUBBLE FILM) (3) WIDTH:1880MM (4) WIDTH ADJUSTMENT: OUT-BLOCK TYPE, SINGLE SIDE IS 250MM (5) HEATING ZONE :FOUR ZONE, ALUMINUM-CASTED HEATER (6) HEATING POWER: 25KW 4. TRACTION PART: (1) AIR BUBBLE FORMING ROLLER 1PC:WIDTH 1880MM FORMING WAY: VACUUM SUBPRESSURE MOULD BUBBLE SPEC:10(DIAMETER)X4MM(HEIGHT),8MM*2.5MM ----------IT ALSO CAN BE DESIGNED WITH ACCORDING TO THE CUSTOMERS. (SCOPE: 6MM—32MM) (2) COOLING WAY: WATER COOLING (3) DRIVING WAY: LP MOTOR IN SHANGHAI (4) SPEED-ADJUSTING WAY: INVERTER ADJUSTMENT (5) DRIVING POWER: 2.2KW (6) THREE TRACTION FLAT ROLLER: Ф47MM 3PCS (7) EQUIPPED WITH CUTTING KNIFES AS CUSTOMER REQUEST. 5. WINDING PART: (1) WITH METER COUNTER, ALARM WARNING (2) TORQUE MOTOR (3) AUTOMATIC COLLECTION. AUTO CHANGER (4) MANUAL CUT FILM (5) WINDING MOTOR POWER:16NM 6.ELECTRICAL PARTS AND MOTORS:MADE IN CHINA ● ELECTRICAL PARTS:CHINA BRAND ● MAIN MOTOR:MADE IN SHANGHAI DED0NG BRAND 30KW( FREQUENCY INVERTER ADJUST SPEED) ● FREQUENCY INVERTER:MADE IN SHANGHAI PARNIER BRAND ● GEAR BOX : HARD TOOTH GEAR BOX ● ALUMINUM CASTING HEATING 7. COOLING SYSTEM: WATER RECYCLING COOLING SYSTEM. YOU CAN CHOOSE WATER TOWER OR CHILLER SPARE PARTS AS INCLUDED: 10 INCH WRENCH: 1 PC HEXAGEONIC WRENCH: 1 SET OIL GUN: 1 PC CROSS POINT SCREWDRIVER: 1 PC ELECTRICITY TESTING PEN: 1 PC MAIN SWITCH: 2 PCS TEMPERATURE CONTROLLER: 1 PC ELECTRIC-THERMAL COUPLE: 2 PCS TOOLS AND TOOL BOX: 1 SET SCREW HEATER: 1 PC CURRENT METER: 1 PC CJX1-22A/22V A.C CONTACTOR: 1 PC FILTER: 1 PC GLOVE: 2 PCS DZ47 1P 32A CIRCUITE BREAKER: 1 PC CUTTER: 5 PC OPERATION MANUAL: 1 PC HEAT PLATE: 1 PC Learn More

PE1800 AIR BUBBLE FILM MAKING MACHINEDESCRIPTION OF MACHINE THIS MACHINE INCLUDES ONCE-THROUGH SHAPING TECHNIQUE, THUS IT HAS HIGH EFFICIENCY AND EXCELLENT PRODUCT QUALITY. AIR BUBBLE SHEET EXTRUSION LINE PRODUCES CONTINUOUS ROLL OF AIR BUBBLE SHEET, AN IDEAL CUSHIONING-PACKAGING AND INSULATING MATERIALS, BY EXTRUDING POLYETHYLENE MELT THROUGH T-DIE OVER A DRIVEN VACUUM FORMING ROLL. FEATURES USER-FRIENDLY SYSTEM WITH AC VARIABLE SPEED DRIVES. PID TEMP. CONTROL & DIGITAL TEMP. DISPLAY. 2-LAYERS WIDTH 1000, 1200,1500, 1800, 2000,2500,3000MM AND CUSTOMIZE WIDTHS. APPLICATIONS OF AIR BUBBLE FILMS: ◆ EXCELLENT SHOCK ABSORBENCY. ◆ VERY LIGHT, TRANSPARENT BUFFER MATERIAL. ◆ HARMLESS AND RESISTANT TO ACID, ALKALI, OIL AND OTHER CHEMICALS. ◆ HIGHLY RESISTANT TO WATER AND MOISTURE. ◆ PRINTING AND LAMINATION WITH OTHER MATERIALS-IN ADDITION TO CUTTING, SLITTING, BAG-MAKING AND PUNCHING-ARE POSSIBLE. ◆ PACKAGE VOLUME REDUCTION PERMITS COST REDUCTION. ◆ EXCELLENT INSULATION EFFECTIVENESS. ◆ VARIED FROM PACKAGING OF FRAGILE ITEMS TO INSULATED COVER FOR SWIMMING POOLS. RAW MATERIAL IS LDPE : YOU CAN USE VIRGIN POZYMER, OR RECLAIMED POLYMERS. CAN BE COLORED FILM WITH NEW POLYMER ( BY RECLAIMED MATERIALS IS NOT VERY TRANSPARENT, MAYBE A LITTLE GRAY. IF YOU WANT TO PRODUCE COLOR FILM. YOU CAN ADD COLOR MASTER BATCH. TECHNICAL PARAMETERS: PRODUCTS PRODUCED: LDPE AIR BUBBLE FILM SHEET IN ROLL RAW MATERIAL : LDPE AND LLDPE WIDTH OF THE FILM :MAX IS 1800MM FILM THICKNESS:0.05MM-0.15MM LINEAR SPEED:800M/H OUTPUT:90KG/H TOTAL POWER:86KW POWER SUPPLY:380V/3PHASE,50HZ (IF THE VOLTAGE IS DIFFERENT PLEASE TELL US, AND THE PRICE MAYBE DIFFERENT) MACHINE WEIGHT:3.5T NEED ONE 40’ CONTAINER EQUIPMENT SPECIFICATIONS: 1. EXTRUDER (1) SCREW( ZHOU SHAN) DIAMETER OF SCREW:90MM L/D: 30:1 (2) SCREW AND BARREL MATERIAL: 38 CRMOAL AFTER NITROGEN TREATMENT WITH OPTIMUM HARDNESS, STRONG CORROSION RESISTANCE AND LONG SERVICE LIFE TIME. (3) HOPPER: CENTRAL FEEDING (4) MAIN MOTOR: 30KW, WITH FREQUENCY INVERTER CONTROL (5) HEATING METHOD: ALUMINUM-CASTED HEATER (6) HEATING ZONE : FOUR-ZONE DIGITAL TEMPERATURE CONTROL (7) GEAR BOX: HARD TOOTH GEAR BOX 2. FILTER PART: (1) LONG-LIFE NET TYPE MANUAL SCREEN CHANGING ( FAST NET CHANGER$800) (2) FILTER OUTSIDE DIA:200MM (3) FILTER INSIDE DIA:105MM 3. T-DIE: (1) WIDTH OF T-DIE: LIKE CLOTH-HANGER, ENABLE THE MELTING MATERIAL BE FLOWED EVENLY. WITH ALUMINUM-CASTED HEATER. (2) FILM STRUCTURE: 2LAYERS( FLAT FILM+ AIR BUBBLE FILM) (3) WIDTH:1880MM (4) WIDTH ADJUSTMENT: OUT-BLOCK TYPE, SINGLE SIDE IS 250MM (5) HEATING ZONE :FOUR ZONE, ALUMINUM-CASTED HEATER (6) HEATING POWER: 25KW 4. TRACTION PART: (1) AIR BUBBLE FORMING ROLLER 1PC:WIDTH 1880MM FORMING WAY: VACUUM SUBPRESSURE MOULD BUBBLE SPEC:10(DIAMETER)X4MM(HEIGHT),8MM*2.5MM ----------IT ALSO CAN BE DESIGNED WITH ACCORDING TO THE CUSTOMERS. (SCOPE: 6MM—32MM) (2) COOLING WAY: WATER COOLING (3) DRIVING WAY: LP MOTOR IN SHANGHAI (4) SPEED-ADJUSTING WAY: INVERTER ADJUSTMENT (5) DRIVING POWER: 2.2KW (6) THREE TRACTION FLAT ROLLER: Ф47MM 3PCS (7) EQUIPPED WITH CUTTING KNIFES AS CUSTOMER REQUEST. 5. WINDING PART: (1) WITH METER COUNTER, ALARM WARNING (2) TORQUE MOTOR (3) AUTOMATIC COLLECTION. AUTO CHANGER (4) MANUAL CUT FILM (5) WINDING MOTOR POWER:16NM 6.ELECTRICAL PARTS AND MOTORS:MADE IN CHINA ● ELECTRICAL PARTS:CHINA BRAND ● MAIN MOTOR:MADE IN SHANGHAI DED0NG BRAND 30KW( FREQUENCY INVERTER ADJUST SPEED) ● FREQUENCY INVERTER:MADE IN SHANGHAI PARNIER BRAND ● GEAR BOX : HARD TOOTH GEAR BOX ● ALUMINUM CASTING HEATING 7. COOLING SYSTEM: WATER RECYCLING COOLING SYSTEM. YOU CAN CHOOSE WATER TOWER OR CHILLER SPARE PARTS AS INCLUDED: 10 INCH WRENCH: 1 PC HEXAGEONIC WRENCH: 1 SET OIL GUN: 1 PC CROSS POINT SCREWDRIVER: 1 PC ELECTRICITY TESTING PEN: 1 PC MAIN SWITCH: 2 PCS TEMPERATURE CONTROLLER: 1 PC ELECTRIC-THERMAL COUPLE: 2 PCS TOOLS AND TOOL BOX: 1 SET SCREW HEATER: 1 PC CURRENT METER: 1 PC CJX1-22A/22V A.C CONTACTOR: 1 PC FILTER: 1 PC GLOVE: 2 PCS DZ47 1P 32A CIRCUITE BREAKER: 1 PC CUTTER: 5 PC OPERATION MANUAL: 1 PC HEAT PLATE: 1 PC Learn More -

BABY DIAPER SEWING SYSTEM YEAR 1998TOTAL AUTOMATIC FOR PRE-FOLDED BABY DIAPERS PRE-FOLDED BABY DIAPERS AT RATES OF UP TO 35 PIECES PER MINUTE FEEDS FROM A HEAVY-DUTY CRADLE INFEED CAPABLE OF ROLL DIAMETERS OF 48” AND WEIGHTS OF 1,000LBS. BASIC SINGLE-STAGE FOLDERS CAN PRODUCE DIAPERS IN THE 2-3-2 STYLE, WITH AND WITHOUT SOAKER INSERTION THE OPTIONAL DUAL-STAGE FOLDERS CAN PRODUCE 2-3-2, 2-4-2, AND 2-5-2 STYLES, WITH AND WITHOUT SOAKER INSERTION THE FOLDER KITS ARE DELIVERED FOR TWO WIDTHS AS PER CUSTOMER SPECIFICATIONS ADDITIONAL FOLDERS CAN BE ADDED AN OPTIONAL PRINTER ATTACHMENT IS AVAILABLE FOR PRINTING A COMPANY LOGO OR TRADEMARK ON THE DIAPERS A STACKER IS ALSO AVAILABLE FOR STACKING THE FINISHED DIAPERS INTO BATCHES. THE BATCH SIZE CAN BE SELECTED ON A COUNTER SS-1BD SEWING SYSTEM THE SS-1BD SEWING SYSTEM DETAILED BELOW HAS BEEN DESIGNED ESPECIALLY FOR THE PRODUCTION OF FOLDED BABY DIAPERS WITH DOUBLE-STAGE FOLD. THE SYSTEM IS ALSO CAPABLE OF USING A STANDARD FELT-TYPE INSERT. THE STANDARD FEATURES ARE: POWERED INFEED CRADLE FOR ONE ROLL OF FABRIC WITH A MAXIMUM WIDTH OF 48”, DIAMETER OF 36”, AND WEIGHT OF 750LB (MASTER ROLL), AND ONE ROLL WITH MAXIMUM WIDTH OF 6”, DIAMETER OF 36”, AND WEIGHT OF 30LB. (SOAKER ROLL). COMPLETE WITH EDGE GUIDE LENGTH FOLDER TO CREATE OVERLAPPING, CONTINUOUS FOLD WITH POSSIBILITY OF INSERTING SOAKER. CAN BE ENTIRELY BYPASSED WHEN FOLDING IS NOT REQUIRED. FIRST SEWING STATION WITH TWO RIGHT HAND CHAIN STITCH SEWING HEADS (TYPE 401) TO SEW THE FOLD IN PLACE. DUAL STAGE PULL ROLLS FEED FROM ITEM 2 INTO A DANCER-BAR ACCUMULATOR MEASURING AND CUTOFF STATION (TRAVERSING ROTARY KNIFE) CUTS DIAPER TO LENGTH WITH +/- 1/8” REPEATABILITY. OUTFEED CONVEYOR WITH RIGHT-ANGLE TRANSFER STATION FOR TRANSFER OF CUT PIECES INTO SECOND SEWING SATION. SECOND SEWING STATION WITH LEFT AND RIGHT HAND SERGERS (TYPE 514) AND UPPER AND LOWER CONVEYOR BELTS TO CARRY THE DIAPER BETWEEN THE SERGERS. LEFT AND RIGHT HAND MECHANICAL CHAIN CUTTERS TO CUT THE THREAD CHAIN BETWEEN DIAPERS ELECTRONIC THREAD MOTION DETECTORS ON ALL SEWING HEADS. FOR SHIPPING: REQUIRES ONE CONTAINER -40 FEET TOTAL WEIGHT- 4,525 KGS Learn More

BABY DIAPER SEWING SYSTEM YEAR 1998TOTAL AUTOMATIC FOR PRE-FOLDED BABY DIAPERS PRE-FOLDED BABY DIAPERS AT RATES OF UP TO 35 PIECES PER MINUTE FEEDS FROM A HEAVY-DUTY CRADLE INFEED CAPABLE OF ROLL DIAMETERS OF 48” AND WEIGHTS OF 1,000LBS. BASIC SINGLE-STAGE FOLDERS CAN PRODUCE DIAPERS IN THE 2-3-2 STYLE, WITH AND WITHOUT SOAKER INSERTION THE OPTIONAL DUAL-STAGE FOLDERS CAN PRODUCE 2-3-2, 2-4-2, AND 2-5-2 STYLES, WITH AND WITHOUT SOAKER INSERTION THE FOLDER KITS ARE DELIVERED FOR TWO WIDTHS AS PER CUSTOMER SPECIFICATIONS ADDITIONAL FOLDERS CAN BE ADDED AN OPTIONAL PRINTER ATTACHMENT IS AVAILABLE FOR PRINTING A COMPANY LOGO OR TRADEMARK ON THE DIAPERS A STACKER IS ALSO AVAILABLE FOR STACKING THE FINISHED DIAPERS INTO BATCHES. THE BATCH SIZE CAN BE SELECTED ON A COUNTER SS-1BD SEWING SYSTEM THE SS-1BD SEWING SYSTEM DETAILED BELOW HAS BEEN DESIGNED ESPECIALLY FOR THE PRODUCTION OF FOLDED BABY DIAPERS WITH DOUBLE-STAGE FOLD. THE SYSTEM IS ALSO CAPABLE OF USING A STANDARD FELT-TYPE INSERT. THE STANDARD FEATURES ARE: POWERED INFEED CRADLE FOR ONE ROLL OF FABRIC WITH A MAXIMUM WIDTH OF 48”, DIAMETER OF 36”, AND WEIGHT OF 750LB (MASTER ROLL), AND ONE ROLL WITH MAXIMUM WIDTH OF 6”, DIAMETER OF 36”, AND WEIGHT OF 30LB. (SOAKER ROLL). COMPLETE WITH EDGE GUIDE LENGTH FOLDER TO CREATE OVERLAPPING, CONTINUOUS FOLD WITH POSSIBILITY OF INSERTING SOAKER. CAN BE ENTIRELY BYPASSED WHEN FOLDING IS NOT REQUIRED. FIRST SEWING STATION WITH TWO RIGHT HAND CHAIN STITCH SEWING HEADS (TYPE 401) TO SEW THE FOLD IN PLACE. DUAL STAGE PULL ROLLS FEED FROM ITEM 2 INTO A DANCER-BAR ACCUMULATOR MEASURING AND CUTOFF STATION (TRAVERSING ROTARY KNIFE) CUTS DIAPER TO LENGTH WITH +/- 1/8” REPEATABILITY. OUTFEED CONVEYOR WITH RIGHT-ANGLE TRANSFER STATION FOR TRANSFER OF CUT PIECES INTO SECOND SEWING SATION. SECOND SEWING STATION WITH LEFT AND RIGHT HAND SERGERS (TYPE 514) AND UPPER AND LOWER CONVEYOR BELTS TO CARRY THE DIAPER BETWEEN THE SERGERS. LEFT AND RIGHT HAND MECHANICAL CHAIN CUTTERS TO CUT THE THREAD CHAIN BETWEEN DIAPERS ELECTRONIC THREAD MOTION DETECTORS ON ALL SEWING HEADS. FOR SHIPPING: REQUIRES ONE CONTAINER -40 FEET TOTAL WEIGHT- 4,525 KGS Learn More -

TT-8347 THEEGARTEN H1 CUT AND WRAP MACHINE, UP TO 1000 PIECES PER MINTT-8347 THEEGARTEN H1 CUT AND WRAP MACHINE, UP TO 1000 PIECES PER MIN 1. BRAND: THEEGARTEN 2. MODEL: H1 3. CONDITION: USED QUANTITY: 1 Learn More

TT-8347 THEEGARTEN H1 CUT AND WRAP MACHINE, UP TO 1000 PIECES PER MINTT-8347 THEEGARTEN H1 CUT AND WRAP MACHINE, UP TO 1000 PIECES PER MIN 1. BRAND: THEEGARTEN 2. MODEL: H1 3. CONDITION: USED QUANTITY: 1 Learn More