Search results for: 'Fra'

- Related search terms

- frame 7

- frame tu

- frame turbine

- frame relay

- frame ben

-

TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024 COATING LINE FROM BATH MAT PLANT LENGTH 97000mm WIDTH 7000mm ARTOS LATEX FOR BATHMATSB YEAR OF CONSTRUCTION: 2024 WORKING WIDTH: 1000mm TO 2600mm MAXIMUM SETTING WIDTH: 2750mm SPEED: 1.7 METERS TO 35 METERS PER MINUTE Learn More

TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024 COATING LINE FROM BATH MAT PLANT LENGTH 97000mm WIDTH 7000mm ARTOS LATEX FOR BATHMATSB YEAR OF CONSTRUCTION: 2024 WORKING WIDTH: 1000mm TO 2600mm MAXIMUM SETTING WIDTH: 2750mm SPEED: 1.7 METERS TO 35 METERS PER MINUTE Learn More -

T-9509 MENZEL COATING RANGE, WORKING WIDTH 2600mm, 35 METERS PER MINUTET-9509 MENZEL COATING RANGE, WORKING WIDTH 2600mm, 35 METERS PER MINUTE GENERAL DESCRIPTION: DIFFERENT METHODS OF PRODUCTION CAN BE REALIZED, MACHINE IS DESIGNED FOR COATING ON A PRECISELY HIGH COATING ROLLER OR AS AN AIR DOCTOR BLADE. EQUIPPED WITH A COLLISION CONTROL SYSTEM AVAILABLE IMMEDIATELY Learn More

T-9509 MENZEL COATING RANGE, WORKING WIDTH 2600mm, 35 METERS PER MINUTET-9509 MENZEL COATING RANGE, WORKING WIDTH 2600mm, 35 METERS PER MINUTE GENERAL DESCRIPTION: DIFFERENT METHODS OF PRODUCTION CAN BE REALIZED, MACHINE IS DESIGNED FOR COATING ON A PRECISELY HIGH COATING ROLLER OR AS AN AIR DOCTOR BLADE. EQUIPPED WITH A COLLISION CONTROL SYSTEM AVAILABLE IMMEDIATELY Learn More -

T-9486 MENZEL COATING RANGE, WIDTH 2600mm, YEAR 2005T-9486 MENZEL COATING RANGE, WIDTH 2600mm, YEAR 2005 SPECIFICATIONS: YEAR: 2005 ROLLER WIDTH: 2800mm COATING ROLLER WITH DOCTOR STRIPPING DEVICE COATING BEAM EQUIPPED WITH 2 COATING KNIVES MATERIAL WIDTH: 2600mm SPEED: 3-35 M/MIN. BURNER CAPACITY: ZONE 1 (INLET) 150 KW, ZONES 2-5 100 KW VOLTAGE: 3X 480 V AC, +/- 10% FREQUENCY: 60 Hz CONTROL VOLTAGE: 24 V DC COMPRESSED AIR: 6 BAR AVAILABLE IMMEDIATELY QUANTITY: 1 Learn More

T-9486 MENZEL COATING RANGE, WIDTH 2600mm, YEAR 2005T-9486 MENZEL COATING RANGE, WIDTH 2600mm, YEAR 2005 SPECIFICATIONS: YEAR: 2005 ROLLER WIDTH: 2800mm COATING ROLLER WITH DOCTOR STRIPPING DEVICE COATING BEAM EQUIPPED WITH 2 COATING KNIVES MATERIAL WIDTH: 2600mm SPEED: 3-35 M/MIN. BURNER CAPACITY: ZONE 1 (INLET) 150 KW, ZONES 2-5 100 KW VOLTAGE: 3X 480 V AC, +/- 10% FREQUENCY: 60 Hz CONTROL VOLTAGE: 24 V DC COMPRESSED AIR: 6 BAR AVAILABLE IMMEDIATELY QUANTITY: 1 Learn More -

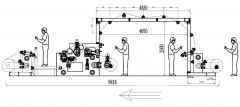

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More -

M-5269 ELITEX ONE HEAD COATING LINE REFURBISHED YEAR 2011 WIDTH 1800mmREFERENCE NUMBER: M-5269 (1313TMJGXX12X) L ELITEX ONE HEAD COATING LINE REFURBISHED YEAR 2011 WIDTH 1800mm TOTALLY REFURBISHED IN YEAR 2011 AND BROUGHT TO AN UP-TO-DATE CONDITION 1-HEAD COATING LINE, MAKE: ELITEX ROLLER WIDTH: 1800mm COATING WIDTH: 1650mm DRYER / STENTER: 6 CHAMBERS CHAIN 1: HORIZONTAL PIN CHAIN CHAIN 2: AS BEFORE, BRAND NEW AS A SPARE HEATING: NATURAL GAS BURNERS: 12 PCS (COUNTERED, 2PCS PER CHAMBER TO ACHIEVE A DIFFERENCING TEMPERATURE PROFILE) MAKE: WEISHAUPT OPERATING BY: SIEMENS TOUCH SCREEN SIMATIC QUANTITY AVAILABLE: 1 Learn More

M-5269 ELITEX ONE HEAD COATING LINE REFURBISHED YEAR 2011 WIDTH 1800mmREFERENCE NUMBER: M-5269 (1313TMJGXX12X) L ELITEX ONE HEAD COATING LINE REFURBISHED YEAR 2011 WIDTH 1800mm TOTALLY REFURBISHED IN YEAR 2011 AND BROUGHT TO AN UP-TO-DATE CONDITION 1-HEAD COATING LINE, MAKE: ELITEX ROLLER WIDTH: 1800mm COATING WIDTH: 1650mm DRYER / STENTER: 6 CHAMBERS CHAIN 1: HORIZONTAL PIN CHAIN CHAIN 2: AS BEFORE, BRAND NEW AS A SPARE HEATING: NATURAL GAS BURNERS: 12 PCS (COUNTERED, 2PCS PER CHAMBER TO ACHIEVE A DIFFERENCING TEMPERATURE PROFILE) MAKE: WEISHAUPT OPERATING BY: SIEMENS TOUCH SCREEN SIMATIC QUANTITY AVAILABLE: 1 Learn More -

TT-2662 STORK COATING LINE ROLLER, WIDTH 2000mm, YEAR 1989TT-2662 STORK COATING LINE ROLLER, WIDTH 2000mm, YEAR 1989 QUANTITY: 1 Learn More

TT-2662 STORK COATING LINE ROLLER, WIDTH 2000mm, YEAR 1989TT-2662 STORK COATING LINE ROLLER, WIDTH 2000mm, YEAR 1989 QUANTITY: 1 Learn More -

YY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLERYY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLER DETAILS: 1. COMBINED COATING MACHINE FOR ONE FINISHING AND COATING NOMINAL WIDTH 1800mm. MAXIMUM COATING WIDTH: BY KNIFE 1650mm, BY ENGRAVED ROLLER 1750mm WITH FOLLOWING WORKING MODES POSSIBILITIES: - REVERSE ROLL - SYNCHRO ROLL - REVERSE ROLL "ON AIR" - SYNCHRO ROLL "ON AIR" - BLADE "ON AIR" - BLADE ON COUNTER- ROLLER COMPOSED OF: - WELDED STEEL FRAMEWORK WITH HIGH; - ORSION RIGIDITY; - RUBBERIZED COUNTER-ROLLER DIAMETER 400mm, OIL AND SOLVENTS RESISTANT; - HARDNESS 85 SHORE A, MAX ECCENTRICITY TOLERANCE ±1/100mm; - A/C GEARMOTOR TO DRIVE THE COUNTER ROLLER; - ROLLER CHANGING DEVICE (BRIDGE), ARRANGED TO MOUNT TWO ENGRAVED ROLLERS AND ONE COATING KNIFE; - PNEUMATIC LIFTING OF CHANGING DEVICE (BRIDGE); - MANUAL ROTATION OF THE ROLLER CHANGING DEVICE; - MOTORIZED MICROMETRIC ADJUSTMENT OF COATING THICKNESS, INDEPENDENT RIGHT/LEFT OR IN TANDEM, WITH DIGITAL DISPLAY ON CONTROL PANEL, BY TWO JACKS; - COATING SIDE LIMITERS, MANUALLY ADJUSTABLE EITHER SINGLE OR TANDEM; - FEEDING THROUGH IN FRONT OF THE COATING KNIFE; - A/C GEARMOTOR TO DRIVE THE ENGRAVED ROLLER; - TWO COLOUR DOCTOR BLADES (SYNCHRO / REVERSE) WITH PNEUMATIC OPENING AND CLOSING FOR A SMOOTHER MOVEMENT OF THE BLADE TOWARDS THE ROLLER, WITH OSCILLATING MOVEMENT; - ENTRY IDLER ROLLER, THE UPPER ONE LIFTABLE BY PNEUMATIC PISTONS FOR "ON AIR" COATING; - PIPING FOR THE WASHING OF THE ENGRAVED ROLLER; - TWO SIDE GUTTERS IN STAINLESS-STEEL WITH TEFLON COATING, WITH SOLVENT RESISTANT RUBBER PIPE FOR WASTEWATER OR CHEMICALS COLLECTION AND RECIRCULATION; - WASTEWATER RECOVERY BASIN, WITH DRAIN, UNDER THE COUNTER-ROLLER; - MANUAL SEAM JUMPER; - VARIABLE SPEED FROM 2,5 TO 50 M/MIN FOR THE COUNTER-ROLLER AND FROM 2,5 TO 99 M/MIN FOR THE ENGRAVED ROLLER; - PIVOTING CONTROL PANEL WITH DIGITAL SCREEN, MOUNTED ON THE MACHINE FRAME, TO CONTROL AND SET THE MACHINE FUNCTIONS; - MAIN ELECTRICAL PANEL EQUIPPED WITH PLC AND INVERTERS, PROTECTION IP54, MOUNTED INSIDE THE LEFT HAND MACHINE SHOULDER; - SET OF MACHINE ACCESSORIES AND INSTRUCTION & MAINTENANCE MANUAL. Learn More

YY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLERYY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLER DETAILS: 1. COMBINED COATING MACHINE FOR ONE FINISHING AND COATING NOMINAL WIDTH 1800mm. MAXIMUM COATING WIDTH: BY KNIFE 1650mm, BY ENGRAVED ROLLER 1750mm WITH FOLLOWING WORKING MODES POSSIBILITIES: - REVERSE ROLL - SYNCHRO ROLL - REVERSE ROLL "ON AIR" - SYNCHRO ROLL "ON AIR" - BLADE "ON AIR" - BLADE ON COUNTER- ROLLER COMPOSED OF: - WELDED STEEL FRAMEWORK WITH HIGH; - ORSION RIGIDITY; - RUBBERIZED COUNTER-ROLLER DIAMETER 400mm, OIL AND SOLVENTS RESISTANT; - HARDNESS 85 SHORE A, MAX ECCENTRICITY TOLERANCE ±1/100mm; - A/C GEARMOTOR TO DRIVE THE COUNTER ROLLER; - ROLLER CHANGING DEVICE (BRIDGE), ARRANGED TO MOUNT TWO ENGRAVED ROLLERS AND ONE COATING KNIFE; - PNEUMATIC LIFTING OF CHANGING DEVICE (BRIDGE); - MANUAL ROTATION OF THE ROLLER CHANGING DEVICE; - MOTORIZED MICROMETRIC ADJUSTMENT OF COATING THICKNESS, INDEPENDENT RIGHT/LEFT OR IN TANDEM, WITH DIGITAL DISPLAY ON CONTROL PANEL, BY TWO JACKS; - COATING SIDE LIMITERS, MANUALLY ADJUSTABLE EITHER SINGLE OR TANDEM; - FEEDING THROUGH IN FRONT OF THE COATING KNIFE; - A/C GEARMOTOR TO DRIVE THE ENGRAVED ROLLER; - TWO COLOUR DOCTOR BLADES (SYNCHRO / REVERSE) WITH PNEUMATIC OPENING AND CLOSING FOR A SMOOTHER MOVEMENT OF THE BLADE TOWARDS THE ROLLER, WITH OSCILLATING MOVEMENT; - ENTRY IDLER ROLLER, THE UPPER ONE LIFTABLE BY PNEUMATIC PISTONS FOR "ON AIR" COATING; - PIPING FOR THE WASHING OF THE ENGRAVED ROLLER; - TWO SIDE GUTTERS IN STAINLESS-STEEL WITH TEFLON COATING, WITH SOLVENT RESISTANT RUBBER PIPE FOR WASTEWATER OR CHEMICALS COLLECTION AND RECIRCULATION; - WASTEWATER RECOVERY BASIN, WITH DRAIN, UNDER THE COUNTER-ROLLER; - MANUAL SEAM JUMPER; - VARIABLE SPEED FROM 2,5 TO 50 M/MIN FOR THE COUNTER-ROLLER AND FROM 2,5 TO 99 M/MIN FOR THE ENGRAVED ROLLER; - PIVOTING CONTROL PANEL WITH DIGITAL SCREEN, MOUNTED ON THE MACHINE FRAME, TO CONTROL AND SET THE MACHINE FUNCTIONS; - MAIN ELECTRICAL PANEL EQUIPPED WITH PLC AND INVERTERS, PROTECTION IP54, MOUNTED INSIDE THE LEFT HAND MACHINE SHOULDER; - SET OF MACHINE ACCESSORIES AND INSTRUCTION & MAINTENANCE MANUAL. Learn More -

J-4406 SULZER P 7150 5400mm LOOM AND MENZEL COATING MACHINE 5400mm (17.7 FEET)J-4406 SULZER P 7150 5400mm LOOM AND MENZEL COATING MACHINE 5400mm (17.7 FEET) LOOM IS IN LINE WITH A MENZEL COATING UNIT QUANTITY: 1 Learn More

J-4406 SULZER P 7150 5400mm LOOM AND MENZEL COATING MACHINE 5400mm (17.7 FEET)J-4406 SULZER P 7150 5400mm LOOM AND MENZEL COATING MACHINE 5400mm (17.7 FEET) LOOM IS IN LINE WITH A MENZEL COATING UNIT QUANTITY: 1 Learn More -

C-4014 MACHTEX SPRAYCOATING AND LAMINATING MACHINE, WORKING WIDTH 1600mm, YEAR 1994

C-4014 MACHTEX SPRAYCOATING AND LAMINATING MACHINE, WORKING WIDTH 1600mm, YEAR 1994C-4014 MACHTEX SPRAYCOATING AND LAMINATING MACHINE, WORKING WIDTH 1600mm, YEAR 1994

MAKE: MACHTEX

TYPE: ES3 - 150

YEAR: 1994

WORKING WIDTH: 1600mm

MACHINE LENGTH: 2250mm

MACHINE WIDTH: 2000mm

MACHINE HIGH: 2200mmQUANTITY: 1

Learn More -

M-5097 CHOCOLATE/SUGAR POLISHING AND COATING MACHINEREFERENCE NUMBER: M-5097 (121225NP11UF) L CHOCOLATE/SUGAR POLISHING AND COATING MACHINE CHOCOLATE/SUGAR COATING & POLISHING MACHINE IS MAINLY USED FOR COATING THE SHELL FOR KINDS OF NUTS, BALL BUBBLE GUM, OR CHEWING GUM, AND SOME MEDICINE PILLS. IT IS THE LAST PROCESSING STEP TO MAKE BALL TYPE PRODUCTS. THE SPEED CAN BE ADJUSTED AND THE HOT AIR BLOWER WILL BE EQUIPPED ON THE MACHINE. THE COATING BOWL IS MADE OF STAINLESS STEEL AND THE FRAME IS MADE OF NORMAL STEEL WITH PAINTING MODEL 75 CAPACITY 75KG TO 80KG/POT BLAST POWER: 0.02KW DIAMETER OF POT: 1000mm REV: 36R/MIN HEATING POWER: 1.8KW WEIGHT: 300KG DIMENSION: 1075mm x 800mm x 1560mm QUANTITY: 1 Learn More

M-5097 CHOCOLATE/SUGAR POLISHING AND COATING MACHINEREFERENCE NUMBER: M-5097 (121225NP11UF) L CHOCOLATE/SUGAR POLISHING AND COATING MACHINE CHOCOLATE/SUGAR COATING & POLISHING MACHINE IS MAINLY USED FOR COATING THE SHELL FOR KINDS OF NUTS, BALL BUBBLE GUM, OR CHEWING GUM, AND SOME MEDICINE PILLS. IT IS THE LAST PROCESSING STEP TO MAKE BALL TYPE PRODUCTS. THE SPEED CAN BE ADJUSTED AND THE HOT AIR BLOWER WILL BE EQUIPPED ON THE MACHINE. THE COATING BOWL IS MADE OF STAINLESS STEEL AND THE FRAME IS MADE OF NORMAL STEEL WITH PAINTING MODEL 75 CAPACITY 75KG TO 80KG/POT BLAST POWER: 0.02KW DIAMETER OF POT: 1000mm REV: 36R/MIN HEATING POWER: 1.8KW WEIGHT: 300KG DIMENSION: 1075mm x 800mm x 1560mm QUANTITY: 1 Learn More