YY-1413 HIGH SPEED PRECISION DIE CUTTING MACHINE, PLATE DIMENSIONS 300 X 290mm, DAYLIGHT 28mm

YY-1413 HIGH SPEED PRECISION DIE CUTTING MACHINE, PLATE DIMENSIONS 300 X 290mm, DAYLIGHT 28mm

SPECIFICATION:

1. PRESS FORCE: 10 TONS

2. DAYLIGHT: 28mm

3. DIE CUTTING SPEED: 220 TIMES PER MINUTE

4. WIDTH ADJUST: ±5mm

5. SHUT HEIGHT OF METAL MOLD: 115mm

6. EFFECTIVE SIZE OF METAL MOLD: 300 X 290mm

7. MOLD SIZE: 350 X 350mm

8. TURNING WAY: ELECTRICALLY ADJUST

9. PRESS STYLE: JOG/SINGLE/CONTINUOUS

10. TYPE OF MOLD: PLASTIC BOARD MOLD, CHEMICAL SCULPTURE MOLD, METAL MOLD

11. MAX FEEDING WIDTH: ≤350mm

12. FEEDING SPEED: ≤30 METERS PER MINUTE

13. PRECISION OF FEEDING: <0.1mm

14. MATERIAL THICKNESS: 0.025 TO 2mm

15. DIE CUTTING PRECISION: ± 0.03mm

16. FEEDING ROLLER: PU/NBR

17. MATERIALS DRIVEN: SERVO MOTORS

18. LUBRICATE: FULLY AUTOMATIC CENTRAL LUBRICATION SYSTEM

19. PROTECTION: 3 OPTICAL SAFETY SENSORS

20. POWER SUPPLY: AC 380 VOLTS 5 KW

21. AIR SOURCE: 0.5 TO 0.6 MPA

22. WEIGHT OF MACHINE: AROUND 2000KGS

23. MACHINE SIZES (L X W X H): 1700 X 1150 X 1500mm

QUANTITY: 1

In stock

SKU

YY-1413

REFERENCE NUMBER: YY-1413

HIGH SPEED PRECISION DIE CUTTING MACHINE, PLATE DIMENSIONS 300 X 290mm, DAYLIGHT 28mm

DETAILS:

PRODUCT PRINCIPLE:

OUR HIGH SPEED PRECISION DIE CUTTING MACHINES DEVELOPED BY OUR COMPANY INDEPENDENTLY HAVE THE FOLLOWING ADVANTAGES, TO INCORPORATE MITSUBISHI BRAND MOTORS AND PLC, SCHNEIDER BRAND LOW VOLTAGE ELECTRICAL APPARATUS AND POWER SUPPLY WHICH MAKE THE MACHINE MORE STABLE; HIGH SPEED, PRECISION AND STABLE PERFORMANCE CHARACTERISTICS, IMPROVE THE MACHINE OPERATION MORE EFFICIENCY, SAVE A LOT OF LABOR; AT THE SAME TIME, THE MACHINE IS LOW NOISE, EASY TO MAINTAIN, EASY TO OPERATE AND SAFE.

THIS MACHINE CAN FULL CUT AND KISS CUT, ESPECIALLY FOR KISS CUT, THIS MACHINE CAN KISS CUT UP TO 0.025mm BASE MATERIAL, THIS PROCESS IS IN THE LEADING POSITION IN THE INDUSTRY.

SPECIFICATION:

1. PRESS FORCE: 10 TONS

2. DAYLIGHT: 28mm

3. DIE CUTTING SPEED: 220 TIMES PER MINUTE

4. WIDTH ADJUST: ±5mm

5. SHUT HEIGHT OF METAL MOLD: 115mm

6. EFFECTIVE SIZE OF METAL MOLD: 300 X 290mm

7. MOLD SIZE: 350 X 350mm

8. TURNING WAY: ELECTRICALLY ADJUST

9. PRESS STYLE: JOG/SINGLE/CONTINUOUS

10. TYPE OF MOLD: PLASTIC BOARD MOLD, CHEMICAL SCULPTURE MOLD, METAL MOLD

11. MAX FEEDING WIDTH: ≤350mm

12. FEEDING SPEED: ≤30 METERS PER MINUTE

13. PRECISION OF FEEDING: <0.1mm

14. MATERIAL THICKNESS: 0.025 TO 2mm

15. DIE CUTTING PRECISION: ± 0.03mm

16. FEEDING ROLLER: PU/NBR

17. MATERIALS DRIVEN: SERVO MOTORS

18. LUBRICATE: FULLY AUTOMATIC CENTRAL LUBRICATION SYSTEM

19. PROTECTION: 3 OPTICAL SAFETY SENSORS

20. POWER SUPPLY: AC 380 VOLTS 5 KW

21. AIR SOURCE: 0.5 TO 0.6 MPA

22. WEIGHT OF MACHINE: AROUND 2000KGS

23. MACHINE SIZES (L X W X H): 1700 X 1150 X 1500mm

CONFIGURATION:

MACHINE DISPLAY:

MACHINE DISPLAY:

PERFORMANCE FEATURE:

1. INDUSTRY HIGHEST PERFORMANCE CHARACTERISTICS.

2. PERFECT FLATNESS, IT CAN KISS CUT TO 0.025mm BASE MATERIAL.

3. ANY ACCELERATION AND DECELERATION IN THE INTERVAL OF 30 TO 100 TIMES/MINUTE DOES NOT AFFECT THE CUTTING DEPTH.

4. WITH AUTOMATIC MOLD CLAMPING FUNCTION, IT ELIMINATES THE DANGER OF CLAMPING AND PUNCHING, AND IT IS EASY TO OPERATE THE EQUIPMENT.

5. A LOW-POINT ACCELERATION PATENT FUNCTION TO SOLVE THE PROBLEM OF LOW PUNCHING PRESSURE OF THE HOST AT LOW SPEED.

6. WITH PROCESS SAVING FUNCTION, THE SPEED ADJUSTMENT TIME IS SHORTENED.

7. PRECISE BLANKING FORCE IS TWICE THAT OF THE SAME TYPE OF EQUIPMENT IN THE INDUSTRY, AND THE BLANKING FORCE IS STILL VERY STABLE.

8. ALL THE SAME MOLD ARE COMMON AND CAN BE INTERCHANGEABLE CONVENIENTLY WITH THE SAME TYPE OF EQUIPMENT.

9. THE OPERATION INTERFACE IS EXTREMELY SIMPLE AND EASY TO USE.

MACHINE DETAILS:

CONTROL PANEL

PERFORMANCE FEATURE:

1. INDUSTRY HIGHEST PERFORMANCE CHARACTERISTICS.

2. PERFECT FLATNESS, IT CAN KISS CUT TO 0.025mm BASE MATERIAL.

3. ANY ACCELERATION AND DECELERATION IN THE INTERVAL OF 30 TO 100 TIMES/MINUTE DOES NOT AFFECT THE CUTTING DEPTH.

4. WITH AUTOMATIC MOLD CLAMPING FUNCTION, IT ELIMINATES THE DANGER OF CLAMPING AND PUNCHING, AND IT IS EASY TO OPERATE THE EQUIPMENT.

5. A LOW-POINT ACCELERATION PATENT FUNCTION TO SOLVE THE PROBLEM OF LOW PUNCHING PRESSURE OF THE HOST AT LOW SPEED.

6. WITH PROCESS SAVING FUNCTION, THE SPEED ADJUSTMENT TIME IS SHORTENED.

7. PRECISE BLANKING FORCE IS TWICE THAT OF THE SAME TYPE OF EQUIPMENT IN THE INDUSTRY, AND THE BLANKING FORCE IS STILL VERY STABLE.

8. ALL THE SAME MOLD ARE COMMON AND CAN BE INTERCHANGEABLE CONVENIENTLY WITH THE SAME TYPE OF EQUIPMENT.

9. THE OPERATION INTERFACE IS EXTREMELY SIMPLE AND EASY TO USE.

MACHINE DETAILS:

CONTROL PANEL

YOU CAN SET ALL PARAMETER IN TOUCH SCREEN, THE LENGTH BATCH QUANTITY, TOTAL QUANTITY, DIE CUTTING SPEED, ETC.

THE LANGUAGE ON THE CONTROL PANEL CAN BE DISPLAYED IN ENGLISH OR ANY OTHER LANGUAGE REQUIRED BY THE CUSTOMER (TRANSLATION REQUIRED IN ADVANCE).

IT'S CONVENIENT FOR WORKERS TO OPERATE.

DIE CUTTING STATION

YOU CAN SET ALL PARAMETER IN TOUCH SCREEN, THE LENGTH BATCH QUANTITY, TOTAL QUANTITY, DIE CUTTING SPEED, ETC.

THE LANGUAGE ON THE CONTROL PANEL CAN BE DISPLAYED IN ENGLISH OR ANY OTHER LANGUAGE REQUIRED BY THE CUSTOMER (TRANSLATION REQUIRED IN ADVANCE).

IT'S CONVENIENT FOR WORKERS TO OPERATE.

DIE CUTTING STATION

1. THIS UNIT IS USED TO DIE CUT MATERIALS; YOU CAN INSTALL THE DIE FROM HERE. WHEN MATERIAL PASSED, IT PUNCHES AND DIE CUTS THE SHAPE OF PRODUCTS.

2. THE SPEED IS ADJUSTABLE, THE DEPTH AND FORCE ARE ADJUSTABLE TOO.

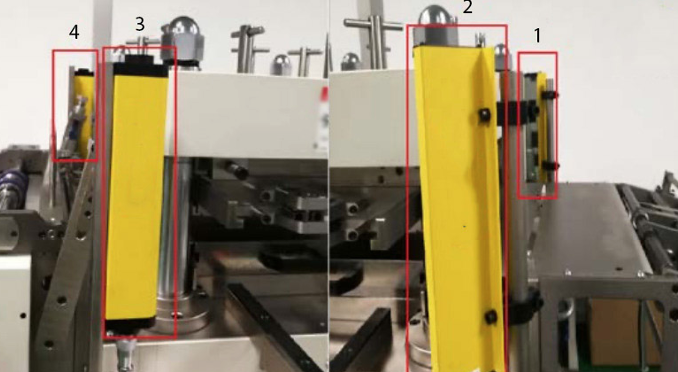

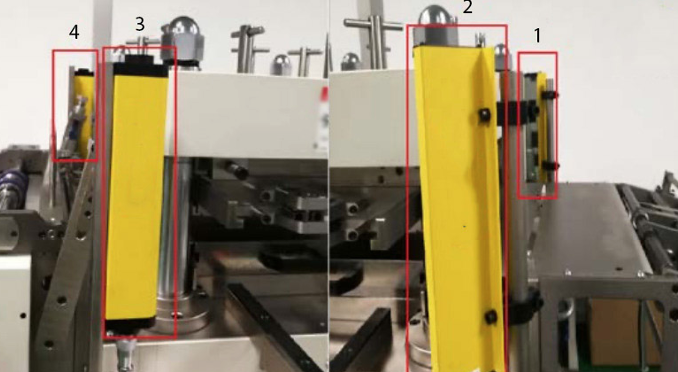

SAFETY PROTECTION

1. THIS UNIT IS USED TO DIE CUT MATERIALS; YOU CAN INSTALL THE DIE FROM HERE. WHEN MATERIAL PASSED, IT PUNCHES AND DIE CUTS THE SHAPE OF PRODUCTS.

2. THE SPEED IS ADJUSTABLE, THE DEPTH AND FORCE ARE ADJUSTABLE TOO.

SAFETY PROTECTION

THERE ARE FOUR ELECTRONIC PROTECTION LIGHT CURTAINS AROUND THE MACHINE.

ONCE THERE IS ANYTHING MATERIALS, SUCH AS THE OPERATOR'S HAND ENTERS THE SENSING RANGE, THE MACHINE WILL STOP WORKING IMMEDIATELY.

FEEDING SERVO MOTOR

THERE ARE FOUR ELECTRONIC PROTECTION LIGHT CURTAINS AROUND THE MACHINE.

ONCE THERE IS ANYTHING MATERIALS, SUCH AS THE OPERATOR'S HAND ENTERS THE SENSING RANGE, THE MACHINE WILL STOP WORKING IMMEDIATELY.

FEEDING SERVO MOTOR

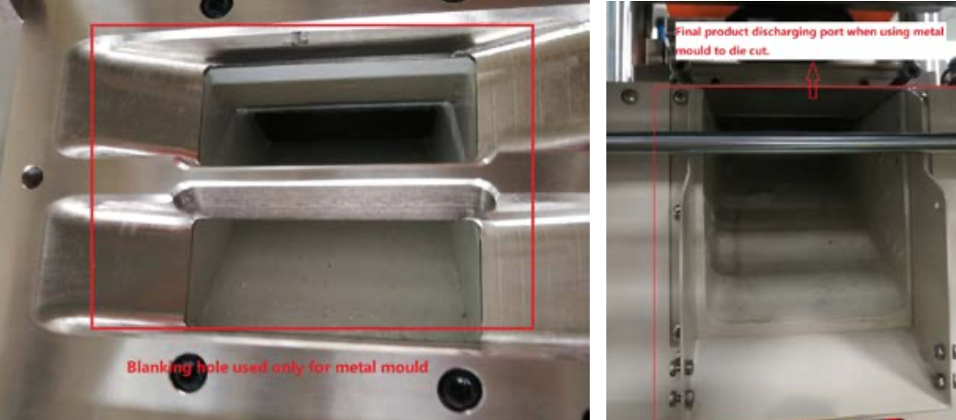

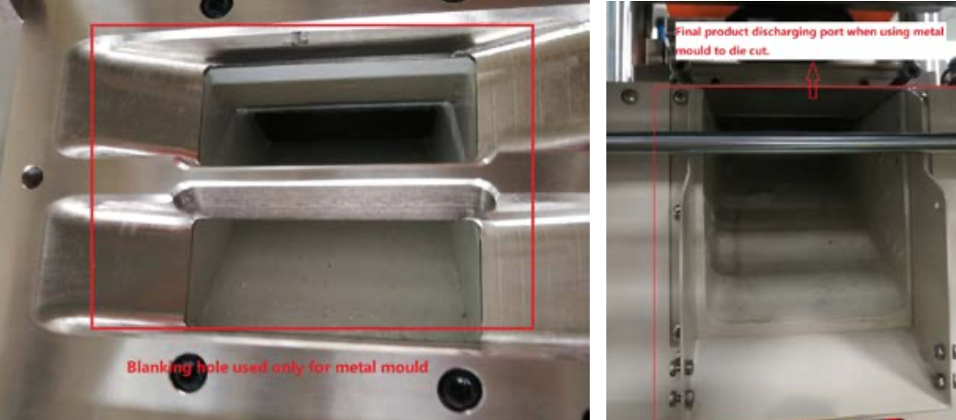

FINAL PRODUCT DISCHARGING PORT (ONLY USED FOR THE PRODUCT DIE CUT VIA METAL MOLD)

FINAL PRODUCT DISCHARGING PORT (ONLY USED FOR THE PRODUCT DIE CUT VIA METAL MOLD)

GAS VOLVE: CONTROL AND DISPLAY AIR PRESSURE

GAS VOLVE: CONTROL AND DISPLAY AIR PRESSURE

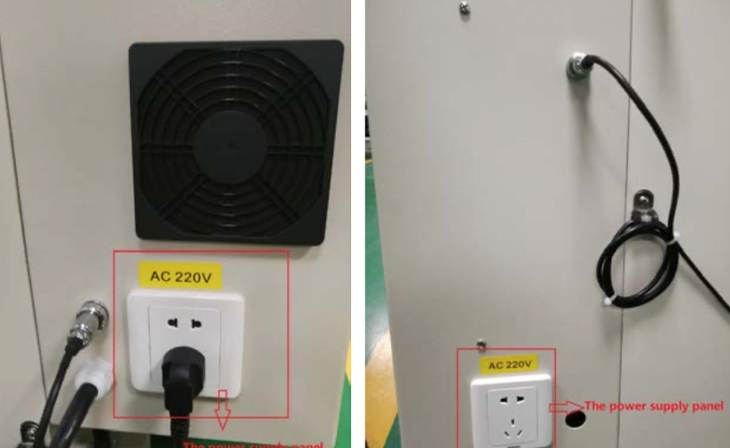

ELECTRONIC SENSOR HEAD

ELECTRONIC SENSOR HEAD

OUR HIGH SPEED PRECISION DIE CUTTING MACHINE HAS TWO ELECTRONIC SENSOR HEADS LOCATED BOTH SIDES OF MACHINE, THEY CAN CONTROL THE RUNNING SPEED AFTER COMBINED WITH LAMINATION MACHINE, UNWINDING MACHINE OR CUTTING MACHINE AUTOMATICALLY.

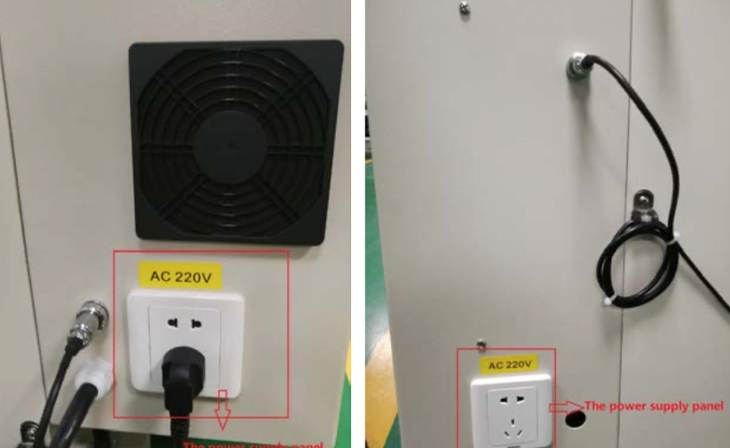

THE POWER SUPPLY PANELS LOCATED BOTH SIDES OF MACHINE, THEY CAN USE FOR THE LAMINATION MACHINE, UNWINDING MACHINE OR CUTTING MACHINE.

OUR HIGH SPEED PRECISION DIE CUTTING MACHINE HAS TWO ELECTRONIC SENSOR HEADS LOCATED BOTH SIDES OF MACHINE, THEY CAN CONTROL THE RUNNING SPEED AFTER COMBINED WITH LAMINATION MACHINE, UNWINDING MACHINE OR CUTTING MACHINE AUTOMATICALLY.

THE POWER SUPPLY PANELS LOCATED BOTH SIDES OF MACHINE, THEY CAN USE FOR THE LAMINATION MACHINE, UNWINDING MACHINE OR CUTTING MACHINE.

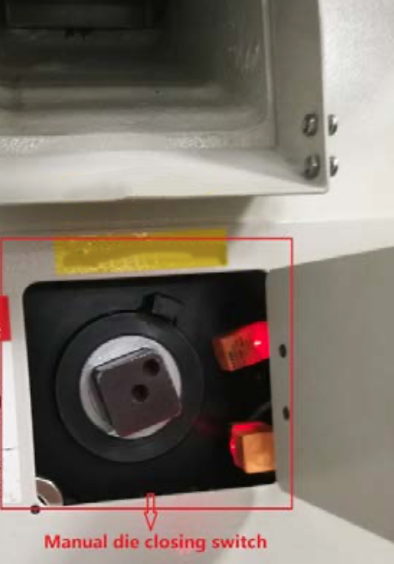

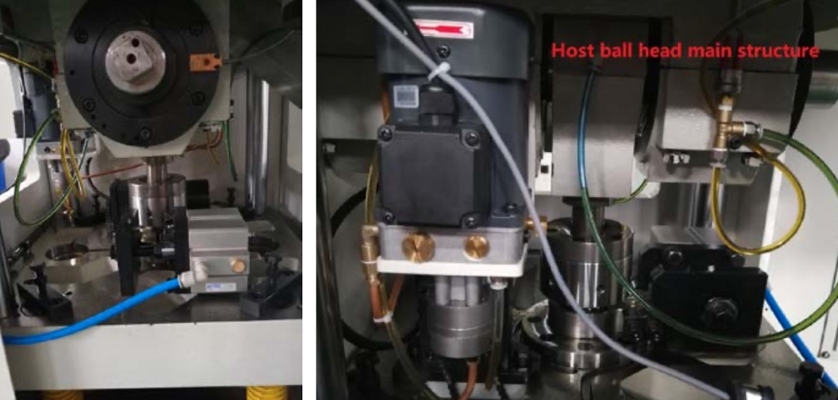

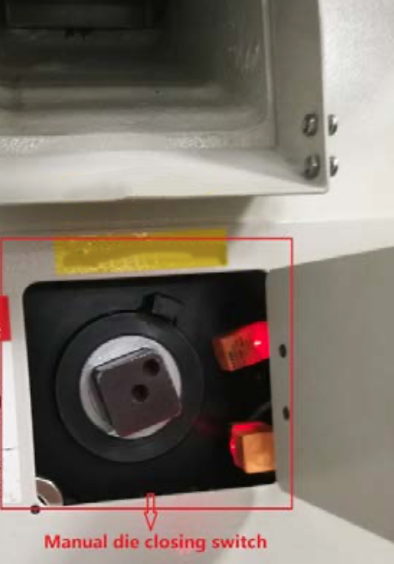

THE DIE CUTTING MACHINE HAS AUTOMATIC DIE CLOSING FUNCTION, ALSO KEPT MANUAL DIE CLOSING FUNCTION.

THE DIE CUTTING MACHINE HAS AUTOMATIC DIE CLOSING FUNCTION, ALSO KEPT MANUAL DIE CLOSING FUNCTION.

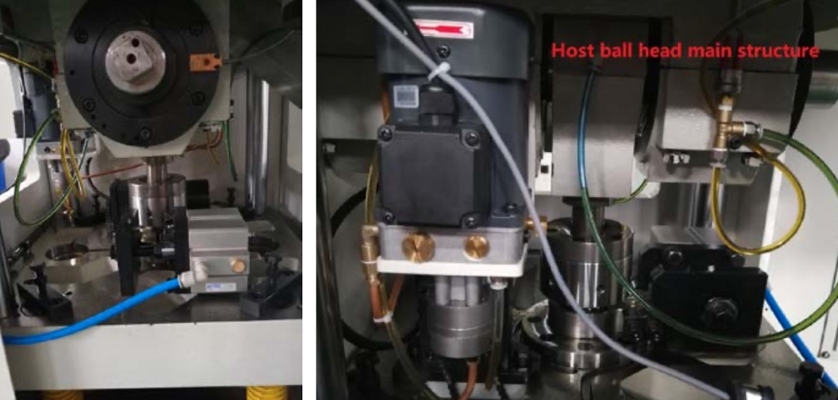

INSIDE HOST BALL HEAD MAIN STRUCTURE

INSIDE HOST BALL HEAD MAIN STRUCTURE

LUBRICATE: FULLY AUTOMATIC CENTRAL LUBRICATION SYSTEM, JUST CHANGE THE OIL ONCE A YEAR.

LUBRICATE: FULLY AUTOMATIC CENTRAL LUBRICATION SYSTEM, JUST CHANGE THE OIL ONCE A YEAR.

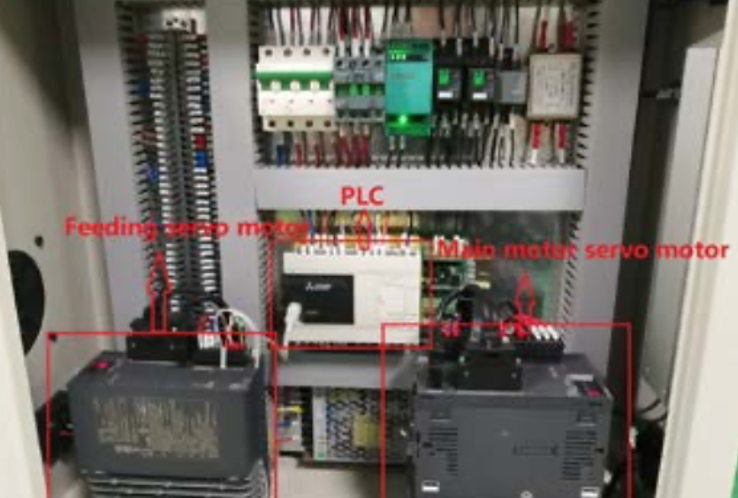

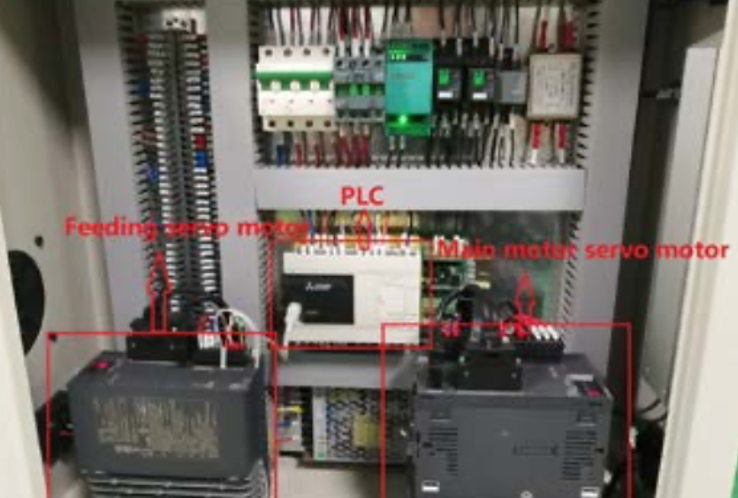

MITSUBISHI MOTORS AND PLC

MITSUBISHI MOTORS AND PLC

LOW-VOLTAGE APPARATUS SET

LOW-VOLTAGE APPARATUS SET

APPLICATION:

OUR HIGH SPEED PRECISION DIE CUTTING MACHINES ARE WIDELY APPLIED IN LAMINATING, SLITTING AND DIE-CUTTING FOR ALL KIND OF SPARE PARTS IN MOBILE PHONE, LAPTOP, LCD, TV, MEDICAL, CAMERA, WEARABLE, E-LABEL, CAR AND PRINTING ETC.

1. DIE-CUTTING FOR 3M DOUBLE SIDE ADHESIVE TAPE, 3M ADHESIVE BACK, FLISH LIGHT ADHESIVE BACK, PE FOAM ADHESIVE TAPE, EVA FOAM DOUBLE SIDED ADHESIVE TAPE, ETC.

DIE CUT FOR EVA FOAM:

APPLICATION:

OUR HIGH SPEED PRECISION DIE CUTTING MACHINES ARE WIDELY APPLIED IN LAMINATING, SLITTING AND DIE-CUTTING FOR ALL KIND OF SPARE PARTS IN MOBILE PHONE, LAPTOP, LCD, TV, MEDICAL, CAMERA, WEARABLE, E-LABEL, CAR AND PRINTING ETC.

1. DIE-CUTTING FOR 3M DOUBLE SIDE ADHESIVE TAPE, 3M ADHESIVE BACK, FLISH LIGHT ADHESIVE BACK, PE FOAM ADHESIVE TAPE, EVA FOAM DOUBLE SIDED ADHESIVE TAPE, ETC.

DIE CUT FOR EVA FOAM:

2. DIE-CUTTING FOR MOBILE PHONE ACCESSORIES, INCLUDING SCREEN PROTECTION FILM, NAMEPLATE, SERIES LABEL, THE HEADSET MICROPHONE O-RING FIXED, DUST SCREEN, LCD FRAME FIXING, DUST-PROOF CUSHION, CABLE FIXED,RECEIVER MICROPHONE CUSHION AND ETC.

3. DIE-CUTTING FOR GASKETS AND SEALS, INCLUDING: CAMERA LENS GASKET, ID / OD FOAM WASHERS, EPDM FOAM, ENVIRONMENTAL SEALING GASKETS, HIGH TEMPERATURE GASKETS, WINDOW / LCD SCREEN GASKET, ANTI-VIBRATION GASKETS, SHOCK / IMPACT PROTECTION GASKETS, CUSHIONING GASKETS, EMI/RFI SHIELDING GASKET, LIGHT SEALING TAPE / GASKET, ETC.

4. DIE-CUTTING FOR BATTERY POSITIVE INSULATION RING ELECTRICAL INSULATING ADHESIVE HIGHLAND BARLEY PAPER:

4.1. INSULATION CLASS: E CLASS (120 °C) - POLYESTER FILM/PRESS PAPER HAS HIGH MECHANICAL

STRENGTH AND EXCELLENT DIELECTRIC PROPERTY.

4.2. AS SLOT, INTERTURN AND LINER INSULATION FOR E-GRADE MOTORS, GENERATORS AND ELECTRIC APPLIANCES.

4.3. ALSO USED FOR SLOT INSULATION, CLOSURES OR COVERS, OVERHANG, INTERPHASE INSULATION AND LAYER INSULATIONS FOR DRY-TYPE TRANSFORMERS AND MOTORS.

2. DIE-CUTTING FOR MOBILE PHONE ACCESSORIES, INCLUDING SCREEN PROTECTION FILM, NAMEPLATE, SERIES LABEL, THE HEADSET MICROPHONE O-RING FIXED, DUST SCREEN, LCD FRAME FIXING, DUST-PROOF CUSHION, CABLE FIXED,RECEIVER MICROPHONE CUSHION AND ETC.

3. DIE-CUTTING FOR GASKETS AND SEALS, INCLUDING: CAMERA LENS GASKET, ID / OD FOAM WASHERS, EPDM FOAM, ENVIRONMENTAL SEALING GASKETS, HIGH TEMPERATURE GASKETS, WINDOW / LCD SCREEN GASKET, ANTI-VIBRATION GASKETS, SHOCK / IMPACT PROTECTION GASKETS, CUSHIONING GASKETS, EMI/RFI SHIELDING GASKET, LIGHT SEALING TAPE / GASKET, ETC.

4. DIE-CUTTING FOR BATTERY POSITIVE INSULATION RING ELECTRICAL INSULATING ADHESIVE HIGHLAND BARLEY PAPER:

4.1. INSULATION CLASS: E CLASS (120 °C) - POLYESTER FILM/PRESS PAPER HAS HIGH MECHANICAL

STRENGTH AND EXCELLENT DIELECTRIC PROPERTY.

4.2. AS SLOT, INTERTURN AND LINER INSULATION FOR E-GRADE MOTORS, GENERATORS AND ELECTRIC APPLIANCES.

4.3. ALSO USED FOR SLOT INSULATION, CLOSURES OR COVERS, OVERHANG, INTERPHASE INSULATION AND LAYER INSULATIONS FOR DRY-TYPE TRANSFORMERS AND MOTORS.

5. DIE-CUTTING FOR THIN FLEXIBLE ELECTRICALLY INSULATING MATERIALS SUCH AS PLASTIC FILMS, RUBBER, FIBERS, AND PAPERS. THESE MATERIALS ARE WIDELY APPLIED MANY INDUSTRIES INCLUDING ELECTRONIC DEVICES, SERVERS AND PERSONAL COMPUTERS, POWER SUPPLIES, TRANSFORMERS, INVERTERS, BATTERY / ELECTRONIC VEHICLE, LIGHTING ASSEMBLIES, AEROSPACE SYSTEMS, MILITARY / DEFENSE, AUTOMOTIVE ELECTRONICS, MEDICAL DEVICES AND ETC.

5. DIE-CUTTING FOR THIN FLEXIBLE ELECTRICALLY INSULATING MATERIALS SUCH AS PLASTIC FILMS, RUBBER, FIBERS, AND PAPERS. THESE MATERIALS ARE WIDELY APPLIED MANY INDUSTRIES INCLUDING ELECTRONIC DEVICES, SERVERS AND PERSONAL COMPUTERS, POWER SUPPLIES, TRANSFORMERS, INVERTERS, BATTERY / ELECTRONIC VEHICLE, LIGHTING ASSEMBLIES, AEROSPACE SYSTEMS, MILITARY / DEFENSE, AUTOMOTIVE ELECTRONICS, MEDICAL DEVICES AND ETC.

WARRANTY PERIOD: WHOLE MACHINE WARRANTY ONE YEAR.

QUANTITY: 1

WARRANTY PERIOD: WHOLE MACHINE WARRANTY ONE YEAR.

QUANTITY: 1

MACHINE DISPLAY:

MACHINE DISPLAY:

PERFORMANCE FEATURE:

1. INDUSTRY HIGHEST PERFORMANCE CHARACTERISTICS.

2. PERFECT FLATNESS, IT CAN KISS CUT TO 0.025mm BASE MATERIAL.

3. ANY ACCELERATION AND DECELERATION IN THE INTERVAL OF 30 TO 100 TIMES/MINUTE DOES NOT AFFECT THE CUTTING DEPTH.

4. WITH AUTOMATIC MOLD CLAMPING FUNCTION, IT ELIMINATES THE DANGER OF CLAMPING AND PUNCHING, AND IT IS EASY TO OPERATE THE EQUIPMENT.

5. A LOW-POINT ACCELERATION PATENT FUNCTION TO SOLVE THE PROBLEM OF LOW PUNCHING PRESSURE OF THE HOST AT LOW SPEED.

6. WITH PROCESS SAVING FUNCTION, THE SPEED ADJUSTMENT TIME IS SHORTENED.

7. PRECISE BLANKING FORCE IS TWICE THAT OF THE SAME TYPE OF EQUIPMENT IN THE INDUSTRY, AND THE BLANKING FORCE IS STILL VERY STABLE.

8. ALL THE SAME MOLD ARE COMMON AND CAN BE INTERCHANGEABLE CONVENIENTLY WITH THE SAME TYPE OF EQUIPMENT.

9. THE OPERATION INTERFACE IS EXTREMELY SIMPLE AND EASY TO USE.

MACHINE DETAILS:

CONTROL PANEL

PERFORMANCE FEATURE:

1. INDUSTRY HIGHEST PERFORMANCE CHARACTERISTICS.

2. PERFECT FLATNESS, IT CAN KISS CUT TO 0.025mm BASE MATERIAL.

3. ANY ACCELERATION AND DECELERATION IN THE INTERVAL OF 30 TO 100 TIMES/MINUTE DOES NOT AFFECT THE CUTTING DEPTH.

4. WITH AUTOMATIC MOLD CLAMPING FUNCTION, IT ELIMINATES THE DANGER OF CLAMPING AND PUNCHING, AND IT IS EASY TO OPERATE THE EQUIPMENT.

5. A LOW-POINT ACCELERATION PATENT FUNCTION TO SOLVE THE PROBLEM OF LOW PUNCHING PRESSURE OF THE HOST AT LOW SPEED.

6. WITH PROCESS SAVING FUNCTION, THE SPEED ADJUSTMENT TIME IS SHORTENED.

7. PRECISE BLANKING FORCE IS TWICE THAT OF THE SAME TYPE OF EQUIPMENT IN THE INDUSTRY, AND THE BLANKING FORCE IS STILL VERY STABLE.

8. ALL THE SAME MOLD ARE COMMON AND CAN BE INTERCHANGEABLE CONVENIENTLY WITH THE SAME TYPE OF EQUIPMENT.

9. THE OPERATION INTERFACE IS EXTREMELY SIMPLE AND EASY TO USE.

MACHINE DETAILS:

CONTROL PANEL

YOU CAN SET ALL PARAMETER IN TOUCH SCREEN, THE LENGTH BATCH QUANTITY, TOTAL QUANTITY, DIE CUTTING SPEED, ETC.

THE LANGUAGE ON THE CONTROL PANEL CAN BE DISPLAYED IN ENGLISH OR ANY OTHER LANGUAGE REQUIRED BY THE CUSTOMER (TRANSLATION REQUIRED IN ADVANCE).

IT'S CONVENIENT FOR WORKERS TO OPERATE.

DIE CUTTING STATION

YOU CAN SET ALL PARAMETER IN TOUCH SCREEN, THE LENGTH BATCH QUANTITY, TOTAL QUANTITY, DIE CUTTING SPEED, ETC.

THE LANGUAGE ON THE CONTROL PANEL CAN BE DISPLAYED IN ENGLISH OR ANY OTHER LANGUAGE REQUIRED BY THE CUSTOMER (TRANSLATION REQUIRED IN ADVANCE).

IT'S CONVENIENT FOR WORKERS TO OPERATE.

DIE CUTTING STATION

1. THIS UNIT IS USED TO DIE CUT MATERIALS; YOU CAN INSTALL THE DIE FROM HERE. WHEN MATERIAL PASSED, IT PUNCHES AND DIE CUTS THE SHAPE OF PRODUCTS.

2. THE SPEED IS ADJUSTABLE, THE DEPTH AND FORCE ARE ADJUSTABLE TOO.

SAFETY PROTECTION

1. THIS UNIT IS USED TO DIE CUT MATERIALS; YOU CAN INSTALL THE DIE FROM HERE. WHEN MATERIAL PASSED, IT PUNCHES AND DIE CUTS THE SHAPE OF PRODUCTS.

2. THE SPEED IS ADJUSTABLE, THE DEPTH AND FORCE ARE ADJUSTABLE TOO.

SAFETY PROTECTION

THERE ARE FOUR ELECTRONIC PROTECTION LIGHT CURTAINS AROUND THE MACHINE.

ONCE THERE IS ANYTHING MATERIALS, SUCH AS THE OPERATOR'S HAND ENTERS THE SENSING RANGE, THE MACHINE WILL STOP WORKING IMMEDIATELY.

FEEDING SERVO MOTOR

THERE ARE FOUR ELECTRONIC PROTECTION LIGHT CURTAINS AROUND THE MACHINE.

ONCE THERE IS ANYTHING MATERIALS, SUCH AS THE OPERATOR'S HAND ENTERS THE SENSING RANGE, THE MACHINE WILL STOP WORKING IMMEDIATELY.

FEEDING SERVO MOTOR

FINAL PRODUCT DISCHARGING PORT (ONLY USED FOR THE PRODUCT DIE CUT VIA METAL MOLD)

FINAL PRODUCT DISCHARGING PORT (ONLY USED FOR THE PRODUCT DIE CUT VIA METAL MOLD)

GAS VOLVE: CONTROL AND DISPLAY AIR PRESSURE

GAS VOLVE: CONTROL AND DISPLAY AIR PRESSURE

ELECTRONIC SENSOR HEAD

ELECTRONIC SENSOR HEAD

OUR HIGH SPEED PRECISION DIE CUTTING MACHINE HAS TWO ELECTRONIC SENSOR HEADS LOCATED BOTH SIDES OF MACHINE, THEY CAN CONTROL THE RUNNING SPEED AFTER COMBINED WITH LAMINATION MACHINE, UNWINDING MACHINE OR CUTTING MACHINE AUTOMATICALLY.

THE POWER SUPPLY PANELS LOCATED BOTH SIDES OF MACHINE, THEY CAN USE FOR THE LAMINATION MACHINE, UNWINDING MACHINE OR CUTTING MACHINE.

OUR HIGH SPEED PRECISION DIE CUTTING MACHINE HAS TWO ELECTRONIC SENSOR HEADS LOCATED BOTH SIDES OF MACHINE, THEY CAN CONTROL THE RUNNING SPEED AFTER COMBINED WITH LAMINATION MACHINE, UNWINDING MACHINE OR CUTTING MACHINE AUTOMATICALLY.

THE POWER SUPPLY PANELS LOCATED BOTH SIDES OF MACHINE, THEY CAN USE FOR THE LAMINATION MACHINE, UNWINDING MACHINE OR CUTTING MACHINE.

THE DIE CUTTING MACHINE HAS AUTOMATIC DIE CLOSING FUNCTION, ALSO KEPT MANUAL DIE CLOSING FUNCTION.

THE DIE CUTTING MACHINE HAS AUTOMATIC DIE CLOSING FUNCTION, ALSO KEPT MANUAL DIE CLOSING FUNCTION.

INSIDE HOST BALL HEAD MAIN STRUCTURE

INSIDE HOST BALL HEAD MAIN STRUCTURE

LUBRICATE: FULLY AUTOMATIC CENTRAL LUBRICATION SYSTEM, JUST CHANGE THE OIL ONCE A YEAR.

LUBRICATE: FULLY AUTOMATIC CENTRAL LUBRICATION SYSTEM, JUST CHANGE THE OIL ONCE A YEAR.

MITSUBISHI MOTORS AND PLC

MITSUBISHI MOTORS AND PLC

LOW-VOLTAGE APPARATUS SET

LOW-VOLTAGE APPARATUS SET

APPLICATION:

OUR HIGH SPEED PRECISION DIE CUTTING MACHINES ARE WIDELY APPLIED IN LAMINATING, SLITTING AND DIE-CUTTING FOR ALL KIND OF SPARE PARTS IN MOBILE PHONE, LAPTOP, LCD, TV, MEDICAL, CAMERA, WEARABLE, E-LABEL, CAR AND PRINTING ETC.

1. DIE-CUTTING FOR 3M DOUBLE SIDE ADHESIVE TAPE, 3M ADHESIVE BACK, FLISH LIGHT ADHESIVE BACK, PE FOAM ADHESIVE TAPE, EVA FOAM DOUBLE SIDED ADHESIVE TAPE, ETC.

DIE CUT FOR EVA FOAM:

APPLICATION:

OUR HIGH SPEED PRECISION DIE CUTTING MACHINES ARE WIDELY APPLIED IN LAMINATING, SLITTING AND DIE-CUTTING FOR ALL KIND OF SPARE PARTS IN MOBILE PHONE, LAPTOP, LCD, TV, MEDICAL, CAMERA, WEARABLE, E-LABEL, CAR AND PRINTING ETC.

1. DIE-CUTTING FOR 3M DOUBLE SIDE ADHESIVE TAPE, 3M ADHESIVE BACK, FLISH LIGHT ADHESIVE BACK, PE FOAM ADHESIVE TAPE, EVA FOAM DOUBLE SIDED ADHESIVE TAPE, ETC.

DIE CUT FOR EVA FOAM:

2. DIE-CUTTING FOR MOBILE PHONE ACCESSORIES, INCLUDING SCREEN PROTECTION FILM, NAMEPLATE, SERIES LABEL, THE HEADSET MICROPHONE O-RING FIXED, DUST SCREEN, LCD FRAME FIXING, DUST-PROOF CUSHION, CABLE FIXED,RECEIVER MICROPHONE CUSHION AND ETC.

3. DIE-CUTTING FOR GASKETS AND SEALS, INCLUDING: CAMERA LENS GASKET, ID / OD FOAM WASHERS, EPDM FOAM, ENVIRONMENTAL SEALING GASKETS, HIGH TEMPERATURE GASKETS, WINDOW / LCD SCREEN GASKET, ANTI-VIBRATION GASKETS, SHOCK / IMPACT PROTECTION GASKETS, CUSHIONING GASKETS, EMI/RFI SHIELDING GASKET, LIGHT SEALING TAPE / GASKET, ETC.

4. DIE-CUTTING FOR BATTERY POSITIVE INSULATION RING ELECTRICAL INSULATING ADHESIVE HIGHLAND BARLEY PAPER:

4.1. INSULATION CLASS: E CLASS (120 °C) - POLYESTER FILM/PRESS PAPER HAS HIGH MECHANICAL

STRENGTH AND EXCELLENT DIELECTRIC PROPERTY.

4.2. AS SLOT, INTERTURN AND LINER INSULATION FOR E-GRADE MOTORS, GENERATORS AND ELECTRIC APPLIANCES.

4.3. ALSO USED FOR SLOT INSULATION, CLOSURES OR COVERS, OVERHANG, INTERPHASE INSULATION AND LAYER INSULATIONS FOR DRY-TYPE TRANSFORMERS AND MOTORS.

2. DIE-CUTTING FOR MOBILE PHONE ACCESSORIES, INCLUDING SCREEN PROTECTION FILM, NAMEPLATE, SERIES LABEL, THE HEADSET MICROPHONE O-RING FIXED, DUST SCREEN, LCD FRAME FIXING, DUST-PROOF CUSHION, CABLE FIXED,RECEIVER MICROPHONE CUSHION AND ETC.

3. DIE-CUTTING FOR GASKETS AND SEALS, INCLUDING: CAMERA LENS GASKET, ID / OD FOAM WASHERS, EPDM FOAM, ENVIRONMENTAL SEALING GASKETS, HIGH TEMPERATURE GASKETS, WINDOW / LCD SCREEN GASKET, ANTI-VIBRATION GASKETS, SHOCK / IMPACT PROTECTION GASKETS, CUSHIONING GASKETS, EMI/RFI SHIELDING GASKET, LIGHT SEALING TAPE / GASKET, ETC.

4. DIE-CUTTING FOR BATTERY POSITIVE INSULATION RING ELECTRICAL INSULATING ADHESIVE HIGHLAND BARLEY PAPER:

4.1. INSULATION CLASS: E CLASS (120 °C) - POLYESTER FILM/PRESS PAPER HAS HIGH MECHANICAL

STRENGTH AND EXCELLENT DIELECTRIC PROPERTY.

4.2. AS SLOT, INTERTURN AND LINER INSULATION FOR E-GRADE MOTORS, GENERATORS AND ELECTRIC APPLIANCES.

4.3. ALSO USED FOR SLOT INSULATION, CLOSURES OR COVERS, OVERHANG, INTERPHASE INSULATION AND LAYER INSULATIONS FOR DRY-TYPE TRANSFORMERS AND MOTORS.

5. DIE-CUTTING FOR THIN FLEXIBLE ELECTRICALLY INSULATING MATERIALS SUCH AS PLASTIC FILMS, RUBBER, FIBERS, AND PAPERS. THESE MATERIALS ARE WIDELY APPLIED MANY INDUSTRIES INCLUDING ELECTRONIC DEVICES, SERVERS AND PERSONAL COMPUTERS, POWER SUPPLIES, TRANSFORMERS, INVERTERS, BATTERY / ELECTRONIC VEHICLE, LIGHTING ASSEMBLIES, AEROSPACE SYSTEMS, MILITARY / DEFENSE, AUTOMOTIVE ELECTRONICS, MEDICAL DEVICES AND ETC.

5. DIE-CUTTING FOR THIN FLEXIBLE ELECTRICALLY INSULATING MATERIALS SUCH AS PLASTIC FILMS, RUBBER, FIBERS, AND PAPERS. THESE MATERIALS ARE WIDELY APPLIED MANY INDUSTRIES INCLUDING ELECTRONIC DEVICES, SERVERS AND PERSONAL COMPUTERS, POWER SUPPLIES, TRANSFORMERS, INVERTERS, BATTERY / ELECTRONIC VEHICLE, LIGHTING ASSEMBLIES, AEROSPACE SYSTEMS, MILITARY / DEFENSE, AUTOMOTIVE ELECTRONICS, MEDICAL DEVICES AND ETC.

WARRANTY PERIOD: WHOLE MACHINE WARRANTY ONE YEAR.

QUANTITY: 1

WARRANTY PERIOD: WHOLE MACHINE WARRANTY ONE YEAR.

QUANTITY: 1

| Video | https://youtu.be/Rxc4t6KL0UM |

|---|

Write Your Own Review