Search results for: 'Open+w'

- Related search terms

- Open+width+com

- open+width+com',))',(;))#-+--

- open+wi

- open+width+com'[0]

- open+width+com',

-

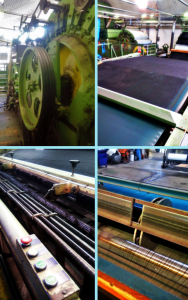

C-3786 STITCH-BONDING LINE, WORKING WIDTH 1800mm TO 2600mm

C-3786 STITCH-BONDING LINE, WORKING WIDTH 1800mm TO 2600mmC-3786 STITCH-BONDING LINE, WORKING WIDTH 1800mm TO 2600mm

OFFER 001

STITCH-BONDING LINECONSISTING OF:

OFFER 002

ALEXANDRE & ANTOINE SINGLE DOFFER CARDOFFER 003

SWIFTOFFER 004

CROSS-LAPPEROFFER 005

MALIMO MALIWATT 14001/25/8 STITCH-BONDING MACHINEOFFER 006

WINDEROFFER 007

LAROCHE EDGE-TRIM OPENERQUANTITY: 1 LINE

Learn More -

C-2481 NONWOVEN LINE FOR WOOLEN INSULATION MATERIAL, WIDTH 2500mm, YEAR 2007 TO 2012REFERENCE NUMBER: C-2481 NONWOVEN LINE FOR WOOLEN INSULATION MATERIAL, WIDTH 2500mm, YEAR 2007 TO 2012 SPECIFICATIONS: NONWOVEN LINE FOR WOOLEN INSULATION MATERIAL YEAR OF CONSTRUCTION: VARIOUS, PLEASE SEE BELOW. THE LINE IS CONSISTING OF: BALE OPENER WITH CARDING WILLOW. METAL SEPARATOR MADE IN APPROX. 2007. PASS THROUGH CLEANER MADE IN APPROX. 2007. HOPPER FEEDER WITH FINE OPENER, RECONDITIONED EQUIPMENT. 2 LARGE BLENDING BINS WITH BIN EMPTIER, RECONDITIONED IN 2009. COMPLETE SUCTION AND AIR FILTRATION UNIT WITH DRUM FILTER AND COARSE FIBER PRE FILTER WITH FIBRE COMPACTOR AS WELL AS FINE DUST SEPARATOR. HOPPER FEEDER WITH RESERVE CHUTE. AIRLAY LINE MADE IN 2011. 2500 mm WORKING WIDTH. DOUBLE BAND OVEN MADE IN 2010, VERY EFFICIENT. LONGITUDINAL CUTTING DEVICE WITH 6 DRIVEN UPPER AND LOWER KNIVES. CROSS CUTTER WITH STRONG POWER, MADE IN 2012. VARIOUS VENTILATORS, CONDENSER, PIPES, PIPE SWITCHES, EVENTUALLY ALSO INCLUDING ELECTRO FORK LIFT WITH BALE CLAMP. THE LINE IS SUITABLE TO PROCESS WOOL AS WELL AS OTHER SHORT AND SHORTEST FIBERS, ALSO RECYCLED COTTON. CAPACITY OF THE LINE: APPROX. 350 TO 400 KG/H. QUANTITY AVAILABLE: 1 Learn More

C-2481 NONWOVEN LINE FOR WOOLEN INSULATION MATERIAL, WIDTH 2500mm, YEAR 2007 TO 2012REFERENCE NUMBER: C-2481 NONWOVEN LINE FOR WOOLEN INSULATION MATERIAL, WIDTH 2500mm, YEAR 2007 TO 2012 SPECIFICATIONS: NONWOVEN LINE FOR WOOLEN INSULATION MATERIAL YEAR OF CONSTRUCTION: VARIOUS, PLEASE SEE BELOW. THE LINE IS CONSISTING OF: BALE OPENER WITH CARDING WILLOW. METAL SEPARATOR MADE IN APPROX. 2007. PASS THROUGH CLEANER MADE IN APPROX. 2007. HOPPER FEEDER WITH FINE OPENER, RECONDITIONED EQUIPMENT. 2 LARGE BLENDING BINS WITH BIN EMPTIER, RECONDITIONED IN 2009. COMPLETE SUCTION AND AIR FILTRATION UNIT WITH DRUM FILTER AND COARSE FIBER PRE FILTER WITH FIBRE COMPACTOR AS WELL AS FINE DUST SEPARATOR. HOPPER FEEDER WITH RESERVE CHUTE. AIRLAY LINE MADE IN 2011. 2500 mm WORKING WIDTH. DOUBLE BAND OVEN MADE IN 2010, VERY EFFICIENT. LONGITUDINAL CUTTING DEVICE WITH 6 DRIVEN UPPER AND LOWER KNIVES. CROSS CUTTER WITH STRONG POWER, MADE IN 2012. VARIOUS VENTILATORS, CONDENSER, PIPES, PIPE SWITCHES, EVENTUALLY ALSO INCLUDING ELECTRO FORK LIFT WITH BALE CLAMP. THE LINE IS SUITABLE TO PROCESS WOOL AS WELL AS OTHER SHORT AND SHORTEST FIBERS, ALSO RECYCLED COTTON. CAPACITY OF THE LINE: APPROX. 350 TO 400 KG/H. QUANTITY AVAILABLE: 1 Learn More -

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More -

L-2274 FOAM CUTTING MACHINE FOR SPAGHETTI OR STRIPS OR CUBES

L-2274 FOAM CUTTING MACHINE FOR SPAGHETTI OR STRIPS OR CUBESREFERENCE NUMBER: L-2274

Learn More

MODEL: P-500

WIDTH: 1200mm

QUANTITY: 1

MODEL: A-500

WIDTH: 1200mm

QUANTITY: 1 -

C-4394 SCHOTT & MEISSNER AIRLAID THERMOBONDING LINE, WORKING WIDTH 3400mm, YEAR 2014

C-4394 SCHOTT & MEISSNER AIRLAID THERMOBONDING LINE, WORKING WIDTH 3400mm, YEAR 2014C-4394 SCHOTT & MEISSNER AIRLAID THERMOBONDING LINE, WORKING WIDTH 3400mm, YEAR 2014

SCHOTT & MEISSNER AIRLAID THERMOBONDING LINE

YEAR: 2014

WORKING WIDTH: 3400mm

ON THE MILL FLOOR BUT NEVER INSTALLED

CONSISTING OF:

1 BO 150 BALE OPENER

1 FO 125 FINE OPENER

1 TFF 30 TRANSPORT FAN

2 FC 150 FILLING CAGES

2 BO 150 BALE OPENERS

3 WPS 150 WEIGHING PLATE SYSTEMS

2 CMO 150 CONTINUOUS MIXING OPENERS

1 TFF 30 TRANSPORT FAN

1 LVB 150 LARGE VOLUME BLENDER

1 TFF 30 TRANSPORT FAN

1 DMX METAL DETECTOR

1 PO 175 BUFFER EQUIPMENT

1 TFF 30 TRANSPORT FAN

1 AWF 344 AIRLAID SYSTEM

1 TOPCON LP OVEN

DOUBLE BELT

2 X 3 M SECTIONS

2 X 2 M COOLING SECTIONS

1 CUTTING AND WINDING UNIT

UP TO 1 400 KG/HQUANTITY: 1 LINE

Learn More -

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mm

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmREFERENCE NUMBER: A-1876

END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmPRODUCT TO BE PROCESSED: NEEDLEPUNCHED NONWOVENS

PRODUCT WIDTH: 4.000 MMWORKING SPEED: 1 – 20 M/MIN

QUANTITY: 1

Learn More -

C-4010 NEEDLE PUNCHING PRODUCTION LINE, WORKING WIDTH 3000mm TO 6000mm, YEAR 2005

C-4010 NEEDLE PUNCHING PRODUCTION LINE, WORKING WIDTH 3000mm TO 6000mm, YEAR 2005REFERENCE NUMBER: C-4010

NEEDLE PUNCHING PRODUCTION LINE, WORKING WIDTH 3000mm TO 6000mm, YEAR 2005

DETAILS:

OFFER 001

NEEDLE PUNCHING PRODUCTION LINE

YEAR: 2005

WORKING WIDTH: 6000mm

WEIGHT: 120 TO 800 G/M²

MATERIAL: PP, PES

CAPACITY: 600 KG/H

WITH FOLLOWING FIBERS:

6.7 DTEX

FIBER LENGTH: 60 TO 90mm

WORKING HOURS: CA. 41000 H

CONSISTS OF:

OFFER 002

BALE OPENER

MAKE: FALUBAZ

FEEDING TABLE: 1000mm WIDTH

2000mm LENGTH

WITH ELECTRONICALLY WEIGH BOXES

COLLECTING CONVEYOR

AND MIXING UNIT

QUANTITY: 4

OFFER 003

CHAMBER FIBER MIXING UNIT

QUANTITY: 6

OFFER 004

FINE OPENER

WITH METAL DETECTOR

QUANTITY: 1

OFFER 005

DUST COLLECTION UNIT

QUANTITY: 2

OFFER 006

FOR VOLUMETRIC HOPPER FEEDER

MAKE: FOR

TYPE: HF

QUANTITY: 1

OFFER 007

FOR CARDING MACHINE

MAKE: FOR

TYPE: WM 2+2

WORKING WIDTH: 3000mm

BREAST: 3X WORKERS / STRIPPERS

TAMBOUR: 4X WORKERS / STRIPPERS

DOUBLE DOOFER

CONDENSING SYSTEM

QUANTITY: 1

OFFER 008

AUTOMATEX CROSSLAPPER

MAKE: AUTOMATEX

TYPE: FA 5000/TC

WITH PROFILING

QUANTITY: 1

OFFER 009

ASSELIN WEB DRAFTER

MAKE: ASSELIN

TYPE: ETO-15

ROLLERS: 15

QUANTITY: 1

OFFER 010

AUTOMATEX PRE – NEEDLE LOOM

MAKE: AUTOMATEX

TYPE: PR160/T

NEEDING: DOUBLE BOARD DOWN

NEEDLES: 2X 8000 N/M

STROKE: 55mm

INCLUSIVE CBF FEEDING SYSTEM

QUANTITY: 1

OFFER 011

AUTOMATEX NEEDLE LOOM

MAKE: AUTOMATEX

TYPE: AG160/TB

NEEDING: 4 BOARD QUATTRO PUNCH

NEEDLES: 4X 8000 N/M

STROKE: 65mm

QUANTITY: 1

OFFER 012

BELMATEX ACCUMULATOR

MAKE: BELMATEX

QUANTITY: 1

OFFER 013

BELMATEX END OF LINE

MAKE: BELMATEX

SLITTER

WINDER

QUANTITY: 1

QUANTITY: 1 LINE

Learn More -

M-6054 EXTRUSION PLANT FOR FOAMED PET, WORKING WIDTH SHEETS 610mm x 240mm

M-6054 EXTRUSION PLANT FOR FOAMED PET, WORKING WIDTH SHEETS 610mm x 240mmM-6054 EXTRUSION PLANT FOR FOAMED PET, WORKING WIDTH SHEETS 610mm x 240mm

OFFER 001

EXTRUSION PLANT

FOR FOAMED PET

WORKING WIDTH: SHEETS 610mm x 240mm

THICKNESS: 5mm TO 60mm

DENSITY: 80 TO 250 KG/M3

CAPACITY: UP TO 500 KG PER HOUROFFER 002

SILO FOR VIRGIN MATERIALOFFER 003

DRYING SYSTEM (SUITABLE FOR 500 KG PER HOUR)OFFER 004

GRAVIMETRIC FEEDING SYSTEMOFFER 005

GAS STOCKING SYSTEMOFFER 006

GAS FEEDING SYSTEMOFFER 007

EXTRUDEROFFER 008

SCREEN CHANGEROFFER 009

STRAND DYE WITH ELEMENTS FOR EXTRUSIONOFFER 010

PNEUMATIC SHAPER FOR SHAPING THE BOARD BY ADJUSTING THE LOADOFFER 011

HAUL OFF UNITOFFER 012

ROLLERS FOR BOARDS CONVEYINGOFFER 013

PULLER HAUL OFFOFFER 014

TRANSVERSAL CUTTING UNITOFFER 015

FINISHING EQUIPMENTOFFER 016

BLOCK WELDING MACHINEOFFER 017

FINISHING PLATFORMOFFER 018

HORIZONTAL CUTTING MACHINEOFFER 019

SHEETS WELDING MACHINEOFFER 020

SCRAPS RECYCLING SYSTEMOFFER 021

GRINDER TO MILL THE PIECES OF MATERIALOFFER 022

COMPACTING UNITOFFER 023

STORING SILOS FOR DENSIFIED FOAM PETOFFER 024

PROCESS ELECTRIC SYSTEM OF EXISTING MACHINES ACCORDING TO THE ACTUAL LAYOUTOFFER 025

CABLES AND CABLING MATERIALSOFFER 026

PIPINGQUANTITY: 1 PLANT

Learn More -

C-2450 MASIAS FIBER OPENER, MASIAS FEEDING UNIT, MASIAS CARD, ANTONIO GUASCH GRANO CROSS LAPPER, ANTONIO GUASCH GRANO CUTTER, YEAR 1988 TO 2000REFERENCE NUMBER: C-2450 MASIAS FIBER OPENER, MASIAS FEEDING UNIT, MASIAS CARD, ANTONIO GUASCH GRANO CROSS LAPPER, ANTONIO GUASCH GRANO CUTTER, YEAR 1988 TO 2000 DETAILS: MASIAS FIBER OPENER YEAR: 2000 TYPE: AD15 MASIAS FEEDING UNIT YEAR: 2000 TYPE: 5T MASIAS CARD YEAR: 2000 TYPE: COMPACT CARD 3-5-10-D WIDTH: 2.5mm PRODUCTION: +/- 400KG/H ANTONIO GUASCH GRANO CROSS LAPPER YEAR: 1988 TYPE: ER/1 ANTONIO GUASCH GRANO CUTTER YEAR: 2000 TYPE: FORMATER QUANTITY AVAILABLE: 1 Learn More

C-2450 MASIAS FIBER OPENER, MASIAS FEEDING UNIT, MASIAS CARD, ANTONIO GUASCH GRANO CROSS LAPPER, ANTONIO GUASCH GRANO CUTTER, YEAR 1988 TO 2000REFERENCE NUMBER: C-2450 MASIAS FIBER OPENER, MASIAS FEEDING UNIT, MASIAS CARD, ANTONIO GUASCH GRANO CROSS LAPPER, ANTONIO GUASCH GRANO CUTTER, YEAR 1988 TO 2000 DETAILS: MASIAS FIBER OPENER YEAR: 2000 TYPE: AD15 MASIAS FEEDING UNIT YEAR: 2000 TYPE: 5T MASIAS CARD YEAR: 2000 TYPE: COMPACT CARD 3-5-10-D WIDTH: 2.5mm PRODUCTION: +/- 400KG/H ANTONIO GUASCH GRANO CROSS LAPPER YEAR: 1988 TYPE: ER/1 ANTONIO GUASCH GRANO CUTTER YEAR: 2000 TYPE: FORMATER QUANTITY AVAILABLE: 1 Learn More -

C-2478 AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM, WIDTH 1300mm, YEAR 2010 TO 2011REFERENCE NUMBER: C-2478 AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM, WIDTH 1300mm, YEAR 2010 TO 2011 SPECIFICATIONS: AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM WORKING WIDTH 1300mm YEAR OF CONSTRUCTION 2010 to 2011. THE AIRLAY LINE IS CONSISTING OF THE FOLLOWING COMPONENTS: BALE OPENER WITH SCALE TO MEASURE THE WEIGHT. CONVEYOR BELT. OPENER. AIRLAY UNIT. CONVEYOR BELT. THERMOBONDING OVEN. EDGE TRIM UNIT. PANEL CUTTER, FULLY AUTOMATIC. LOADING DEVICE TO LOAD READY MADE PANELS ONTO A PALETTE. THE THERMOBONDING OVEN IS MADE BY SICAM AND IS GAS HEATED. QUANTITY AVAILABLE: 1 Learn More

C-2478 AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM, WIDTH 1300mm, YEAR 2010 TO 2011REFERENCE NUMBER: C-2478 AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM, WIDTH 1300mm, YEAR 2010 TO 2011 SPECIFICATIONS: AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM WORKING WIDTH 1300mm YEAR OF CONSTRUCTION 2010 to 2011. THE AIRLAY LINE IS CONSISTING OF THE FOLLOWING COMPONENTS: BALE OPENER WITH SCALE TO MEASURE THE WEIGHT. CONVEYOR BELT. OPENER. AIRLAY UNIT. CONVEYOR BELT. THERMOBONDING OVEN. EDGE TRIM UNIT. PANEL CUTTER, FULLY AUTOMATIC. LOADING DEVICE TO LOAD READY MADE PANELS ONTO A PALETTE. THE THERMOBONDING OVEN IS MADE BY SICAM AND IS GAS HEATED. QUANTITY AVAILABLE: 1 Learn More