Search results for: 'aut'

- Related search terms

- automatic V

- AUTOMATIC'

- Automatic d

- Automatic+4

- aut''

-

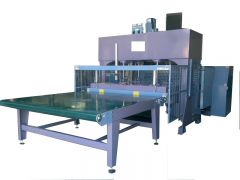

V-1210 AUTOMATIC MATTRESS COMPRESSION MACHINE WITH REMOVING TABLE

V-1210 AUTOMATIC MATTRESS COMPRESSION MACHINE WITH REMOVING TABLEREFERENCE NUMBER: V-1210

AUTOMATIC MATTRESS COMPRESSION MACHINE WITH REMOVING TABLEMODEL: G-21M

SIZE OF PRESSURE PLATE: 2100 X 2300mm

WORKING PRESSURE: 50T

DISTANCE OF OPENNING GEAR: 500M

NUMBER OF OIL CYLINDER: 4PCS

NUMBER OF AIR CYLINDER: 6PCS

NUMBER OF CONVEYER BELT: 1PIECE

POWER OF OIL PRESSURE: 5.5KW

HEATING POWER: 3KW

PUMP POWER: 3KW

TRANSMISSION POWER: 3KW

EXTERMAL DIMENSION: 5500mm X 2800mm X 2300mm

NET WEIGHT: 4000KGQUANTITY: 1

Learn More -

K-8928 AUTOMATIC BORDER LENGTH MEASURE AND CUTTINGREFERENCE NUMBER: K-8928 AUTOMATIC BORDER LENGTH MEASURE AND CUTTING - NEW MACHINE QUANTITY AVAILABLE: 1 Learn More

K-8928 AUTOMATIC BORDER LENGTH MEASURE AND CUTTINGREFERENCE NUMBER: K-8928 AUTOMATIC BORDER LENGTH MEASURE AND CUTTING - NEW MACHINE QUANTITY AVAILABLE: 1 Learn More -

G-8018 BEDLINE FULL AUTOMATIC MATTRESS FINISHING LINEREFERENCE NUMBER: G-8018 BEDLINE FULL AUTOMATIC MATTRESS FINISHING LINE QUANTITY AVAILABLE: 1 Learn More

G-8018 BEDLINE FULL AUTOMATIC MATTRESS FINISHING LINEREFERENCE NUMBER: G-8018 BEDLINE FULL AUTOMATIC MATTRESS FINISHING LINE QUANTITY AVAILABLE: 1 Learn More -

M-5329 GOLIATH AUTOMATIC UPHOLSTERED MATTRESS PRESSREFERENCE NUMBER: M-5329 (22015ZTP1RX) L GOLIATH AUTOMATIC UPHOLSTERED MATTRESS PRESS TECHNICAL FEATURES: CNC CONTROLLED – KEYPAD ON PLC BOARD PRESS ACTION: HYDRAULIC FUNCTION: 380 V THREE PHASES (OR AS PER CLIENT REQUIREMENTS) DIMENSIONS: 3100mm x 1400mm HEIGHT: 2200mm WEIGHT: 800 KG APPROXIMATELY IMMEDIATELY AVAILABLE FOR DELIVERY QUANTITY AVAILABLE: 1 Learn More

M-5329 GOLIATH AUTOMATIC UPHOLSTERED MATTRESS PRESSREFERENCE NUMBER: M-5329 (22015ZTP1RX) L GOLIATH AUTOMATIC UPHOLSTERED MATTRESS PRESS TECHNICAL FEATURES: CNC CONTROLLED – KEYPAD ON PLC BOARD PRESS ACTION: HYDRAULIC FUNCTION: 380 V THREE PHASES (OR AS PER CLIENT REQUIREMENTS) DIMENSIONS: 3100mm x 1400mm HEIGHT: 2200mm WEIGHT: 800 KG APPROXIMATELY IMMEDIATELY AVAILABLE FOR DELIVERY QUANTITY AVAILABLE: 1 Learn More -

M-3010 PORTER 2000 AUTOMATIC FLANGER

M-3010 PORTER 2000 AUTOMATIC FLANGERREFERENCE NUMBER: M-3010

PORTER 2000 AUTOMATIC FLANGER

MODEL: PFM 2000

IT INCLUDES SEWING TABLE WITH MOTOR, VACUUM SYSTEM, BOBBIN HOLDER, SEWING ARM AND FABRIC PULLING SYSTEM,NEEDLE POSITIONER

QUANTITY: 1

Learn More -

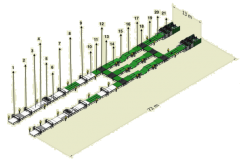

K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WIDTH: 2200mm CAPACITY: 1,000 MATTRESSES PER 8-HOUR SHIFT 1ST BRIDGE: 3 PNEUMATICALLY MOVING GUNS WITH 4 NOZZLES ON EACH HOTMELT GUN. CAN BE CONVERTED TO SPRAY AT NO EXTRA COST. 2ND BRIDGE: 2 GUNS FOR THE EDGE: ONE HAS 8 NOZZLES (T-SHAPED), THE OTHER HAS 4 NOZZLES. 3RD BRIDGE: 3 PNEUMATICALLY MOVING GUNS. THEY ARE SPRAY; LINE NOZZLES CAN BE ADDED 4TH BRIDGE: EXACTLY THE SAME AS 3RD BRIDGE. FLOORSPACE DIMENSIONS: 72000mm X 13000mm QUANTITY AVAILABLE: 1 Learn More

K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WIDTH: 2200mm CAPACITY: 1,000 MATTRESSES PER 8-HOUR SHIFT 1ST BRIDGE: 3 PNEUMATICALLY MOVING GUNS WITH 4 NOZZLES ON EACH HOTMELT GUN. CAN BE CONVERTED TO SPRAY AT NO EXTRA COST. 2ND BRIDGE: 2 GUNS FOR THE EDGE: ONE HAS 8 NOZZLES (T-SHAPED), THE OTHER HAS 4 NOZZLES. 3RD BRIDGE: 3 PNEUMATICALLY MOVING GUNS. THEY ARE SPRAY; LINE NOZZLES CAN BE ADDED 4TH BRIDGE: EXACTLY THE SAME AS 3RD BRIDGE. FLOORSPACE DIMENSIONS: 72000mm X 13000mm QUANTITY AVAILABLE: 1 Learn More -

K-4728 ELECTRONIC CUTTING MACHINE FOR STRETCH FABRIC FOR MATTRESSESREFERENCE NUMBER: K-4728 ELECTRONIC CUTTING MACHINE FOR STRETCH FABRIC FOR MATTRESSES HIGH PRECISION CAPABLE OF DOING THE JOB OF CUTTING PADDED QUILTED FABRICS WITH EASE AND PRECISION. QUANTITY AVAILABLE: 1 Learn More

K-4728 ELECTRONIC CUTTING MACHINE FOR STRETCH FABRIC FOR MATTRESSESREFERENCE NUMBER: K-4728 ELECTRONIC CUTTING MACHINE FOR STRETCH FABRIC FOR MATTRESSES HIGH PRECISION CAPABLE OF DOING THE JOB OF CUTTING PADDED QUILTED FABRICS WITH EASE AND PRECISION. QUANTITY AVAILABLE: 1 Learn More -

V-1053 POCKET COILER AND ASSEMBLER, NEW

V-1053 POCKET COILER AND ASSEMBLER, NEWREFERENCE NUMBER: V-1053

POCKET COILER AND ASSEMBLER, NEW

MODEL 12PA AUTO POCKET SPRING PRODUCTION LINE

MODEL 12PA AUTO POCKET SPRING PRODUCTION LINE IS MADE UP OF MODEL-12P POCKET SPRING MACHINE AND MODEL-08A AUTO POCKET SPRING ASSEMBLING MACHINE.

COMPLETELY AUTOMATIC, IT CAN FINISH ALL THE PROCESS OF PRODUCTION FROM POCKET SPRING TO MATTRESS.

EASY TO OPERATE, HIGH EFFICIENCY, AND LOW NOISE.

THE PRODUCTION LINE HAS A SMALL FOOT PRINT ON THE PLANT FLOOR.

THE PRODUCTION LINE IS CONTROLLED BY SERVO MOTORS, SO ACCURACY IS HIGH.

THE CONTROL PARAMETERS CAN BE SET BY THE CUSTOMER FOR DIVERSE DEMANDS.

AUTO STOP WHEN RUN OUT OF MATERIALS. (WITH CE CERTIFICATE)

TECHNICAL SPECIFICATIONS:

DESIGNATION MODEL 12P + MODEL 08A

PRODUCT EFFICIENCY 70 coils / min

SPRING DIAMETER End 45mm-60mm; Center 60mm-80mm

SPRING HEIGHT 80mm-120mm / 120mm-180mm / 160mm-220mm

STEEL WIRE DIAMETER 1.8mm-2.2mm

TOP AND BOTTOM With and without

NON-WOVEN

MAXIMUM POWER 32KW

SPACE DIMENSION (L X W X H) 9500mm x 3000mm x 1850mm

WEIGHT 4000kgs

Learn More -

K-4679 WRAPPING MANUAL FOR MATTRESSESREFERENCE NUMBER: K-4679 WRAPPING MANUAL FOR MATTRESSES SEMI-AUTOMATIC PACKAGING MACHINE FOR BAGGING MATTRESSES ON 4 SIDES COMPLETE WITH STAND MATTRESS QUANTITY AVAILABLE: 1 Learn More

K-4679 WRAPPING MANUAL FOR MATTRESSESREFERENCE NUMBER: K-4679 WRAPPING MANUAL FOR MATTRESSES SEMI-AUTOMATIC PACKAGING MACHINE FOR BAGGING MATTRESSES ON 4 SIDES COMPLETE WITH STAND MATTRESS QUANTITY AVAILABLE: 1 Learn More -

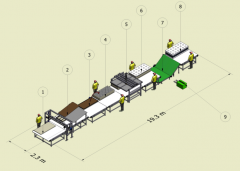

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More