Search results for: 'Electric di'

- Related search terms

- Electric dia

- electric con

- electrica

- Electrical sa

- Electrical ca

-

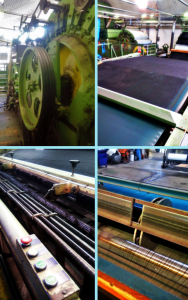

AUTEFA, DILO, SPINNBAU COMPLETE NONWOVEN LINEREFERENCE NUMBER: T-6855 AUTEFA, DILO, SPINNBAU COMPLETE NONWOVEN LINE BRAND: AUTEFA, DILO, SPINNBAU SHORT DESCRIPTION: COMPLETE NONWOVEN LINE ITEM 001 SINGLE DOFFER CARD BY “BESSI” - ITALY YEAR 1966 - WORKING WIDTH 2500mm - HOPPER-FEEDER WITH SCALE (WEIGHPAN) AND TOP SILO - INLET UNIT WITH ROLLERS - BREAST UNIT DIAMETER 1500mm WITH 3 PAIRS WORKERS/ STRIPPER (ORIGINALLY EQUIPPED WITH 5 PAIRS, UNUSED 2 PAIRS STILL AVAILABLE) - FANCY ROLL - TRANSPORT ROLL DIAMETER 1200mm - SWIFT DIAMETER 1500mm WITH 3 PAIRS WORKERS/ STRIPPER (ORIGINALLY EQUIPPED WITH 5 PAIRS, UNUSED 2 PAIRS STILL AVAILABLE) - DOFFER DIAMETER 1500mm WITH FLY-COMB - FLEXIBLE AND RIGID METALLIC WIRES IN EXCELLENT CONDITIONS QUANTITY: 1 ITEM 002 CROSS-LAPPER BY “MAK-AUTEFA” - GERMANY MODEL 101-42 YEAR 1965 - INLET WORKING WIDTH 2500mm - EXIT WORKING WIDTH 3000mm QUANTITY: 1 ITEM 003 PRE-NEEDLER BY “DILO” - GERMANY MODEL NFZ 3000 YEAR 1967 - WORKING WIDTH 3000mm - 2 NEEDLE BOARDS WITH TOTALLY 3000 NEEDLES / LIN MT - WITH BATT INLET UNIT QUANTITY: 1 ITEM 004 FINISH NEEDLERS BY “DILO” MODEL OD II 25 YEAR 1979 EACH - WORKING WIDTH 2500mm EACH - EACH ONE WITH 2 NEEDLE BOARDS WITH TOTALLY 5000 NEEDLES / LIN MT QUANTITY: 2 ITEM 005 TRANSVERSAL CUTTER BY “SPINNBAU-AUTEFA” - GERMANY. YEAR 1973 - WORKING WIDTH 2500mm QUANTITY: 1 ITEM 006 LONGITUDINAL CUTTER ITALIAN MAKE + ROLL WINDER ITALIAN MAKE ON ELECTRONIC WEIGHTING CELLS. WORKING WIDTH 2500mm QUANTITY: 1 ITEM 007 ROLLS LIFTING CRANE QUANTITY: 1 ALL ELECTRIC MOTORS AND CONTROL PANELS 400 V / 50 Hz Learn More

AUTEFA, DILO, SPINNBAU COMPLETE NONWOVEN LINEREFERENCE NUMBER: T-6855 AUTEFA, DILO, SPINNBAU COMPLETE NONWOVEN LINE BRAND: AUTEFA, DILO, SPINNBAU SHORT DESCRIPTION: COMPLETE NONWOVEN LINE ITEM 001 SINGLE DOFFER CARD BY “BESSI” - ITALY YEAR 1966 - WORKING WIDTH 2500mm - HOPPER-FEEDER WITH SCALE (WEIGHPAN) AND TOP SILO - INLET UNIT WITH ROLLERS - BREAST UNIT DIAMETER 1500mm WITH 3 PAIRS WORKERS/ STRIPPER (ORIGINALLY EQUIPPED WITH 5 PAIRS, UNUSED 2 PAIRS STILL AVAILABLE) - FANCY ROLL - TRANSPORT ROLL DIAMETER 1200mm - SWIFT DIAMETER 1500mm WITH 3 PAIRS WORKERS/ STRIPPER (ORIGINALLY EQUIPPED WITH 5 PAIRS, UNUSED 2 PAIRS STILL AVAILABLE) - DOFFER DIAMETER 1500mm WITH FLY-COMB - FLEXIBLE AND RIGID METALLIC WIRES IN EXCELLENT CONDITIONS QUANTITY: 1 ITEM 002 CROSS-LAPPER BY “MAK-AUTEFA” - GERMANY MODEL 101-42 YEAR 1965 - INLET WORKING WIDTH 2500mm - EXIT WORKING WIDTH 3000mm QUANTITY: 1 ITEM 003 PRE-NEEDLER BY “DILO” - GERMANY MODEL NFZ 3000 YEAR 1967 - WORKING WIDTH 3000mm - 2 NEEDLE BOARDS WITH TOTALLY 3000 NEEDLES / LIN MT - WITH BATT INLET UNIT QUANTITY: 1 ITEM 004 FINISH NEEDLERS BY “DILO” MODEL OD II 25 YEAR 1979 EACH - WORKING WIDTH 2500mm EACH - EACH ONE WITH 2 NEEDLE BOARDS WITH TOTALLY 5000 NEEDLES / LIN MT QUANTITY: 2 ITEM 005 TRANSVERSAL CUTTER BY “SPINNBAU-AUTEFA” - GERMANY. YEAR 1973 - WORKING WIDTH 2500mm QUANTITY: 1 ITEM 006 LONGITUDINAL CUTTER ITALIAN MAKE + ROLL WINDER ITALIAN MAKE ON ELECTRONIC WEIGHTING CELLS. WORKING WIDTH 2500mm QUANTITY: 1 ITEM 007 ROLLS LIFTING CRANE QUANTITY: 1 ALL ELECTRIC MOTORS AND CONTROL PANELS 400 V / 50 Hz Learn More -

L-7129 NONWOVEN SMS PRODUCTION LINE, 1600mm, SPUNBONDED, MELT BLOWN

L-7129 NONWOVEN SMS PRODUCTION LINE, 1600mm, SPUNBONDED, MELT BLOWNPP CHIPS FOR MELTBLOWN: 1200 TO 2000

FABRIC WIDTH: 1600mm

2 SPINNING BEAMS FOR SPUNBOND & 1 FOR MELTBLOWN

BASIC WEIGHT: SMS 9 TO 80 GRAMS PER SQUARE METER

SS: 15 TO 100 GRAMS PER SQUARE METERPRODUCT:

SMS LAMINATED NONWOVEN FABRIC

SS SPUNBOND NONWOVEN FABRIC SS

M MELTBLOWN NONWOVEN FABRIC MTO MAKE HYGENIC FABRICS SUCH AS BABY DIAPERS, SANITARY NAPKINS, ADULT DIAPERS, MEDICAL OPERATION SUITS, OPERATION CAPS, OPERATIONS SHOES, MASKS, ETC.

CONSISTING OF:

3 X FEEDING SYSTEMS

AUTOMATIC VACUUM SUCTION FOR BOTH MAIN MATERIAL AND ADDITIVES

CAPACITY (SB + MB) 2 X 520 KGS/H, (SB) 2 X 200 KGS/HR

WITH THREE HOPPERS, THREE SUPPLIYING DEVICESSPUNBOND SYSTEM

2 X EXTRUDERS

DIAMETER: 150mm

CAPACITY: 450 KGS/HR

L/D 30:1

DRIVE POWER: 110 KW

HEATING POWER: 90 KW2 X RECYCLING SYSTEMS

DIAMETER: 105mm

CAPACITY: 100 KGS PER HOUR

L/D: 15:12 X MELT FILTERS

WORKING TEMPERATURE: UP TO 280 CELSIUS

FILTRATION CAPACITY: 520 KGS PER HOUR2 X METERING PUMPS

TYPE: GEAR PUMP

FLOW VOLUME: 250 ML/R

DESIGNING TEMPERATURE: 280 CELSIUS2 X MELT PIPELINES

WITH STATIC MIXER2 X MONOMER EXHAUSTER

INCLUDING BLOWER, CHILLER, PIPELINE, VALVE, INSULATION, ETC2 X SPINNING BEAMS

SINGLE COAT-HANGER MELT DISTRIBUTION

DESIGNING PRESSURE: 9MPA

WORKING TEMPERATURE: MAX 280 CELSIUS4 X SPINNERETS

HOLE DIAMETER: 0.45mm

L/D: 5:1

15,500 HOLESMELTBLOWN SYSTEM

1 X EXTRUDER

DIAMETER 120mm

CAPACITY: 280 KGS/HR

L/D: 30:1

DRIVE POWER: 75 KW

HEATING POWER: 80 KW1 X MELT FILTER

FILTRATION PRECISION: 20 TO 60 MICROMETERS

FILTRATION: 280 KGS PER HOUR1 X METERING PUMP

GEAR PUMP

MAX. FLOW VOLUME: 100ML/R

DESIGNED TEMPERATURE: 300 CELSIUS1 X MELT PIPELINE

WITH STATIC MIXER1 X SPINNING BEAM

INCLUDING STRETCHING CHANNEL, NOZZLE, ETC. WITH INSULATION MATERIAL

DESIGNED PRESSURE: 6 MPA2 X SPINNING DIE PACKS

COMPACT DIE PACKS

HOLE DIAMETER: 0.35mm

L/D: 12:1

# OF HOLES: 42HPI1 X SCREW BLOWER

INCLUDING MUFFLE, PRESSURE REDUCER VALVE, PIPELINE, ETC.

POWER: 200 KW1 X HOT AIR SYSTEM

FLOW VOLUME: 6000 CUBIC METERS PER HOUR

WORKING TEMP: MAX 350 CELSIUS

INCLUDING HEATER, STAINLESS STEEL PIPELINE, ETC.

POWER: 290 KW1 X OFF-LINE CONVEYOR

RANGE OF SPEED: 5 TO 100 METERS PER MINUTE1 X CONVEYOR

MECHANICAL SPEED: MAX 400 METERS PER MINUTE

BELT WIDTH AND PENETRATION

3800±10mm, 10000 CUBIC METERS PER H.M21 X CALENDAR

DOUBLE ROLLS HEATED BY OIL

PROCESS SPEED: 350 METERS PER MINUTE

EMBOSSING WIDTH: UP TO 2000mm

MAX LINEAR PRESSURE: 110 DAN/C

MAX. TEMP OF EMBOSSING ROLLER, 180 CELSIUS1 X WINDER

ONLINE CHANGING ROLL, ONLINE EDGE CUTTING, TENSION CONTROL

MAX. LINEAR SPEED: 350 METERS PER MINUTE

WIDTH: 1600mm

WIND DIAMETER: MAX 1500mm1 X SLITTER

MAX. LINE SPEED: 600 METERS PER MINUTE

MAX. WIND DIAMETER: 1200mm

MIN. SLITTING WIDE: 120mm

22 CIRCULAR BLADES1 X STEEL PLATFORM

1 X ELECTRICAL CONTROL SYSTEM

2 X OIL OVEN

1 X AIR CONDITIONING SYSTEM

1 X WATER COOLING SYSTEM

1 X CLEANING EQUIPMENTS FOR DIE PACK

1 X AUXILIARY PLATFORM

1 X AUXILIARY EQUIPMENTS

1 X LABORATORY TESTING DEVICE

Learn More -

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More -

SPINNBAU CARDING LINE, YEAR 2013REFERENCE NUMBER: T-6848 SPINNBAU CARDING LINE, YEAR 2013 BRAND: SPINNBAU SHORT DESCRIPTION: CARDING LINE YEAR: 2013 INSTALLED 2014 LIKE NEW, LITTLE RUN TIME 4 HOPPER TEMAFA BLEND LINE, 1600mm WIDE, 1 WITH CONDENSER FED FROM TRIM MACHINE CARDING WILLOW – 800mm WIDE FEED BELT AND 1200mm WIDE – TEMAFA TEMAFA MIXMASTER BLENDING BIN – 3000mm WIDE X 8000mm LONG X 4600mm HIGH (FILL HEIGHT 3000mm). 72 CUBIC METER CAPACITY. TEMAFA FINE OPENER – 2000mm WIDE WITH PINS 3000mm SPINNBAU CARD FEEDING UNIT – FEED TRUNK, VIBRATING CHUTE, WEIGHT BELT 708mm BREAST SECTION WITH 3 WORKERS AND STRIPPERS, 1500mm MAIN WITH 5 W/S AND (2) 708mm DOFFERS. 1 FOUNDATIONS AND PLATFORMS. DILO PROFILINE – BATT WEIGHT CONTROL SYSTEM MAHLO WEIGHT MEASURING UNIT – QUALISCAN CMS-12 DILO LAYER CROSSLAPPER – TYPE DLS 30/60 – 3000mm INFEED AND UP TO 6000mm LAYDOWN. MAX WEB HEIGHT 650mm. MAXIMUM SPEED 125M/MIN. SPINNBAU LAP DRAFTER TYPE VST 19 – MAX 6000mm WORKING WIDTH. 9 ROLLER PAIRS. LIFTING DEVICE TO ALLOW FOR 600mm CLEARANCE. 159mm ROLLER DIAMETER. INFEED HEIGHT 650 mm BRUCKNER THERMOBONDING OVEN – 5000mm OVEN WITH 3 HEATING AND 2 COOLING ZONE. MAGNETIC BELT. 3 NATURAL GAS MAXON BURNER. SLITTING – 9 POSITION BRUCKNER CRUSH CUTTER SLITTING HEADS. PNEUMATIC LIFTING. 450mm KNIFE DIAMETER CROSS CUTTER – ROTARY CUTTER STYLE WITH CLAMPING. CAPABLE OF 3 CUTS/MINUTES FOR MATERIALS UP TO 200mm THICK. WINDING – ASCENDING BATCH STYLE WINDER. MAX ROLL DIAMETER OF 1200mm. 3000mm DRIVEN FEED CONVEYOR. MANDREL GUIDANCE SYSTEM, MANUALLY ADJUSTABLE BRAKE SYSTEM FOR CONTROLLING TENSILE FORCE AND COMPACTION. TEMAFA FILTER HOUSE – TFS 50. MAX FLOW 50,000 CUBIC METER/H ELECTRICL INFO – 3 X 480V/60Hz. CONTROLS 110V AC/24 DC. SIEMENS PLC QUANTITY: 1 Learn More

SPINNBAU CARDING LINE, YEAR 2013REFERENCE NUMBER: T-6848 SPINNBAU CARDING LINE, YEAR 2013 BRAND: SPINNBAU SHORT DESCRIPTION: CARDING LINE YEAR: 2013 INSTALLED 2014 LIKE NEW, LITTLE RUN TIME 4 HOPPER TEMAFA BLEND LINE, 1600mm WIDE, 1 WITH CONDENSER FED FROM TRIM MACHINE CARDING WILLOW – 800mm WIDE FEED BELT AND 1200mm WIDE – TEMAFA TEMAFA MIXMASTER BLENDING BIN – 3000mm WIDE X 8000mm LONG X 4600mm HIGH (FILL HEIGHT 3000mm). 72 CUBIC METER CAPACITY. TEMAFA FINE OPENER – 2000mm WIDE WITH PINS 3000mm SPINNBAU CARD FEEDING UNIT – FEED TRUNK, VIBRATING CHUTE, WEIGHT BELT 708mm BREAST SECTION WITH 3 WORKERS AND STRIPPERS, 1500mm MAIN WITH 5 W/S AND (2) 708mm DOFFERS. 1 FOUNDATIONS AND PLATFORMS. DILO PROFILINE – BATT WEIGHT CONTROL SYSTEM MAHLO WEIGHT MEASURING UNIT – QUALISCAN CMS-12 DILO LAYER CROSSLAPPER – TYPE DLS 30/60 – 3000mm INFEED AND UP TO 6000mm LAYDOWN. MAX WEB HEIGHT 650mm. MAXIMUM SPEED 125M/MIN. SPINNBAU LAP DRAFTER TYPE VST 19 – MAX 6000mm WORKING WIDTH. 9 ROLLER PAIRS. LIFTING DEVICE TO ALLOW FOR 600mm CLEARANCE. 159mm ROLLER DIAMETER. INFEED HEIGHT 650 mm BRUCKNER THERMOBONDING OVEN – 5000mm OVEN WITH 3 HEATING AND 2 COOLING ZONE. MAGNETIC BELT. 3 NATURAL GAS MAXON BURNER. SLITTING – 9 POSITION BRUCKNER CRUSH CUTTER SLITTING HEADS. PNEUMATIC LIFTING. 450mm KNIFE DIAMETER CROSS CUTTER – ROTARY CUTTER STYLE WITH CLAMPING. CAPABLE OF 3 CUTS/MINUTES FOR MATERIALS UP TO 200mm THICK. WINDING – ASCENDING BATCH STYLE WINDER. MAX ROLL DIAMETER OF 1200mm. 3000mm DRIVEN FEED CONVEYOR. MANDREL GUIDANCE SYSTEM, MANUALLY ADJUSTABLE BRAKE SYSTEM FOR CONTROLLING TENSILE FORCE AND COMPACTION. TEMAFA FILTER HOUSE – TFS 50. MAX FLOW 50,000 CUBIC METER/H ELECTRICL INFO – 3 X 480V/60Hz. CONTROLS 110V AC/24 DC. SIEMENS PLC QUANTITY: 1 Learn More -

C-3964 JAGENBERG CUTTING MACHINE, WIDTH 1800mm, YEAR 1973 TO 2006

C-3964 JAGENBERG CUTTING MACHINE, WIDTH 1800mm, YEAR 1973 TO 2006C-3964 JAGENBERG CUTTING MACHINE, WIDTH 1800mm, YEAR 1973 TO 2006

JAGENBERG CUTTING MACHINE

BRAND: JAGENBERG

YEAR: 1973 TO 2006

WIDTH: 1800mmQUANTITY: 1

Learn More -

M-5251 DILO SNO 25 LOOP NEEDLE LOOM YEAR 1971 WIDTH 2500mmREFERENCE NUMBER: M-5251 (1313725BK12RX) L DILO SNO 25 LOOP NEEDLE LOOM YEAR 1971 WIDTH 2500mm DILO LOOP NEEDLE LOOM MAKE: DILO TYPE: SNO 25 YEAR: 1971 WORKING WIDTH: 2500mm NEEDLES: CA. 3,000 NEEDLES NEEDLING: SINGLE BOARD DOWN LAMELLA GAUGE: 3.5mm QUANTITY AVAILABLE: 1 Learn More

M-5251 DILO SNO 25 LOOP NEEDLE LOOM YEAR 1971 WIDTH 2500mmREFERENCE NUMBER: M-5251 (1313725BK12RX) L DILO SNO 25 LOOP NEEDLE LOOM YEAR 1971 WIDTH 2500mm DILO LOOP NEEDLE LOOM MAKE: DILO TYPE: SNO 25 YEAR: 1971 WORKING WIDTH: 2500mm NEEDLES: CA. 3,000 NEEDLES NEEDLING: SINGLE BOARD DOWN LAMELLA GAUGE: 3.5mm QUANTITY AVAILABLE: 1 Learn More -

M-1804 DILO OD IV 25-FOUR BOARD DOWN STROKE NEEDLE LOOM-2500mm-YEAR 1983REFERENCE NUMBER: M-1804 (770685GH7RX) DILO OD IV 25-FOUR BOARD DOWN STROKE NEEDLE LOOM-2500mm-YEAR 1983 MAKE: DILO MODEL: DILO OD IV 25 WORKING WIDTH 2500mm YEAR 1983 QUANTITY AVAILABLE: 1 Learn More

M-1804 DILO OD IV 25-FOUR BOARD DOWN STROKE NEEDLE LOOM-2500mm-YEAR 1983REFERENCE NUMBER: M-1804 (770685GH7RX) DILO OD IV 25-FOUR BOARD DOWN STROKE NEEDLE LOOM-2500mm-YEAR 1983 MAKE: DILO MODEL: DILO OD IV 25 WORKING WIDTH 2500mm YEAR 1983 QUANTITY AVAILABLE: 1 Learn More -

V-1360 SANTEX THERMOBONDING COMPRESSION OVEN FOR NONWOVENS ON ROLL, 80 TO 400 G/M, YEAR 1986

V-1360 SANTEX THERMOBONDING COMPRESSION OVEN FOR NONWOVENS ON ROLL, 80 TO 400 G/M, YEAR 1986V-1360 SANTEX THERMOBONDING COMPRESSION OVEN FOR NONWOVENS ON ROLL, 80 TO 400 G/M, YEAR 1986

WORKING WIDTH: 2500mm

ROLL FACE WIDTH: WORKING WIDTH + 50mm

MATERIAL FIBERS: NONWOVEN WEB OF POLYESTER OR DIFFERENT FIBERS MIXED WITH 10 TO 25% POLYESTER BI-COMPONENT BINDER FIBERS OR DIFFERENT BINDER FIBERS

MACHINE SPEED: 1 TO 20 M/MIN. (OTHERS UPON REQUEST)

COMPOSITION OVEN: 2 HEATING ZONES OF 2 M EACH + 1 COOLING SECTIONQUANTITY: 1

Learn More -

M-5138 SQUARE COTTON PAD PRODUCTION MACHINEREFERENCE NUMBER: M-5138 (12121745V11UX) L SQUARE COTTON PAD PRODUCTION MACHINE MODEL: XF SPEED: 1800 TO 3000 PCS/MINUTE PRODUCT SIZE: WIDTH: 40 TO 100mm, LENGTH 40 TO 100mm RAW MATERIAL SIZE: 1000mm, DIAMETER LESS THAN 1000mm POWER: 380V FREQUENCY: 50 HZ TOTAL POWER: 4.5KW DIMENSION: LENGTH: 2500mm, WIDTH: 1900mm, HEIGHT: 1600mm WEIGHT: 2500KG QUANTITY AVAILABLE: 1 Learn More

M-5138 SQUARE COTTON PAD PRODUCTION MACHINEREFERENCE NUMBER: M-5138 (12121745V11UX) L SQUARE COTTON PAD PRODUCTION MACHINE MODEL: XF SPEED: 1800 TO 3000 PCS/MINUTE PRODUCT SIZE: WIDTH: 40 TO 100mm, LENGTH 40 TO 100mm RAW MATERIAL SIZE: 1000mm, DIAMETER LESS THAN 1000mm POWER: 380V FREQUENCY: 50 HZ TOTAL POWER: 4.5KW DIMENSION: LENGTH: 2500mm, WIDTH: 1900mm, HEIGHT: 1600mm WEIGHT: 2500KG QUANTITY AVAILABLE: 1 Learn More -

T-7949 NEEDLE PUNCHING MACHINE, WIDTH 3300mmT-7949 NEEDLE PUNCHING MACHINE, WIDTH 3300mm QUANTITY: 1 Learn More

T-7949 NEEDLE PUNCHING MACHINE, WIDTH 3300mmT-7949 NEEDLE PUNCHING MACHINE, WIDTH 3300mm QUANTITY: 1 Learn More