Face Mask Making Machine

-

J-3392 AUTOMATIC 3-PLEAT HEADBAND FISH-STYLE FACE MASK MACHINE -CAPACITY: 45 TO 50 PIECES PER MINUTE -INCLUDES PRINTING ON MASKS -INCLUDES NOSE FOAM INSERTION (CLOSED CELL FOAM)J-3392 AUTOMATIC 3-PLEAT HEADBAND FISH-STYLE FACE MASK MACHINE -CAPACITY: 45 TO 50 PIECES PER MINUTE -INCLUDES PRINTING ON MASKS -INCLUDES NOSE FOAM INSERTION (CLOSED CELL FOAM) REQUIRES 1 TO 2 OPERATORS WITH PLC CONTROLS WEIGHT: 1600 KGS VOLTAGE: 220 VOLTS POWER: 6 KW ULTRASONIC FREQUENCY: 20 kHz GAS PRESSURE: 6 KG PER cm2 QUANTITY: 1 Learn More

J-3392 AUTOMATIC 3-PLEAT HEADBAND FISH-STYLE FACE MASK MACHINE -CAPACITY: 45 TO 50 PIECES PER MINUTE -INCLUDES PRINTING ON MASKS -INCLUDES NOSE FOAM INSERTION (CLOSED CELL FOAM)J-3392 AUTOMATIC 3-PLEAT HEADBAND FISH-STYLE FACE MASK MACHINE -CAPACITY: 45 TO 50 PIECES PER MINUTE -INCLUDES PRINTING ON MASKS -INCLUDES NOSE FOAM INSERTION (CLOSED CELL FOAM) REQUIRES 1 TO 2 OPERATORS WITH PLC CONTROLS WEIGHT: 1600 KGS VOLTAGE: 220 VOLTS POWER: 6 KW ULTRASONIC FREQUENCY: 20 kHz GAS PRESSURE: 6 KG PER cm2 QUANTITY: 1 Learn More -

VJ-1116 FULLY AUTOMATIC FLAT FACE MASK PRODUCTION LINE, 300 MASKS PER MINUTEVJ-1116 FULLY AUTOMATIC FLAT FACE MASK PRODUCTION LINE, 300 MASKS PER MINUTE MASK BODY PRODUCTION WITH AUTOMATIC FEEDING TO EAR LOOP WELDING FOR COMPLETE, AUTOMATED PRODUCTION MASK TYPE: SURGICAL, FLAT MASK WITH EAR LOOPS MASK DIMENSIONS: 175 x 95mm CAPACITY: 250 TO 300 PIECES PER MINUTE (FINISHED PRODUCT) NONWOVEN MATERIAL: SPUNBONDED AND MELT-BLOWN FABRIC QUANTITY: 1 Learn More

VJ-1116 FULLY AUTOMATIC FLAT FACE MASK PRODUCTION LINE, 300 MASKS PER MINUTEVJ-1116 FULLY AUTOMATIC FLAT FACE MASK PRODUCTION LINE, 300 MASKS PER MINUTE MASK BODY PRODUCTION WITH AUTOMATIC FEEDING TO EAR LOOP WELDING FOR COMPLETE, AUTOMATED PRODUCTION MASK TYPE: SURGICAL, FLAT MASK WITH EAR LOOPS MASK DIMENSIONS: 175 x 95mm CAPACITY: 250 TO 300 PIECES PER MINUTE (FINISHED PRODUCT) NONWOVEN MATERIAL: SPUNBONDED AND MELT-BLOWN FABRIC QUANTITY: 1 Learn More -

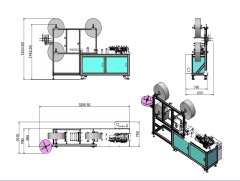

VJ-1117 MASK MAKING MACHINE WITH HIGH SPEED 300 TO 400 MASKS PER MINUTEVJ-1117 MASK MAKING MACHINE WITH HIGH SPEED 300 TO 400 MASKS PER MINUTE MACHINE WEIGHT: 450 KGS MACHINE DIMENSIONS: 3400 LONG X 800 WIDE X 2020 mm HIGH VOLTAGE: 220V SINGLE PHASE POWER: 3 KW Learn More

VJ-1117 MASK MAKING MACHINE WITH HIGH SPEED 300 TO 400 MASKS PER MINUTEVJ-1117 MASK MAKING MACHINE WITH HIGH SPEED 300 TO 400 MASKS PER MINUTE MACHINE WEIGHT: 450 KGS MACHINE DIMENSIONS: 3400 LONG X 800 WIDE X 2020 mm HIGH VOLTAGE: 220V SINGLE PHASE POWER: 3 KW Learn More -

INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINEREFERENCE NUMBER: A-2490 INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF THE MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.5 TO 0.7 MPA USAGE FLOW: 150 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 90 PCS/min FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EARBELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More

INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINEREFERENCE NUMBER: A-2490 INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF THE MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.5 TO 0.7 MPA USAGE FLOW: 150 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 90 PCS/min FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EARBELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More -

OUTER EARLOOP MASK PRODUCTION LINEREFERENCE NUMBER: A-2489 OUTER EARLOOP MASK PRODUCTION LINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, WITH BEAUTIFUL STYLE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm ULTRASONIC: 3 PCS, 20 K 2000W NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.4 TO 0.7 MPA USAGE FLOW: 300 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 70 PCS/min ACCURACY: ≥99% EXCLUDING RAW MATERIAL DEFECTS AND MISOPERATION FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EAR BELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More

OUTER EARLOOP MASK PRODUCTION LINEREFERENCE NUMBER: A-2489 OUTER EARLOOP MASK PRODUCTION LINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, WITH BEAUTIFUL STYLE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm ULTRASONIC: 3 PCS, 20 K 2000W NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.4 TO 0.7 MPA USAGE FLOW: 300 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 70 PCS/min ACCURACY: ≥99% EXCLUDING RAW MATERIAL DEFECTS AND MISOPERATION FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EAR BELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More -

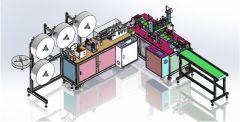

FULLY AUTOMATIC MASK MACHINEREFERENCE NUMBER: P-8845 FULLY AUTOMATIC MASK MACHINE THIS EQUIPMENT IS A FULL-AUTOMATIC ONE-TIME PLANE MASK FORMING MACHINE, WHICH IS USED FOR THE FORMING OF ONE-TIME RECTANGULAR EAR HANGING THREE DRAWER MASKS. ONE MAIN MACHINE IS EQUIPPED WITH TWO EAR BELT SPOT WELDING MACHINES (ONE FOR TWO). THE DRIVING MOTOR IS SERVO MOTOR, SO IT HAS THE ADVANTAGES OF HIGH RELIABILITY, EASY OPERATION, ACCURATE TRANSMISSION, STABLE CONTROL, ADJUSTABLE SPEED, LOW COST AND CONVENIENT MAINTENANCE, ESPECIALLY SUITABLE FOR THE PRODUCTION OF HIGH-QUALITY MASKS. SPECIFICATIONS TEMPERATURE: 10 TO 350, HUMIDITY 5 TO 35%, NO FLAMMABILITY AND NONCORROSIVE GAS VOLTAGE: 220V POWER FREQUENCY: 50Hz PER 60Hz TOTAL POWER OF EQUIPMENT: 8.5KW ULTRASONIC FREQUENCY: 5 TO 20KHz MAX FEEDING WITH OVERALL DIMENSION OF EQUIPMENT: 6100 x 3300 x 1800 MACHINE WEIGHT: 2 TONS PRODUCTION EFFICIENCY: 80 TO 120 TABLETS PER MIN (EACH WORKING STATION 60 PCS PER MIN, AS WE HAVE TWO WORKING STATION). OPERATOR: 1 PERSON QUANTITY: 1 Learn More

FULLY AUTOMATIC MASK MACHINEREFERENCE NUMBER: P-8845 FULLY AUTOMATIC MASK MACHINE THIS EQUIPMENT IS A FULL-AUTOMATIC ONE-TIME PLANE MASK FORMING MACHINE, WHICH IS USED FOR THE FORMING OF ONE-TIME RECTANGULAR EAR HANGING THREE DRAWER MASKS. ONE MAIN MACHINE IS EQUIPPED WITH TWO EAR BELT SPOT WELDING MACHINES (ONE FOR TWO). THE DRIVING MOTOR IS SERVO MOTOR, SO IT HAS THE ADVANTAGES OF HIGH RELIABILITY, EASY OPERATION, ACCURATE TRANSMISSION, STABLE CONTROL, ADJUSTABLE SPEED, LOW COST AND CONVENIENT MAINTENANCE, ESPECIALLY SUITABLE FOR THE PRODUCTION OF HIGH-QUALITY MASKS. SPECIFICATIONS TEMPERATURE: 10 TO 350, HUMIDITY 5 TO 35%, NO FLAMMABILITY AND NONCORROSIVE GAS VOLTAGE: 220V POWER FREQUENCY: 50Hz PER 60Hz TOTAL POWER OF EQUIPMENT: 8.5KW ULTRASONIC FREQUENCY: 5 TO 20KHz MAX FEEDING WITH OVERALL DIMENSION OF EQUIPMENT: 6100 x 3300 x 1800 MACHINE WEIGHT: 2 TONS PRODUCTION EFFICIENCY: 80 TO 120 TABLETS PER MIN (EACH WORKING STATION 60 PCS PER MIN, AS WE HAVE TWO WORKING STATION). OPERATOR: 1 PERSON QUANTITY: 1 Learn More