Search results for: 'Polystyre'

- Related search terms

- Polystyrene

-

K-0750 FILLING MACHINE FOR POLYSTYRENE VIRGIN BEADSREFERENCE NUMBER: K-0750 FILLING MACHINE FOR POLYSTYRENE VIRGIN BEADS EPS POLYSTYRENE BEANS FILLING MACHINE DIMENSIONS: 1600MM X 1400MM X 2100MM VOLTAGE: 380V 50HZ 3PHASE (OR AS CLIENT'S REQUIREMENT) POWER: 7.2KW CAPACITY: 500 TO 600 KGS PER HOUR WEIGHT: 320 KG PER HOUR FILLING SLOT: 2 SLOTS QUANTITY AVAILABLE: 1 Learn More

K-0750 FILLING MACHINE FOR POLYSTYRENE VIRGIN BEADSREFERENCE NUMBER: K-0750 FILLING MACHINE FOR POLYSTYRENE VIRGIN BEADS EPS POLYSTYRENE BEANS FILLING MACHINE DIMENSIONS: 1600MM X 1400MM X 2100MM VOLTAGE: 380V 50HZ 3PHASE (OR AS CLIENT'S REQUIREMENT) POWER: 7.2KW CAPACITY: 500 TO 600 KGS PER HOUR WEIGHT: 320 KG PER HOUR FILLING SLOT: 2 SLOTS QUANTITY AVAILABLE: 1 Learn More -

TT-7711 MIL-TEK EPS 2000 US1 POLYSTYRENE COMPACTOR, 6KW, YEAR 2019TT-7711 MIL-TEK EPS 2000 US1 POLYSTYRENE COMPACTOR, 6KW, YEAR 2019 1. BRAND MIL-TEK 2. MODEL EPS 2000 US1 3. SINCE YEAR 2019 4. CONDITION USED QUANTITY: 1 Learn More

TT-7711 MIL-TEK EPS 2000 US1 POLYSTYRENE COMPACTOR, 6KW, YEAR 2019TT-7711 MIL-TEK EPS 2000 US1 POLYSTYRENE COMPACTOR, 6KW, YEAR 2019 1. BRAND MIL-TEK 2. MODEL EPS 2000 US1 3. SINCE YEAR 2019 4. CONDITION USED QUANTITY: 1 Learn More -

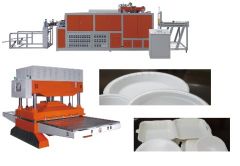

L-5827 AUTOMATIC MECHANICAL POLYSTYRENE FAST FOOD CONTAINER MACHINE

L-5827 AUTOMATIC MECHANICAL POLYSTYRENE FAST FOOD CONTAINER MACHINEREFERENCE NUMBER: L-5827

AUTOMATIC MECHANICAL POLYSTYRENE FAST FOOD CONTAINER MACHINE

EFFECTIVE FORMING AREA: 1100 X 1400mm

HEATING OVEN LENGTH: 4400mm

HYDRAULIC CYLINDER BORE: 220mm

QUANTITY: 1

Learn More -

L-5818 POLYSTYRENE FOAM PLATE FORMING MACHINE

L-5818 POLYSTYRENE FOAM PLATE FORMING MACHINEREFERENCE NUMBER: L-5818

POLYSTYRENE FOAM PLATE FORMING MACHINE

RATED POWER: 90 KW

SHEET WIDTH: 800 TO 1080mm

MAX FORMING AREA: 1000 X 1300mm

WORKING SPEED: 17 TO 22 TIMES PER MINUTE

This machine is semi-automatic.

After forming, hydraulic cutting machine will be needed to cut out each product.

QUANTITY: 1

Learn More -

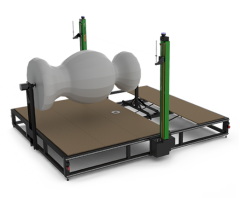

L-4593 FROG WIRE CNC CUTTING MACHINE FOR POLYSTYRENE

L-4593 FROG WIRE CNC CUTTING MACHINE FOR POLYSTYRENEREFERENCE NUMBER: L-4593

Learn More

QUANTITY: 1 -

M-1020 COMBINATION FIBER AND POLYSTYRENE PELLET FILLING MACHINEA) HOPPER MODEL L1500 MIXING SYSTEM B) OPENER MODEL F1000 – FOR THE FIRST OPENING OF THE FIBERS C)DISPENSER SILOS MODEL C5 D) SHREDDING MACHINE – SHREDDING FOAM MODEL F430 E) FILLING MACHINE WITH ELECTRONIC CONTROL WEIGHT MODEL W11 F) SPECIAL SEWING MACHINE MODEL 164C Learn More

M-1020 COMBINATION FIBER AND POLYSTYRENE PELLET FILLING MACHINEA) HOPPER MODEL L1500 MIXING SYSTEM B) OPENER MODEL F1000 – FOR THE FIRST OPENING OF THE FIBERS C)DISPENSER SILOS MODEL C5 D) SHREDDING MACHINE – SHREDDING FOAM MODEL F430 E) FILLING MACHINE WITH ELECTRONIC CONTROL WEIGHT MODEL W11 F) SPECIAL SEWING MACHINE MODEL 164C Learn More -

V-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTINGV-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTING For Max. Block Size: Length 2440 mm (96 in), Width 1220 mm (48 in), Height 600 mm (23.6 in) Machine for cutting pipe insulation A programmed-control cutting machine which runs on AutoCAD, controlled by computer. Main Features of Contour Cutter: 1. Integrated design & cutting program. Simply design and cut; 2. Big cost savings by automatically arranging the product; 3. Support numeric instrument; 4. Higher material utilization resulting from computer aided nesting of shapes; 5. Cut speed can be set to achieve the best-cut speed for different foam material; 6. Can pre-cut on the computer to check cutting course; 7. With Nesting System Learn More

V-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTINGV-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTING For Max. Block Size: Length 2440 mm (96 in), Width 1220 mm (48 in), Height 600 mm (23.6 in) Machine for cutting pipe insulation A programmed-control cutting machine which runs on AutoCAD, controlled by computer. Main Features of Contour Cutter: 1. Integrated design & cutting program. Simply design and cut; 2. Big cost savings by automatically arranging the product; 3. Support numeric instrument; 4. Higher material utilization resulting from computer aided nesting of shapes; 5. Cut speed can be set to achieve the best-cut speed for different foam material; 6. Can pre-cut on the computer to check cutting course; 7. With Nesting System Learn More -

TT-6334 EPS FOAM CRUSHER MACHINE, 12 KW, SIZE 1680 X 1580 X 172 mmTT-6334 EPS FOAM CRUSHER MACHINE, 12 KW, SIZE 1680 X 1580 X 172 mm 1. EPS FOAM CRUSHER MACHINE AS KNOWN AS EPS CRUSHER, EPS CRUSHER MACHINE, OR EPS POLYSTYRENE CRUSHER. 2. EPS FOAM CRUSHER MACHINE DESIGNED FOR EXPANDED POLYSTYRENE. 3. IT CAN CRUSH WASTE EPS FOAM INTO SMALL PIECES, AND THEN THE CRUSHED EPS BEAN CAN BE USED FOR RECYCLING OR MELTING IT. 4. FEATURE OF EPS FOAM RECYCLING CRUSHER MACHINE: 5. ADOPTING DEAFENER IOW IN NOISE. 6. ADOPTING REMOVABLE BLADES WHICH CAN BE SEPARATELY REMOVED AND SHARPENED AFTER GETTING BLUNT. 7. SUITBALE FOR SMASHING KINDS OF SOFT, HARD AND FOAMED PLASTICS. 8. EASY TO OPERATE AND HIGH OUTPUT. Learn More

TT-6334 EPS FOAM CRUSHER MACHINE, 12 KW, SIZE 1680 X 1580 X 172 mmTT-6334 EPS FOAM CRUSHER MACHINE, 12 KW, SIZE 1680 X 1580 X 172 mm 1. EPS FOAM CRUSHER MACHINE AS KNOWN AS EPS CRUSHER, EPS CRUSHER MACHINE, OR EPS POLYSTYRENE CRUSHER. 2. EPS FOAM CRUSHER MACHINE DESIGNED FOR EXPANDED POLYSTYRENE. 3. IT CAN CRUSH WASTE EPS FOAM INTO SMALL PIECES, AND THEN THE CRUSHED EPS BEAN CAN BE USED FOR RECYCLING OR MELTING IT. 4. FEATURE OF EPS FOAM RECYCLING CRUSHER MACHINE: 5. ADOPTING DEAFENER IOW IN NOISE. 6. ADOPTING REMOVABLE BLADES WHICH CAN BE SEPARATELY REMOVED AND SHARPENED AFTER GETTING BLUNT. 7. SUITBALE FOR SMASHING KINDS OF SOFT, HARD AND FOAMED PLASTICS. 8. EASY TO OPERATE AND HIGH OUTPUT. Learn More -

YY-2229 PP PE FILMS AGGLOMERATOR, VOLUME 500LYY-2229 PP PE FILMS AGGLOMERATOR, VOLUME 500L AGGLOMERATOR IS USED FOR PROCESS A WASTE OF THERMOPLASTIC FILM WITH A THICKNESS OF LESS THAN 2 MILLIMETERS; PRODUCTS WHICH CAN BE SOFT PVC, HDPE, LDP, LLDPE (HIGH OR LOW PRESSURE POLYETHYLENE), PS (POLYSTYRENE), PP (POLYPROPYLENE) AND OTHER THERMOPLASTICS WASTE PRODUCTS, AND ALSO FOR EPS (EXPANDED POLYSTYRENE) WASTE PRODUCTS GRANULATED. QUANTITY: 1 Learn More

YY-2229 PP PE FILMS AGGLOMERATOR, VOLUME 500LYY-2229 PP PE FILMS AGGLOMERATOR, VOLUME 500L AGGLOMERATOR IS USED FOR PROCESS A WASTE OF THERMOPLASTIC FILM WITH A THICKNESS OF LESS THAN 2 MILLIMETERS; PRODUCTS WHICH CAN BE SOFT PVC, HDPE, LDP, LLDPE (HIGH OR LOW PRESSURE POLYETHYLENE), PS (POLYSTYRENE), PP (POLYPROPYLENE) AND OTHER THERMOPLASTICS WASTE PRODUCTS, AND ALSO FOR EPS (EXPANDED POLYSTYRENE) WASTE PRODUCTS GRANULATED. QUANTITY: 1 Learn More -

TT-2609 ROLAND R804-5, 4 COLORS, 89 X 126, YEAR 1986 TO 2000, RCI, ROLANDMATICTT-2609 ROLAND R804-5, 4 COLORS, 89 X 126, YEAR 1986 TO 2000, RCI, ROLANDMATIC ROLAND R804-5 4 COLORS 89 X 126 ROLANDMATIC QUANTITY: 1 Learn More

TT-2609 ROLAND R804-5, 4 COLORS, 89 X 126, YEAR 1986 TO 2000, RCI, ROLANDMATICTT-2609 ROLAND R804-5, 4 COLORS, 89 X 126, YEAR 1986 TO 2000, RCI, ROLANDMATIC ROLAND R804-5 4 COLORS 89 X 126 ROLANDMATIC QUANTITY: 1 Learn More