J-4363 AUTOMATIC PET PAD MAKING MACHINE, 200 PADS PER MINUTE

REFERENCE NUMBER: J-4363

AUTOMATIC PET PAD MAKING MACHINE, 200 PADS PER MINUTE

FOR PRODUCTS 450 TO 1500mm, COTTON CORE BETWEEN 400 TO 1000mm

TOUCH SCREEN WITH ADJUSTABLE PRODUCT REQUIREMENTS IN 450 TO 600mm, COTTON CORE IN 400 TO 550mm

PRODUCT STRUCTURE: SURFACE LAYER, BACKING PAPER, COTTON CORE, SAP, BASEMENT MEMBRANE

STABLE PRODUCTION SPEED: 120 METERS PER MINUTE

IF THE SIZE OF THE FINISHED PRODUCT IS 600 x 600mm, THE MACHINE RUNNING SPEED IS 200 PIECES PER MINUTE (8 HOUR OUTPUT IS 96,000 PIECES)

MACHINE DIMENSIONS: 16000 x 2200 x 2600mm (LENGTH x WIDTH x HEIGHT)

POWER SUPPLY: 380 VOLTS, 50 Hz

TOTAL POWER: ABOUT 80 KW (NOT INCLUDING GLUE)

PRESSURE: 1100 LITERS PER MINUTE, 6 TO 8 BARS

YIELD: 98% OR GREATER (EXCLUDING ERRORS DUE TO GLUE MACHINE, MATERIAL EXCHANGE AND JOINTS CAUSED BY DEFECTIVE GOODS)

QUANTITY: 1

In stock

SKU

J-4363

REFERENCE NUMBER: J-4363

AUTOMATIC PET PAD MAKING MACHINE, 200 PADS PER MINUTE

FOR PRODUCTS 450 TO 1500mm, COTTON CORE BETWEEN 400 TO 1000mm

TOUCH SCREEN WITH ADJUSTABLE PRODUCT REQUIREMENTS IN 450 TO 600mm, COTTON CORE IN 400 TO 550mm

PRODUCT STRUCTURE: SURFACE LAYER, BACKING PAPER, COTTON CORE, SAP, BASEMENT MEMBRANE

STABLE PRODUCTION SPEED: 120 METERS PER MINUTE

IF THE SIZE OF THE FINISHED PRODUCT IS 600 x 600mm, THE MACHINE RUNNING SPEED IS 200 PIECES PER MINUTE (8 HOUR OUTPUT IS 96,000 PIECES)

MACHINE DIMENSIONS: 16000 x 2200 x 2600mm (LENGTH x WIDTH x HEIGHT)

POWER SUPPLY: 380 VOLTS, 50 Hz

TOTAL POWER: ABOUT 80 KW (NOT INCLUDING GLUE)

PRESSURE: 1100 LITERS PER MINUTE, 6 TO 8 BARS

YIELD: 98% OR GREATER (EXCLUDING ERRORS DUE TO GLUE MACHINE, MATERIAL EXCHANGE AND JOINTS CAUSED BY DEFECTIVE GOODS)

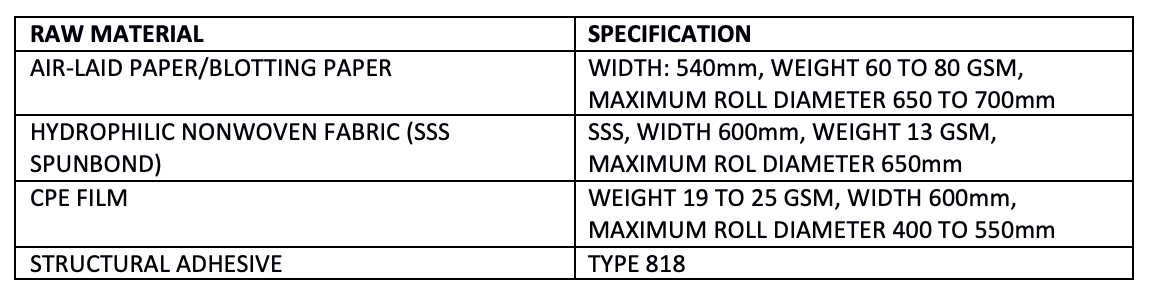

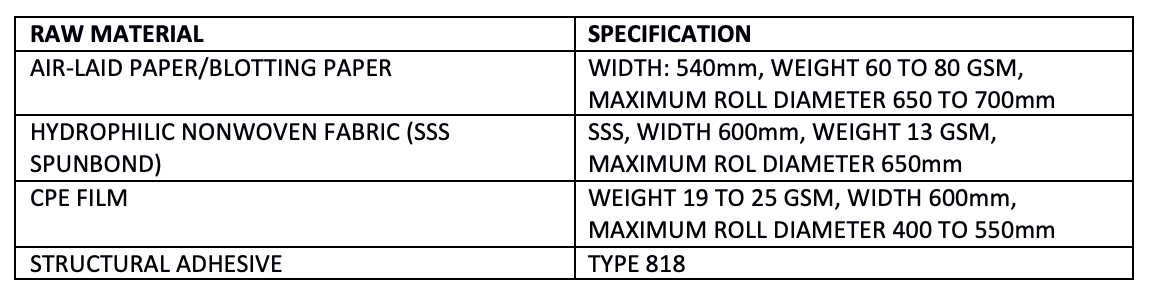

THERE ARE 3 LAYERS OF RAW MATERIALS IN TOTAL. THEY ARE PE FILM, ABSORBENT LAYER, HYDROPHILIC NONWOVEN FABRIC. THE ABSORBEN LAYER IS COMPOSED OF TWO LAYERS OF TISSUE WITH SAP AND FLUFF BETWEEN THEM.

THE MIDDLE ABSORBENT LAYER IS A SEMI-FINISHED PRODUCT. WOOD PULP PAPER AND SAP ARE PRE-MIXED AND SANDWICHED BETWEEN THE UPPER AND LOWER ABSORBENT PAPERS.

PERCENTAGE OF SAP: 20 TO 25%

PERCENTAGE OF WOOD PULP PAPER: 45 TO 60%

RAW MATERIALS PER 40 FOOT CONTAINER: DEPENDS ON THE SIZE OF THE FINISHED PRODUCT BEING PRODUCED. FOR EXAMPLE, FINISHED PRODUCT SIZE OF 600 x 600mm: A 40 FOOT CONTAINER HOLDS ABOUT 100 ROLLS OF PE FILM, 100 ROLLS OF HYDROPHILIC NONWOVEN FABRIC AND 150 ROLLS OF ABSORBENT LAYER

UNWINDING PART: ACTIVE UNCOILING OF RAW MATERIALS

• BELT FRICTION TO MATCH A SET OF CORE BODY VOLUME INFINITELY ADJUSTABLE-SPEED PULLEY FRICTION

• FABRIC BELT FRICTION TO MATCH A SET OF INFINITE SPEED FRICTION PULLEY VOLUME

• BOTTOM MEMBRANE ROLLING WITH AN INFINITELY ADJUSTABLE-SPEED PULLEY BELT FRICTION VOLUME

KNIFE MOLD PART:

• ABSORBER EMBOSSING DEVICE, 1 SET

• ABSORBER CUTTING (INTERNAL CUTTING) DEVICE, 1 SET (WITH 1 SET SERVO DRIVE)

• PRODUCTS TRI-FOLDING DEVICE, 1 SET (WITH 2 SERVO DRIVES) (CUSTOM 5 PANEL FOLD IS AVAILABLE)

• PRODUCTS PRESSURE DEVICE, 1 SET

• CUTTER DEVICE, 1 SET (WITH SERVO DRIVE)

• OUTPUT CONVEYOR BELT DEVICE, 1 SET

FRAME WALLBOARD, TRANSMISSION PART:

• PANEL USES 20mm STEEL PLATE AND BASE FRAME USES 120 x 120mm SQUARE TUBING

• MACHINE USES MECHANICAL DRIVE OF COUPLING, TIMING BELT AND MULTI-AXIS CONNECTION

• MAIN DRIVE USES HIGH-PRECISION HELICAL GEARBOX UNIVERSAL JOINT CONNECTION TO ENSURE MORE STABLE HIGH-SPEED OPERATION

• FINISHED PRODUCT IS ARRANGED AND OUTPUT BY THE OUTPUT MECHANISM

AIR CIRCUIT PART:

• AIR CIRCUIT OF THE MACHINE IS MADE OF IRON PIPE AND THE HIGH-PRESSURE UNIFIED AIR SUPPLY IS USED.

• THE BRAND AIR PIPE IS CONNECTED WITH REINFORCED PLASTIC PIPE AND THE SUCTION OF EACH SECTION OF AIR IS ADJUSTABLE

ELECTRICAL PARTS:

• FREQUENCY CONVERSION AND SERVO MOTOR OF THE DRIVE ARE DRIVEN BY PULSE SERVO SPEED CONTROL OF THE PLC MOTION CONTROLLER

• CUTTING KNIFE AND FOLDING KNIFE ARE DRIVEN BY SERVO MOTOR AND THE SPECIFICATIONS ARE ADJUSTABLE

• AUTOMATIC TEMPERATURE CONTROL OF HEATING MOLD AND TEMPERATURE METER DISPLAYS THE CURENT TEMPERATURE IN REAL TIME USING A CONDUCTIVE COLLECTOR RING

• FRONT AND BACK OF THE MACHINE ARE INSTALLED IN MANY PLACES TO PROMPT THE BELL BUTTON AND ELEVATOR BUTTON

• A “LIFELINE” IS INSTALLED ON THE TRANSMISSION SIDE

• COOPERATES WITH THE GLUE GUN OF THE GLUE MACHINE TO AUTOMATICALLY TRACK THE GLUE APPLICATION AMOUNT. THE MAIN MACHINE AND THE GLUE MELTER CAN REALIZE AUTOMATIC GLUE APPLICATION AND AUTOMATICALLY STOP AT SHUT DOWN. MANUAL CONTROL ALSO POSSIBLE.

• GLUE MACHINE BRAND IS CHINESE “GOLD” BRAND

• GLUE MACHINE TANK CAPACITY: 30 KG

COMPONENTS:

RAW MATERIALS PER 40 FOOT CONTAINER: DEPENDS ON THE SIZE OF THE FINISHED PRODUCT BEING PRODUCED. FOR EXAMPLE, FINISHED PRODUCT SIZE OF 600 x 600mm: A 40 FOOT CONTAINER HOLDS ABOUT 100 ROLLS OF PE FILM, 100 ROLLS OF HYDROPHILIC NONWOVEN FABRIC AND 150 ROLLS OF ABSORBENT LAYER

UNWINDING PART: ACTIVE UNCOILING OF RAW MATERIALS

• BELT FRICTION TO MATCH A SET OF CORE BODY VOLUME INFINITELY ADJUSTABLE-SPEED PULLEY FRICTION

• FABRIC BELT FRICTION TO MATCH A SET OF INFINITE SPEED FRICTION PULLEY VOLUME

• BOTTOM MEMBRANE ROLLING WITH AN INFINITELY ADJUSTABLE-SPEED PULLEY BELT FRICTION VOLUME

KNIFE MOLD PART:

• ABSORBER EMBOSSING DEVICE, 1 SET

• ABSORBER CUTTING (INTERNAL CUTTING) DEVICE, 1 SET (WITH 1 SET SERVO DRIVE)

• PRODUCTS TRI-FOLDING DEVICE, 1 SET (WITH 2 SERVO DRIVES) (CUSTOM 5 PANEL FOLD IS AVAILABLE)

• PRODUCTS PRESSURE DEVICE, 1 SET

• CUTTER DEVICE, 1 SET (WITH SERVO DRIVE)

• OUTPUT CONVEYOR BELT DEVICE, 1 SET

FRAME WALLBOARD, TRANSMISSION PART:

• PANEL USES 20mm STEEL PLATE AND BASE FRAME USES 120 x 120mm SQUARE TUBING

• MACHINE USES MECHANICAL DRIVE OF COUPLING, TIMING BELT AND MULTI-AXIS CONNECTION

• MAIN DRIVE USES HIGH-PRECISION HELICAL GEARBOX UNIVERSAL JOINT CONNECTION TO ENSURE MORE STABLE HIGH-SPEED OPERATION

• FINISHED PRODUCT IS ARRANGED AND OUTPUT BY THE OUTPUT MECHANISM

AIR CIRCUIT PART:

• AIR CIRCUIT OF THE MACHINE IS MADE OF IRON PIPE AND THE HIGH-PRESSURE UNIFIED AIR SUPPLY IS USED.

• THE BRAND AIR PIPE IS CONNECTED WITH REINFORCED PLASTIC PIPE AND THE SUCTION OF EACH SECTION OF AIR IS ADJUSTABLE

ELECTRICAL PARTS:

• FREQUENCY CONVERSION AND SERVO MOTOR OF THE DRIVE ARE DRIVEN BY PULSE SERVO SPEED CONTROL OF THE PLC MOTION CONTROLLER

• CUTTING KNIFE AND FOLDING KNIFE ARE DRIVEN BY SERVO MOTOR AND THE SPECIFICATIONS ARE ADJUSTABLE

• AUTOMATIC TEMPERATURE CONTROL OF HEATING MOLD AND TEMPERATURE METER DISPLAYS THE CURENT TEMPERATURE IN REAL TIME USING A CONDUCTIVE COLLECTOR RING

• FRONT AND BACK OF THE MACHINE ARE INSTALLED IN MANY PLACES TO PROMPT THE BELL BUTTON AND ELEVATOR BUTTON

• A “LIFELINE” IS INSTALLED ON THE TRANSMISSION SIDE

• COOPERATES WITH THE GLUE GUN OF THE GLUE MACHINE TO AUTOMATICALLY TRACK THE GLUE APPLICATION AMOUNT. THE MAIN MACHINE AND THE GLUE MELTER CAN REALIZE AUTOMATIC GLUE APPLICATION AND AUTOMATICALLY STOP AT SHUT DOWN. MANUAL CONTROL ALSO POSSIBLE.

• GLUE MACHINE BRAND IS CHINESE “GOLD” BRAND

• GLUE MACHINE TANK CAPACITY: 30 KG

COMPONENTS:

RECOMMENDED SPARE PARTS: INTERNAL AND EXTERNAL CUTTING BLADES, ELECTRIC HEATING TUBES, FLAT BELTS AND SYNCHRONOUS BELTS

REQUIRED FLOORSPACE: LENGTH 16000 x WIDTH 2200 x HEIGHT 2600mm

REQUIRES 1 40 FOOT HQ CONTAINER AND 1 20 FOOT CONTAINER TO SHIP

QUANTITY: 1

RECOMMENDED SPARE PARTS: INTERNAL AND EXTERNAL CUTTING BLADES, ELECTRIC HEATING TUBES, FLAT BELTS AND SYNCHRONOUS BELTS

REQUIRED FLOORSPACE: LENGTH 16000 x WIDTH 2200 x HEIGHT 2600mm

REQUIRES 1 40 FOOT HQ CONTAINER AND 1 20 FOOT CONTAINER TO SHIP

QUANTITY: 1

RAW MATERIALS PER 40 FOOT CONTAINER: DEPENDS ON THE SIZE OF THE FINISHED PRODUCT BEING PRODUCED. FOR EXAMPLE, FINISHED PRODUCT SIZE OF 600 x 600mm: A 40 FOOT CONTAINER HOLDS ABOUT 100 ROLLS OF PE FILM, 100 ROLLS OF HYDROPHILIC NONWOVEN FABRIC AND 150 ROLLS OF ABSORBENT LAYER

UNWINDING PART: ACTIVE UNCOILING OF RAW MATERIALS

• BELT FRICTION TO MATCH A SET OF CORE BODY VOLUME INFINITELY ADJUSTABLE-SPEED PULLEY FRICTION

• FABRIC BELT FRICTION TO MATCH A SET OF INFINITE SPEED FRICTION PULLEY VOLUME

• BOTTOM MEMBRANE ROLLING WITH AN INFINITELY ADJUSTABLE-SPEED PULLEY BELT FRICTION VOLUME

KNIFE MOLD PART:

• ABSORBER EMBOSSING DEVICE, 1 SET

• ABSORBER CUTTING (INTERNAL CUTTING) DEVICE, 1 SET (WITH 1 SET SERVO DRIVE)

• PRODUCTS TRI-FOLDING DEVICE, 1 SET (WITH 2 SERVO DRIVES) (CUSTOM 5 PANEL FOLD IS AVAILABLE)

• PRODUCTS PRESSURE DEVICE, 1 SET

• CUTTER DEVICE, 1 SET (WITH SERVO DRIVE)

• OUTPUT CONVEYOR BELT DEVICE, 1 SET

FRAME WALLBOARD, TRANSMISSION PART:

• PANEL USES 20mm STEEL PLATE AND BASE FRAME USES 120 x 120mm SQUARE TUBING

• MACHINE USES MECHANICAL DRIVE OF COUPLING, TIMING BELT AND MULTI-AXIS CONNECTION

• MAIN DRIVE USES HIGH-PRECISION HELICAL GEARBOX UNIVERSAL JOINT CONNECTION TO ENSURE MORE STABLE HIGH-SPEED OPERATION

• FINISHED PRODUCT IS ARRANGED AND OUTPUT BY THE OUTPUT MECHANISM

AIR CIRCUIT PART:

• AIR CIRCUIT OF THE MACHINE IS MADE OF IRON PIPE AND THE HIGH-PRESSURE UNIFIED AIR SUPPLY IS USED.

• THE BRAND AIR PIPE IS CONNECTED WITH REINFORCED PLASTIC PIPE AND THE SUCTION OF EACH SECTION OF AIR IS ADJUSTABLE

ELECTRICAL PARTS:

• FREQUENCY CONVERSION AND SERVO MOTOR OF THE DRIVE ARE DRIVEN BY PULSE SERVO SPEED CONTROL OF THE PLC MOTION CONTROLLER

• CUTTING KNIFE AND FOLDING KNIFE ARE DRIVEN BY SERVO MOTOR AND THE SPECIFICATIONS ARE ADJUSTABLE

• AUTOMATIC TEMPERATURE CONTROL OF HEATING MOLD AND TEMPERATURE METER DISPLAYS THE CURENT TEMPERATURE IN REAL TIME USING A CONDUCTIVE COLLECTOR RING

• FRONT AND BACK OF THE MACHINE ARE INSTALLED IN MANY PLACES TO PROMPT THE BELL BUTTON AND ELEVATOR BUTTON

• A “LIFELINE” IS INSTALLED ON THE TRANSMISSION SIDE

• COOPERATES WITH THE GLUE GUN OF THE GLUE MACHINE TO AUTOMATICALLY TRACK THE GLUE APPLICATION AMOUNT. THE MAIN MACHINE AND THE GLUE MELTER CAN REALIZE AUTOMATIC GLUE APPLICATION AND AUTOMATICALLY STOP AT SHUT DOWN. MANUAL CONTROL ALSO POSSIBLE.

• GLUE MACHINE BRAND IS CHINESE “GOLD” BRAND

• GLUE MACHINE TANK CAPACITY: 30 KG

COMPONENTS:

RAW MATERIALS PER 40 FOOT CONTAINER: DEPENDS ON THE SIZE OF THE FINISHED PRODUCT BEING PRODUCED. FOR EXAMPLE, FINISHED PRODUCT SIZE OF 600 x 600mm: A 40 FOOT CONTAINER HOLDS ABOUT 100 ROLLS OF PE FILM, 100 ROLLS OF HYDROPHILIC NONWOVEN FABRIC AND 150 ROLLS OF ABSORBENT LAYER

UNWINDING PART: ACTIVE UNCOILING OF RAW MATERIALS

• BELT FRICTION TO MATCH A SET OF CORE BODY VOLUME INFINITELY ADJUSTABLE-SPEED PULLEY FRICTION

• FABRIC BELT FRICTION TO MATCH A SET OF INFINITE SPEED FRICTION PULLEY VOLUME

• BOTTOM MEMBRANE ROLLING WITH AN INFINITELY ADJUSTABLE-SPEED PULLEY BELT FRICTION VOLUME

KNIFE MOLD PART:

• ABSORBER EMBOSSING DEVICE, 1 SET

• ABSORBER CUTTING (INTERNAL CUTTING) DEVICE, 1 SET (WITH 1 SET SERVO DRIVE)

• PRODUCTS TRI-FOLDING DEVICE, 1 SET (WITH 2 SERVO DRIVES) (CUSTOM 5 PANEL FOLD IS AVAILABLE)

• PRODUCTS PRESSURE DEVICE, 1 SET

• CUTTER DEVICE, 1 SET (WITH SERVO DRIVE)

• OUTPUT CONVEYOR BELT DEVICE, 1 SET

FRAME WALLBOARD, TRANSMISSION PART:

• PANEL USES 20mm STEEL PLATE AND BASE FRAME USES 120 x 120mm SQUARE TUBING

• MACHINE USES MECHANICAL DRIVE OF COUPLING, TIMING BELT AND MULTI-AXIS CONNECTION

• MAIN DRIVE USES HIGH-PRECISION HELICAL GEARBOX UNIVERSAL JOINT CONNECTION TO ENSURE MORE STABLE HIGH-SPEED OPERATION

• FINISHED PRODUCT IS ARRANGED AND OUTPUT BY THE OUTPUT MECHANISM

AIR CIRCUIT PART:

• AIR CIRCUIT OF THE MACHINE IS MADE OF IRON PIPE AND THE HIGH-PRESSURE UNIFIED AIR SUPPLY IS USED.

• THE BRAND AIR PIPE IS CONNECTED WITH REINFORCED PLASTIC PIPE AND THE SUCTION OF EACH SECTION OF AIR IS ADJUSTABLE

ELECTRICAL PARTS:

• FREQUENCY CONVERSION AND SERVO MOTOR OF THE DRIVE ARE DRIVEN BY PULSE SERVO SPEED CONTROL OF THE PLC MOTION CONTROLLER

• CUTTING KNIFE AND FOLDING KNIFE ARE DRIVEN BY SERVO MOTOR AND THE SPECIFICATIONS ARE ADJUSTABLE

• AUTOMATIC TEMPERATURE CONTROL OF HEATING MOLD AND TEMPERATURE METER DISPLAYS THE CURENT TEMPERATURE IN REAL TIME USING A CONDUCTIVE COLLECTOR RING

• FRONT AND BACK OF THE MACHINE ARE INSTALLED IN MANY PLACES TO PROMPT THE BELL BUTTON AND ELEVATOR BUTTON

• A “LIFELINE” IS INSTALLED ON THE TRANSMISSION SIDE

• COOPERATES WITH THE GLUE GUN OF THE GLUE MACHINE TO AUTOMATICALLY TRACK THE GLUE APPLICATION AMOUNT. THE MAIN MACHINE AND THE GLUE MELTER CAN REALIZE AUTOMATIC GLUE APPLICATION AND AUTOMATICALLY STOP AT SHUT DOWN. MANUAL CONTROL ALSO POSSIBLE.

• GLUE MACHINE BRAND IS CHINESE “GOLD” BRAND

• GLUE MACHINE TANK CAPACITY: 30 KG

COMPONENTS:

RECOMMENDED SPARE PARTS: INTERNAL AND EXTERNAL CUTTING BLADES, ELECTRIC HEATING TUBES, FLAT BELTS AND SYNCHRONOUS BELTS

REQUIRED FLOORSPACE: LENGTH 16000 x WIDTH 2200 x HEIGHT 2600mm

REQUIRES 1 40 FOOT HQ CONTAINER AND 1 20 FOOT CONTAINER TO SHIP

QUANTITY: 1

RECOMMENDED SPARE PARTS: INTERNAL AND EXTERNAL CUTTING BLADES, ELECTRIC HEATING TUBES, FLAT BELTS AND SYNCHRONOUS BELTS

REQUIRED FLOORSPACE: LENGTH 16000 x WIDTH 2200 x HEIGHT 2600mm

REQUIRES 1 40 FOOT HQ CONTAINER AND 1 20 FOOT CONTAINER TO SHIP

QUANTITY: 1

| Video | https://youtu.be/41w_LqI-vpM |

|---|

Write Your Own Review