Search results for: 'pillow+com''

-

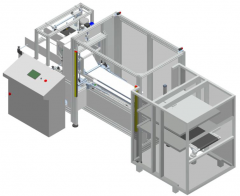

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More -

G-6925 ELECTRONIC STUFFING MACHINE FOR PILLOWS AND FURNISHING CUSHIONREFERENCE NUMBER: G-6925 ELECTRONIC STUFFING MACHINE FOR PILLOWS AND FURNISHING CUSHION QUANTITY AVAILABLE: 1 Learn More

G-6925 ELECTRONIC STUFFING MACHINE FOR PILLOWS AND FURNISHING CUSHIONREFERENCE NUMBER: G-6925 ELECTRONIC STUFFING MACHINE FOR PILLOWS AND FURNISHING CUSHION QUANTITY AVAILABLE: 1 Learn More -

E-9988 AUTOMATIC PILLOW MACHINEREFERENC ENUMBER: E-9988 AUTOMATIC PILLOW MACHINE MODEL: CF INSTALLATION AREA: 9000 X 5000 X 2100mm (29.5 FEET X 16.4 FEET X 82 INCHES) MIXING CHAMBER SIZE: AROUND 300KG (600 LBS) VOLTAGE: AS PER CUSTOMER REQUIREMENT POWER: 11.8KW CAPACITY: 6 PILLOWS PER MINUTE WEIGHING: ACCORDING TO THE TIME OF FILLING DISCHARGE. WEIGHT: 1.8MT (4000 LBS) LABOR: 1 OPERATOR CONTROL SYSTEM: COMPUTERIZED CONTROL SYSTEM QUANTITY AVAILABLE: 1 Learn More

E-9988 AUTOMATIC PILLOW MACHINEREFERENC ENUMBER: E-9988 AUTOMATIC PILLOW MACHINE MODEL: CF INSTALLATION AREA: 9000 X 5000 X 2100mm (29.5 FEET X 16.4 FEET X 82 INCHES) MIXING CHAMBER SIZE: AROUND 300KG (600 LBS) VOLTAGE: AS PER CUSTOMER REQUIREMENT POWER: 11.8KW CAPACITY: 6 PILLOWS PER MINUTE WEIGHING: ACCORDING TO THE TIME OF FILLING DISCHARGE. WEIGHT: 1.8MT (4000 LBS) LABOR: 1 OPERATOR CONTROL SYSTEM: COMPUTERIZED CONTROL SYSTEM QUANTITY AVAILABLE: 1 Learn More -

M-7753 DOWN PILLOW FILLING MACHINE WITHOUT WEIGHING SYSTEM

M-7753 DOWN PILLOW FILLING MACHINE WITHOUT WEIGHING SYSTEMREFERENCE NUMBER: M-7753

DOWN PILLOW FILLING MACHINE WITHOUT WEIGHING SYSTEM

DOWN PILLOW FILLING MACHINE

WITHOUT WEIGHING SYSTEM

BEST MACHINE IF YOU DON’T NEED EXACT WEIGHT FOR EVERY PILLOW

QUANTITY: 1

Learn More -

K-4611 LINE VACUUM FOR PILLOWS AND QUILTSREFERENCE NUMBER: K-4611 LINE VACUUM FOR PILLOWS AND QUILTS SMALL PLANT FOR BAGGING, VACUUM PRESS AND ROLL PILLOWS. IN THE LINE YOU INSERT CUSHIONS FIBER, LATEX AND POLYURETHANE OF VARIOUS DENSITIES, SHAPES AND SIZES, AS WELL AS DUVETS, QUILTS, ETC. WITH VOLUME REDUCTION UP TO MINUS (NEGATIVE) 70 PERCENT. QUANTITY AVAILABLE: 1 Learn More

K-4611 LINE VACUUM FOR PILLOWS AND QUILTSREFERENCE NUMBER: K-4611 LINE VACUUM FOR PILLOWS AND QUILTS SMALL PLANT FOR BAGGING, VACUUM PRESS AND ROLL PILLOWS. IN THE LINE YOU INSERT CUSHIONS FIBER, LATEX AND POLYURETHANE OF VARIOUS DENSITIES, SHAPES AND SIZES, AS WELL AS DUVETS, QUILTS, ETC. WITH VOLUME REDUCTION UP TO MINUS (NEGATIVE) 70 PERCENT. QUANTITY AVAILABLE: 1 Learn More -

G-6926 SYSTEM FOR THE PRODUCTION OF PILLOWS AND FURNISHING CUSHIONSREFERENCE NUMBER: G-6926 SYSTEM FOR THE PRODUCTION OF PILLOWS AND FURNISHING CUSHIONS QUANTITY AVAILABLE: 1 Learn More

G-6926 SYSTEM FOR THE PRODUCTION OF PILLOWS AND FURNISHING CUSHIONSREFERENCE NUMBER: G-6926 SYSTEM FOR THE PRODUCTION OF PILLOWS AND FURNISHING CUSHIONS QUANTITY AVAILABLE: 1 Learn More -

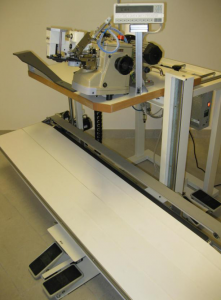

K-1428 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSREFERENCE NUMBER: K-1428 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONS FOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) QUANTITY AVAILABLE: 1 Learn More

K-1428 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSREFERENCE NUMBER: K-1428 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONS FOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) QUANTITY AVAILABLE: 1 Learn More -

V-1376 AKAB MACHINES, COMFORTER SHELL MAKERS, YEAR 1992, WIDTH 115” AND UNLIMITED LENGTH

V-1376 AKAB MACHINES, COMFORTER SHELL MAKERS, YEAR 1992, WIDTH 115” AND UNLIMITED LENGTHREFERENCE NUMBER: V-1376

AKAB MACHINES, COMFORTER SHELL MAKERS, YEAR 1992, WIDTH 115” AND UNLIMITED LENGTHAKAB MACHINES

COMFORTER SHELL MAKERS

MAXIMUM WIDTH: 115”

YEAR: 1992

WIDTH: 115 INCHESQUANTITY: 2

Learn More -

G-0967 PILLOW VACUUM PACKING MACHINEREFERENCE NUMBER: G-0967 PILLOW VACUUM PACKING MACHINE DESCRIPTION: SUITABLE FOR ALL KINDS OF HOME TEXTILE PRODUCS WHICH ARE PACKED WITH PLASTIC BAGS, SUCH AS PILLOWS, CUSHIONS AND PLUSH TOYS, SOFA CUSHION ETC THOSE SOFT STUFFING PRODUCTIONS. THE SUITABLE BAG MATERIAL CAN BE PP, PO & PE, PA, OPP, ETC. HIGH AUTOMATIC LEVEL OF CONTROL IMPORTED. THE SEALING TIME AND COOLING TIME CAN BE ADJUSTED ACCORDING TO THE BAG MATERIAL THICKNESS, NORMALLY IT IS 2 TO 3 SECONDS. EACH SEALING SIDE CAN BE HANDLED BY ONLY ONE OPERATOR. CAPACITY: 3 PIECES PER MINUTE QUANTITY AVAILABLE: 1 Learn More

G-0967 PILLOW VACUUM PACKING MACHINEREFERENCE NUMBER: G-0967 PILLOW VACUUM PACKING MACHINE DESCRIPTION: SUITABLE FOR ALL KINDS OF HOME TEXTILE PRODUCS WHICH ARE PACKED WITH PLASTIC BAGS, SUCH AS PILLOWS, CUSHIONS AND PLUSH TOYS, SOFA CUSHION ETC THOSE SOFT STUFFING PRODUCTIONS. THE SUITABLE BAG MATERIAL CAN BE PP, PO & PE, PA, OPP, ETC. HIGH AUTOMATIC LEVEL OF CONTROL IMPORTED. THE SEALING TIME AND COOLING TIME CAN BE ADJUSTED ACCORDING TO THE BAG MATERIAL THICKNESS, NORMALLY IT IS 2 TO 3 SECONDS. EACH SEALING SIDE CAN BE HANDLED BY ONLY ONE OPERATOR. CAPACITY: 3 PIECES PER MINUTE QUANTITY AVAILABLE: 1 Learn More -

J-4091 2 NOZZLE LARGE PILLOW FILLING MACHINE FOR DOWN AND FIBER – NEWJ-40912 NOZZLE LARGE PILLOW FILLING MACHINE FOR DOWN AND FIBER – NEW MAXIMUM THEORETICAL PRODUCTION: 900 KGS PER NOZZLE PER HOUR ACTUAL/PRACTICAL PRODUCTION: 450 KGS PER NOZZLE PER HOUR (FOR A 2 NOZZLE MACHINE THE REALISTIC PRODUCTION IS 900 KGS PER HOUR TOTAL) QUANTITY: 1 Learn More

J-4091 2 NOZZLE LARGE PILLOW FILLING MACHINE FOR DOWN AND FIBER – NEWJ-40912 NOZZLE LARGE PILLOW FILLING MACHINE FOR DOWN AND FIBER – NEW MAXIMUM THEORETICAL PRODUCTION: 900 KGS PER NOZZLE PER HOUR ACTUAL/PRACTICAL PRODUCTION: 450 KGS PER NOZZLE PER HOUR (FOR A 2 NOZZLE MACHINE THE REALISTIC PRODUCTION IS 900 KGS PER HOUR TOTAL) QUANTITY: 1 Learn More