Search results for: 'Machine+we'

- Related search terms

- Machine+weight

-

C-3985 COMPLETE CFS AQUARIUS BALL LOLLIPOP LINE, YEAR 2004 TO 2006

C-3985 COMPLETE CFS AQUARIUS BALL LOLLIPOP LINE, YEAR 2004 TO 2006C-3985 COMPLETE CFS AQUARIUS BALL LOLLIPOP LINE, YEAR 2004 TO 2006

OFFER 001

COMPLETE CFS AQUARIUS BALL LOLLIPOP LINE

YEAR: 2004 TO 2006OFFER 002

KLOCKNER HANSEL PROCESSING BATCH ROLLER

YEAR: 2006OFFER 003

KLOCKNER HANSEL PROCESSING ROPE SIZER

YEAR: 2006OFFER 004

CFS AQUARIUS B.V. BALL FORMER 1000

YEAR: 2005OFFER 005

CFS AQUARIUS CONVEYOR BELT

YEAR: 2004OFFER 006

LOLLIPOP COOLER B

YEAR: 2005OFFER 007

CFS AQUARIUS B.V. BUNCH WRAPPER 600

YEAR: 2005QUANTITY: 1 LINE

Learn More -

A-2523 MELTBLOWN FABRIC PRODUCTION MACHINE 600 mmA-2523 MELTBLOWN FABRIC PRODUCTION MACHINE 600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 600mm PRODUCTION SPEED: 13 TO 17 M/min EXTRUDER DIAMETER IN mm: 65mm EXTRUDER MOTOR IN KW: 22KW PRODUCT WEIGHT RANGE: 5000 TO 6000 KGS MELTBLOWN FABRIC THICKNESS: 25 TO 30 GSM MAX OUTPUT: 300 TO 400 KG / 24 HOURS DIMENSION: 15000 X 3000 X 3000 mm WEIGHT: 5000 TO 6000 KGS POWER (TOTAL KW): 96 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 PRODUCTION TIME: 15 DAYS Learn More

A-2523 MELTBLOWN FABRIC PRODUCTION MACHINE 600 mmA-2523 MELTBLOWN FABRIC PRODUCTION MACHINE 600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 600mm PRODUCTION SPEED: 13 TO 17 M/min EXTRUDER DIAMETER IN mm: 65mm EXTRUDER MOTOR IN KW: 22KW PRODUCT WEIGHT RANGE: 5000 TO 6000 KGS MELTBLOWN FABRIC THICKNESS: 25 TO 30 GSM MAX OUTPUT: 300 TO 400 KG / 24 HOURS DIMENSION: 15000 X 3000 X 3000 mm WEIGHT: 5000 TO 6000 KGS POWER (TOTAL KW): 96 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 PRODUCTION TIME: 15 DAYS Learn More -

A-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mmA-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 1600mm PRODUCTION SPEED: 24 TO 30 M/min EXTRUDER DIAMETER IN mm: 90mm EXTRUDER MOTOR IN KW: 45 KW PRODUCT WEIGHT RANGE: 8000 TO 1000 KGS MELTBLOWN FABRIC THICKNESS: 25 TO 30 GSM MAX OUTPUT: 1500 TO 1800 KG / 24 HOURS DIMENSION: 20000 X 8000 X 9000 mm WEIGHT: 8000 TO 1000 KGS POWER (TOTAL KW): 575 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 + 1 X 20 PRODUCTION TIME: 45 DAYS Learn More

A-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mmA-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 1600mm PRODUCTION SPEED: 24 TO 30 M/min EXTRUDER DIAMETER IN mm: 90mm EXTRUDER MOTOR IN KW: 45 KW PRODUCT WEIGHT RANGE: 8000 TO 1000 KGS MELTBLOWN FABRIC THICKNESS: 25 TO 30 GSM MAX OUTPUT: 1500 TO 1800 KG / 24 HOURS DIMENSION: 20000 X 8000 X 9000 mm WEIGHT: 8000 TO 1000 KGS POWER (TOTAL KW): 575 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 + 1 X 20 PRODUCTION TIME: 45 DAYS Learn More -

F-1422 BALE BREAKER/FIBER MIXING SYSTEM 03E (NEW)REFERENCE NUMBER: F-1422 BALE BREAKER/FIBER MIXING SYSTEM 03E (NEW) MACHINE IS USED TO MIX FIBERS (SILICONIZED, NON-SILICONIZED POLYESTER, LOW MELT POLYESTER, CONJUGATE, HOLLOW POLYESTER FIBER) IN DIFFERENT RATIO AND SEND TO THE CARDING MACHINE. TECHNIQUE DATA: CAPACITY: 400 TO 600KG/H TOTAL POWER: 4.45KW PRE-OPENING MACHINE POWER: 7KW MACHINE WORKING WIDTH: 1200mm PRE-OPENER WORKING WIDTH: 1000mm WEIGHING CAPACITY: 1500GM WEIGHING TOLERANCE: 6% VOLUME OF WEIGHING HOPPER: 0.3M³ WEIGHING SPEED: 3 TO 5 TIMES/MIN OVERALL MACHINE DIMENSIONS: 6300mm × 3360mm × 1300mm QUANTITY AVAILABLE: 1 Learn More

F-1422 BALE BREAKER/FIBER MIXING SYSTEM 03E (NEW)REFERENCE NUMBER: F-1422 BALE BREAKER/FIBER MIXING SYSTEM 03E (NEW) MACHINE IS USED TO MIX FIBERS (SILICONIZED, NON-SILICONIZED POLYESTER, LOW MELT POLYESTER, CONJUGATE, HOLLOW POLYESTER FIBER) IN DIFFERENT RATIO AND SEND TO THE CARDING MACHINE. TECHNIQUE DATA: CAPACITY: 400 TO 600KG/H TOTAL POWER: 4.45KW PRE-OPENING MACHINE POWER: 7KW MACHINE WORKING WIDTH: 1200mm PRE-OPENER WORKING WIDTH: 1000mm WEIGHING CAPACITY: 1500GM WEIGHING TOLERANCE: 6% VOLUME OF WEIGHING HOPPER: 0.3M³ WEIGHING SPEED: 3 TO 5 TIMES/MIN OVERALL MACHINE DIMENSIONS: 6300mm × 3360mm × 1300mm QUANTITY AVAILABLE: 1 Learn More -

M-5138 SQUARE COTTON PAD PRODUCTION MACHINEREFERENCE NUMBER: M-5138 (12121745V11UX) L SQUARE COTTON PAD PRODUCTION MACHINE MODEL: XF SPEED: 1800 TO 3000 PCS/MINUTE PRODUCT SIZE: WIDTH: 40 TO 100mm, LENGTH 40 TO 100mm RAW MATERIAL SIZE: 1000mm, DIAMETER LESS THAN 1000mm POWER: 380V FREQUENCY: 50 HZ TOTAL POWER: 4.5KW DIMENSION: LENGTH: 2500mm, WIDTH: 1900mm, HEIGHT: 1600mm WEIGHT: 2500KG QUANTITY AVAILABLE: 1 Learn More

M-5138 SQUARE COTTON PAD PRODUCTION MACHINEREFERENCE NUMBER: M-5138 (12121745V11UX) L SQUARE COTTON PAD PRODUCTION MACHINE MODEL: XF SPEED: 1800 TO 3000 PCS/MINUTE PRODUCT SIZE: WIDTH: 40 TO 100mm, LENGTH 40 TO 100mm RAW MATERIAL SIZE: 1000mm, DIAMETER LESS THAN 1000mm POWER: 380V FREQUENCY: 50 HZ TOTAL POWER: 4.5KW DIMENSION: LENGTH: 2500mm, WIDTH: 1900mm, HEIGHT: 1600mm WEIGHT: 2500KG QUANTITY AVAILABLE: 1 Learn More -

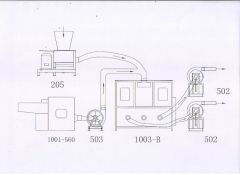

L-2926 COMBINATION PILLOW AND CUSHION FILLING MACHINE FIBER OPENER AND FOAM SHREDDER LINE

L-2926 COMBINATION PILLOW AND CUSHION FILLING MACHINE FIBER OPENER AND FOAM SHREDDER LINEREFERENCE NUMBER: L-2926

Learn More

1 X FIBER CARDING MACHINE

MODEL: 1001-560

1 X FIBER FEEDING MACHINE

MODEL: 503

1 X MIXING MACHINE

MODEL: 1003-B

2 X FILLING MACHINES

MODEL: 502

QUANTITY: 1 SET

FOAM SHREDDER

MODEL: 205

QUANTITY: 1 -

M-6054 EXTRUSION PLANT FOR FOAMED PET, WORKING WIDTH SHEETS 610mm x 240mm

M-6054 EXTRUSION PLANT FOR FOAMED PET, WORKING WIDTH SHEETS 610mm x 240mmM-6054 EXTRUSION PLANT FOR FOAMED PET, WORKING WIDTH SHEETS 610mm x 240mm

OFFER 001

EXTRUSION PLANT

FOR FOAMED PET

WORKING WIDTH: SHEETS 610mm x 240mm

THICKNESS: 5mm TO 60mm

DENSITY: 80 TO 250 KG/M3

CAPACITY: UP TO 500 KG PER HOUROFFER 002

SILO FOR VIRGIN MATERIALOFFER 003

DRYING SYSTEM (SUITABLE FOR 500 KG PER HOUR)OFFER 004

GRAVIMETRIC FEEDING SYSTEMOFFER 005

GAS STOCKING SYSTEMOFFER 006

GAS FEEDING SYSTEMOFFER 007

EXTRUDEROFFER 008

SCREEN CHANGEROFFER 009

STRAND DYE WITH ELEMENTS FOR EXTRUSIONOFFER 010

PNEUMATIC SHAPER FOR SHAPING THE BOARD BY ADJUSTING THE LOADOFFER 011

HAUL OFF UNITOFFER 012

ROLLERS FOR BOARDS CONVEYINGOFFER 013

PULLER HAUL OFFOFFER 014

TRANSVERSAL CUTTING UNITOFFER 015

FINISHING EQUIPMENTOFFER 016

BLOCK WELDING MACHINEOFFER 017

FINISHING PLATFORMOFFER 018

HORIZONTAL CUTTING MACHINEOFFER 019

SHEETS WELDING MACHINEOFFER 020

SCRAPS RECYCLING SYSTEMOFFER 021

GRINDER TO MILL THE PIECES OF MATERIALOFFER 022

COMPACTING UNITOFFER 023

STORING SILOS FOR DENSIFIED FOAM PETOFFER 024

PROCESS ELECTRIC SYSTEM OF EXISTING MACHINES ACCORDING TO THE ACTUAL LAYOUTOFFER 025

CABLES AND CABLING MATERIALSOFFER 026

PIPINGQUANTITY: 1 PLANT

Learn More -

M-5148 COTTON PAD MAKING MACHINEREFERENCE NUMBER: M-5148 (121215HNF11U) L COTTON PAD MAKING MACHINE MODEL: YM-01 BREADTH: 1020mm FEEDING FORM: MECHANICAL FREQUENCY CONTROL & TWICE-WEIGHING WEIGHT UNEVENNESS FOR FEEDING: 0.7% ~ 1.7% APPLICABLE FIBER LENGTH: 24 TO 75mm DRAFT MULTIPLE 6 7.3~120.2 OUTPUT PER MACHINE HOUR: 5~25KG TOTAL POWER OF MOTORS: 7.37KG TOTAL WEIGHT OF THE MACHINE: APPROXIMATELY 7.5 TONS TOTAL FLOOR SPACE (LxW): 7500mm x 2000mm QUANTITY AVAILABLE: 1 Learn More

M-5148 COTTON PAD MAKING MACHINEREFERENCE NUMBER: M-5148 (121215HNF11U) L COTTON PAD MAKING MACHINE MODEL: YM-01 BREADTH: 1020mm FEEDING FORM: MECHANICAL FREQUENCY CONTROL & TWICE-WEIGHING WEIGHT UNEVENNESS FOR FEEDING: 0.7% ~ 1.7% APPLICABLE FIBER LENGTH: 24 TO 75mm DRAFT MULTIPLE 6 7.3~120.2 OUTPUT PER MACHINE HOUR: 5~25KG TOTAL POWER OF MOTORS: 7.37KG TOTAL WEIGHT OF THE MACHINE: APPROXIMATELY 7.5 TONS TOTAL FLOOR SPACE (LxW): 7500mm x 2000mm QUANTITY AVAILABLE: 1 Learn More -

H-1305 BATT FEEDING SYSTEM - WORKING WIDTH 3000mm

H-1305 BATT FEEDING SYSTEM - WORKING WIDTH 3000mmH-1305 BATT FEEDING SYSTEM - WORKING WIDTH 3000mm

WORKING WIDTH: 3000mm

CONTROL SYSTEM INCLUDEDCOMPOSITION OF THE MACHINE:

- LOWER PVC INCLINED CONVEYOR BELT FOR THE TRANSPORT OF THE WEB FROM THE CROSS LAPPER TO THE ENTRANCE OF THE NEEDLE LOOM.

- UPPER PVC COMPRESSION BELT FOR THE PRE-COMPRESSION OF THE WEB BEFORE ENTERING THE FEEDING ROLLS.

- LOWER PVC CONVEYOR AND UPPER PVC BELT DRIVEN BY ONE GEARBOX MOTOR WITH INDEPENDENT FREQUENCY INVERTER.

- PAIR OF FEEDING ROLLS WITH PLASTIC FINGERS TO GUIDE THE COMPRESSED WEB CLOSE TO FIRST NEEDLE ZONE OF THE PRE-NEEDLE LOOM. ROLLER PAIR DRIVEN BY GEARBOX MOTOR WITH INDEPENDENT FREQUENCY INVERTER.

- BATT FEEDING SYSTEM INSTALLED ON RAIL SYSTEM AND EASY REMOVABLE FOR MAINTENANCE OF THE NEEDLE LOOMTECHNICAL DATA:

ELECTRICAL INFORMATION:

ELECTRIC: MAIN VOLTAGE 400 V, 50 HZ, 3 PH.

CONTROL VOLTAGE: DC - 24 V / AC - 230 V

OTHER INFORMATION:

AIR PRESSURE (CONSTANT): MIN. 6 BAR (AT SITE)

OPERATOR SIDE LEFT OR RIGHT (IN WEB RUNNING DIRECTION)

LACQUER COATING:

MAIN COLOR OF THE MACHINES: RAL 7035 (LIGHT GREY)

CONTROL CABINET AND CONTROL DESK RAL 7035 (LIGHT GREY)

LABELING: ENGLISH

TECHNICAL DOCUMENTATION: ONE TIME ON CD-ROM (FURTHER SETS AVAILABLE AT ADDITIONAL COST)

LANGUAGE FOR OPERATING INSTRUCTIONS: ENGLISH

LANGUAGE FOR FURTHER DOCUMENTATION (SPARE PART LISTS, WIRING DIAGRAM, ETC): ENGLISHENVIRONMENTAL CONDITIONS:

INSTALLATION HEIGHT ABOVE SEA LEVEL: LESS THAN OR EQUAL TO 1,000 METERS

TEMPERATURE: 24° C (±2° C)

RELATIVE HUMIDITY: 65% (±5%)

ABSOLUTE WATER CONTENT: 9 TO 12 G/KG DRY AIR

NOTE: PLEASE MAKE SURE THAT THE TEMPERATURE INSIDE THE CONTROL CABINET DOES NOT EXCEED 450 CENTIGRADE. IN CASE OF EXCESSIVE ROOM TEMPERATURES WE RECOMMEND AN AIR-CONDITIONING SYSTEM FOR THE CONTROL CABINETS TO AVOID MALFUNCTION OF ELECTRICAL COMPONENTSQUANTITY: 1

Learn More -

X-1016 NONWOVEN LINE FOR PRODUCING POLYESTER BATTING WIDTH 3600 mm (NEW 2015)REFERENCE NUMBER: X-1016 NONWOVEN LINE FOR PRODUCING POLYESTER BATTING WIDTH 3600 mm (NEW 2015) 1) –Opening and Blending line 2) - CROSSLAPER 3)- Thermobonding Oven 4) – Including main control panel. 3 YEAR EXTENDED WARRANTY OUR COMPANY OFFERS INSTALLATION AND COMMISSIONING OF THIS LINE FOR OUR MACHINES 2 TECHNICAL IN THE PLACE TO BE APPOINTED BY THE CUSTOMER. Learn More

X-1016 NONWOVEN LINE FOR PRODUCING POLYESTER BATTING WIDTH 3600 mm (NEW 2015)REFERENCE NUMBER: X-1016 NONWOVEN LINE FOR PRODUCING POLYESTER BATTING WIDTH 3600 mm (NEW 2015) 1) –Opening and Blending line 2) - CROSSLAPER 3)- Thermobonding Oven 4) – Including main control panel. 3 YEAR EXTENDED WARRANTY OUR COMPANY OFFERS INSTALLATION AND COMMISSIONING OF THIS LINE FOR OUR MACHINES 2 TECHNICAL IN THE PLACE TO BE APPOINTED BY THE CUSTOMER. Learn More