Search results for: 'lamina'

- Related search terms

- Lamination

- Laminating m

- Lamination machine

- laminators

- Laminato

-

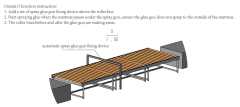

YY-1485-D MATTRESS CONVEYOR LINE WITH SPRAY BRIDGE FOR LAMINATING OR APPLYING GLUEYY-1485-D MATTRESS CONVEYOR LINE WITH SPRAY BRIDGE FOR LAMINATING OR APPLYING GLUE QUANTITY: 1 Learn More

YY-1485-D MATTRESS CONVEYOR LINE WITH SPRAY BRIDGE FOR LAMINATING OR APPLYING GLUEYY-1485-D MATTRESS CONVEYOR LINE WITH SPRAY BRIDGE FOR LAMINATING OR APPLYING GLUE QUANTITY: 1 Learn More -

J-3785 GRIBETZ STRATA LAMINATOR, YEAR 2016, WORKING WIDTH 1400 TO 2200mmJ-3785 GRIBETZ STRATA LAMINATOR, YEAR 2016, WORKING WIDTH 1400 TO 2200mm 3 POSITION CREEL FOR: SCRIM GLUE FABRICS AREA 4000 x 3000mm QUANTITY: 1 Learn More

J-3785 GRIBETZ STRATA LAMINATOR, YEAR 2016, WORKING WIDTH 1400 TO 2200mmJ-3785 GRIBETZ STRATA LAMINATOR, YEAR 2016, WORKING WIDTH 1400 TO 2200mm 3 POSITION CREEL FOR: SCRIM GLUE FABRICS AREA 4000 x 3000mm QUANTITY: 1 Learn More -

YY-1293 FLAME LAMINATING MACHINE, WORKING WIDTH 2200mmYY-1293 FLAME LAMINATING MACHINE, WORKING WIDTH 2200mm ROLL WIDTH: 2400mm ELECTRIC POWER: 220/380V, 50/60Hz (OPTION) QUANTITY: 1 Learn More

YY-1293 FLAME LAMINATING MACHINE, WORKING WIDTH 2200mmYY-1293 FLAME LAMINATING MACHINE, WORKING WIDTH 2200mm ROLL WIDTH: 2400mm ELECTRIC POWER: 220/380V, 50/60Hz (OPTION) QUANTITY: 1 Learn More -

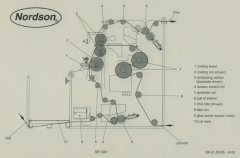

J-2342 NORDSON HOTMELT LAMINATOR/COATING STAND WITH MELTERSJ-2342 NORDSON HOTMELT LAMINATOR/COATING STAND WITH MELTERS STATUS: DISMANTLED QUANTITY: 1 Learn More

J-2342 NORDSON HOTMELT LAMINATOR/COATING STAND WITH MELTERSJ-2342 NORDSON HOTMELT LAMINATOR/COATING STAND WITH MELTERS STATUS: DISMANTLED QUANTITY: 1 Learn More -

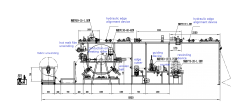

J-3175 HOT MELT FILM LAMINATING MACHINE FOR PLAIN WOVEN FABRICJ-3175 HOT MELT FILM LAMINATING MACHINE FOR PLAIN WOVEN FABRIC MACHINE SPEED: 20 TO 40 METERS PER MINUTE ESTIMATED MACHINE DIMENSIONS: 8850mm x 2450mm x 2200mm (L*W*H) ESTIMATED MACHINE WEIGHT: 6000 KG MOTOR BRAND: SIEMENS ELECTRIC BRAND: SCHNEIDER QUANTITY: 1 Learn More

J-3175 HOT MELT FILM LAMINATING MACHINE FOR PLAIN WOVEN FABRICJ-3175 HOT MELT FILM LAMINATING MACHINE FOR PLAIN WOVEN FABRIC MACHINE SPEED: 20 TO 40 METERS PER MINUTE ESTIMATED MACHINE DIMENSIONS: 8850mm x 2450mm x 2200mm (L*W*H) ESTIMATED MACHINE WEIGHT: 6000 KG MOTOR BRAND: SIEMENS ELECTRIC BRAND: SCHNEIDER QUANTITY: 1 Learn More -

J-3163 PUR HOT MELT GLUE LAMINATING MACHINE, WORKING WIDTH 2200mmJ-3163 PUR HOT MELT GLUE LAMINATING MACHINE, WORKING WIDTH 2200mm WORKING WIDTH: 2200mm ROLLER WIDTH: 2400mm LAMINATES FABRIC TO FABRIC AND FABRIC TO FILM GLUE TYPE: HOT MELT PUR GLUE WORKING SPEED: 0 TO 40M/MIN HEATING METHOD: ELECTRICITY, THERMAL OIL INSTALLED CAPACITY: ABOUT 80KVA COMPRESSED AIR: 4-8BAR HEATED PIPE LENGTH: 5M MAIN CONFIGURATION PART ONE BASE FABRIC UNWINDING DEVICE UNWINDING RACK - 4 SET φ74 PNEUMATIC SHAFT - 4 PC DAMPING DEVICE - 4 SET UNWINDING UNIT - 4 EA EPC POSITION ADJUST DEVICE - 1 SET φ75 ALUMINUM ALLOY ROLLER - 5 PC MACHINE RACK - 1 SET FOOTBOARD - 1 EA Learn More

J-3163 PUR HOT MELT GLUE LAMINATING MACHINE, WORKING WIDTH 2200mmJ-3163 PUR HOT MELT GLUE LAMINATING MACHINE, WORKING WIDTH 2200mm WORKING WIDTH: 2200mm ROLLER WIDTH: 2400mm LAMINATES FABRIC TO FABRIC AND FABRIC TO FILM GLUE TYPE: HOT MELT PUR GLUE WORKING SPEED: 0 TO 40M/MIN HEATING METHOD: ELECTRICITY, THERMAL OIL INSTALLED CAPACITY: ABOUT 80KVA COMPRESSED AIR: 4-8BAR HEATED PIPE LENGTH: 5M MAIN CONFIGURATION PART ONE BASE FABRIC UNWINDING DEVICE UNWINDING RACK - 4 SET φ74 PNEUMATIC SHAFT - 4 PC DAMPING DEVICE - 4 SET UNWINDING UNIT - 4 EA EPC POSITION ADJUST DEVICE - 1 SET φ75 ALUMINUM ALLOY ROLLER - 5 PC MACHINE RACK - 1 SET FOOTBOARD - 1 EA Learn More -

YY-1126 EASY MELT LAMINATING MACHINEYY-1126 EASY MELT LAMINATING MACHINE DETAILS: -TYPE EASY -YEAR 2013 -ROTOGRAVURE SYSTEM FOR COATING -3 ROLLERS ON THE MACHINE (ONE WORKING, TWO IN STAND-BY MODE) -INLET FROM ROLL -OUTLET WITH ROLL -CONTROL PANEL -NORDSON MELTING UNIT FOR PUR, YEAR 2015 Learn More

YY-1126 EASY MELT LAMINATING MACHINEYY-1126 EASY MELT LAMINATING MACHINE DETAILS: -TYPE EASY -YEAR 2013 -ROTOGRAVURE SYSTEM FOR COATING -3 ROLLERS ON THE MACHINE (ONE WORKING, TWO IN STAND-BY MODE) -INLET FROM ROLL -OUTLET WITH ROLL -CONTROL PANEL -NORDSON MELTING UNIT FOR PUR, YEAR 2015 Learn More -

J-1937 LAMINATING MACHINE FOR FOAM TO FABRIC – CONTINUOUS WITH SLITTING, NEW

J-1937 LAMINATING MACHINE FOR FOAM TO FABRIC – CONTINUOUS WITH SLITTING, NEWSILICON COATED NOMEX FELT (ITB BRAND – ITALIAN)

BLANKET THICKNESS: 8mm

PNEUMATICALLY ADJUSTABLE FELT PRESSURE

MAXIMUM WORKING WIDTH: 2100mm (82.6”)

EVA HOT MELT FILM, FILM ROLL MIMIMUM 500 METERS, MAXIMUM 1000 METERS

36 KW HEATER RESISTANCE

MAIN DRUM DIAMETER: 500mm

TEFLON COATED MAIN CYLINDER

PNEUMATIC BLANKET EDGE CONTROL BY PHOTOCELL

WORKING SPEED: 5 TO 10 METERS PER MINUTE, DEPENDING ON FABRIC THICKNESS (THICK FABRIC IS SLOWER, NORMAL FABRIC IS FASTER)

PLC CONTROLLER WITH TOUCH SCREEN OPERATOR PANEL

PROGRAMMABLE HEATING UP AND COOLING DOWN

ROLL TO ROLL WORKING SYSTEM

SLITTING UNIT WITH 3 PIECE PNEUMATIC CUTTER AND DUAL CENTER REWINDING UNIT (OPTIONAL)

440 V 3-PHASE, 60 Hz, 55 AMPLEAD TIME: 6 TO 8 WEEKS AFTER RECEIPT OF DEPOSIT

Learn More