Search results for: 'line''

-

TT-7521 MONFORTS COATING LINE, WIDTH 3400mm, YEAR 1996 TO 2024TT-7521 MONFORTS COATING LINE, WIDTH 3400mm, YEAR 1996 TO 2024 1. MONFORTS COATING LINE 2. YEAR 1996 TO 2024 3. WORKING WIDTH: 3400mm 4. YEAR FULLY REBUILT: 2024 QUANTITY: 1 Learn More

TT-7521 MONFORTS COATING LINE, WIDTH 3400mm, YEAR 1996 TO 2024TT-7521 MONFORTS COATING LINE, WIDTH 3400mm, YEAR 1996 TO 2024 1. MONFORTS COATING LINE 2. YEAR 1996 TO 2024 3. WORKING WIDTH: 3400mm 4. YEAR FULLY REBUILT: 2024 QUANTITY: 1 Learn More -

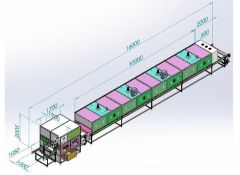

TT-5470 FULL AUTOMATIC COATER LINE FOR GLASS SUBSTRATE, 305mmTT-5470 FULL AUTOMATIC COATER LINE FOR GLASS SUBSTRATE, 305mm COATER FOR GLASS SUBSTRATE TO COAT 12” X 12” (305mm X 305mm) GLASS SUBSTRATE FULL AUTOMATIC COATER LINE (SPRAY MACHINE WITH OVEN) Learn More

TT-5470 FULL AUTOMATIC COATER LINE FOR GLASS SUBSTRATE, 305mmTT-5470 FULL AUTOMATIC COATER LINE FOR GLASS SUBSTRATE, 305mm COATER FOR GLASS SUBSTRATE TO COAT 12” X 12” (305mm X 305mm) GLASS SUBSTRATE FULL AUTOMATIC COATER LINE (SPRAY MACHINE WITH OVEN) Learn More -

M-5268 ISOTEX TWO HEAD COATING LINE FOR PVC AWNINGS AND TARPAULINS YEAR 1976-2005 – 1600mmREFERENCE NUMBER: M-5268 (1313BSLTXX12X) L ISOTEX TWO HEAD COATING LINE FOR PVC AWNINGS AND TARPAULINS YEAR 1976-2005 – 1600mm 2-HEAD COATING LINE FOR PVC AWNINGS AND OTHER APPLICATIONS MANUFACTURER: ISOTEX / ITALY YEAR OF CONSTRUCTION: 1976 / 2005 ROLLER WIDTH: 1800mm WORKING WIDTH: 1600mm WORKING VELOCITY: 0 ~ 20 M/MIN TEMPERATURE MAXIMUM: 270 °C QUANTITY AVAILABLE: 1 Learn More

M-5268 ISOTEX TWO HEAD COATING LINE FOR PVC AWNINGS AND TARPAULINS YEAR 1976-2005 – 1600mmREFERENCE NUMBER: M-5268 (1313BSLTXX12X) L ISOTEX TWO HEAD COATING LINE FOR PVC AWNINGS AND TARPAULINS YEAR 1976-2005 – 1600mm 2-HEAD COATING LINE FOR PVC AWNINGS AND OTHER APPLICATIONS MANUFACTURER: ISOTEX / ITALY YEAR OF CONSTRUCTION: 1976 / 2005 ROLLER WIDTH: 1800mm WORKING WIDTH: 1600mm WORKING VELOCITY: 0 ~ 20 M/MIN TEMPERATURE MAXIMUM: 270 °C QUANTITY AVAILABLE: 1 Learn More -

M-4860 STORK/BRUCKNER COATING AND FLOCKING LINE YEAR 1982-1998 WIDTH 1600-2000mmREFERENCE NUMBER: M-4860 (1111198ZVF10RX) L STORK/BRUCKNER COATING AND FLOCKING LINE YEAR 1982-1998 WIDTH 1600-2000mm COATING AND FLOCKING LINE CONSISTING OF: ENTRANCE ACCUMULATOR STORK SINGLE COLOR PRINTING MACHINE SINGLE HEAD KNIFE COATING UNIT FLOCKING UNIT MULTI LAYER STENTER, THERMO OIL HEATED, YEAR 1982 COOLING, EMBOSSING UNIT, WINDER MAKE: BRUCKNER / STORK WORKING WIDTH: 1600mm FOR FLOCKING WORKING WIDTH: 2000mm FOR COATING YEAR: 1994 / 1998 ENLARGED & REVISED QUANTITY AVAILABLE: 1 Learn More

M-4860 STORK/BRUCKNER COATING AND FLOCKING LINE YEAR 1982-1998 WIDTH 1600-2000mmREFERENCE NUMBER: M-4860 (1111198ZVF10RX) L STORK/BRUCKNER COATING AND FLOCKING LINE YEAR 1982-1998 WIDTH 1600-2000mm COATING AND FLOCKING LINE CONSISTING OF: ENTRANCE ACCUMULATOR STORK SINGLE COLOR PRINTING MACHINE SINGLE HEAD KNIFE COATING UNIT FLOCKING UNIT MULTI LAYER STENTER, THERMO OIL HEATED, YEAR 1982 COOLING, EMBOSSING UNIT, WINDER MAKE: BRUCKNER / STORK WORKING WIDTH: 1600mm FOR FLOCKING WORKING WIDTH: 2000mm FOR COATING YEAR: 1994 / 1998 ENLARGED & REVISED QUANTITY AVAILABLE: 1 Learn More -

YY-2597 1 X 2.0M SELLERS PVC COATING LINE, YEAR 2000, WORKING WIDTH 2000mmYY-2597 1 X 2.0M SELLERS PVC COATING LINE, YEAR 2000, WORKING WIDTH 2000mm MANUFACTURER: SELLERS WORKING WIDTH: 2000mm YEAR: 2000 QUANTITY: 1 Learn More

YY-2597 1 X 2.0M SELLERS PVC COATING LINE, YEAR 2000, WORKING WIDTH 2000mmYY-2597 1 X 2.0M SELLERS PVC COATING LINE, YEAR 2000, WORKING WIDTH 2000mm MANUFACTURER: SELLERS WORKING WIDTH: 2000mm YEAR: 2000 QUANTITY: 1 Learn More -

TT-2458 COATEMA COATING MACHINERY GMBH IMPREGNATION LINE UV(A), WIDTH 1300mmTT-2458 COATEMA COATING MACHINERY GMBH IMPREGNATION LINE UV(A), WIDTH 1300mm VERY GOOD WORKING CONDITION QUANTITY: 1 Learn More

TT-2458 COATEMA COATING MACHINERY GMBH IMPREGNATION LINE UV(A), WIDTH 1300mmTT-2458 COATEMA COATING MACHINERY GMBH IMPREGNATION LINE UV(A), WIDTH 1300mm VERY GOOD WORKING CONDITION QUANTITY: 1 Learn More -

M-5947 THOMAS MITCHELL & SONS BLADE COATING LINE SIZE 1300mm YEAR 2003

M-5947 THOMAS MITCHELL & SONS BLADE COATING LINE SIZE 1300mm YEAR 2003M-5947 THOMAS MITCHELL & SONS BLADE COATING LINE, SIZE 1300mm, YEAR 2003

BLADE COATING LINE

MAKE: THOMAS MITCHELL AND SONS

YEAR: 2003

SIZE: 1300mmQUANTITY: 1

Learn More -

K-3774 LACOM HOT MELT COATING AND LAMINATING LINE FOR MATTRESS TICKING 2400mm YEAR 2002-LIKE NEWREFERENCE NUMBER: K-3774 LACOM HOT MELT COATING AND LAMINATING LINE FOR MATTRESS TICKING 2400mm YEAR 2002-LIKE NEW SUITABLE FOR MATTRESS TICKING LAMINATION MULTIROLLER SYSTEM WITH EXTRUDER AND DRUM MELTER (MELTING WITH BOTH SYSTEM IS POSSIBLE) POLIMERS TO BE USED ARE; EVA, PP, PE, REACTIVE PU QUANTITY AVAILABLE: 1 Learn More

K-3774 LACOM HOT MELT COATING AND LAMINATING LINE FOR MATTRESS TICKING 2400mm YEAR 2002-LIKE NEWREFERENCE NUMBER: K-3774 LACOM HOT MELT COATING AND LAMINATING LINE FOR MATTRESS TICKING 2400mm YEAR 2002-LIKE NEW SUITABLE FOR MATTRESS TICKING LAMINATION MULTIROLLER SYSTEM WITH EXTRUDER AND DRUM MELTER (MELTING WITH BOTH SYSTEM IS POSSIBLE) POLIMERS TO BE USED ARE; EVA, PP, PE, REACTIVE PU QUANTITY AVAILABLE: 1 Learn More -

YY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLERYY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLER DETAILS: 1. COMBINED COATING MACHINE FOR ONE FINISHING AND COATING NOMINAL WIDTH 1800mm. MAXIMUM COATING WIDTH: BY KNIFE 1650mm, BY ENGRAVED ROLLER 1750mm WITH FOLLOWING WORKING MODES POSSIBILITIES: - REVERSE ROLL - SYNCHRO ROLL - REVERSE ROLL "ON AIR" - SYNCHRO ROLL "ON AIR" - BLADE "ON AIR" - BLADE ON COUNTER- ROLLER COMPOSED OF: - WELDED STEEL FRAMEWORK WITH HIGH; - ORSION RIGIDITY; - RUBBERIZED COUNTER-ROLLER DIAMETER 400mm, OIL AND SOLVENTS RESISTANT; - HARDNESS 85 SHORE A, MAX ECCENTRICITY TOLERANCE ±1/100mm; - A/C GEARMOTOR TO DRIVE THE COUNTER ROLLER; - ROLLER CHANGING DEVICE (BRIDGE), ARRANGED TO MOUNT TWO ENGRAVED ROLLERS AND ONE COATING KNIFE; - PNEUMATIC LIFTING OF CHANGING DEVICE (BRIDGE); - MANUAL ROTATION OF THE ROLLER CHANGING DEVICE; - MOTORIZED MICROMETRIC ADJUSTMENT OF COATING THICKNESS, INDEPENDENT RIGHT/LEFT OR IN TANDEM, WITH DIGITAL DISPLAY ON CONTROL PANEL, BY TWO JACKS; - COATING SIDE LIMITERS, MANUALLY ADJUSTABLE EITHER SINGLE OR TANDEM; - FEEDING THROUGH IN FRONT OF THE COATING KNIFE; - A/C GEARMOTOR TO DRIVE THE ENGRAVED ROLLER; - TWO COLOUR DOCTOR BLADES (SYNCHRO / REVERSE) WITH PNEUMATIC OPENING AND CLOSING FOR A SMOOTHER MOVEMENT OF THE BLADE TOWARDS THE ROLLER, WITH OSCILLATING MOVEMENT; - ENTRY IDLER ROLLER, THE UPPER ONE LIFTABLE BY PNEUMATIC PISTONS FOR "ON AIR" COATING; - PIPING FOR THE WASHING OF THE ENGRAVED ROLLER; - TWO SIDE GUTTERS IN STAINLESS-STEEL WITH TEFLON COATING, WITH SOLVENT RESISTANT RUBBER PIPE FOR WASTEWATER OR CHEMICALS COLLECTION AND RECIRCULATION; - WASTEWATER RECOVERY BASIN, WITH DRAIN, UNDER THE COUNTER-ROLLER; - MANUAL SEAM JUMPER; - VARIABLE SPEED FROM 2,5 TO 50 M/MIN FOR THE COUNTER-ROLLER AND FROM 2,5 TO 99 M/MIN FOR THE ENGRAVED ROLLER; - PIVOTING CONTROL PANEL WITH DIGITAL SCREEN, MOUNTED ON THE MACHINE FRAME, TO CONTROL AND SET THE MACHINE FUNCTIONS; - MAIN ELECTRICAL PANEL EQUIPPED WITH PLC AND INVERTERS, PROTECTION IP54, MOUNTED INSIDE THE LEFT HAND MACHINE SHOULDER; - SET OF MACHINE ACCESSORIES AND INSTRUCTION & MAINTENANCE MANUAL. Learn More

YY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLERYY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLER DETAILS: 1. COMBINED COATING MACHINE FOR ONE FINISHING AND COATING NOMINAL WIDTH 1800mm. MAXIMUM COATING WIDTH: BY KNIFE 1650mm, BY ENGRAVED ROLLER 1750mm WITH FOLLOWING WORKING MODES POSSIBILITIES: - REVERSE ROLL - SYNCHRO ROLL - REVERSE ROLL "ON AIR" - SYNCHRO ROLL "ON AIR" - BLADE "ON AIR" - BLADE ON COUNTER- ROLLER COMPOSED OF: - WELDED STEEL FRAMEWORK WITH HIGH; - ORSION RIGIDITY; - RUBBERIZED COUNTER-ROLLER DIAMETER 400mm, OIL AND SOLVENTS RESISTANT; - HARDNESS 85 SHORE A, MAX ECCENTRICITY TOLERANCE ±1/100mm; - A/C GEARMOTOR TO DRIVE THE COUNTER ROLLER; - ROLLER CHANGING DEVICE (BRIDGE), ARRANGED TO MOUNT TWO ENGRAVED ROLLERS AND ONE COATING KNIFE; - PNEUMATIC LIFTING OF CHANGING DEVICE (BRIDGE); - MANUAL ROTATION OF THE ROLLER CHANGING DEVICE; - MOTORIZED MICROMETRIC ADJUSTMENT OF COATING THICKNESS, INDEPENDENT RIGHT/LEFT OR IN TANDEM, WITH DIGITAL DISPLAY ON CONTROL PANEL, BY TWO JACKS; - COATING SIDE LIMITERS, MANUALLY ADJUSTABLE EITHER SINGLE OR TANDEM; - FEEDING THROUGH IN FRONT OF THE COATING KNIFE; - A/C GEARMOTOR TO DRIVE THE ENGRAVED ROLLER; - TWO COLOUR DOCTOR BLADES (SYNCHRO / REVERSE) WITH PNEUMATIC OPENING AND CLOSING FOR A SMOOTHER MOVEMENT OF THE BLADE TOWARDS THE ROLLER, WITH OSCILLATING MOVEMENT; - ENTRY IDLER ROLLER, THE UPPER ONE LIFTABLE BY PNEUMATIC PISTONS FOR "ON AIR" COATING; - PIPING FOR THE WASHING OF THE ENGRAVED ROLLER; - TWO SIDE GUTTERS IN STAINLESS-STEEL WITH TEFLON COATING, WITH SOLVENT RESISTANT RUBBER PIPE FOR WASTEWATER OR CHEMICALS COLLECTION AND RECIRCULATION; - WASTEWATER RECOVERY BASIN, WITH DRAIN, UNDER THE COUNTER-ROLLER; - MANUAL SEAM JUMPER; - VARIABLE SPEED FROM 2,5 TO 50 M/MIN FOR THE COUNTER-ROLLER AND FROM 2,5 TO 99 M/MIN FOR THE ENGRAVED ROLLER; - PIVOTING CONTROL PANEL WITH DIGITAL SCREEN, MOUNTED ON THE MACHINE FRAME, TO CONTROL AND SET THE MACHINE FUNCTIONS; - MAIN ELECTRICAL PANEL EQUIPPED WITH PLC AND INVERTERS, PROTECTION IP54, MOUNTED INSIDE THE LEFT HAND MACHINE SHOULDER; - SET OF MACHINE ACCESSORIES AND INSTRUCTION & MAINTENANCE MANUAL. Learn More -

M-5056 COATEMA UNIVERSAL COATING PLANT YEAR 2007 WIDTH 2000mmREFERENCE NUMBER: M-5056 (1212RDDTXX11) L COATEMA UNIVERSAL COATING PLANT YEAR 2007 WIDTH 2000mm QUANTITY AVAILABLE: 1 Learn More

M-5056 COATEMA UNIVERSAL COATING PLANT YEAR 2007 WIDTH 2000mmREFERENCE NUMBER: M-5056 (1212RDDTXX11) L COATEMA UNIVERSAL COATING PLANT YEAR 2007 WIDTH 2000mm QUANTITY AVAILABLE: 1 Learn More