Search results for: 'pillow co'

- Related search terms

- pillow+b

- pillow press

- pillow+machine

- pillow fillin

- PILLOW+PA

-

E-9860 FIBER OPENING MACHINEINVENTORY NUMBER: E-9860 FIBER OPENING MACHINE USED TO OPEN POLYESTER FIBERS FOR PILLOW FILLING, PLUSH STUFFED TOY, SOFA, CUSHION, BEDDING, DECORATIVE PILLOW AND QUILT ETC. THE MACHINE IS MAINLY USED FOR OPENING REGULAR OR HOLLOW CONJUGATE SILICONIZED POLYESTER FIBER SHORTER THAN 100mm LENGTH (4 INCHES). HIGH OUTPUT. WITH METAL ALARM SYSTEM PROTECTING THE OPENER ROLLER, AVOIDING DAMAGE TO ROLLS. ASSEMBLED WITH METALLIC SELF-LOCK WIRE SO THAT THE FIBER CAN BE OPENED FOR MORE THAN 98% AND NOT BE DAMAGED. 150KG TO 320KG PRODUCTION PER HOUR DEPENDING ON THE DIFFERENT MACHINE MODELS AND FIBERS. BALANCED ROLLERS. ELECTRONIC OVERLOAD PROTECTION. QUANTITY AVAILABLE: 1 Learn More

E-9860 FIBER OPENING MACHINEINVENTORY NUMBER: E-9860 FIBER OPENING MACHINE USED TO OPEN POLYESTER FIBERS FOR PILLOW FILLING, PLUSH STUFFED TOY, SOFA, CUSHION, BEDDING, DECORATIVE PILLOW AND QUILT ETC. THE MACHINE IS MAINLY USED FOR OPENING REGULAR OR HOLLOW CONJUGATE SILICONIZED POLYESTER FIBER SHORTER THAN 100mm LENGTH (4 INCHES). HIGH OUTPUT. WITH METAL ALARM SYSTEM PROTECTING THE OPENER ROLLER, AVOIDING DAMAGE TO ROLLS. ASSEMBLED WITH METALLIC SELF-LOCK WIRE SO THAT THE FIBER CAN BE OPENED FOR MORE THAN 98% AND NOT BE DAMAGED. 150KG TO 320KG PRODUCTION PER HOUR DEPENDING ON THE DIFFERENT MACHINE MODELS AND FIBERS. BALANCED ROLLERS. ELECTRONIC OVERLOAD PROTECTION. QUANTITY AVAILABLE: 1 Learn More -

E-8999 SINGLE NOZZLE PILLOW FILLING MACHINEINVENTORY NUMBER: E-8999 SINGLE NOZZLE PILLOW FILLING MACHINE-NEW DIMENSIONS: 3100 x 1200 x 1020mm VOLTAGE: AS PER CUSTOMER REQUEST POWER: 8.45kw CAPACITY: APPROXIMATELY 90KG/H WEIGHT: 620kg NOZZLE DIAMETER: 70mm OR 100mm QUANTITY AVAILABLE: 1 Learn More

E-8999 SINGLE NOZZLE PILLOW FILLING MACHINEINVENTORY NUMBER: E-8999 SINGLE NOZZLE PILLOW FILLING MACHINE-NEW DIMENSIONS: 3100 x 1200 x 1020mm VOLTAGE: AS PER CUSTOMER REQUEST POWER: 8.45kw CAPACITY: APPROXIMATELY 90KG/H WEIGHT: 620kg NOZZLE DIAMETER: 70mm OR 100mm QUANTITY AVAILABLE: 1 Learn More -

E-8998 DOUBLE NOZZLE PILLOW FILLING MACHINEINVENTORY NUMBER: E-8998 DOUBLE NOZZLE PILLOW FILLING MACHINE -NEW DIMENSIONS: 3300 X 2600 X 1020mm (130" X 102" X 40") VOLTAGE: AS PER CUSTOMER REQUIREMENT POWER: 10.65kw CAPACITY: 150-180kg/H (300 TO 400 LBS PER HOUR) WEIGHT: 710kg (1560 LBS) QUANTITY AVAILABLE: 1 Learn More

E-8998 DOUBLE NOZZLE PILLOW FILLING MACHINEINVENTORY NUMBER: E-8998 DOUBLE NOZZLE PILLOW FILLING MACHINE -NEW DIMENSIONS: 3300 X 2600 X 1020mm (130" X 102" X 40") VOLTAGE: AS PER CUSTOMER REQUIREMENT POWER: 10.65kw CAPACITY: 150-180kg/H (300 TO 400 LBS PER HOUR) WEIGHT: 710kg (1560 LBS) QUANTITY AVAILABLE: 1 Learn More -

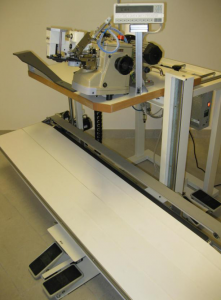

K-1428 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSREFERENCE NUMBER: K-1428 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONS FOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) QUANTITY AVAILABLE: 1 Learn More

K-1428 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSREFERENCE NUMBER: K-1428 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONS FOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) QUANTITY AVAILABLE: 1 Learn More -

K-9173 DOWN, FEATHER, POLY, SILK BEDDING QUILTS, BEDSPREADS, PILLOWS, MATTRESS PROTECTORS, FILLING MATERIALSNATURAL PRODUCTS SYNTHETIC PRODUCTS BEDDING PRODUCTS FILLING MATERIALS Learn More

K-9173 DOWN, FEATHER, POLY, SILK BEDDING QUILTS, BEDSPREADS, PILLOWS, MATTRESS PROTECTORS, FILLING MATERIALSNATURAL PRODUCTS SYNTHETIC PRODUCTS BEDDING PRODUCTS FILLING MATERIALS Learn More -

K-1322 CUSHION FILLING MACHINETHIS MACHINE PROVIDED WITH A BRAKING SYSTEM WHICH PERMITS THE FILLING OF WADDING PILLOWS AND QUILTS WITH ALL MATERIALS (POLYESTER, FEATHER, EXPANDED POLYURETHANE, COTTON, WOOL, ETC.) THE PARTICULAR WIDENED SHAPE OF THE TURBINE MAKES IT POSSIBLE TO OBTAIN REMARKABLE PERFORMANCES IN THE FILLING UP USING THE SPECIAL TUBE IT IS POSSIBLE TO SUCK UP THE MATERIAL DIRECTLY FROM THE VARIOUS CONTAINERS. THE BRAKING IS VERY RAPID (ABOUT 1/10 OF SECOND) AND DOES NOT REQUIRE MAINTENANCE SINCE IT IS OBTAINED THROUGH A PNEUMATIC DEVICE. THE CONTROL DEVICE IS A PNEUMATIC FOOT-LEVER WHICH LEAVES THE OPERATOR’S HANDS UNENGAGED. SAFETY MOTOR PROTECTOR SWITCH. IT CAN BE SUPPLIED BOTH IN A ONE-PHASE AND IN A THREE-PHASE VERSION. THE MACHINE IS CONSTRUCTED IN CONFORMITY WITH THE EEC DIRECTIVES 2006/42/CE, 2004/108/CE E 2006/95/CE AND SUCCESSIVE MODIFICATIONS AND MARKED CE. ON REQUEST WITH SPEED VARIATION THE FAN SPEED IS ADJUSTABLE FROM 2000 TO 4200 RPM, IN ORDER TO OPTIMIZE THE SPEED OF FILLING TO THE SHAPE AND THE SIZE OF THE PILLOW AT MAXIMUM SPEED, THE AMOUNT OF MATERIAL FILLED IS ABOUT 200 GRAMS PER SECOND. ON THE PART OF THE MACHINE THE LOAD OF THE MATERIAL, THERE ARE 2 DAMPERS. THIS PREVENTS THE OVERLOADING OF THE TURBINE AND THE BLOCK OF MATERIAL, BECAUSE WHEN I RELASE THE PEDAL, FIRST I BLOCK THE FLOW OF MATERIAL AND THEN THE AIR FLOW. THE PARTICULAR SHAPE OF THE OUTLET PIPE ALLOWS TO FILL THE PILLOWS THAT HAVE AIR-TIGHT LINING. THE TURBINE IS MADE OF A CAST ALUMINUM. THE COMMAND TO THE DUMPERS IS GIVEN BY A PEDAL, SO THE OPERATOR HAS BOTH HANDS FREE. THE APPLICATION OF THE GRIPPERS ON THE OUTLET PIPE OF THE FILLER R 3PV ALLOWS A SINGLE OPERATOR TO USE MORE FILLERS. FURTHERMORE, IT IS POSSIBLE CHANGE THE TIME THAT THE GRIPPERS STAY CLOSED. THIS ALLOWS TO SET THE AMOUNT OF MATERIAL TO PUT INSIDE HE PILLOW, WITH A GOOD PRECISION. THE TIME IS ADJUSTABLE TO FILL DIFFERENT KINDS OF PILLOWS WITH DIFFERENT AMOUNTS OF MATERIAL. QUANTITY: 1 Learn More

K-1322 CUSHION FILLING MACHINETHIS MACHINE PROVIDED WITH A BRAKING SYSTEM WHICH PERMITS THE FILLING OF WADDING PILLOWS AND QUILTS WITH ALL MATERIALS (POLYESTER, FEATHER, EXPANDED POLYURETHANE, COTTON, WOOL, ETC.) THE PARTICULAR WIDENED SHAPE OF THE TURBINE MAKES IT POSSIBLE TO OBTAIN REMARKABLE PERFORMANCES IN THE FILLING UP USING THE SPECIAL TUBE IT IS POSSIBLE TO SUCK UP THE MATERIAL DIRECTLY FROM THE VARIOUS CONTAINERS. THE BRAKING IS VERY RAPID (ABOUT 1/10 OF SECOND) AND DOES NOT REQUIRE MAINTENANCE SINCE IT IS OBTAINED THROUGH A PNEUMATIC DEVICE. THE CONTROL DEVICE IS A PNEUMATIC FOOT-LEVER WHICH LEAVES THE OPERATOR’S HANDS UNENGAGED. SAFETY MOTOR PROTECTOR SWITCH. IT CAN BE SUPPLIED BOTH IN A ONE-PHASE AND IN A THREE-PHASE VERSION. THE MACHINE IS CONSTRUCTED IN CONFORMITY WITH THE EEC DIRECTIVES 2006/42/CE, 2004/108/CE E 2006/95/CE AND SUCCESSIVE MODIFICATIONS AND MARKED CE. ON REQUEST WITH SPEED VARIATION THE FAN SPEED IS ADJUSTABLE FROM 2000 TO 4200 RPM, IN ORDER TO OPTIMIZE THE SPEED OF FILLING TO THE SHAPE AND THE SIZE OF THE PILLOW AT MAXIMUM SPEED, THE AMOUNT OF MATERIAL FILLED IS ABOUT 200 GRAMS PER SECOND. ON THE PART OF THE MACHINE THE LOAD OF THE MATERIAL, THERE ARE 2 DAMPERS. THIS PREVENTS THE OVERLOADING OF THE TURBINE AND THE BLOCK OF MATERIAL, BECAUSE WHEN I RELASE THE PEDAL, FIRST I BLOCK THE FLOW OF MATERIAL AND THEN THE AIR FLOW. THE PARTICULAR SHAPE OF THE OUTLET PIPE ALLOWS TO FILL THE PILLOWS THAT HAVE AIR-TIGHT LINING. THE TURBINE IS MADE OF A CAST ALUMINUM. THE COMMAND TO THE DUMPERS IS GIVEN BY A PEDAL, SO THE OPERATOR HAS BOTH HANDS FREE. THE APPLICATION OF THE GRIPPERS ON THE OUTLET PIPE OF THE FILLER R 3PV ALLOWS A SINGLE OPERATOR TO USE MORE FILLERS. FURTHERMORE, IT IS POSSIBLE CHANGE THE TIME THAT THE GRIPPERS STAY CLOSED. THIS ALLOWS TO SET THE AMOUNT OF MATERIAL TO PUT INSIDE HE PILLOW, WITH A GOOD PRECISION. THE TIME IS ADJUSTABLE TO FILL DIFFERENT KINDS OF PILLOWS WITH DIFFERENT AMOUNTS OF MATERIAL. QUANTITY: 1 Learn More -

M-5005 BALL FIBER MACHINEREFERENCE NUMBER: M-5005 (1212WAJWHH11) L BALL FIBER MACHINE 300KG/H, 600KG/H CAN STILL CHANGE THE CAPACITY OF THIS MACHINE ACCORDING TO REQUIREMENTS OPERATION OF THE PRODUCTION LINE IS VERY SIMPLE: PUT THE FIBER OR THE COTTON ON THE OPENING MACHINE, THEN VIA THE OPENING MACHINE, CAN MAKE THE COTTON AND FIBER LOOSER (MORE OPEN) THAN BEFORE. THE BLOWER IS CONNECTED BETWEEN THE OPENING MACHINE AND THE BALL FIBER MACHINE IN ORDER TO SEND THE FIBER INTO THE BALL FIBER MACHINE. THE BALL FIBER MACHINE MAKES THE FIBER INTO FIBER BALL. ADVANTAGE OF THIS MACHINE: THIS MACHINE CAN SAVE ON THE COST OF LABOR. TWO BALL FIBER MACHINES CAN BE HANDLED BY ONE OPERATOR THAT CAN OPERATE THE OPENING MACHINE AND BALL FIBER MACHINE. THE POWER, 36.85KW/H. SMALL WORKING AREA, JUST NEED 5500mm x 3500mm x 2300mm (MODEL 002) BALL FIBER MACHINE USING RANGE: PILLOW, JACKET, QUILT PRODUCTIVITY: 160 TO 250KG/H (IF INCLUDING OPENING MACHINE, THE PRODUCTIVITY CAN BE UP TO 300KG/H) POWER: 17.75KW VOLTAGE: AS PER CUSTOMER REQUIREMENT WEIGHT: 1450KG DIMENSION OF BOX: 2500mm x 900mm x 1300mm (PACKAGING OPENING MACHINE AND DISTRIBUTION BOX) 2400mm x 1150mm x 1300mm (BALL FIBER MACHINE) TWO WOODEN CASES SHIPPING DIMENSION: 4500mm x 3500mm x 1500mm AN OPENING MACHINE, A BALL FIBER MACHINE, AND A BLOWER (MODEL 003) BALL FIBER MACHINE USING RANGE: PILLOW, JACKET, QUILT PRODUCTIVITY: 300 TO 400KG/H (PRODUCTIVITY CAN BE UP TO 600KG/H) POWER: 36.85KW VOLTAGE: AS PER CUSTOMER REQUIREMENT WEIGHT: 2300KG DIMENSION OF BOX: 2500mm x 900mm x 1300mm (OPENING MACHINE AND DISTRIBUTION MACHINE) 2400mm x 1150mm x 1300mm (BALL FIBER MACHINE) 2400mm x 1150mm x 1300mm (BALL FIBER MACHINE) THREE WOODEN CASES SHIPPING DIMENSION: 5500mm x 3500mm x 2300mm AN OPENING MACHINE, TWO BALL FIBER MACHINES, AND TWO BLOWERS QUANTITY AVAILABLE: 1 Learn More

M-5005 BALL FIBER MACHINEREFERENCE NUMBER: M-5005 (1212WAJWHH11) L BALL FIBER MACHINE 300KG/H, 600KG/H CAN STILL CHANGE THE CAPACITY OF THIS MACHINE ACCORDING TO REQUIREMENTS OPERATION OF THE PRODUCTION LINE IS VERY SIMPLE: PUT THE FIBER OR THE COTTON ON THE OPENING MACHINE, THEN VIA THE OPENING MACHINE, CAN MAKE THE COTTON AND FIBER LOOSER (MORE OPEN) THAN BEFORE. THE BLOWER IS CONNECTED BETWEEN THE OPENING MACHINE AND THE BALL FIBER MACHINE IN ORDER TO SEND THE FIBER INTO THE BALL FIBER MACHINE. THE BALL FIBER MACHINE MAKES THE FIBER INTO FIBER BALL. ADVANTAGE OF THIS MACHINE: THIS MACHINE CAN SAVE ON THE COST OF LABOR. TWO BALL FIBER MACHINES CAN BE HANDLED BY ONE OPERATOR THAT CAN OPERATE THE OPENING MACHINE AND BALL FIBER MACHINE. THE POWER, 36.85KW/H. SMALL WORKING AREA, JUST NEED 5500mm x 3500mm x 2300mm (MODEL 002) BALL FIBER MACHINE USING RANGE: PILLOW, JACKET, QUILT PRODUCTIVITY: 160 TO 250KG/H (IF INCLUDING OPENING MACHINE, THE PRODUCTIVITY CAN BE UP TO 300KG/H) POWER: 17.75KW VOLTAGE: AS PER CUSTOMER REQUIREMENT WEIGHT: 1450KG DIMENSION OF BOX: 2500mm x 900mm x 1300mm (PACKAGING OPENING MACHINE AND DISTRIBUTION BOX) 2400mm x 1150mm x 1300mm (BALL FIBER MACHINE) TWO WOODEN CASES SHIPPING DIMENSION: 4500mm x 3500mm x 1500mm AN OPENING MACHINE, A BALL FIBER MACHINE, AND A BLOWER (MODEL 003) BALL FIBER MACHINE USING RANGE: PILLOW, JACKET, QUILT PRODUCTIVITY: 300 TO 400KG/H (PRODUCTIVITY CAN BE UP TO 600KG/H) POWER: 36.85KW VOLTAGE: AS PER CUSTOMER REQUIREMENT WEIGHT: 2300KG DIMENSION OF BOX: 2500mm x 900mm x 1300mm (OPENING MACHINE AND DISTRIBUTION MACHINE) 2400mm x 1150mm x 1300mm (BALL FIBER MACHINE) 2400mm x 1150mm x 1300mm (BALL FIBER MACHINE) THREE WOODEN CASES SHIPPING DIMENSION: 5500mm x 3500mm x 2300mm AN OPENING MACHINE, TWO BALL FIBER MACHINES, AND TWO BLOWERS QUANTITY AVAILABLE: 1 Learn More -

F-1361 PILLOW WEIGHT SETTING FILLING MACHINEREFERENCE NUMBER: F-1361 PILLOW WEIGHT SETTING FILLING MACHINE FILLING MACHINES WITH PADDING DEVICES ENSURE HIGH SPEED AND TOP QUALITY FILLING. THE OPERATORS CAN SET THE WEIGHT OF EACH PILLOW/CUSHION APPROXIMATELY FIBER CARDING MACHINE: DIMENSIONS: 2150 X 1150 X 980 POWER: 6.35kW NET WEIGHT: 800kg CAPACITY: APPROX. 160 TO 190kg PER HOUR VOLTAGE: AS PER CUSTOMER OFFERS MORE SAFETY: THE FIBER CARDING MACHINE HAS AN OVERLOADING ALARM SYSTEM TO AVOID THE MACHINE BEING DAMAGED SAVES ON COSTS: IF AN ADDITIONAL BALE OPENING MACHINE IS ADDED, ONLY ONE PERSON IS NEEDED TO RUN THE WHOLE LINE WITH TWO FILLER HEADS FILLING MACHINE: DIMENSIONS: 3350 X 1900 X 1450 POWER: 4.74kW NET WEIGHT: 400kg AIR PRESSURE: 1mpa CAPACITY: APPROX. 160 TO 190kg PER HOUR VOLTAGE: AS PER CUSTOMER QUANTITY AVAILABLE: 1 Learn More

F-1361 PILLOW WEIGHT SETTING FILLING MACHINEREFERENCE NUMBER: F-1361 PILLOW WEIGHT SETTING FILLING MACHINE FILLING MACHINES WITH PADDING DEVICES ENSURE HIGH SPEED AND TOP QUALITY FILLING. THE OPERATORS CAN SET THE WEIGHT OF EACH PILLOW/CUSHION APPROXIMATELY FIBER CARDING MACHINE: DIMENSIONS: 2150 X 1150 X 980 POWER: 6.35kW NET WEIGHT: 800kg CAPACITY: APPROX. 160 TO 190kg PER HOUR VOLTAGE: AS PER CUSTOMER OFFERS MORE SAFETY: THE FIBER CARDING MACHINE HAS AN OVERLOADING ALARM SYSTEM TO AVOID THE MACHINE BEING DAMAGED SAVES ON COSTS: IF AN ADDITIONAL BALE OPENING MACHINE IS ADDED, ONLY ONE PERSON IS NEEDED TO RUN THE WHOLE LINE WITH TWO FILLER HEADS FILLING MACHINE: DIMENSIONS: 3350 X 1900 X 1450 POWER: 4.74kW NET WEIGHT: 400kg AIR PRESSURE: 1mpa CAPACITY: APPROX. 160 TO 190kg PER HOUR VOLTAGE: AS PER CUSTOMER QUANTITY AVAILABLE: 1 Learn More -

FILLING MACHINE FOR BLOWING PILLOWS, CUSHIONS, AND QUILTSMACHINE DIMENSIONS: 2200 X 800 X H. 1550 CM NET WEIGHT: 180 KG POWER: 380V THREE PHASE KW. 2.5 COMPRESSED AIR: 3 BARS COMMODITY CODE: 8445.19.29 Learn More

FILLING MACHINE FOR BLOWING PILLOWS, CUSHIONS, AND QUILTSMACHINE DIMENSIONS: 2200 X 800 X H. 1550 CM NET WEIGHT: 180 KG POWER: 380V THREE PHASE KW. 2.5 COMPRESSED AIR: 3 BARS COMMODITY CODE: 8445.19.29 Learn More -

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINE

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINEI. FUNCTION

Learn More

THIS MACHINE IS USED TO PACK DISPOSABLE SURGICAL FACE MASK WITH THE SIZE OF 190 X 65mm. IT CAN ALSO BE USED TO PACK OTHER PRODUCTS SUCH AS WET TISSUE.

II. FEATURES:

1. ONE SET OF INK TO INJECT PRINTER IS INCLUDED; IT CAN BE USED TO PRINT THE DATA AND OTHER INFORMATION.

2. THE AIR COMPRESSOR EQUIPMENT IS OPTIONAL.

3. PACKING MATERIAL: SINGLE TO SIDE HEAT TO SEALING PACKAGING FILM MATERIALS, SUCH AS OPP, CPP, OPP COMPOSITE PE, PET COMPOSITE PE, SINGLE TO LAYER OR COMPOSITE PACKAGING FILM MATERIALS.

4. BAG FORM: BACK TO SEALED PACKING, CAN BE CUSTOMIZED.

5. VERTICAL/HORIZONTAL SEAL: RETICULATED PACKAGING/VERTICAL AND RETICULATED PACKAGING.

III. SPECIFICATION:

NAME: PILLOW PACKING MACHINE

TYPE KD TO 350

APPLICATION: FOR ALL KINDS OF OPP HEAT TO SEALING FILM, COMPOSITE FILM, SPRAY FILM PAPER, ALUMINUM FOIL FILM, ALUMINUM PLASTIC COMPOSITE FILM

MACHINE SIZE: 4600 X 850 X 1500

PACKING SPEED: 60 TO 220 BAG/MIN

MAX. PACKING SIZE: 330mm, 150mm, 80mm. LENGTH: 330mm, WIDTH: 150mm, HEIGHT: 80mm

MIN. PACKING SIZE: 50mm, 10mm, 5mm. LENGTH: 50mm, WIDTH: 10mm, HEIGHT: 5mm

ELECTRICAL: AC220V, 2.7KW

AIR PRESSURE 0.5 TO 0.7 MPA

AIR CONSUMPTION: >0.36 (M3/H)

(DB) NOISE: 60 TO 70DB

MACHINE WEIGHT: 550KG

MOTOR FREQUENCY ADJUST: 0 TO 50HZ

AUTOMATIC CONTROL

AUTOMATIC PRINTING

STANDARD: GMP STANDARD, PACKAGING MACHINE ENTERPRISE STANDARD

APPROVAL: ISO9001:2000, CE ISO:2000