Search results for: 'pillow fi'

- Related search terms

- pillow

- pillow f

- pillow+c

- pillow p

- Pillow+r.".))(),',

-

TT-4057 PILLOW/BOLSTER PILLOW/CUSHION FILLING, 14KW, WITH TWO FILLING FANSTT-4057 PILLOW/BOLSTER PILLOW/CUSHION FILLING, 14KW, WITH TWO FILLING FANS PILLOW/BOLSTER PILLOW/CUSHION FILLING POWER SUPPLY: 3-PHASE 4-WIRE 380V POWER: 14KW QUANTITY: 1 Learn More

TT-4057 PILLOW/BOLSTER PILLOW/CUSHION FILLING, 14KW, WITH TWO FILLING FANSTT-4057 PILLOW/BOLSTER PILLOW/CUSHION FILLING, 14KW, WITH TWO FILLING FANS PILLOW/BOLSTER PILLOW/CUSHION FILLING POWER SUPPLY: 3-PHASE 4-WIRE 380V POWER: 14KW QUANTITY: 1 Learn More -

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More -

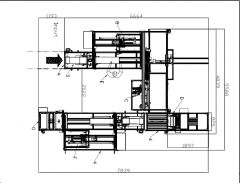

M-1385 PILLOW FILLING MACHINEREFERENCE NUMBER: M-1385 (66032TYC5UF) PILLOW FILLING MACHINE PRODUCTION NAME PILLOW FILLING MACHINE ITEM NO. L001C VOLTAGE AS PER CUSTOMER POWER 22.05KW OPENER WIDTH 1000mm BALE BREAKER WIDTH 1200mm OPENER CAPACITY 400KG/H FILLING CAPACITY 8PCS/MIN UP FIBER OPENING RATE MAX.100% AIR PRESSURE 1M3/MIN; 0.8MPA CONTROL SYSTEM SIEMENS PLC PROGRAM DIMENSION 9824 x 2417 x 2400mm LABOR NEED 2 WEIGHT 3840KG QUANTITY AVAILABLE: 1 Learn More

M-1385 PILLOW FILLING MACHINEREFERENCE NUMBER: M-1385 (66032TYC5UF) PILLOW FILLING MACHINE PRODUCTION NAME PILLOW FILLING MACHINE ITEM NO. L001C VOLTAGE AS PER CUSTOMER POWER 22.05KW OPENER WIDTH 1000mm BALE BREAKER WIDTH 1200mm OPENER CAPACITY 400KG/H FILLING CAPACITY 8PCS/MIN UP FIBER OPENING RATE MAX.100% AIR PRESSURE 1M3/MIN; 0.8MPA CONTROL SYSTEM SIEMENS PLC PROGRAM DIMENSION 9824 x 2417 x 2400mm LABOR NEED 2 WEIGHT 3840KG QUANTITY AVAILABLE: 1 Learn More -

AA-1166 PILLOW FILLING MACHINE FOR FEATHERS AND DOWN, 2 NOZZLES -FOR FIBER, POLYESTER FIBER, PP COTTON, WOOLAA-1166 PILLOW FILLING MACHINE FOR FEATHERS AND DOWN, 2 NOZZLES -FOR FIBER, POLYESTER FIBER, PP COTTON, WOOL VOLTAGE: 220 VOLTS / 60 Hz AIR PRESSURE: 0.7 TO 0.8 MPa PACKED DIMENSIONS: 1500 x 1180 x 1840mm NET WEIGHT: 360 KGS GROSS WEIGHT: 429 KGS FILLING: FIBER, POLYESTER FIBER, PP COTTON, WOOL Learn More

AA-1166 PILLOW FILLING MACHINE FOR FEATHERS AND DOWN, 2 NOZZLES -FOR FIBER, POLYESTER FIBER, PP COTTON, WOOLAA-1166 PILLOW FILLING MACHINE FOR FEATHERS AND DOWN, 2 NOZZLES -FOR FIBER, POLYESTER FIBER, PP COTTON, WOOL VOLTAGE: 220 VOLTS / 60 Hz AIR PRESSURE: 0.7 TO 0.8 MPa PACKED DIMENSIONS: 1500 x 1180 x 1840mm NET WEIGHT: 360 KGS GROSS WEIGHT: 429 KGS FILLING: FIBER, POLYESTER FIBER, PP COTTON, WOOL Learn More -

M-1456 COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATEDREFERENCE NUMBER: M-1456 (660211BTC5R) COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATED QUANTITY AVAILABLE: 1 Learn More

M-1456 COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATEDREFERENCE NUMBER: M-1456 (660211BTC5R) COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATED QUANTITY AVAILABLE: 1 Learn More -

K-6063 AUTOMATIC PILLOW FILLING MACHINE SIEMENS PLCREFERENCE NUMBER: K-6063 AUTOMATIC PILLOW FILLING MACHINE SIEMENS PLC AUTOMATIC PILLOW MACHINE POWER: 23.45 KW CAPACITY: 6-8 PIECES/MIN CONTROL SYSTEM: SIEMENS PLC LABOR: 1 PERSON VOLTAGE: 380V, 50HZ, 3-PHASE FIBER OPENING RATE: 98% UP WEIGHT: 3650KG CONJUGATE HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm MICRO FIBER 0.6D-15D QUANTITY AVAILABLE: 1 Learn More

K-6063 AUTOMATIC PILLOW FILLING MACHINE SIEMENS PLCREFERENCE NUMBER: K-6063 AUTOMATIC PILLOW FILLING MACHINE SIEMENS PLC AUTOMATIC PILLOW MACHINE POWER: 23.45 KW CAPACITY: 6-8 PIECES/MIN CONTROL SYSTEM: SIEMENS PLC LABOR: 1 PERSON VOLTAGE: 380V, 50HZ, 3-PHASE FIBER OPENING RATE: 98% UP WEIGHT: 3650KG CONJUGATE HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm MICRO FIBER 0.6D-15D QUANTITY AVAILABLE: 1 Learn More -

M-5004 PILLOW FILLING MACHINESREFERENCE NUMBER: M-5004 (1212CKWDHH11) L PILLOW FILLING MACHINES DIFFERENT CAPACITIES FOR THIS MACHINE 100KG/H, 120KG/H, 220KG/H, 250KG/H FUNCTION OF THE PILLOW FILLING MACHINE: THE SMALL PIECES OF RAW COTTON OPENING INTO A FLUFFY IMITATION SILK, COTTON, AND USED THE WIND SUCTION OUT FROM OPENING MACHINE, IMITATION SILK COTTON BY METAL DUCT INTO THE CUSHION OR PILLOW. OPERATOR CONTROL THE COTTON FILLING TIME. IT WILL CONNECT WITH THE FIBER OPENING MACHINE THE PRODUCTION LINE INCLUDES FIBER OPENING, CONVEYING, MIXED STIRRING AND STUFFING. IT MIXES AND STIRS MANY KINDS OF STUFFING MATERIALS AND THEN FILLS THEM INTO THROW PILLOWS, CUSHIONS, PILLOWS, PET PRODUCTS, BIG PLUSH TOYS, AND OTHERS. THE OPENING RATE OF THE MACHINE IS UP TO 100%, NO DAMAGES TO FIBER CRIMP AND SLIPPERY. THE STUFFED PRODUCT IS FLUFFY, ELASTIC, AND SOFT. REASONABLE AND EFFICIENT STRUCTURAL CONFIGURATION IMPROVES MANUFACTURING EFFICIENCY, SAVES COT FOR CUSTOMERS, AND DECREASES LABOR INTENSITY. ALL WORK TEETH ARE PROCESSED WITH DYNAMIC BALANCE, NO VIBRATION AND LOW NOISE IN THE OPERATION. THE MACHINE CAN BE FREELY COMBINED BASED ON CUSTOMER’S CHOICE OF AN OPENER AND A FILLING MACHINE, SATISFYING DIFFERENT CUSTOMER’S REQUIREMENTS. CE CERTIFICATION (MODEL: 001) PILLOW FILLING MACHINE CAPACITY: 100KG/H POWER: 6.7KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 680KG DIMENSION: 3200mm x 1500mm x 1330mm (MODEL: 002) PILLOW FILLING MACHINE CAPACITY: 120KG/H POWER: 6.7KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 700KG DIMENSION: 3500mm x 1500mm x 1330mm (MODEL: 003) PILLOW FILLING MACHINE CAPACITY: 220KG/H POWER: 10.45KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 900KG DIMENSION: 4000mm x 2200mm x 1200mm (MODEL: 004) PILLOW FILLING MACHINE CAPACITY: 250KG/H POWER: 10.45KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 1050KG DIMENSION: 4500mm x 2500mm x 2050mm QUANTITY AVAILABLE: 1 Learn More

M-5004 PILLOW FILLING MACHINESREFERENCE NUMBER: M-5004 (1212CKWDHH11) L PILLOW FILLING MACHINES DIFFERENT CAPACITIES FOR THIS MACHINE 100KG/H, 120KG/H, 220KG/H, 250KG/H FUNCTION OF THE PILLOW FILLING MACHINE: THE SMALL PIECES OF RAW COTTON OPENING INTO A FLUFFY IMITATION SILK, COTTON, AND USED THE WIND SUCTION OUT FROM OPENING MACHINE, IMITATION SILK COTTON BY METAL DUCT INTO THE CUSHION OR PILLOW. OPERATOR CONTROL THE COTTON FILLING TIME. IT WILL CONNECT WITH THE FIBER OPENING MACHINE THE PRODUCTION LINE INCLUDES FIBER OPENING, CONVEYING, MIXED STIRRING AND STUFFING. IT MIXES AND STIRS MANY KINDS OF STUFFING MATERIALS AND THEN FILLS THEM INTO THROW PILLOWS, CUSHIONS, PILLOWS, PET PRODUCTS, BIG PLUSH TOYS, AND OTHERS. THE OPENING RATE OF THE MACHINE IS UP TO 100%, NO DAMAGES TO FIBER CRIMP AND SLIPPERY. THE STUFFED PRODUCT IS FLUFFY, ELASTIC, AND SOFT. REASONABLE AND EFFICIENT STRUCTURAL CONFIGURATION IMPROVES MANUFACTURING EFFICIENCY, SAVES COT FOR CUSTOMERS, AND DECREASES LABOR INTENSITY. ALL WORK TEETH ARE PROCESSED WITH DYNAMIC BALANCE, NO VIBRATION AND LOW NOISE IN THE OPERATION. THE MACHINE CAN BE FREELY COMBINED BASED ON CUSTOMER’S CHOICE OF AN OPENER AND A FILLING MACHINE, SATISFYING DIFFERENT CUSTOMER’S REQUIREMENTS. CE CERTIFICATION (MODEL: 001) PILLOW FILLING MACHINE CAPACITY: 100KG/H POWER: 6.7KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 680KG DIMENSION: 3200mm x 1500mm x 1330mm (MODEL: 002) PILLOW FILLING MACHINE CAPACITY: 120KG/H POWER: 6.7KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 700KG DIMENSION: 3500mm x 1500mm x 1330mm (MODEL: 003) PILLOW FILLING MACHINE CAPACITY: 220KG/H POWER: 10.45KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 900KG DIMENSION: 4000mm x 2200mm x 1200mm (MODEL: 004) PILLOW FILLING MACHINE CAPACITY: 250KG/H POWER: 10.45KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 1050KG DIMENSION: 4500mm x 2500mm x 2050mm QUANTITY AVAILABLE: 1 Learn More -

TT-1018 TATHAM BLOW FILLING PRODUCTION LINE FOR PILLOW/CUSHIONS, 2 NOZZLESTT-1018 TATHAM BLOW FILLING PRODUCTION LINE FOR PILLOW/CUSHIONS, 2 NOZZLES TATHAM BLOW FILLING PRODUCTION LINE FOR PILLOW/CUSHIONS NEW TATHAM BLOWFILL FIBRE OPENING AND FILLING LINE HOPPER 900mm WIDTH CARD OPENER FOR FIBRE 900mm WIDTH TWIN PNEUMATIC PILLOW FILLING POSITIONS PRODUCTION 250KG PER HOUR QUANTITY: 1 Learn More

TT-1018 TATHAM BLOW FILLING PRODUCTION LINE FOR PILLOW/CUSHIONS, 2 NOZZLESTT-1018 TATHAM BLOW FILLING PRODUCTION LINE FOR PILLOW/CUSHIONS, 2 NOZZLES TATHAM BLOW FILLING PRODUCTION LINE FOR PILLOW/CUSHIONS NEW TATHAM BLOWFILL FIBRE OPENING AND FILLING LINE HOPPER 900mm WIDTH CARD OPENER FOR FIBRE 900mm WIDTH TWIN PNEUMATIC PILLOW FILLING POSITIONS PRODUCTION 250KG PER HOUR QUANTITY: 1 Learn More -

AA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINEAA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINE FOUR NOZZLES PILLOW FILLING MACHINE: IT IS SUITABLE FOR OPENING AND PROCESSING FIBER RAW MATERIAL, FILLING PILLOW CORE AND CUSHION. CHARACTERISTICS: LESS INVESTMENT, HIGH EFFICIENCY, SIMPLE OPERATION, WITH FREQUENCY CONVERSION DEVICE. RAW MATERIAL REQUIREMENTS: FIBERS ABOVE 0.78D, CAN BE OPENED AT ONE TIME. Learn More

AA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINEAA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINE FOUR NOZZLES PILLOW FILLING MACHINE: IT IS SUITABLE FOR OPENING AND PROCESSING FIBER RAW MATERIAL, FILLING PILLOW CORE AND CUSHION. CHARACTERISTICS: LESS INVESTMENT, HIGH EFFICIENCY, SIMPLE OPERATION, WITH FREQUENCY CONVERSION DEVICE. RAW MATERIAL REQUIREMENTS: FIBERS ABOVE 0.78D, CAN BE OPENED AT ONE TIME. Learn More -

M-7753 DOWN PILLOW FILLING MACHINE WITHOUT WEIGHING SYSTEM

M-7753 DOWN PILLOW FILLING MACHINE WITHOUT WEIGHING SYSTEMREFERENCE NUMBER: M-7753

DOWN PILLOW FILLING MACHINE WITHOUT WEIGHING SYSTEM

DOWN PILLOW FILLING MACHINE

WITHOUT WEIGHING SYSTEM

BEST MACHINE IF YOU DON’T NEED EXACT WEIGHT FOR EVERY PILLOW

QUANTITY: 1

Learn More