Search results for: 'Panel+c''

-

TORRES MODEL MICROPUNT-153 YEAR 2000 WIDTH 2000mmTORRES MODEL MICROPUNT-153 SUEDING/EMERIZING MACHINE YEAR 2000 WIDTH 2000mm COMPLETE WITH DUST SUCTION FILTERS IT IS THE ONLY MACHINE ON THE MARKET WHICH CAN REALLY SUEDE BOTH HEAVY COTTON TWILL AND A LIGHT AND ELASTIC KNITTED FABRIC SUCH AS LYCRA. AS THE FABRIC CONTENT IS WITHIN THE WORKING AREA (ONLY 65 CM.), THE TENSION OF THE SAME CAN BE CONTROLLED PERFECTLY, AND THIS IS A MUST, IF YOU WANT TO OBTAIN A UNIFORM FINISH. EXTREMELY HIGH ABRASIVE/FABRIC EXCHANGE DUE TO THE FACT THAT ITS SUEDING ROLLERS ARE MANUFACTURED WITH HIGHLY ACCURATE CALIBRATED STEEL TUBE, DYNAMICALLY BALANCED AND TURN AROUND BEARINGS AT EXTREMELY HIGH SPEED (18 M/S). INNER COOLING OF THE SUEDING ROLLERS BY FORCED AIR FLOW. FABRIC SPEED BY MEANS OF ASYNCHRONOUS MOTORS DRIVEN BY A VECTORIAL INVERTER. FABRIC TENSIONING BY MEANS OF A PNEUMATIC SYSTEM OF OUR OWN DESIGN. CONTACT ARC VARIABLE BY MEANS OF A MOTORIZED SYSTEM. POSSIBILITY OF USING A CONVENTIONAL AND/OR A DIAMOND (LONG LIFE) ABRASIVE. AUTOMATIC SEAM PASSAGE. STATIC ELIMINATOR. FABRIC CLEANING BY MEANS OF A BEATING/BRUSHING PROCESS WITH A SUCTION NOZZLE. DUST SUCTION AND COLLECTION SYSTEM. ALL THE WORKING PARAMETERS ARE SHOWN ON THE PANEL AND THEY MAY BE REPRODUCED FAITHFULLY Learn More

TORRES MODEL MICROPUNT-153 YEAR 2000 WIDTH 2000mmTORRES MODEL MICROPUNT-153 SUEDING/EMERIZING MACHINE YEAR 2000 WIDTH 2000mm COMPLETE WITH DUST SUCTION FILTERS IT IS THE ONLY MACHINE ON THE MARKET WHICH CAN REALLY SUEDE BOTH HEAVY COTTON TWILL AND A LIGHT AND ELASTIC KNITTED FABRIC SUCH AS LYCRA. AS THE FABRIC CONTENT IS WITHIN THE WORKING AREA (ONLY 65 CM.), THE TENSION OF THE SAME CAN BE CONTROLLED PERFECTLY, AND THIS IS A MUST, IF YOU WANT TO OBTAIN A UNIFORM FINISH. EXTREMELY HIGH ABRASIVE/FABRIC EXCHANGE DUE TO THE FACT THAT ITS SUEDING ROLLERS ARE MANUFACTURED WITH HIGHLY ACCURATE CALIBRATED STEEL TUBE, DYNAMICALLY BALANCED AND TURN AROUND BEARINGS AT EXTREMELY HIGH SPEED (18 M/S). INNER COOLING OF THE SUEDING ROLLERS BY FORCED AIR FLOW. FABRIC SPEED BY MEANS OF ASYNCHRONOUS MOTORS DRIVEN BY A VECTORIAL INVERTER. FABRIC TENSIONING BY MEANS OF A PNEUMATIC SYSTEM OF OUR OWN DESIGN. CONTACT ARC VARIABLE BY MEANS OF A MOTORIZED SYSTEM. POSSIBILITY OF USING A CONVENTIONAL AND/OR A DIAMOND (LONG LIFE) ABRASIVE. AUTOMATIC SEAM PASSAGE. STATIC ELIMINATOR. FABRIC CLEANING BY MEANS OF A BEATING/BRUSHING PROCESS WITH A SUCTION NOZZLE. DUST SUCTION AND COLLECTION SYSTEM. ALL THE WORKING PARAMETERS ARE SHOWN ON THE PANEL AND THEY MAY BE REPRODUCED FAITHFULLY Learn More -

DORNIER LTNF 6J TERRY WEAVING LOOMS WITH JACQUARD YEAR 1997 WIDTH 2600mmYEAR: 1997 TERRY AIR JET WEAVING LOOMS DORNIER LTNF-6J WITH JACQUARD WIDTH 2600mm 6 COLORS 6 WEFT FEEDERS ELECTRONIC TAKE-UP AND LET OFF PREDISPOSED FOR CLOTH ROLL 4 BEAMS PER LOOM 2 LOOMS FROM 1997 WITH PANEL CONTROL 1 AND JACQUARD CX960 (YEAR 1997) CONTROLER JC4 FORMAT 3072 HOOKS Learn More

DORNIER LTNF 6J TERRY WEAVING LOOMS WITH JACQUARD YEAR 1997 WIDTH 2600mmYEAR: 1997 TERRY AIR JET WEAVING LOOMS DORNIER LTNF-6J WITH JACQUARD WIDTH 2600mm 6 COLORS 6 WEFT FEEDERS ELECTRONIC TAKE-UP AND LET OFF PREDISPOSED FOR CLOTH ROLL 4 BEAMS PER LOOM 2 LOOMS FROM 1997 WITH PANEL CONTROL 1 AND JACQUARD CX960 (YEAR 1997) CONTROLER JC4 FORMAT 3072 HOOKS Learn More -

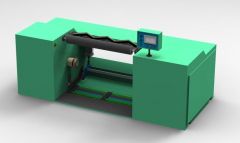

AUTOMATIC HIGH-PRECISION COPY WARPING MACHINE FOR 30”×42” AND 21”X42” BEAM AND 1400-POSITION CREELMACHINE FEATURES: - WITH NC SERVICE ROLLER, AUTOMATIC ADDING OIL DEVICE, BACKING YARN STORAGE DEVICE, DEVICE YARN NEEDLE, YARN COLLECTING PLAT AND AUTO STOP DEVICE. -THE MAIN MOTOR IS CONTROLLED BY INVERTER AND PLC. -THE CREEL IS CONTROLLED BY PNEUMATIC, AND ITS POSITION IS ACCURACY CONTROLLED BY PHOTOELECTRIC SENSOR AND THE PLC AUTOMATICALLY. -THE MAIN BRAKE ADEPTS PNEUMATIC BUTTERFLY BRAKE. THE BREAKING TRAY WITH MIDDLE UNOCCUPIED HAS A NICE HEAT-DISSIPATED FUNCTION. ON THE OTHER HAND, THE USING OF BREAK PINCER WITH AUTO-COMPENSATION AND THE HOOFED PIECE MAKES THE BUTTERFLY BRAKE STABLE AND LAST A LONG LIFE. -THE BRAKE OF POSITIVE ROLLER AND SPEED ROLLER CAN MAKE DIFFERENT BRAKE PRESSURES ACCORDING TO DIFFERENT SPEEDS (MORE THAN 200 M/MIN). THESE DIFFERENT PRESSURES, TOGETHER WITH THE MAIN BEAM BREAK, GUARANTEES THE YARN TENSION IN THE BREAKING TIME IS THE SAME AS THE TENSION UNDER THE CONSTANT SPEED. -WITH TOUCH SCREEN. ALL THE ELECTRICAL TROUBLES AND WRONG OPERATION INFORMATION ARE DISPLAYED ON THE SCREEN. THE PNEUMATIC PART, AORTIC, IS MADE IN TAIWAN. -THE POSITIVE ROLLER IS COVERED BY HIGH-HARDNESS COATING, SO THE SMOOTH SURFACE IMPROVES THE ABSORPTION TO THE YARN. THE AC HIGH-SPEED SERVO SYSTEM PROVIDES A POWER TO THE ABOVE ROLLER, MATCHING WITH THE PLC, BOTH OF WHICH SERVICE FOR THE MAIN WINDING SYSTEM, TO ENSURE THE CONSTANT TENSION OF YARN. -WITH REMOTE DEBUGGING TO MONITOR THE CURRENT WORKING CONDITIONS. CONSISTS OF: (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM TECHNICAL DATA: LINE SPEED 0 TO 1000M/MIN MAX. TENSION OF LINE 1000N BRAKE TORQUE 3200NM UP AND DOWN OF BEAM PNEUMATIC CONTROL TIGHT AND RELEASE OF BEAM PNEUMATIC CONTROL DIAMETER OF SPEED ROLLER Ø120mm POWER OF MAIN MOTOR 15KW CONTROL TYPE OF MAIN MOTOR INVERTER CONTROL MONITORING WAY IMMEDIATE MONITOR BY MICROCOMPUTER CONTROLLED TOUCH SCREEN CONTROL TYPE OF POSITIVE YARN-SEND ROLLER AC HIGH-SPEED SERVO CONTROL SYSTEM OF MITSUBISHI DIAMETER OF POSITIVE YARN-SEND ROLLER Ø100mm PRESSURE OF PNEUMATIC SOURCE 6 BAR MAIN PARTS: MAIN MOTOR SIEMENS OF GERMANGY HIGH-SPEED SERVO SYSTEM MITSUBISHI OF JAPAN CONVERTER EMERSON OF USA TEST COMPONENTS A AUTONICS OF SOUTH KOREA TEST COMPONENTS B KOYO OF JAPAN PNEUMATIC COMPONENTS AIRTAC OF TAIWAN PLC OMRON OF JAPAN TOUCH SCREEN MCGS OF BEIJING OPERATING COMPONENTS SCHNEIDER OF FRANCE TERMINAL COMPONENTS PHOENIXCONTACT OF GERMANGY BEARING NSK OF JAPAN (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER MAJOR PARTS: 1. MOTOR 2. ROLLER SPEED DETECTOR 3. CONTROL PANEL 4. REED 5. SIZING PARTS 6. LUBRICATING DEVICE 7. YARN STORAGE 8. TENSION ROLLER 9. STATIC ELIMINATOR 10. NEEDLES 11. YARN COLLECTING BOARD DELIVERY TIME: 37-45 DAYS Learn More

AUTOMATIC HIGH-PRECISION COPY WARPING MACHINE FOR 30”×42” AND 21”X42” BEAM AND 1400-POSITION CREELMACHINE FEATURES: - WITH NC SERVICE ROLLER, AUTOMATIC ADDING OIL DEVICE, BACKING YARN STORAGE DEVICE, DEVICE YARN NEEDLE, YARN COLLECTING PLAT AND AUTO STOP DEVICE. -THE MAIN MOTOR IS CONTROLLED BY INVERTER AND PLC. -THE CREEL IS CONTROLLED BY PNEUMATIC, AND ITS POSITION IS ACCURACY CONTROLLED BY PHOTOELECTRIC SENSOR AND THE PLC AUTOMATICALLY. -THE MAIN BRAKE ADEPTS PNEUMATIC BUTTERFLY BRAKE. THE BREAKING TRAY WITH MIDDLE UNOCCUPIED HAS A NICE HEAT-DISSIPATED FUNCTION. ON THE OTHER HAND, THE USING OF BREAK PINCER WITH AUTO-COMPENSATION AND THE HOOFED PIECE MAKES THE BUTTERFLY BRAKE STABLE AND LAST A LONG LIFE. -THE BRAKE OF POSITIVE ROLLER AND SPEED ROLLER CAN MAKE DIFFERENT BRAKE PRESSURES ACCORDING TO DIFFERENT SPEEDS (MORE THAN 200 M/MIN). THESE DIFFERENT PRESSURES, TOGETHER WITH THE MAIN BEAM BREAK, GUARANTEES THE YARN TENSION IN THE BREAKING TIME IS THE SAME AS THE TENSION UNDER THE CONSTANT SPEED. -WITH TOUCH SCREEN. ALL THE ELECTRICAL TROUBLES AND WRONG OPERATION INFORMATION ARE DISPLAYED ON THE SCREEN. THE PNEUMATIC PART, AORTIC, IS MADE IN TAIWAN. -THE POSITIVE ROLLER IS COVERED BY HIGH-HARDNESS COATING, SO THE SMOOTH SURFACE IMPROVES THE ABSORPTION TO THE YARN. THE AC HIGH-SPEED SERVO SYSTEM PROVIDES A POWER TO THE ABOVE ROLLER, MATCHING WITH THE PLC, BOTH OF WHICH SERVICE FOR THE MAIN WINDING SYSTEM, TO ENSURE THE CONSTANT TENSION OF YARN. -WITH REMOTE DEBUGGING TO MONITOR THE CURRENT WORKING CONDITIONS. CONSISTS OF: (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM TECHNICAL DATA: LINE SPEED 0 TO 1000M/MIN MAX. TENSION OF LINE 1000N BRAKE TORQUE 3200NM UP AND DOWN OF BEAM PNEUMATIC CONTROL TIGHT AND RELEASE OF BEAM PNEUMATIC CONTROL DIAMETER OF SPEED ROLLER Ø120mm POWER OF MAIN MOTOR 15KW CONTROL TYPE OF MAIN MOTOR INVERTER CONTROL MONITORING WAY IMMEDIATE MONITOR BY MICROCOMPUTER CONTROLLED TOUCH SCREEN CONTROL TYPE OF POSITIVE YARN-SEND ROLLER AC HIGH-SPEED SERVO CONTROL SYSTEM OF MITSUBISHI DIAMETER OF POSITIVE YARN-SEND ROLLER Ø100mm PRESSURE OF PNEUMATIC SOURCE 6 BAR MAIN PARTS: MAIN MOTOR SIEMENS OF GERMANGY HIGH-SPEED SERVO SYSTEM MITSUBISHI OF JAPAN CONVERTER EMERSON OF USA TEST COMPONENTS A AUTONICS OF SOUTH KOREA TEST COMPONENTS B KOYO OF JAPAN PNEUMATIC COMPONENTS AIRTAC OF TAIWAN PLC OMRON OF JAPAN TOUCH SCREEN MCGS OF BEIJING OPERATING COMPONENTS SCHNEIDER OF FRANCE TERMINAL COMPONENTS PHOENIXCONTACT OF GERMANGY BEARING NSK OF JAPAN (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER MAJOR PARTS: 1. MOTOR 2. ROLLER SPEED DETECTOR 3. CONTROL PANEL 4. REED 5. SIZING PARTS 6. LUBRICATING DEVICE 7. YARN STORAGE 8. TENSION ROLLER 9. STATIC ELIMINATOR 10. NEEDLES 11. YARN COLLECTING BOARD DELIVERY TIME: 37-45 DAYS Learn More -

FEHRER DREF 2000 FT FRICTION SPINNING 2000-2002FEHRER DREF 2000 FT FRICTION SPINNING MACHINE 12 POSITIONS EACH MODEL 12E12K 1 X YEAR 2000 – RUNNING HOURS: 30,500 1 X YEAR 2002 – RUNNING HOURS: 20,300 COMPRISING 2 MODULES OF 6 SPINNING HEADS EACH Z/S TWIST 440 VOLTS / 50/60HZ TUBE TAKE UP 230mm X 80mm, PACKAGES UP TO 8KGS FIBER LENGTH: 10 TO 120mm 36 ROVING AND 12 FILAMENT SENSORS MAXIMUM SPEED: 250 MTS/MIN POSSIBLE COUNTS: NM 0.5-25 CONTROL PANEL HIGH CAPACITY CREEL EXTRACTOR FAN + 2 BAG FILTER ORIGINAL OPERATING MANUALS QUANTITY: 2 Learn More

FEHRER DREF 2000 FT FRICTION SPINNING 2000-2002FEHRER DREF 2000 FT FRICTION SPINNING MACHINE 12 POSITIONS EACH MODEL 12E12K 1 X YEAR 2000 – RUNNING HOURS: 30,500 1 X YEAR 2002 – RUNNING HOURS: 20,300 COMPRISING 2 MODULES OF 6 SPINNING HEADS EACH Z/S TWIST 440 VOLTS / 50/60HZ TUBE TAKE UP 230mm X 80mm, PACKAGES UP TO 8KGS FIBER LENGTH: 10 TO 120mm 36 ROVING AND 12 FILAMENT SENSORS MAXIMUM SPEED: 250 MTS/MIN POSSIBLE COUNTS: NM 0.5-25 CONTROL PANEL HIGH CAPACITY CREEL EXTRACTOR FAN + 2 BAG FILTER ORIGINAL OPERATING MANUALS QUANTITY: 2 Learn More -

M-3769 L GRIBETZ QUILTER 86” ULTRA 12 DG 2200 CHAIN/COMP

M-3769 L GRIBETZ QUILTER 86” ULTRA 12 DG 2200 CHAIN/COMPREFERENCE NUMBER: M-3769

GRIBETZ QUILTER 86” ULTRA 12 DG 2200 CHAIN/COMP

GRIBETZ QUILTER 86” ULTRA 12 DG2200 CHAIN/COMP

PLATE INFO:

TYPE/MODEL: DG 2200 CHAIN/COMP

MACHINE SIZE: 86” ULTRA 12

NEEDLE SPACING: 1×3×6

WIDTH OF BARS: 86” INCHES

MACHINE WIRED: 220V 3PH 60HZ

AUX. TRANSFORMER: 208V 3PH 60HZ

INCLUDES:

(1) CAT WALK

(1) CLOTH TRAY

(2) THREAD RACK

(100) LOOPERS

(10) CIRCULAR BLADES ON THE BACK

(1) TRANSFORMER

CONTROL PANEL:

(1) MSC 850

(1) RAD 02 2033 SN: 991150

(1) RAD 02 2062 SN: 991167

(1) RAD 02 2062 SN: 961305

QUANTITY: 1

Learn More -

GRIBETZ QUILTER 90” MODEL DG5500 LOCKSTITCHPLATE INFO: TYPE/MODEL: DG5500 LOCKSTITCH MACHINE SIZE: 90” NEEDLE SPACING: 1×3×6 MACHINE WIRED: 220V 3PH 60HZ AUX. TRANSFORMER: 220V 3PH 60HZ WITH (11) CIRCULAR BLADES ON THE BACK, (1) CAM, CAT WALK, CLOTH TRAY (1) THREAD RACK (1) HOME-MADE PANEL CUTTER (NO PLATE IS AVAILABLE) NOTE: BOTH MACHINES ARE ON THE SECOND FLOOR QUANTITY: 1 Learn More

GRIBETZ QUILTER 90” MODEL DG5500 LOCKSTITCHPLATE INFO: TYPE/MODEL: DG5500 LOCKSTITCH MACHINE SIZE: 90” NEEDLE SPACING: 1×3×6 MACHINE WIRED: 220V 3PH 60HZ AUX. TRANSFORMER: 220V 3PH 60HZ WITH (11) CIRCULAR BLADES ON THE BACK, (1) CAM, CAT WALK, CLOTH TRAY (1) THREAD RACK (1) HOME-MADE PANEL CUTTER (NO PLATE IS AVAILABLE) NOTE: BOTH MACHINES ARE ON THE SECOND FLOOR QUANTITY: 1 Learn More