Search results for: 'Machine+fe''

-

M-0428 CATTLE SLAUGHTERING AND PROCESSING EQUIPMENT FOR 200 CATTLES PER DAYREFERENCE NUMBER: M-0428-SHORT VERSION CATTLE SLAUGHTERING AND PROCESSING EQUIPMENT FOR 200 CATTLES PER DAY 200 CATTLES PER DAY QUANTITY AVAILABLE: 1 Learn More

M-0428 CATTLE SLAUGHTERING AND PROCESSING EQUIPMENT FOR 200 CATTLES PER DAYREFERENCE NUMBER: M-0428-SHORT VERSION CATTLE SLAUGHTERING AND PROCESSING EQUIPMENT FOR 200 CATTLES PER DAY 200 CATTLES PER DAY QUANTITY AVAILABLE: 1 Learn More -

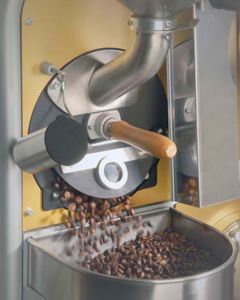

P-5077 PROBAT L25 ROASTER 25 KILOS

P-5077 PROBAT L25 ROASTER 25 KILOSP-5077 PROBAT L25 ROASTER 25 KILOS

PROBAT 25 FOLLOWS YEARS OF TRADITION IN BUILDING REALLY TOUGH EASY TO REPAIR TYPE MACHINERY. THIS NEW MODEL IS EVEN MORE FRIENDLY AS IT HAS ELIMINATED ALL THE CHAINS AND BELTS OF YEARS GONE BY . . . AND HOW IS TOTALLY DIRECT DRIVE MOTORS - 4 OF THEM . . . ONE FOR EACH FUNCTION OF THE MACHINE. DON'T FORGET THAT THIS MACHINE IS TALL ENOUGH TO REQUIRE A LOADER AND THIS BASIC MODEL DOES NOT INCLUDE THE LOADER OR A DESTONER OR AN AFTERBURNER . . . AS ALL THESE ITEMS MUST BE ADDED TO THE BASIC MACHINE.

PROFILE EDITION: PLEASE NOTE THAT PROBAT IS OFFERING A PROFILE PACKAGE THAT CAN BE ADDED TO THIS MACHINE.

SPECIFICATIONS:

CAPACITY PER BATCH: 26–55 LBS (11.8–25 KG)

BATCHES PER HOUR: 4

CAPACITY PER HOUR: 220 LBS (100 KG)

NATURAL GAS OR PROPANE: 190,000 BTU / HR

INLET FITTING: ½ INCHES

VOLTAGE: 230 / 460 V

FREQUENCY: 60 HZ

PHASE: 3

MAX. LOAD: 40 / 20 AMPS

DIMENSIONS: 7 FEET 6 INCHES H X 3 FEET 6 INCHES W X 6 FEET D

WEIGHT: 2,500 LBSQUANTITY: 1

Learn More -

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINEREFERENCE NUMBER: M-7873

CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

AUTOMATIC LINE

FOR CHOCOLATE CEREAL AND GRANOLA BARS

AUTOMATIC COMBINATION BETWEEN THE FREEZING, FORMING, AND PRESSING ROLLERS, AND THE SLITTING TECHNOLOGY.

THIS PRODUCING LINE IS A MULTI-FUNCTION LINE WHICH CONSISTS OF KITCHEN EQUIPMENTS, FORMING AND SHEETING SYSTEM, NUTS SPRINKLING SYSTEM, FORMING AND PRESSING ROLLER, REFRIGERATION SYSTEM, COOLING TUNNEL, CANDY BAR SLITTING, CUTTING AND CONVEYING SYSTEM, AND CHOCOLATE ENROBING MACHINE, ETC.

THIS LINE TAKES THE PLACE OF THE TRADITIONAL, MANUAL WORKSHOP PRODUCTION WITH FULL AUTOMATIC MACHINERY PRODUCTION. THIS LINE WILL BE IDEAL FOR THE CANDY BAR LEISURE FOOD INDUSTRY, WITH MODERN AND LARGE QUANTITY PRODUCTION.

Learn More -

R-6856 FUTURA K AUTOMATIC ROASTING MACHINES

R-6856 FUTURA K AUTOMATIC ROASTING MACHINESR-6856 FUTURA K AUTOMATIC ROASTING MACHINES

AUTOMATIC ROASTING MACHINES RESULT OF LONG STUDIES AND LIVED EXPERIENCE.

THE ROASTING MACHINES SERIES FUTURA K ARE THE RESULT OF LONG STUDIES AND LIVED EXPERIENCE ALONGSIDE OUR CLIENTS COFFEE ROASTERS, FOR THE REALIZATION OF THE MOST ADVANCED MACHINERIES IN THE FIELD OF INDUSTRIAL COFFEE ROASTING.

THE COMPACT DIMENSIONS, RELIABILITY OF THE MATERIALS AND COMPONENTS, THERMAL MANAGEMENT WITH IMMEDIATE RESPONSE, CALIBRATED AND PARTICULARLY FUEL EFFICIENT, HIGH THERMAL AND ACOUSTIC INSULATION AND OTHER POSITIVE FEATURES, MAKE THESE MACHINES REFERENCEGUIDE IN PROFESSIONAL ROASTING FIELD.MAIN COMPONENTS:

FEEDING HOPPER INSULATED WITH PNEUMATIC FILLER DEVICE, MOVABLE INLET, ELECTROPNEUMATIC UNLOADING CONTROL.

ROASTING DRUM MADE BY A FIXED HOUSING WITH DOUBLE INSULATING WALLS FOR THERMAL PROTECTION AND SUPPORTING THE ROTARY CYCLINDER THAT MOVES THE PRODUCT. THE WHOLE CYCLINDER IS MADE OF COMPOUND STEEL TO WITHSTAND THERMAL SHOCKS, ABSOLUTELY ODOURLESS, WITH PERFORATED SHEET FOR PRODUCT CONTAINEMENT, RIGHT AND LEFT BLENDERS SETTLED AT DIFFERENT LEVELS TO OBTAIN PERFECT MIXTURE.

WHEN THE ROASTING PROCESS IS FINISHED, THE COFFEE IS UNLOADED THROUGH A LARGE DOOR WITH ELECTROPNEUMATIC CONTROL OF OPENING AND CLOSING.

THE HEATING GENERATOR IS SPECIFICALLY DESIGNED FOR ROASTING LINE APPLICATIONS. THE PRINCIPLE OF HEATING IS BASED ON HOT AIR FLOWS BY CONVECTION. GAS OR GASOIL BURNER TYPE MODULATING OR MULTI LEVEL- FLAMES ACCORDING THE APPLICATION.

COOLING TANK WITH LARGE STAINLESS STEEL SURFACE, SELF CLEANING, WHERE THE PRODUCT IS MOVED BY MEANS OF 4 CROSSED ARMS. TWO DISCHARGES: ONE IS ELECTROPNEUMATICALLY DRIVEN AND THE OTHER IS MANUAL FOR EMERGENCY. DOOR OF INSPECTION AND EASY CLEANING OF THE LOWER SIDE.

PELLICLES SEPARATOR WITH EXTRACTION, BY WORM CONVEYOR OR INCINERATOR FOR CONSTANT EFFICIENCY OF THE AIR CHAFFS SEPARATION SYSTEM.

SUPPORTING FRAME IN TUBULAR PROFILES, STEEL MADE, TO CONTAIN AND SUPPORT THE OPERATING DEVICES, SO TO OBTAIN A COMPACT MACHINE-LIMITED ENCUMBRANCE, COMPLETE WITH PANELS FOR HEATING AND NOISE CONTAINMENT.

INDEPENDENT ELECTRIC CONTROL BOARD WITH PLC + TOUCH SCREEN AND ALL DEVICES FOR MACHINE CONTROL AND

MANAGEMENT, CAREFULLY WIRED AND EQUIPPED WITH ALL SIGNALS USEFULL FOR ROASTING PROCESS.STANDARD EQUIPMENT:

AUTOMATIC ROASTING SYSTEM MANAGED BY PLC + TOUCH SCREEN WITH RECORDING FOR ROASTING CURVES – PROFILES.

VISUALIZATION BY MONITOR OF TEMPERATURES AND ROASTING FUNTIONS.

FIRE PREVENTION EQUIPMENT ON THE ROASTING DRUM AND COOLING TANK; ON THE CYCLONE-CHAFFS SEPARATOR IF EQUIPPED WITH WORM CONVEYOR FOR CHAFFS EXTRACTION.

ALARM SYSTEM BY BUZZER AND SIGNAL LAMP, UPON INTERVENTION OF THE OVERLOAD PROTECTION DEVICES ON THE ELECTRIC-MOTORS AND ON THE BURNER.

PROTECTING SAFETY SYSTEMS.

CYCLONE FOR COOLING TANK: STANDARD ON MOD. 240-300- 360-480.

OPTIONALS EQUIPMENTCOMPUTERIZED AUTOMATIC ROASTING PROCESS CARP MANAGED BY PC AND MONITOR.

Learn More

HEATING RECOVERY SYSTE

SMOKE BURNER TYPE THERMICAL AND/OR CATALYST

CLEAN AIR ROASTING SYSTEM

CHAFFS COMPACTOR. -

G-4424-A COMPLETE CHICKEN SLAUGHTER LINE 500 PER HOURREFERENCE NUMBER: G-4424-A COMPLETE CHICKEN SLAUGHTER LINE 500 PER HOUR QUANTITY AVAILABLE: 1 Learn More

G-4424-A COMPLETE CHICKEN SLAUGHTER LINE 500 PER HOURREFERENCE NUMBER: G-4424-A COMPLETE CHICKEN SLAUGHTER LINE 500 PER HOUR QUANTITY AVAILABLE: 1 Learn More -

G-4424 COMPLETE CHICKEN SLAUGHTER LINE 500 PER HOURREFERENCE NUMBER: G-4424 COMPLETE CHICKEN SLAUGHTER LINE 500 PER HOUR QUANTITY AVAILABLE: 1 Learn More

G-4424 COMPLETE CHICKEN SLAUGHTER LINE 500 PER HOURREFERENCE NUMBER: G-4424 COMPLETE CHICKEN SLAUGHTER LINE 500 PER HOUR QUANTITY AVAILABLE: 1 Learn More -

R-6858 LITTLE COFFEE ROASTERS

R-6858 LITTLE COFFEE ROASTERSR-6858 LITTLE COFFEE ROASTERS

ROASTING MACHINE MODEL EXPO 500

THE LITTLE ROASTING MACHINE MODEL EXPO IS USED FOR LABORATORY TESTS OR TO SEARCH FOR NEW BLENDS AND FLAVORS. TECHNOLOGICALLY ADVANCED, CONFIRMS ITSELF AS IDEAL TOOL FOR LABORATORYES TEST, LIKE QUALITY CONTROL ON RAW COFFEE.

ROASTER MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, IS AVAILABLE WITH HEATING GENERATOR TYPE ELECTRIC RESISTANCE OR GAS, WITH MANUAL CONTROL SYSTEM.COMPONENTS:

HOPPER OF CHARGE

HEATING GENERATOR BY ELECTRIC RESISTANCE OR GAS BURNER

COOLING TANK

2 ELECTRONIC DISPLAYS TO CONTROL THE PRODUCT TEMPERATURE INSIDE

THE ROASTING DRUM AND HEATING GENERATOR.SAFETY DEVICE FOR ELECTRIC RESISTANCE SWITCHING OFF

DRUM ROTATION BY GEARED MOTOR

ELECTRIC FAN FOR ROASTING DRUM AND COOLING TANK

CYCLONE WITH REMOVABLE CONTAINER

COLOURS AVAILABLE: ACCORDING CLIENTS REQUEST

ROASTING MACHINE MOD.ROAST.1000

ROASTING MACHINE PARTICULARLY SUITABLE FOR SPECIALIZED ACTIVITIES IN SMALL BATCHES OF ROASTED COFFEE OF SUPERIOR QUALITY, SUCH AS THE MARKET “SLOW FOOD”, COFFEE SHOPS, CONFECTIONERY SHOP. TECHNOLOGICALLY ADVANCED, CONFIRMS ITSELF AS IDEAL TOOL SPECIALIZED IN PRODUCTION OF SELECTED ROASTED COFFEES OF HIGH QUALITY. MACHINE MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTERS, IS AVAILABLE WITH HEATING GENERATOR BY ELECTRIC RESISTANCE AND PLC CONTROL SYSTEM OR AUTOMATIC.

COMPONENTS:HOPPER OF CHARGE

Learn More

HEATING GENERATOR BY ELECTRIC RESISTANCE OR GAS BURNER

COOLING TANK

MONITOR TOUCH SCREEN TO SEE AND CONTROL ALL THE ROASTING PROCESS FUNCTIONS.

SAFETY DEVICE FOR ELECTRIC RESISTANCES SWITCHING OFF

DRUM ROTATION BY GEARED MOTOR

ELECTRIC FAN FOR ROASTING DRUM

ELECTRIC FAN FOR COOLING TANK

CYCLONE WITH REMOVABLE CONTAINER

DEVICE FOR AUTOMATIC UNLOADING AT THE END OF ROASTING CYCLE

ACOUSTIC ALARM ADVISING THE ENDING OF ROASTING CYCLE

AVAILABLE COLOURS: ALUMINIUM / BRASS -

Z-1670 CHOCOLATE TEMPERING MACHINEZ-1670 CHOCOLATE TEMPERING MACHINE MODEL: W250 FLOW CAPACITY (KGS PER HOUR): 250 POWER (KW): 8.3 REFRIGERATING UNIT (HP): 3 WEIGHT (KG): 580 MACHINE SIZE: 1100X800X1900 MODEL: 500 POWER: 10.57 REFRIGERATING UNIT (HP): 3 WEIGHT (KG): 880 MACHINE SIZE: 1200X1000X1900 QUANTITY: 1 Learn More

Z-1670 CHOCOLATE TEMPERING MACHINEZ-1670 CHOCOLATE TEMPERING MACHINE MODEL: W250 FLOW CAPACITY (KGS PER HOUR): 250 POWER (KW): 8.3 REFRIGERATING UNIT (HP): 3 WEIGHT (KG): 580 MACHINE SIZE: 1100X800X1900 MODEL: 500 POWER: 10.57 REFRIGERATING UNIT (HP): 3 WEIGHT (KG): 880 MACHINE SIZE: 1200X1000X1900 QUANTITY: 1 Learn More -

H-1150 WERNER & PFLEIDERER WIDE HARD AND SEMI SWEET DOUGH MULTIPURPOSE BISCUIT/COOKIE PRODUCTION LINE 1200mm

H-1150 WERNER & PFLEIDERER WIDE HARD AND SEMI SWEET DOUGH MULTIPURPOSE BISCUIT/COOKIE PRODUCTION LINE 1200mmREFERENCE NUMBER: H-1150

WERNER & pfleiderer wide hard and semi sweet dough multipurpose biscuit/cookie production line 1200mm

complete with biscuit stacking and full wrapping station

product DETAILS

ITEM PRODUCT NAME DIMENSIONS WEIGHT PPM

1 TEA BISCUIT 60Х45Х5.2 90 GRAM 127

2 TEA BISCUIT 60Х50Х6.3 180 GRAM 80

3 TEA BISCUIT 60Х50Х5.2 165 GRAM 90

4 CRACKER ROUND 40 Х5MM 42 GRAM 140

5 CRACKER TAIB 65Х50Х6.5 80 GRAM 130

6 CREAM SANDWICH 46Х34Х12 90 GRAM 70

7 HONEY GLUCOSE 48Х38Х6.5 50 GRAM 160

8 MINI SANDWICH Rnd. 27Х5 35 GRAM 45

9 MINI CRACKER ROUND 28Х5MM 35 GRAM 45

MACHINE DETAILS

M/C TYPE

1 WATER METER

2 MIXER TYPE Z K 900

3 DOUGH TROLLY

4 DOUGH FEEDING SYSTEM

5 LAMINATOR TYPE LU 800 E

6 ROTARY CUTTING TYPE RTA-G 1000

7 MOULDING MACHINE TYPE RTA-G 1000

8 CUTTING ROLLER TYPE 1000

9 MOULDING UNIT TYPE 1000

10 EGG WSH APPLICATOR TYPE DSV 1000

MACHINE DETAILS (CONT.)

M/C TYPE

11 TOPPING APPLICATOR TYPE 1000

12 WIRE MESH BAND OVEN SN 1000/60M

13 ARCAL SPRAY UNIT TYPE 1000

14 COOLING SYSTEM CONVEYOR

15 CONVEYOR # 1 CAVANNA

16 CONVEYOR #2 CAVANNA

17 BY PASS CONVEYOR CAVANNA

18 SLIDE CONVEYOR CAVANNA

19 TRACK CONVEYOR CAVANNA

20 PHASING CONVEYOR CAVANNA

21 ACCUMULATION CONVEYOR CAVANNA

22 VIBRATING UNIT CAVANNA

AND CONVEYOR BELT

23 SLUG BISCUIT FEEDER CAVANNA

24 PENNY STACKET CAVANNA

25 TRANSFERRING GROUP CAVANNA

26 CAVANNA PACKGAIN MACHINE ZERO5 NKZ

27 SINLON PACKAGE MACHINE SL500

28 COOKIES CAPPER MODEL 200 MK V1-3 METRIC

LINE DIMENSIONS:

TOTAL LENGTH OF LINE: 192 meters

LAMINATOR CONVEYOR: 20 meters

OVEN:

TOTAL LENGTH 75 meters

WORKING WIDTH: 1200mm

TOTAL WIDTH including: OVEN BODY: 2140mm

LINE DIMENSIONS:

COOLING CONVEYOR

LENGTH: 68 Meters

WIDTH of BELT: 1090mm

FRAME: 130mm

CAVANNA WRAPING AREA

LENGTH: 20 meters

CAVANNA WRAPPING MACHINE 05 NKZ

LENGTH: 9 Meters

Learn More -

R-3266 SIROCCO SR 35 ROASTER - 35 KILOS

R-3266 SIROCCO SR 35 ROASTER - 35 KILOSR-3266 SIROCCO SR 35 ROASTER - 35 KILOS

SEVEN “MACHINES” IN ONE BODY. THAT SAVES YOU PRECIOUS SPACE, EXPENSIVE ENERGY, REDUCES WASTE AND TOTALLY QUIET. WHEN COMPARING, REMEMBER THAT YOU WILL NEVER NEED TO BUY OXIDIZER, AND A AFTERBURNER, SINCE IT IS ALL INCLUDED.

AFTERBURNER

INCINERATOR

CHAFF COLLECTOR

MANUALLY & PROGRAMMED PROFILE CONTROLLER

VARIABLE AIR SPEED CONTROLLER

SEPARATE HEAT CONTROLLER

GAS MODULATING CONTROLLERCOMPLETE ROASTING PROCESS WITH ALL FEATURES BUILT INSIDE ONE MACHINE

GENTLE CAST IRON ROASTING ENVIRONMENT

MECHANICALLY FLUIDIZED BEAN MOVEMENT

INTEGRATED AFTERBURNER AND INCINERATOR

TO ELIMINATE SMOKE, ODOR AND CHAFF

GRAPHICAL TOUCH SCREEN WITH PROFILE MEMORY

OVERSIZED INSPECTION PORTS

STIRFLEX COOLING TRAY

QUICK-RELEASE COOLER WITH REMOVABLE SCREEN

MAINTENANCE FREE SEALED ROASTING DRUM

BUILT-IN STONER BOOT

LOW PROFILE INFEED HOPPER

WEB-ENABLED FOR FACTORY ASSISTANCE AND DIAGNOSTICS

AUTOMATIC OR SEMI-AUTOMATIC OPERATION FOR CONSISTENT BATCHES

CLEAR PROCESS INFORMATION INCLUDES BEAN TEMP., ELAPSED TIME,

TEMPERATURE CHANGE AND STATUSSPECIFICATIONS:

MODEL #: SR 35

BATCH CAPACITY: 35 KGS

DIMENSIONS: 35" W X 112" L X 84" H

COOLER DIAMETER: 40

HEAT SPECIFICATIONS: GAS & 380K-760K

WEIGHT: 3600 LBSQUANTITY: 1

Learn More