Search results for: 'ass'

- Related search terms

- assem

- assemb

- assembly

- assembly machine

- assembl

-

J-3787 HUAJIAN AND VEYSEL KUTUKLU BONELL COILERS AND ASSEMBLERS FOR MATTRESS SPRINGSJ-3787 HUAJIAN AND VEYSEL KUTUKLU BONELL COILERS AND ASSEMBLERS FOR MATTRESS SPRINGS ITEM 001 MAKE: HUAJIAN QUANTITY: 2 ITEM 002 MAKE: VEYSEL KUTUKLU QUANTITY: 2 ITEM 003 MAKE: VEYSEL KUTUKLU ITEM 004 MAKE: VEYSEL KUTUKLU QUANTITY: 1 ITEM 005 MAKE: VEYSEL KUTUKLU QUANTITY: 1 ITEM 006 MAKE: VEYSEL KUTUKLU QUANTITY: 1 Learn More

J-3787 HUAJIAN AND VEYSEL KUTUKLU BONELL COILERS AND ASSEMBLERS FOR MATTRESS SPRINGSJ-3787 HUAJIAN AND VEYSEL KUTUKLU BONELL COILERS AND ASSEMBLERS FOR MATTRESS SPRINGS ITEM 001 MAKE: HUAJIAN QUANTITY: 2 ITEM 002 MAKE: VEYSEL KUTUKLU QUANTITY: 2 ITEM 003 MAKE: VEYSEL KUTUKLU ITEM 004 MAKE: VEYSEL KUTUKLU QUANTITY: 1 ITEM 005 MAKE: VEYSEL KUTUKLU QUANTITY: 1 ITEM 006 MAKE: VEYSEL KUTUKLU QUANTITY: 1 Learn More -

G-3651-A POCKET SPRING ASSEMBLY MACHINES (NEW): 07A MANUAL POCKET SPRING ASSEMBLING MACHINE

G-3651-A POCKET SPRING ASSEMBLY MACHINES (NEW): 07A MANUAL POCKET SPRING ASSEMBLING MACHINEREFERENCE NUMBER: G-3651-A

POCKET SPRING ASSEMBLY MACHINES (NEW):

07A MANUAL POCKET SPRING ASSEMBLING MACHINE

MANUAL POCKET SPRING ASSEMBLING MACHINE, MAINLY USE FOR ASSEMBLING DIFFERENT SIZE OF MATTRESS INNER. MANUEL INPUT THE SPRING LINE ON TO PRESS BOARD SPRAY OVERTURN PRESS, WHOLE ACTION WILL BE FINISHED AUTOMATIC. EASY CONTROL, HIGHLY EFFICIENCY.

DIMENSIONS: 3500MM×1640MM×1580MM

SPRING HEIGHT: 125-180MM

SPRING DIAMETER: ∮50-∮80MM

MAX WORKING WIDTH: 32PCS OF SPRING

GLUING TYPE: LINE/POINT

NON-WOVEN WIDTH: ≤2200MM

NON-WOVEN: ≥50G/M2

AIR PRESSURE: 6KGS/

MAX NON-WOVEN DIAMETER: ∮400MM

WORKING EFFICIENCY: 3ROWS/MIN(32COILS/ROW)

POWER: 4.5KW

WEIGHT: 880KG

Learn More -

J-1260 FIDES COIL ASSEMBLER, MODEL AS-4, 24 JAWS, COIL DIAMETER 2.75 INCH ES, YEAR 2009

J-1260 FIDES COIL ASSEMBLER, MODEL AS-4, 24 JAWS, COIL DIAMETER 2.75 INCH ES, YEAR 2009REFERENCE NUMBER: J-1260

Learn More

YEAR : 2009 (INSTALLED IN 2010)

COIL DIAMETER : 2.75 INCHES

MODEL: AS-4

QUANTITY: 1 -

V-1053 POCKET COILER AND ASSEMBLER, NEW

V-1053 POCKET COILER AND ASSEMBLER, NEWREFERENCE NUMBER: V-1053

POCKET COILER AND ASSEMBLER, NEW

MODEL 12PA AUTO POCKET SPRING PRODUCTION LINE

MODEL 12PA AUTO POCKET SPRING PRODUCTION LINE IS MADE UP OF MODEL-12P POCKET SPRING MACHINE AND MODEL-08A AUTO POCKET SPRING ASSEMBLING MACHINE.

COMPLETELY AUTOMATIC, IT CAN FINISH ALL THE PROCESS OF PRODUCTION FROM POCKET SPRING TO MATTRESS.

EASY TO OPERATE, HIGH EFFICIENCY, AND LOW NOISE.

THE PRODUCTION LINE HAS A SMALL FOOT PRINT ON THE PLANT FLOOR.

THE PRODUCTION LINE IS CONTROLLED BY SERVO MOTORS, SO ACCURACY IS HIGH.

THE CONTROL PARAMETERS CAN BE SET BY THE CUSTOMER FOR DIVERSE DEMANDS.

AUTO STOP WHEN RUN OUT OF MATERIALS. (WITH CE CERTIFICATE)

TECHNICAL SPECIFICATIONS:

DESIGNATION MODEL 12P + MODEL 08A

PRODUCT EFFICIENCY 70 coils / min

SPRING DIAMETER End 45mm-60mm; Center 60mm-80mm

SPRING HEIGHT 80mm-120mm / 120mm-180mm / 160mm-220mm

STEEL WIRE DIAMETER 1.8mm-2.2mm

TOP AND BOTTOM With and without

NON-WOVEN

MAXIMUM POWER 32KW

SPACE DIMENSION (L X W X H) 9500mm x 3000mm x 1850mm

WEIGHT 4000kgs

Learn More -

G-3980 MANUAL POCKET SPRING ASSEMBLY MACHINE

G-3980 MANUAL POCKET SPRING ASSEMBLY MACHINEREFERENCE NUMBER: G-3980

MANUAL POCKET SPRING ASSEMBLY MACHINE

THIS MACHINE CAN MAKE BOTH SIDE BY SIDE AND CROSS ASSEMBLING

DIMENSIONS: 3500mm×1425mm x 1400mm(EXCEPT THE WORKTABLE)

SPRING HEIGHT: 125 TO 180mm

SPRING DIAMETER: Ø50 TO Ø80mm

MAX WORKING WIDTH: 32 PCS OF SPRING

GLUING TYPE: LINE OR POINT

NON-WOVEN WIDTH: ≤2200mm

NON-WOVEN: ≥50G/M²

AIR PRESSURE: 6KGS/CM3

MAX NON-WOVEN DIAMETER: Ø400mm

WORKING EFFICIENCY: 3 ROWS/MIN(32COILS/ROW)

POWER: 3.5KW

WEIGHT: 750kg

UP AND DOWN NON-WOVEN: WITHOUT

Learn More -

J-0135 GRIBETZ INTERNATIONAL DG 3200 110” 360° COMPUTERIZED DOUBLE THREAD CHAINSTITCH QUILTER

J-0135 GRIBETZ INTERNATIONAL DG 3200 110” 360° COMPUTERIZED DOUBLE THREAD CHAINSTITCH QUILTERJ-0135 GRIBETZ INTERNATIONAL DG 3200 110” 360° COMPUTERIZED DOUBLE THREAD CHAINSTITCH QUILTER

GRIBETZ

BUILT IN 1990

CLASS III

3 NEEDLE BAR 1x3x6

(12”) 300mm CARRIAGE TRAVEL

WIDTH: 110”MACHINE SUPPLIED WITH FOLLOWING FEATURES:

3*3” FEED ROLLERS

2 THREAD RACKS FOR TOP THREAD AND LOOPER THREAD

2 SPECIAL BUTTERFLY THREAD TAKE-UP ASSEMBLIES FOR TOP AND BOTTOM THREAD

2 AUXILIARY FEED ROLL BRACKETS

3 PUSH BUTTON STATIONS

6 ECCENTRICS

1 YARDAGE COUNTER

120 NEEDLES

120 LOOPERS

40 STANDARD PATTERNS

EQUI-STITCHSPECIAL EQUIPMENT:

CATWALK WITH MATERIAL HANDLING PACK

ELECTRONIC THREAD BREAK DETECTOR

BACK CANOPY WITH MOTORIZED WIND-UPQUANTITY: 1

Learn More -

M-5724 OSTHOFF VP-97 SINGEING MACHINE YEAR 2001 WIDTH 2200mm

M-5724 OSTHOFF VP-97 SINGEING MACHINE YEAR 2001 WIDTH 2200mmM-5724 OSTHOFF VP-97 SINGEING MACHINE YEAR 2001 WIDTH 2200mm

SINGEING MACHINE

MAKE: OSTHOFF

MODEL: VP 97

YEAR: 2001

WIDTH: 2200mm

INCLUDES BRUSHER, WASHER, AND PADDER

STILL ASSEMBLED, BUT NOT RUNNINGQUANTITY: 1

Learn More -

M-6042 VACUUM PRESSING AND ROLLING UP MATTRESSES LINE

M-6042 VACUUM PRESSING AND ROLLING UP MATTRESSES LINEREFERENCE NUMBER: M-6042 (880699GY7RX) L

VACUUM PRESSING AND ROLLING UP MATTRESSES LINECOMPLETE LINE FOR VACUUM PRESSING AND ROLLING UP MATTRESSES

PRODUCTION: 3 MATTRESSES PER MINUTE

CAN WORK: VISCO / POLYURETHANE / LATEX / BONNELL SPRING / POCKET SPRING / ETC.QUANTITY: 1

Learn More -

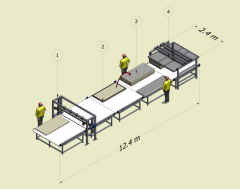

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More -

K-4724 AUTOMATIC LINE FOR HOT-MELT GLUING FOAM MATRESSESREFERENCE NUMBER: K-4724 AUTOMATIC LINE FOR HOT-MELT GLUING FOAM MATRESSES ONE LOCATION, SMALL SPACE REQUIREMENT AND EXTREME FUNCTIONALITY ENABLE AUTOMATIC OPERATION OF TIPPING, GLUEING THE FABRIC AND FINAL ASSEMBLY OF THE MATTRESS. WITH THIS LINE YOU CAN CONSTANTLY MANAGE THE QUANTITY OF GLUE BY TYPE OF PRODUCT REGARDLESS OF THE SIZE OR THE SHAPE, DETERMINE THE POINTS OF BONDING IN RELATION TO PROGRAMS AND CUSTOMIZED RECIPES, QUANTIFY A CERTAIN COST. QUANTITY AVAILABLE: 1 Learn More

K-4724 AUTOMATIC LINE FOR HOT-MELT GLUING FOAM MATRESSESREFERENCE NUMBER: K-4724 AUTOMATIC LINE FOR HOT-MELT GLUING FOAM MATRESSES ONE LOCATION, SMALL SPACE REQUIREMENT AND EXTREME FUNCTIONALITY ENABLE AUTOMATIC OPERATION OF TIPPING, GLUEING THE FABRIC AND FINAL ASSEMBLY OF THE MATTRESS. WITH THIS LINE YOU CAN CONSTANTLY MANAGE THE QUANTITY OF GLUE BY TYPE OF PRODUCT REGARDLESS OF THE SIZE OR THE SHAPE, DETERMINE THE POINTS OF BONDING IN RELATION TO PROGRAMS AND CUSTOMIZED RECIPES, QUANTIFY A CERTAIN COST. QUANTITY AVAILABLE: 1 Learn More