Search results for: 'LABEL P'

- Related search terms

- Label loom

- Label loom M

- Label looms

- label printing

- Label loom M/?

-

J-4056 LABEL CUTTING AND FOLDING MACHINE, HIGHLY CONFIGURABLE FOR MULTIPLE LABEL TYPESJ-4056 LABEL CUTTING AND FOLDING MACHINE, HIGHLY CONFIGURABLE FOR MULTIPLE LABEL TYPES LABEL SHEARING AND FOLDING MACHINE AUTOMATIC SLIDING PATH OF LABEL ABLE TO SHEAR AND FOLD 5 TYPES OF LABELS BY ONLY REPLACING THE MOLD ADJUSTABLE LABEL LENGTH WITHOUT ANY TOOLS AND CAN BE SEPARATELY FITTED WITH ELECTRONIC EYE SYSTEM IF NEEDED USED FOR PRINTING LABELS AND CUTTING AND FOLDING WITHOUT PUSH-LINE SHEARING AND FOLDING TYPES: END FOLD, CENTER FOLD, TRIANGLE FOLD, LENGTHFOLD CUTTING LENGTH: 15 TO 16mm CUTTING WIDTH: 10 TO 75mm CUTTER TYPE: COOLED SHEARING, HOT SHEARING CUTTING SPEED: 30 TO 200 METERS PER MINUTE POWER: 220 VOLTS, SINGLE PHASE, 60 OR 50 Hz TOTAL POWER: 1.8 KW HORSEPOWER: ½ HP WEIGHT: 295 KG PACKED DIMENSIONS: 1100 x 950 x 1620mm QUANTITY: 1 Learn More

J-4056 LABEL CUTTING AND FOLDING MACHINE, HIGHLY CONFIGURABLE FOR MULTIPLE LABEL TYPESJ-4056 LABEL CUTTING AND FOLDING MACHINE, HIGHLY CONFIGURABLE FOR MULTIPLE LABEL TYPES LABEL SHEARING AND FOLDING MACHINE AUTOMATIC SLIDING PATH OF LABEL ABLE TO SHEAR AND FOLD 5 TYPES OF LABELS BY ONLY REPLACING THE MOLD ADJUSTABLE LABEL LENGTH WITHOUT ANY TOOLS AND CAN BE SEPARATELY FITTED WITH ELECTRONIC EYE SYSTEM IF NEEDED USED FOR PRINTING LABELS AND CUTTING AND FOLDING WITHOUT PUSH-LINE SHEARING AND FOLDING TYPES: END FOLD, CENTER FOLD, TRIANGLE FOLD, LENGTHFOLD CUTTING LENGTH: 15 TO 16mm CUTTING WIDTH: 10 TO 75mm CUTTER TYPE: COOLED SHEARING, HOT SHEARING CUTTING SPEED: 30 TO 200 METERS PER MINUTE POWER: 220 VOLTS, SINGLE PHASE, 60 OR 50 Hz TOTAL POWER: 1.8 KW HORSEPOWER: ½ HP WEIGHT: 295 KG PACKED DIMENSIONS: 1100 x 950 x 1620mm QUANTITY: 1 Learn More -

TT-4438 GALLUS / KO-PACK / FRANCHINI LABEL MACHINES, WIDTH 170mm TO 250mm, YEAR 1979 TO 1992TT-4438 GALLUS / KO-PACK / FRANCHINI LABEL MACHINES, WIDTH 170mm TO 250mm, YEAR 1979 TO 1992 ITEM 001 GALLUS R160 B02 LABEL LETTERPRESS PRINTING MACHINE YEAR 1986 OVERHAULED ON 1998 QUANTITY: 1 ITEM 002 KO-PACK 250 LABEL LETTERPRESS PRINTING MACHINE YEAR 1979 OVERHAULED ON 1996 QUANTITY: 1 ITEM 003 FRANCHINI F330 LABEL MACHINE YEAR 1992 QUANTITY: 1 Learn More

TT-4438 GALLUS / KO-PACK / FRANCHINI LABEL MACHINES, WIDTH 170mm TO 250mm, YEAR 1979 TO 1992TT-4438 GALLUS / KO-PACK / FRANCHINI LABEL MACHINES, WIDTH 170mm TO 250mm, YEAR 1979 TO 1992 ITEM 001 GALLUS R160 B02 LABEL LETTERPRESS PRINTING MACHINE YEAR 1986 OVERHAULED ON 1998 QUANTITY: 1 ITEM 002 KO-PACK 250 LABEL LETTERPRESS PRINTING MACHINE YEAR 1979 OVERHAULED ON 1996 QUANTITY: 1 ITEM 003 FRANCHINI F330 LABEL MACHINE YEAR 1992 QUANTITY: 1 Learn More -

TT-7625 NILPETER FA4250 FLEXO LABEL PRINTING PRESS, YEAR 2007TT-7625 NILPETER FA4250 FLEXO LABEL PRINTING PRESS, YEAR 2007 1. BRAND: NILPETER 2. MODEL: FA 4250 3. YEAR: 2007 4. NUMBER OF COLORS: 8 QUANTITY: 1 Learn More

TT-7625 NILPETER FA4250 FLEXO LABEL PRINTING PRESS, YEAR 2007TT-7625 NILPETER FA4250 FLEXO LABEL PRINTING PRESS, YEAR 2007 1. BRAND: NILPETER 2. MODEL: FA 4250 3. YEAR: 2007 4. NUMBER OF COLORS: 8 QUANTITY: 1 Learn More -

TT-1908 FRANCHINI SERIGON 350 LABEL SCREEN PRINTING, WIDTH 350mm, YEAR 2008TT-1908 FRANCHINI SERIGON 350 LABEL SCREEN PRINTING, WIDTH 350mm, YEAR 2008 QUANTITY: 1 Learn More

TT-1908 FRANCHINI SERIGON 350 LABEL SCREEN PRINTING, WIDTH 350mm, YEAR 2008TT-1908 FRANCHINI SERIGON 350 LABEL SCREEN PRINTING, WIDTH 350mm, YEAR 2008 QUANTITY: 1 Learn More -

T-9660 COMCO FLEXO LABEL PRESS, 11 COLORS, 22”, YEAR 1999T-9660 COMCO FLEXO LABEL PRESS, 11 COLORS, 22”, YEAR 1999 NOTES: INCLUDES GAS FIRED DRYING SYSTEM IN P/S 1-10, CHAMBERED DR. BLADE ASSEMBLIES, UV LAMINATION IN P/S 11, FORWARD/REVERSE PRINT IN P/S 1, KTI LS BUTT SPLICER ON UNWIND, KTI MR TWO-SPINDLE TURRET REWIND, KTI LAM UNWIND W/WEB GUIDE, 2012 ENERCON COMPAK 2000 CORONA TREATER AND 2006 CARRIER AQUA-SNAP 22-TON CHILLER. COMPLETE PRESS REBUILD IN 2012. 1. IN ADDITION WATER BASED LAMINATION CAPABILITIES IN STATION 11 WITH RUN SPEEDS UP TO 425 FPM DEPENDING ON STRUCTURE. 2. ENERCON TREATER REBUILT ON 6/5/2020. 3. COATING SLEEVE CYLINDER AND SLEEVE CHANGE OUT AIR STAND FOR GLUE STATION. 4. EXTENSIVE PLATE CYLINDER LIBRARY 5. ADDITIONAL DOCTOR BLADE CHAMBERS Learn More

T-9660 COMCO FLEXO LABEL PRESS, 11 COLORS, 22”, YEAR 1999T-9660 COMCO FLEXO LABEL PRESS, 11 COLORS, 22”, YEAR 1999 NOTES: INCLUDES GAS FIRED DRYING SYSTEM IN P/S 1-10, CHAMBERED DR. BLADE ASSEMBLIES, UV LAMINATION IN P/S 11, FORWARD/REVERSE PRINT IN P/S 1, KTI LS BUTT SPLICER ON UNWIND, KTI MR TWO-SPINDLE TURRET REWIND, KTI LAM UNWIND W/WEB GUIDE, 2012 ENERCON COMPAK 2000 CORONA TREATER AND 2006 CARRIER AQUA-SNAP 22-TON CHILLER. COMPLETE PRESS REBUILD IN 2012. 1. IN ADDITION WATER BASED LAMINATION CAPABILITIES IN STATION 11 WITH RUN SPEEDS UP TO 425 FPM DEPENDING ON STRUCTURE. 2. ENERCON TREATER REBUILT ON 6/5/2020. 3. COATING SLEEVE CYLINDER AND SLEEVE CHANGE OUT AIR STAND FOR GLUE STATION. 4. EXTENSIVE PLATE CYLINDER LIBRARY 5. ADDITIONAL DOCTOR BLADE CHAMBERS Learn More -

M-3011 PORTER AUTOMATIC LABEL SEWERREFERENCE NUMBER: M-3011 (770KIDEXX6) PORTER AUTOMATIC LABEL SEWER AUTOMATIC LABEL SEWER MODEL: PALS-4000 QUANTITY AVAILABLE: 1 Learn More

M-3011 PORTER AUTOMATIC LABEL SEWERREFERENCE NUMBER: M-3011 (770KIDEXX6) PORTER AUTOMATIC LABEL SEWER AUTOMATIC LABEL SEWER MODEL: PALS-4000 QUANTITY AVAILABLE: 1 Learn More -

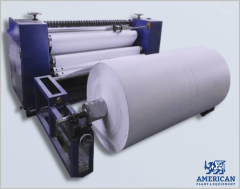

YY-2703 SLITTER REWINDER FOR PLASTIC FILMS LABEL MATERIAL, ETC., UP TO 1600mm WIDEYY-2703 SLITTER REWINDER FOR PLASTIC FILMS LABEL MATERIAL, ETC., UP TO 1600mm WIDE FEATURES: HOT BLADE CUTTING SYSTEM FOR WOVEN LABELS COLD BLADE CUTTING SYSTEM FOR NON-WOVEN LABELS EASY OPERATION STABLE WORKING AND LONG LIFE QUANTITY: 1 Learn More

YY-2703 SLITTER REWINDER FOR PLASTIC FILMS LABEL MATERIAL, ETC., UP TO 1600mm WIDEYY-2703 SLITTER REWINDER FOR PLASTIC FILMS LABEL MATERIAL, ETC., UP TO 1600mm WIDE FEATURES: HOT BLADE CUTTING SYSTEM FOR WOVEN LABELS COLD BLADE CUTTING SYSTEM FOR NON-WOVEN LABELS EASY OPERATION STABLE WORKING AND LONG LIFE QUANTITY: 1 Learn More -

TT-6699 COMPLETE BOTTLING LINE, YEAR 2013TT-6699 COMPLETE BOTTLING LINE, YEAR 2013 1. COMPOSED OF FILLING MONOBLOCK + LABELING MACHINE 2. SPEED: 700 BPH 3. CONTAINERS: GLASS 4. FORMATS: 0.33 L 5. PRODUCT: BEER 6. FILL TYPE: ISOBARIC QUANTITY: 1 Learn More

TT-6699 COMPLETE BOTTLING LINE, YEAR 2013TT-6699 COMPLETE BOTTLING LINE, YEAR 2013 1. COMPOSED OF FILLING MONOBLOCK + LABELING MACHINE 2. SPEED: 700 BPH 3. CONTAINERS: GLASS 4. FORMATS: 0.33 L 5. PRODUCT: BEER 6. FILL TYPE: ISOBARIC QUANTITY: 1 Learn More -

J-1563 COFFEE, SYRUP, LABELERS, CARTONERS AND SIMILAR EQUIPMENT

J-1563 COFFEE, SYRUP, LABELERS, CARTONERS AND SIMILAR EQUIPMENTCOFFEE, SYRUP, LABELERS, CARTONERS AND SIMILAR EQUIPMENT

Learn More -

P-4325 WET WIPES PRODUCTION LINE

P-4325 WET WIPES PRODUCTION LINEREFERENCE NUMBER: P-4325

WET WIPES PRODUCTION LINE

Model L40

Machine Characteristic

Control system: Multi-Axis Motion Controller

Drive element: servo motor

Operate interface: 10" LCD touch screen

Cutting: synchronous flail knife

Packing style: end seal & reciprocating type(connecting 2 packing machine need explain)

Unwinding structure: 40 sets, 40 electronic eyes detect online(16 sets big rolls material)

Auto splicing: film automatic splicing, label automatic switching

Frequency division detection: nonwoven, film, label detect respectively

Frequency division pulling: 2 sets dry wipes pulling , 2 sets wet wipes pulling

Auto splicing: film automatic splicing, label automatic switching

Frequency division detection: nonwoven ,film, label detect respectively

Metal detect: online metal detector

Inferior eliminate: aluminizing paste connector rejected online

Flow control: 2.5-4 times, flow meter control, no liquid recovery

Moisture type: 40 fluid pipes spray independently

SUS Agitate tank: 2 sets, 1000L stainless steel agitate tank

Liquid level control: electronic detection, auto control

Specifications

Raw material: spunlaced nonwoven, therbond etc. nonwovens

Raw material specification: max W220mm, φ1400mm, max W1050mm, φ1000mm

Axis QTY settings:40 rolls raw materials (auto splicing type 32 rolls)

Diameter of ventilating shaft: 3"

Suitable packing material :BOPP PET/PE PET/AL/PE etc. heat-seal material

Packing Film specification: max W420mm, φ350mm

Axis QTY settings: 2 sets film, automatic splicing without stopping machine

Diameter of ventilating shaft: 3"

Suitable label: transparent label & opaque label

Label size: max W100mm φ400mm

Axis QTY settings: 2 sets label, automatic switching without stopping(can be set as safety label)

Diameter of ventilating shaft: 3"

Folding type: single extraction & interfold type

Wet wipes size:L120-220mm W90-110mm

Open size: L120-220mm W150-220mm

Package size: L150-350mm W80-120mm H10-80mm

Design speed: 60bags/min &250cutting/min

Production speed: 50 bags/min &200 cutting/min

Machine space: L31000mm W2500mm H2100mm. L32600mm W3600mm H2100mm(auto splicing machine)

Power: AC 380V 50/60Hz 22KW(auto splicing machine:25KW)

Compressed air: 0.6-0.8Mpa 400L/min

Machine net weight :22000kg(auto splicing machine 25000Kg)

Option equipment: Coding machine Big roll material automatic splicingQUANTITY: 1

Learn More