Search results for: 'looper'

-

YY-1366 (USERS MANUAL) BAG CLOSING MACHINE HEAD, INSTRUCTION MANUALYY-1366 BAG CLOSING MACHINE HEAD, INSTRUCTION MANUAL FOR OPENRATOR SAFETY: - THIS MANUAL BOOK CONTAINS INSTRUCTIONS AND PRECAUTIONS FOR USING THE BAG CLOSING MACHINE HEAD. BE SURE TO READ AND UNDERSTAND THE MANUAL BOOK BEFORE USING THE MACHINES. - KEEP THIS MANUAL BOOK NEAR THE SEWING MACHINE FOR REFERENCE. BE SURE TO ATTACH THIS MANUAL BOOK TO THE MACHINE WHEN LENDING OR TRANSFER IT TO ANOTHER PERSON OR COMPANY. - PLEASE CONTACT THIS MANUAL BOOK FROM US IF IT LOST. - THE CONTENTS OF THIS MANUAL BOOK ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE FOR IMPROVEMENT AND SAFETY PURPOSE. Learn More

YY-1366 (USERS MANUAL) BAG CLOSING MACHINE HEAD, INSTRUCTION MANUALYY-1366 BAG CLOSING MACHINE HEAD, INSTRUCTION MANUAL FOR OPENRATOR SAFETY: - THIS MANUAL BOOK CONTAINS INSTRUCTIONS AND PRECAUTIONS FOR USING THE BAG CLOSING MACHINE HEAD. BE SURE TO READ AND UNDERSTAND THE MANUAL BOOK BEFORE USING THE MACHINES. - KEEP THIS MANUAL BOOK NEAR THE SEWING MACHINE FOR REFERENCE. BE SURE TO ATTACH THIS MANUAL BOOK TO THE MACHINE WHEN LENDING OR TRANSFER IT TO ANOTHER PERSON OR COMPANY. - PLEASE CONTACT THIS MANUAL BOOK FROM US IF IT LOST. - THE CONTENTS OF THIS MANUAL BOOK ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE FOR IMPROVEMENT AND SAFETY PURPOSE. Learn More -

K-1048 LOOPED FOAM CUTTING MACHINE (LOOPER)REFERENCE NUMBER: K-1048 LOOPED FOAM CUTTING MACHINE (LOOPER) TECHNICAL SPECIFICATIONS: CUTTING SIZE: LENGTH 48 METERS TO 52 METERS X WIDTH 1000mm TO 2200mm X HEIGHT 1300mm CUTTING PRECISION: ±0.1 TO 0.2mm/(THICKNESS 2 TO 10mm) ±0.2mm/(THICKNESS 11 TO 30mm) CUTTING DENSITY: 6 TO 40KG/m3 CUTTING SPEED: 0 TO 120 METERS/MIN FOAM SHEET ROLLING SIZE: DIAMETER X WIDTH: 1800 X 1000 TO 2300mm TOTAL POWER: 50KW EXTERNAL SIZE: 28 METERS X 6200mm X 8000mm QUANTITY AVAILABLE: 1 Learn More

K-1048 LOOPED FOAM CUTTING MACHINE (LOOPER)REFERENCE NUMBER: K-1048 LOOPED FOAM CUTTING MACHINE (LOOPER) TECHNICAL SPECIFICATIONS: CUTTING SIZE: LENGTH 48 METERS TO 52 METERS X WIDTH 1000mm TO 2200mm X HEIGHT 1300mm CUTTING PRECISION: ±0.1 TO 0.2mm/(THICKNESS 2 TO 10mm) ±0.2mm/(THICKNESS 11 TO 30mm) CUTTING DENSITY: 6 TO 40KG/m3 CUTTING SPEED: 0 TO 120 METERS/MIN FOAM SHEET ROLLING SIZE: DIAMETER X WIDTH: 1800 X 1000 TO 2300mm TOTAL POWER: 50KW EXTERNAL SIZE: 28 METERS X 6200mm X 8000mm QUANTITY AVAILABLE: 1 Learn More -

G-2168 FOAM LOOPED CUTTING MACHINE (LOOPER) 2100mm WIDEREFERENCE NUMBER: G-2168 FOAM LOOPED CUTTING MACHINE (LOOPER) 2100mm WIDE QUANTITY AVAILABLE: 1 Learn More

G-2168 FOAM LOOPED CUTTING MACHINE (LOOPER) 2100mm WIDEREFERENCE NUMBER: G-2168 FOAM LOOPED CUTTING MACHINE (LOOPER) 2100mm WIDE QUANTITY AVAILABLE: 1 Learn More -

YY-2073 COMPUTERIZED CHAIN STITCH NON-SHUTTLE MULTI-NEEDLE QUILTING MACHINE, QUILTING WIDTH 2450mm -PRODUCTION SPEED 60 TO 300 METERS PER HOURYY-2073 COMPUTERIZED CHAIN STITCH NON-SHUTTLE MULTI-NEEDLE QUILTING MACHINE, QUILTING WIDTH 2450mm -PRODUCTION SPEED 60 TO 300 METERS PER HOUR DETAILS: TECHNICAL PARAMETERS DIMENSIONS (L X W X H): 5400 X 1650 X 2360mm GROSS WEIGHT: 5800 KG MAIN SHAFT SPEED: 500 TO 1300 RPM PRODUCTION SPEED: 60 TO 300 METERS PER HOUR STITCH LENGTH: 3 TO 8mm NEEDLE TYPE: 24/180, 23/160, 22/140, 21/130 SPACE BETWEEN NEEDLE ROWS: (50.8, 76.2, 127) 5″, (76.2, 76.2, 152.4) 6″ SPACE BETWEEN NEEDLES: 12.7 / 25.4mm MAXIMUM HORIZONTAL MOVEMENT: 304.8mm QUILTING WIDTH: 2450mm QUILTING THICKNESS: ≤80mm VOLTAGE: 220 VOLTS OR 380 VOLTS, 50/60Hz, 3-PHASE POWER: 11 KW QUANTITY: 1 Learn More

YY-2073 COMPUTERIZED CHAIN STITCH NON-SHUTTLE MULTI-NEEDLE QUILTING MACHINE, QUILTING WIDTH 2450mm -PRODUCTION SPEED 60 TO 300 METERS PER HOURYY-2073 COMPUTERIZED CHAIN STITCH NON-SHUTTLE MULTI-NEEDLE QUILTING MACHINE, QUILTING WIDTH 2450mm -PRODUCTION SPEED 60 TO 300 METERS PER HOUR DETAILS: TECHNICAL PARAMETERS DIMENSIONS (L X W X H): 5400 X 1650 X 2360mm GROSS WEIGHT: 5800 KG MAIN SHAFT SPEED: 500 TO 1300 RPM PRODUCTION SPEED: 60 TO 300 METERS PER HOUR STITCH LENGTH: 3 TO 8mm NEEDLE TYPE: 24/180, 23/160, 22/140, 21/130 SPACE BETWEEN NEEDLE ROWS: (50.8, 76.2, 127) 5″, (76.2, 76.2, 152.4) 6″ SPACE BETWEEN NEEDLES: 12.7 / 25.4mm MAXIMUM HORIZONTAL MOVEMENT: 304.8mm QUILTING WIDTH: 2450mm QUILTING THICKNESS: ≤80mm VOLTAGE: 220 VOLTS OR 380 VOLTS, 50/60Hz, 3-PHASE POWER: 11 KW QUANTITY: 1 Learn More -

PP-1148 ATLANTA ATTACHMENT SERGER FLANGER WITH YAMATO HEADPP-1148 ATLANTA ATTACHMENT SERGER FLANGER WITH YAMATO HEAD CHAINSTITCH 220 VOLTS, SINGLE-PHASE QUANTITY: 1 Learn More

PP-1148 ATLANTA ATTACHMENT SERGER FLANGER WITH YAMATO HEADPP-1148 ATLANTA ATTACHMENT SERGER FLANGER WITH YAMATO HEAD CHAINSTITCH 220 VOLTS, SINGLE-PHASE QUANTITY: 1 Learn More -

J-2326 QUILTER FOR RAGS, 12 INCH WIDTH – NEW – RAG QUILTER

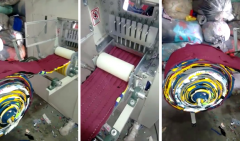

J-2326 QUILTER FOR RAGS, 12 INCH WIDTH – NEW – RAG QUILTERREFERENCE NUMBER: J-2326

QUILTER FOR RAGS, 12 INCH WIDTH – NEW – RAG QUILTERQUILTING MACHINE FOR RAGS

SEWS RAGS CONTINUOUSLY

SEW HEAD: 7 NEEDLES AND 7 LOOPERS

MAKES A CHAIN STITCH ON THE CONVEYED RAGS

USES OVERLOCK THREAD

DISTANCE BETWEEN NEEDLES: 250mm (ENSURES THAT EVEN SMALL RAGS ARE SEWN)

1 HP MOTOR, 3-PHASE, 220 VOLT

WITH FREQUENCY INVERTER TO ADJUST THE ROTATION SPEED OF THE MOTOR AS NEEDED

HEIGHT: 1800mm

WIDTH: 960mm

DEPTH; 370mm

CONVEYOR WIDTH: 200mm

CONVEYOR LENGTH: 1560mm

MACHINE TOTAL LENGTH WITH CONVEYOR: 2800mmAFTER SEWING, THE QUILT IS TRANSPORTED OUT INTO ROLLS WHICH CAN BE CUT ACCORDING TO CUSTOMER NEEDS

Learn More

OPERATION: PLACE A LARGER RAG AS THE BOTTOM LAYER, SMALLER RAGS AS FILLING, AND ANOTHER LARGER RAG AS THE TOP LAYER. OPERATION REQUIRES 2 TO 3 OPERATORS.

TO REDUCE THE NUMBER OF OPERATORS REQUIRED, A FIBER ROLL AS CAN BE USED AS THE LOWER LAYER. THIS ALSO INCREASES THE PRODUCTION RATE.

DAILY PRODUCTION: VARIES BETWEEN 300 TO 500 KG PER 8 HOURS OF OPERATION

FOR KNIT FABRICS SUCH AS COTTON, VISCOSE, SWEATSHIRT FLEECE, NYLON STRETCH-FABRIC, PIQUET AND POPELINE

THERE IS NO MATERIAL WASTE AS THE MACHINE USES 100% OF THE RAGS

WORKING WIDTH: 12 INCHES

NEEDLE SPACING: 1 INCH

WITH LOOPER STRUCTURE SIMILAR TO THE DIAGRAM BELOW (REDUCES BOTTOM THREAD BREAKAGE)

MACHINE IS NEW, MADE TO ORDER

LEAD TIME: 10 DAYS -

J-0135 GRIBETZ INTERNATIONAL DG 3200 110” 360° COMPUTERIZED DOUBLE THREAD CHAINSTITCH QUILTER

J-0135 GRIBETZ INTERNATIONAL DG 3200 110” 360° COMPUTERIZED DOUBLE THREAD CHAINSTITCH QUILTERJ-0135 GRIBETZ INTERNATIONAL DG 3200 110” 360° COMPUTERIZED DOUBLE THREAD CHAINSTITCH QUILTER

GRIBETZ

BUILT IN 1990

CLASS III

3 NEEDLE BAR 1x3x6

(12”) 300mm CARRIAGE TRAVEL

WIDTH: 110”MACHINE SUPPLIED WITH FOLLOWING FEATURES:

3*3” FEED ROLLERS

2 THREAD RACKS FOR TOP THREAD AND LOOPER THREAD

2 SPECIAL BUTTERFLY THREAD TAKE-UP ASSEMBLIES FOR TOP AND BOTTOM THREAD

2 AUXILIARY FEED ROLL BRACKETS

3 PUSH BUTTON STATIONS

6 ECCENTRICS

1 YARDAGE COUNTER

120 NEEDLES

120 LOOPERS

40 STANDARD PATTERNS

EQUI-STITCHSPECIAL EQUIPMENT:

CATWALK WITH MATERIAL HANDLING PACK

ELECTRONIC THREAD BREAK DETECTOR

BACK CANOPY WITH MOTORIZED WIND-UPQUANTITY: 1

Learn More -

A-1245 CARPETING RELATED MACHINERYREFERENCE NUMBER: A-1245 (0101GHBXX12) A CARPETING RELATED MACHINERY REFERENCE #300: 100 HIRSCHBURGER WINDING HEADS, CYLINDRIC TUBES, TRAVERSE 250MM REFERENCE #301: GILBOS WINDERS, 4 SETS OF 6 SPINDLES EACH REFERENCE #302: 1 ICBT TWO-FOR-ONE TWISTER – 2X36 POSITIONS – UP TO TWIST 10.000 DEN REFERENCE #303: 1X12 POSITIONS GILBOS WINDERS WITH AUTODOFFING REFERENCE #304: 1 CARPET FORMING MACHINE FOR STAIR CARPET PIECES REFERENCE #305: 1 AUTOCLAVE FOR CARPET YARNS, LENGTH 5.60 M, INNER DIAMETER 1.60 M REFERENCE #307: 2 MENDING-GUNS REFERENCE #308: KNIFES, NEEDLES, LOOPERS FOR TUFTING MACHINERY REFERENCE #309: 2 X DIETZE & SCHELL – AIRENTANGLING – EACH 4 POSISITONS + 4 WINDERS QUANTITY AVAILABLE: 9 Learn More

A-1245 CARPETING RELATED MACHINERYREFERENCE NUMBER: A-1245 (0101GHBXX12) A CARPETING RELATED MACHINERY REFERENCE #300: 100 HIRSCHBURGER WINDING HEADS, CYLINDRIC TUBES, TRAVERSE 250MM REFERENCE #301: GILBOS WINDERS, 4 SETS OF 6 SPINDLES EACH REFERENCE #302: 1 ICBT TWO-FOR-ONE TWISTER – 2X36 POSITIONS – UP TO TWIST 10.000 DEN REFERENCE #303: 1X12 POSITIONS GILBOS WINDERS WITH AUTODOFFING REFERENCE #304: 1 CARPET FORMING MACHINE FOR STAIR CARPET PIECES REFERENCE #305: 1 AUTOCLAVE FOR CARPET YARNS, LENGTH 5.60 M, INNER DIAMETER 1.60 M REFERENCE #307: 2 MENDING-GUNS REFERENCE #308: KNIFES, NEEDLES, LOOPERS FOR TUFTING MACHINERY REFERENCE #309: 2 X DIETZE & SCHELL – AIRENTANGLING – EACH 4 POSISITONS + 4 WINDERS QUANTITY AVAILABLE: 9 Learn More -

M-3014 GRIBETZ COMPUTERIZED QUILTING MACHINE-MODEL G.I.1200 (BEIGE COLOR)-86 INCH

M-3014 GRIBETZ COMPUTERIZED QUILTING MACHINE-MODEL G.I.1200 (BEIGE COLOR)-86 INCHREFERENCE NUMBER: M-3014

GRIBETZ COMPUTERIZED QUILTING MACHINE-MODEL G.I.1200 (BEIGE COLOR)-86 INCH

QUILTING MACHINE

COMPUTERIZED

GRIBETZ

TYPE/MODEL: GI2000

MACHINE SIZES: 86”

NEEDLE SPACING: 1×3×6

MACHINE WIRED: 220V 3PH 60HZ

AUX. TRANSFORMER: V- PH- HZ-

NOTE: THE QUILTER INCLUDES

(3) COMPLETE BARS

(1) CLOTH TRAY

(2) THREAD RACKS (ONE ON THE TOP AND THE OTHER ON THE BOTTOM)

(1) CATWALK

(1) TRANSFORMER

(2) CIRCULAR KNIVES

(27) LOOPERS

(2) SERVO MOTORS (TOSHIBA)

(1) FOAM RACK

(1) FABRIC COMPENSATOR

(1) SPUHL ANDERSON PANEL CUTTER

WITH (1) CROSSCUT BLADE

WITHOUT CIRCULAR KNIFE TO CUT BORDER

PLATE INFO:

MODEL: PC 8

(1) CONTROL PANEL WHICH HAS (4) DRIVES

FIRST DRIVE: INDUSTRIAL INDEXING SYSTEMS INC.

PART NR: AMP 4301

MODEL: RA DRIVER-RAD 02-2062

SECOND DRIVE: INDUSTRIAL INDEXING SYSTEMS INC.

PART NR: AMP 4300

MODEL: RA DRIVER-RAD 02-2062

THIRD DRIVE: INDUSTRIAL INDEXING SYSTEMS INC.

PART NR: AMP 4300

MODEL: RA DRIVER-RAD 02-2061

FOURTH DRIVE: INDUSTRIAL INDEXING SYSTEMS INC.

PART NR: MSC-850

NOTE: THE MACHINE HAS A NEMATRON-OPTI TOUCH

QUANTITY: 1

Learn More