Search results for: 'spray'

- Related search terms

- spray dryer

- spray d

- spray bonding line

- spray paint gun

- spray adhesive

-

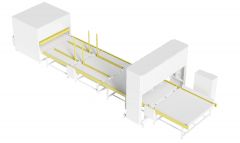

TT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXITTT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXIT AUTOMATIC GLUE SPRAY MACHINE APPLICATION: THE AUTOMATIC GLUE SPRAY MACHINE IS HIGHLY AUTOMATED. THROUGH INFRARED MEASUREMENT, IT CAN AUTOMATICALLY IDENTIFY THE HEIGHT AND WIDTH OF THE MATERIAL, AND AUTOMATICALLY ADJUST THE POSITION OF THE GLUE NOZZLE FOR SPRAYING ACCORDING TO THE DETECTION HEIGHT. AUTOMATIC GLUE SPRAY MACHINE CAN COMPLETE SUCH PROCESSES AS AUTOMATICALLY GLUE SPRAYING, PNEUMATIC TURNING OVER OF THE UNIT AND AUTOMATICALLY PRESSING. WITH PLC CONTROL, HIGH PRODUCTION EFFICIENCY, SINGLE SPRAYING IS ABOUT 30 SECONDS PER SHEET. IT IS SUITABLE FOR SHEETS WITH WIDTH OF 850 TO 2200mm AND HEIGHT OF 5 TO 400mm THE GLUE SPRAYING MACHINE IS SUITABLE FOR FOAM, LATEX, MATTRESS AND HOME TEXTILE INDUSTRIES. Learn More

TT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXITTT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXIT AUTOMATIC GLUE SPRAY MACHINE APPLICATION: THE AUTOMATIC GLUE SPRAY MACHINE IS HIGHLY AUTOMATED. THROUGH INFRARED MEASUREMENT, IT CAN AUTOMATICALLY IDENTIFY THE HEIGHT AND WIDTH OF THE MATERIAL, AND AUTOMATICALLY ADJUST THE POSITION OF THE GLUE NOZZLE FOR SPRAYING ACCORDING TO THE DETECTION HEIGHT. AUTOMATIC GLUE SPRAY MACHINE CAN COMPLETE SUCH PROCESSES AS AUTOMATICALLY GLUE SPRAYING, PNEUMATIC TURNING OVER OF THE UNIT AND AUTOMATICALLY PRESSING. WITH PLC CONTROL, HIGH PRODUCTION EFFICIENCY, SINGLE SPRAYING IS ABOUT 30 SECONDS PER SHEET. IT IS SUITABLE FOR SHEETS WITH WIDTH OF 850 TO 2200mm AND HEIGHT OF 5 TO 400mm THE GLUE SPRAYING MACHINE IS SUITABLE FOR FOAM, LATEX, MATTRESS AND HOME TEXTILE INDUSTRIES. Learn More -

YY-2356 CHAMP DISTILLATE SPRAY GUNYY-2356 CHAMP DISTILLATE SPRAY GUN SPRAY HEATED MOLTEN DISTILLATE MATERIAL WITH SPEED, ACCURACY AND LOW MAINTENANCE. CHAMP DISTILLATE SPRAY GUN ELIMINATES THE NEED FOR ADDITIVES. CUSTOMER TO PROVIDE COMPRESSED AIR ( 3.5 SCFM AT 80PSI). QUANTITY: 1 Learn More

YY-2356 CHAMP DISTILLATE SPRAY GUNYY-2356 CHAMP DISTILLATE SPRAY GUN SPRAY HEATED MOLTEN DISTILLATE MATERIAL WITH SPEED, ACCURACY AND LOW MAINTENANCE. CHAMP DISTILLATE SPRAY GUN ELIMINATES THE NEED FOR ADDITIVES. CUSTOMER TO PROVIDE COMPRESSED AIR ( 3.5 SCFM AT 80PSI). QUANTITY: 1 Learn More -

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More -

RAIN TEST CHAMBER WATER SPRAY SIMULATIONREFERENCE NUMBER: Y-2073 RAIN TEST CHAMBER WATER SPRAY SIMULATION THIS EQUIPMENT IS APPLICABLE TO THE TEST OF RAINPROOF DUST AND SAND SOAKED WATER OF VARIOUS AUTO PARTS, ELECTRONIC APPLIANCES, AND OTHER INDUSTRIAL ELECTRONIC PRODUCTS. AUTO PARTS INCLUDE THE TEST OF FULL SEALING STABILITY OF THE SYSTEM SUCH AS LAMPS, DOOR LOCKS, ELECTRICAL, INSTRUMENTS, DUST COVERS, ELECTRONIC HOUSEHOLD APPLIANCES, ETC. THE TESTED ITEMS ARE INSTALLED OR PLACE IN THE CENTER OF SEMICIRCLE BENDING TUBES AND BOTTOM AND SWING OF THE SPLASHED SAMPLES. THE AXIS IS IN A HORIZONTAL POSITION, AND THE SAMPLES ROTATES AROUND THE CENTERLINE DURING THE TEST. TECHNICAL PARAMETERS: CHAMBER SIZE: 600mm X 600mm X 600mm (WxDxH) DIAMETER OF SPRAY: ⊄0.4mm SPACING OF SPRAY HOLES: 50mm SPRAY PIPE DIAMETER: 16mm NOZZLE ANGLE ADJUSTABLE: 120 (IPX3) 180(IPX4) RADIUS OF SPRAY RING: R 375mm WATER PRESSURE: ADJUSTABLE WATER FLOW AS REQUIRED FLOW: 1 TO 7L PER MINUTE, FLOW SPEED ADJUSTABLE AIR VELOCITY: 10mm PER SECOND TEST TIME: 0 TO 999 MIN ADJUSTABLE SWING ANGLE AMPLITUDE OF SWING TUBE: ±45˙ ± 60˙ ±180˙ PENDULUM TUBE: IT IS DRIVEN BY SERVO MOTOR, WITH HIGH PRECISION AND ACCURATE TIME AND SWING WATER SUPPLY PIPELINE: PPR PIPE IS USED FOR EQUIPMENT WATER SUPPLY, WHICH IS ARRANGE ACCORDING TO BOX DISTRIBUTION AND CONTROLLED BY EQUIPMENT CONTROL SYSTEM CABINET. HEATING MODE: INCORPORATE STAINLESS STEEL HEATING PIPE, SHALLOW WATER PLATE SURFACE EVAPORATION. SPRAY CYCLE: THE SPRAY CYCLE IN THE BOX IS ADJUSTABLE, AND THE DOOR IS EQUIPPED WITH AN OBSERVATION WINDOW TO OBSERVE THE STATE OF THE SAMPLE IN THE BOX. WINDOW WIPED INSTALLED. QUANTITY: 1 Learn More

RAIN TEST CHAMBER WATER SPRAY SIMULATIONREFERENCE NUMBER: Y-2073 RAIN TEST CHAMBER WATER SPRAY SIMULATION THIS EQUIPMENT IS APPLICABLE TO THE TEST OF RAINPROOF DUST AND SAND SOAKED WATER OF VARIOUS AUTO PARTS, ELECTRONIC APPLIANCES, AND OTHER INDUSTRIAL ELECTRONIC PRODUCTS. AUTO PARTS INCLUDE THE TEST OF FULL SEALING STABILITY OF THE SYSTEM SUCH AS LAMPS, DOOR LOCKS, ELECTRICAL, INSTRUMENTS, DUST COVERS, ELECTRONIC HOUSEHOLD APPLIANCES, ETC. THE TESTED ITEMS ARE INSTALLED OR PLACE IN THE CENTER OF SEMICIRCLE BENDING TUBES AND BOTTOM AND SWING OF THE SPLASHED SAMPLES. THE AXIS IS IN A HORIZONTAL POSITION, AND THE SAMPLES ROTATES AROUND THE CENTERLINE DURING THE TEST. TECHNICAL PARAMETERS: CHAMBER SIZE: 600mm X 600mm X 600mm (WxDxH) DIAMETER OF SPRAY: ⊄0.4mm SPACING OF SPRAY HOLES: 50mm SPRAY PIPE DIAMETER: 16mm NOZZLE ANGLE ADJUSTABLE: 120 (IPX3) 180(IPX4) RADIUS OF SPRAY RING: R 375mm WATER PRESSURE: ADJUSTABLE WATER FLOW AS REQUIRED FLOW: 1 TO 7L PER MINUTE, FLOW SPEED ADJUSTABLE AIR VELOCITY: 10mm PER SECOND TEST TIME: 0 TO 999 MIN ADJUSTABLE SWING ANGLE AMPLITUDE OF SWING TUBE: ±45˙ ± 60˙ ±180˙ PENDULUM TUBE: IT IS DRIVEN BY SERVO MOTOR, WITH HIGH PRECISION AND ACCURATE TIME AND SWING WATER SUPPLY PIPELINE: PPR PIPE IS USED FOR EQUIPMENT WATER SUPPLY, WHICH IS ARRANGE ACCORDING TO BOX DISTRIBUTION AND CONTROLLED BY EQUIPMENT CONTROL SYSTEM CABINET. HEATING MODE: INCORPORATE STAINLESS STEEL HEATING PIPE, SHALLOW WATER PLATE SURFACE EVAPORATION. SPRAY CYCLE: THE SPRAY CYCLE IN THE BOX IS ADJUSTABLE, AND THE DOOR IS EQUIPPED WITH AN OBSERVATION WINDOW TO OBSERVE THE STATE OF THE SAMPLE IN THE BOX. WINDOW WIPED INSTALLED. QUANTITY: 1 Learn More -

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More -

YY-2353 ECONOCHAMP HOT MELT SWIRL/SPRAY GUNYY-2353 ECONOCHAMP HOT MELT SWIRL/SPRAY GUN HIGHEST QUALITY INDUSTRIAL HIGH FLOW HOT MELT HANDGUN FOR THE PRECISE SWIRL/SPRAY APPLICATION OF HOT MELT ADHESIVE. THESE HOT MELT GLUE GUNS USED WITH THE ECONOMELT HOT MELT TANKS IT REQUIRES A FLEXIBLE HEATED HOSE. QUANTITY: 1 Learn More

YY-2353 ECONOCHAMP HOT MELT SWIRL/SPRAY GUNYY-2353 ECONOCHAMP HOT MELT SWIRL/SPRAY GUN HIGHEST QUALITY INDUSTRIAL HIGH FLOW HOT MELT HANDGUN FOR THE PRECISE SWIRL/SPRAY APPLICATION OF HOT MELT ADHESIVE. THESE HOT MELT GLUE GUNS USED WITH THE ECONOMELT HOT MELT TANKS IT REQUIRES A FLEXIBLE HEATED HOSE. QUANTITY: 1 Learn More -

C-3785 AIRLAID THERMOBONDING AND SPRAY-BONDING LINE, WORKING WIDTH 2700mm, YEAR 2012

C-3785 AIRLAID THERMOBONDING AND SPRAY-BONDING LINE, WORKING WIDTH 2700mm, YEAR 2012C-3785 AIRLAID THERMOBONDING AND SPRAY-BONDING LINE, WORKING WIDTH 2700mm, YEAR 2012

OFFER 001

AIRLAID THERMOBONDING AND SPRAY-BONDING LINECONSISTING OF:

OFFER 002

АС-1500 BALE OPENERSOFFER 003

АS-204 BALE OPENEROFFER 004

SP-205 WEIGHT CONTROL TOWEROFFER 005

CONVEYOR BELTOFFER 006

AF-700 FINE OPENEROFFER 007

SF-1500 FINE OPENEROFFER 008

CF DOUBLE FILTEROFFER 009

BEMABLOW OPENEROFFER 010

T MAX FORMEROFFER 011

BEMAMULTISCALE ELECTRONIC CONTINUOUS WEIGHING SYSTEMOFFER 012

CF DOUBLE FILTEROFFER 013

SPRAY CABINOFFER 014

BOMBI TFP/2N OVENOFFER 015

CALENDEROFFER 016

COOLING SECIONOFFER 017

CUTTING SYSTEMLINEQUANTITY: 1 LINE

Learn More -

C-4014 MACHTEX SPRAYCOATING AND LAMINATING MACHINE, WORKING WIDTH 1600mm, YEAR 1994

C-4014 MACHTEX SPRAYCOATING AND LAMINATING MACHINE, WORKING WIDTH 1600mm, YEAR 1994C-4014 MACHTEX SPRAYCOATING AND LAMINATING MACHINE, WORKING WIDTH 1600mm, YEAR 1994

MAKE: MACHTEX

TYPE: ES3 - 150

YEAR: 1994

WORKING WIDTH: 1600mm

MACHINE LENGTH: 2250mm

MACHINE WIDTH: 2000mm

MACHINE HIGH: 2200mmQUANTITY: 1

Learn More -

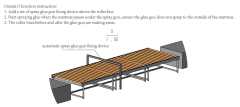

YY-1485-D MATTRESS CONVEYOR LINE WITH SPRAY BRIDGE FOR LAMINATING OR APPLYING GLUEYY-1485-D MATTRESS CONVEYOR LINE WITH SPRAY BRIDGE FOR LAMINATING OR APPLYING GLUE QUANTITY: 1 Learn More

YY-1485-D MATTRESS CONVEYOR LINE WITH SPRAY BRIDGE FOR LAMINATING OR APPLYING GLUEYY-1485-D MATTRESS CONVEYOR LINE WITH SPRAY BRIDGE FOR LAMINATING OR APPLYING GLUE QUANTITY: 1 Learn More -

HERGETH, HUNTER SPRAY BOND LINE, YEAR 1980 TO 1990REFERENCE NUMBER: T-6851 HERGETH, HUNTER SPRAY BOND LINE, YEAR 1980 TO 1990 BRAND: HERGETH, HUNTER SHORT DESCRIPTION: SPRAY BOND LINE YEAR: 1980 TO 1990 SPRAY BOND LINE, 160” CONSISTING OF: 1 FIBER CONTROL BLEND LINE (3 HOPPERS - 2-60” AND 1-36” W/FLOOR CONV.) 1 HUNTER BLEND LINE (3 HOPPERS- 72” 48”, 36” W/ FLOOR CONV.) 1 HERGETH BLEND LINE (4 HOPPERS- 36” W/FLOOR CONV.) 3 HERGETH FINE OPENERS 1200mm WIDE 3 SPINBAU 2000mm CARDS WITH CHUTE FEEDS 3 CROSSLAPPERS 160” WIDE (P&S/ WISE) 1 P&S SPRAY STATION - 160” 1 P&S 160” FLUTE OVEN 2 TEMP ZONES 2000mm BTU EACH P&S SLITTERS 9 KNIFES W/HOT WIRE CUTOFF AND 2 ROLL WINDER ALL FLOOR CONVEYORS AND SUPPORT EQUIPMENT CLARK 48 INCH 4 BARS CLAW PICKER FOR RECYCLE ALL EQUIPMENT RUNS ON 220/440 3 PHASE LATE 1980S-EARLY 90S THIS LINE IS CURRENTLY RUNNING QUANTITY: 3 Learn More

HERGETH, HUNTER SPRAY BOND LINE, YEAR 1980 TO 1990REFERENCE NUMBER: T-6851 HERGETH, HUNTER SPRAY BOND LINE, YEAR 1980 TO 1990 BRAND: HERGETH, HUNTER SHORT DESCRIPTION: SPRAY BOND LINE YEAR: 1980 TO 1990 SPRAY BOND LINE, 160” CONSISTING OF: 1 FIBER CONTROL BLEND LINE (3 HOPPERS - 2-60” AND 1-36” W/FLOOR CONV.) 1 HUNTER BLEND LINE (3 HOPPERS- 72” 48”, 36” W/ FLOOR CONV.) 1 HERGETH BLEND LINE (4 HOPPERS- 36” W/FLOOR CONV.) 3 HERGETH FINE OPENERS 1200mm WIDE 3 SPINBAU 2000mm CARDS WITH CHUTE FEEDS 3 CROSSLAPPERS 160” WIDE (P&S/ WISE) 1 P&S SPRAY STATION - 160” 1 P&S 160” FLUTE OVEN 2 TEMP ZONES 2000mm BTU EACH P&S SLITTERS 9 KNIFES W/HOT WIRE CUTOFF AND 2 ROLL WINDER ALL FLOOR CONVEYORS AND SUPPORT EQUIPMENT CLARK 48 INCH 4 BARS CLAW PICKER FOR RECYCLE ALL EQUIPMENT RUNS ON 220/440 3 PHASE LATE 1980S-EARLY 90S THIS LINE IS CURRENTLY RUNNING QUANTITY: 3 Learn More