Search results for: 'pillow c'

- Related search terms

- pillow+b

- pillow co

- pillow+machine

- PILLOW+PA

- pillow p

-

J-1653 FIBER OPENER AND PILLOW FILLERJ-1653 FIBER OPENER AND PILLOW FILLER FIBER OPENER CONVEYOR DIMENSIONS: 14” WIDTH, 46” LENGTH Learn More

J-1653 FIBER OPENER AND PILLOW FILLERJ-1653 FIBER OPENER AND PILLOW FILLER FIBER OPENER CONVEYOR DIMENSIONS: 14” WIDTH, 46” LENGTH Learn More -

AA-1169 PILLOW FILLING MACHINE WITH DOWN AND FEATHERAA-1169 PILLOW FILLING MACHINE WITH DOWN AND FEATHER MAIN SILO CAPACITY: 40KG IN TOTAL VOLTAGE: 220V/60Hz POWER: 2.3KW DIMENSIONS: 2500 x 1000 x 2500mm WEIGHT: 960KG Learn More

AA-1169 PILLOW FILLING MACHINE WITH DOWN AND FEATHERAA-1169 PILLOW FILLING MACHINE WITH DOWN AND FEATHER MAIN SILO CAPACITY: 40KG IN TOTAL VOLTAGE: 220V/60Hz POWER: 2.3KW DIMENSIONS: 2500 x 1000 x 2500mm WEIGHT: 960KG Learn More -

AA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINEAA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINE FOUR NOZZLES PILLOW FILLING MACHINE: IT IS SUITABLE FOR OPENING AND PROCESSING FIBER RAW MATERIAL, FILLING PILLOW CORE AND CUSHION. CHARACTERISTICS: LESS INVESTMENT, HIGH EFFICIENCY, SIMPLE OPERATION, WITH FREQUENCY CONVERSION DEVICE. RAW MATERIAL REQUIREMENTS: FIBERS ABOVE 0.78D, CAN BE OPENED AT ONE TIME. Learn More

AA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINEAA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINE FOUR NOZZLES PILLOW FILLING MACHINE: IT IS SUITABLE FOR OPENING AND PROCESSING FIBER RAW MATERIAL, FILLING PILLOW CORE AND CUSHION. CHARACTERISTICS: LESS INVESTMENT, HIGH EFFICIENCY, SIMPLE OPERATION, WITH FREQUENCY CONVERSION DEVICE. RAW MATERIAL REQUIREMENTS: FIBERS ABOVE 0.78D, CAN BE OPENED AT ONE TIME. Learn More -

M-7753 DOWN PILLOW FILLING MACHINE WITHOUT WEIGHING SYSTEM

M-7753 DOWN PILLOW FILLING MACHINE WITHOUT WEIGHING SYSTEMREFERENCE NUMBER: M-7753

DOWN PILLOW FILLING MACHINE WITHOUT WEIGHING SYSTEM

DOWN PILLOW FILLING MACHINE

WITHOUT WEIGHING SYSTEM

BEST MACHINE IF YOU DON’T NEED EXACT WEIGHT FOR EVERY PILLOW

QUANTITY: 1

Learn More -

E-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBERE-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBER FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. CAPACITY 250 KGS PER HOUR X 400 HOURS PER MONTH = 100,000 KGS PER MONTH AT 100% EFFICIENCY HOPPER FEED (REF G-3768) WITH 4.5 KW MOTOR FIBER OPENER TRANSFER FAN MIXING MACHINE (SILO WITH FOUR EXITS) FILLING STATION (FAN) , FOUR FILLING FANS WITH NOZZLE CLAMPS AND WITH TABLES SPARE PARTS SUGGESTED Learn More

E-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBERE-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBER FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. CAPACITY 250 KGS PER HOUR X 400 HOURS PER MONTH = 100,000 KGS PER MONTH AT 100% EFFICIENCY HOPPER FEED (REF G-3768) WITH 4.5 KW MOTOR FIBER OPENER TRANSFER FAN MIXING MACHINE (SILO WITH FOUR EXITS) FILLING STATION (FAN) , FOUR FILLING FANS WITH NOZZLE CLAMPS AND WITH TABLES SPARE PARTS SUGGESTED Learn More -

TT-5884 GRAUFF PILLOW FILLING MACHINE, YEAR 1986TT-5884 GRAUFF PILLOW FILLING MACHINE, YEAR 1986 GRAUFF PILLOW FILLING MACHINE YEAR 1986 QUANTITY: 1 Learn More

TT-5884 GRAUFF PILLOW FILLING MACHINE, YEAR 1986TT-5884 GRAUFF PILLOW FILLING MACHINE, YEAR 1986 GRAUFF PILLOW FILLING MACHINE YEAR 1986 QUANTITY: 1 Learn More -

TT-1010 MASIAS VAC 2 PILLOW FILLING MACHINE, 8 PILLOWS PER MINUTE, YEAR 1991TT-1010 MASIAS VAC 2 PILLOW FILLING MACHINE, 8 PILLOWS PER MINUTE, YEAR 1991 MACHINE INLUDES: 1 MATERIAL TRANSPORT FAN 3000 RPM, 5.5 KW 1 RESERVE DOSING SILO 1 DOUBLE WEIGHING TOWER WITH ELECTRONIC SCALE 1 VACUUM FAN, DISTRIBUTOR FOR 2 VACUUM BOXES 2 PILLOW FILLING BOXES TYPE VTL 2 - EACH FOR TWO PILLOWS 1 CONTROL CABINET QUANTITY: 1 Learn More

TT-1010 MASIAS VAC 2 PILLOW FILLING MACHINE, 8 PILLOWS PER MINUTE, YEAR 1991TT-1010 MASIAS VAC 2 PILLOW FILLING MACHINE, 8 PILLOWS PER MINUTE, YEAR 1991 MACHINE INLUDES: 1 MATERIAL TRANSPORT FAN 3000 RPM, 5.5 KW 1 RESERVE DOSING SILO 1 DOUBLE WEIGHING TOWER WITH ELECTRONIC SCALE 1 VACUUM FAN, DISTRIBUTOR FOR 2 VACUUM BOXES 2 PILLOW FILLING BOXES TYPE VTL 2 - EACH FOR TWO PILLOWS 1 CONTROL CABINET QUANTITY: 1 Learn More -

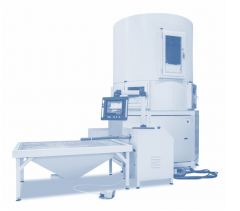

J-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHERJ-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHER SILO VOLUME: 6.0m3 AUTOMATIC PRE-WEIGHING UNITS: 2 UNITS WITH 210 LITER CAPACITY FILLING NOZZLE: 1 OUTPUT CAPACITY: UP TO 700 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 6 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 7.4 KW – 32 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db Learn More

J-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHERJ-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHER SILO VOLUME: 6.0m3 AUTOMATIC PRE-WEIGHING UNITS: 2 UNITS WITH 210 LITER CAPACITY FILLING NOZZLE: 1 OUTPUT CAPACITY: UP TO 700 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 6 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 7.4 KW – 32 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db Learn More -

J-4155 FULLY AUTOMATIC PILLOW WEIGHING AND FILLING LINEJ-4155 FULLY AUTOMATIC PILLOW WEIGHING AND FILLING LINE ITEM 001 FIBER CARDING MACHINE ITEM 002 FAN FEEDING MACHINE ITEM 003 WEIGHING SYSTEM ITEM 004 FILLING MACHINE Learn More

J-4155 FULLY AUTOMATIC PILLOW WEIGHING AND FILLING LINEJ-4155 FULLY AUTOMATIC PILLOW WEIGHING AND FILLING LINE ITEM 001 FIBER CARDING MACHINE ITEM 002 FAN FEEDING MACHINE ITEM 003 WEIGHING SYSTEM ITEM 004 FILLING MACHINE Learn More -

J-4091 2 NOZZLE LARGE PILLOW FILLING MACHINE FOR DOWN AND FIBER – NEWJ-40912 NOZZLE LARGE PILLOW FILLING MACHINE FOR DOWN AND FIBER – NEW MAXIMUM THEORETICAL PRODUCTION: 900 KGS PER NOZZLE PER HOUR ACTUAL/PRACTICAL PRODUCTION: 450 KGS PER NOZZLE PER HOUR (FOR A 2 NOZZLE MACHINE THE REALISTIC PRODUCTION IS 900 KGS PER HOUR TOTAL) QUANTITY: 1 Learn More

J-4091 2 NOZZLE LARGE PILLOW FILLING MACHINE FOR DOWN AND FIBER – NEWJ-40912 NOZZLE LARGE PILLOW FILLING MACHINE FOR DOWN AND FIBER – NEW MAXIMUM THEORETICAL PRODUCTION: 900 KGS PER NOZZLE PER HOUR ACTUAL/PRACTICAL PRODUCTION: 450 KGS PER NOZZLE PER HOUR (FOR A 2 NOZZLE MACHINE THE REALISTIC PRODUCTION IS 900 KGS PER HOUR TOTAL) QUANTITY: 1 Learn More