Search results for: 'Filling lin''

- Related search terms

- Filling mac

- Filling machine

- Filling li

- filling mach

- filling machine d

-

TT-8694 A1 TETRA PAK ASEPTIC 16400 BPH FILLING MACHINE, YEAR 2006TT-8694 A1 TETRA PAK ASEPTIC 16400 BPH FILLING MACHINE, YEAR 2006 1. FILLING MACHINE 2. BRAND: TETRA PAK® 3. MODEL: A1-TETRA CLASSIC ASEPTIC (TCA) 4. YEAR: 2006 5. SPEED: 16400 BOXES/HOUR 6. PRODUCTS: DAIRY, JUICE Learn More

TT-8694 A1 TETRA PAK ASEPTIC 16400 BPH FILLING MACHINE, YEAR 2006TT-8694 A1 TETRA PAK ASEPTIC 16400 BPH FILLING MACHINE, YEAR 2006 1. FILLING MACHINE 2. BRAND: TETRA PAK® 3. MODEL: A1-TETRA CLASSIC ASEPTIC (TCA) 4. YEAR: 2006 5. SPEED: 16400 BOXES/HOUR 6. PRODUCTS: DAIRY, JUICE Learn More -

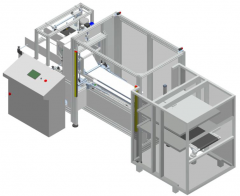

E-9901 AUTOMATIC COMPUTERIZED PILLOW FILLINGREFERENCE NUMBER: E-9901 AUTOMATIC COMPUTERIZED PILLOW FILLING LINE FILLING HEAD IS CONTROLLED BY A PLC MODEL: CF FLOORSPACE REQUIRED: 9000 X 5000 X 2100mm (29.5 FEET X 16.4 FEET X 82 INCHES) QUANTITY AVAILABLE: 1 Learn More

E-9901 AUTOMATIC COMPUTERIZED PILLOW FILLINGREFERENCE NUMBER: E-9901 AUTOMATIC COMPUTERIZED PILLOW FILLING LINE FILLING HEAD IS CONTROLLED BY A PLC MODEL: CF FLOORSPACE REQUIRED: 9000 X 5000 X 2100mm (29.5 FEET X 16.4 FEET X 82 INCHES) QUANTITY AVAILABLE: 1 Learn More -

M-1483 FIBER FEEDER SYSTEMREFERENCE NUMBER: M-1483 (66032FTG5UF) FIBER FEEDER SYSTEM SUITABLE RAW MATERIALS: CONJUGATE HOLLOW SILICONIZED POLYESTER FIBER≤100mm; HOLLOW SILICONIZED POLYESTER FIBER≤100mm; MICROFIBER 0.7D-3D, LENGTH 32mm-64mm; FIRE PROOF FIBER THIS PRODUCTION LINE IS MAINLY USED FOR PILLOW FILLING, CUSHION AND CHAIRPAD FILLING. IT CAN BE OPERATED BY TWO OPERATORS, ADJUSTED BY FOOT SWITCHES, AND CONTROLLED BY SIEMENS PLC. QUANTITY AVAILABLE: 1 Learn More

M-1483 FIBER FEEDER SYSTEMREFERENCE NUMBER: M-1483 (66032FTG5UF) FIBER FEEDER SYSTEM SUITABLE RAW MATERIALS: CONJUGATE HOLLOW SILICONIZED POLYESTER FIBER≤100mm; HOLLOW SILICONIZED POLYESTER FIBER≤100mm; MICROFIBER 0.7D-3D, LENGTH 32mm-64mm; FIRE PROOF FIBER THIS PRODUCTION LINE IS MAINLY USED FOR PILLOW FILLING, CUSHION AND CHAIRPAD FILLING. IT CAN BE OPERATED BY TWO OPERATORS, ADJUSTED BY FOOT SWITCHES, AND CONTROLLED BY SIEMENS PLC. QUANTITY AVAILABLE: 1 Learn More -

YY-3145 BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGH-CAPACITY POLYESTER STAPLE FIBER LINEYY-3145 BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGH-CAPACITY POLYESTER STAPLE FIBER LINE HIGH-CAPACITY POLYESTER STAPLE FIBER LINE BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGHLY VERSATILE COMPLETE STAPLE FIBER LINE, HIGH PRODUCTIVITY AND COULD BE RUN SEPARATELY FROM VIRGIN PET OR AS WELL PET BOTTLE FLAKES, CHIPS AND R-PET. QUANTITY: 1 Learn More

YY-3145 BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGH-CAPACITY POLYESTER STAPLE FIBER LINEYY-3145 BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGH-CAPACITY POLYESTER STAPLE FIBER LINE HIGH-CAPACITY POLYESTER STAPLE FIBER LINE BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGHLY VERSATILE COMPLETE STAPLE FIBER LINE, HIGH PRODUCTIVITY AND COULD BE RUN SEPARATELY FROM VIRGIN PET OR AS WELL PET BOTTLE FLAKES, CHIPS AND R-PET. QUANTITY: 1 Learn More -

F-1431 FEATHER FILLING MACHINE MODEL SR-5

F-1431 FEATHER FILLING MACHINE MODEL SR-5REFERENCE NUMBER: F-1431

FEATHER FILLING MACHINE MODEL SR-5

PRODUCT FEATURES

• FULLY ENCLOSED DESIGN TO KEEP SURROUNDINGS CLEAN AND TO SAVE MATERIAL

• AUTOMATIC WEIGHING WITH ACCURATE LOAD CELL TO ENSURE PRODUCTION QUALITY

• FILLING TIME IS 2 TO 5 SECONDS

• NICE DESIGN SUITABLE FOR ALL KINDS OF FABRIC

• CE CERTIFICATE

• TYPE : SR-5

• DIMENSION: 1200 x 1500 x 2000MM

• VOLTAGE: 200/380/415V 50/60HZ 3PHASE

• POWER: 1.5 KW

• FILLING RANGE: 0.5 TO 50 GRAMS, DEPENDING ON THE MATERIAL

• AIR PRESSURE: 0.5 TO 0.8MPA

• THE VACUUM FILLING FUNCTION DOES NOT HURT THE MATERIAL AND KEEPS THE ORIGINAL ELASTICITY AND SOFT HAND FEELING.

• THE WHOLE LINE CAN BE HANDLED BY ONLY TWO OPERATORS

• THE AVERAGE FILLING TIME CAN BE 4 TO 10 SECONDS (DEPENDING ON THE ACCURACY) AND THE FILLING TIME CAN BE ADJUSTED.

• Material hopper: 1200 x 900 x 2000mm 1pcs

• Weighing system: 1200 x 600 x 1000mm 1pcs

• Blower: 1 set

• Pipe system: 1 pc

Learn More -

E-9990 COMPUTERIZED PILLOW FILLING MACHINEREFERENCE NUMBER: E-9990 COMPUTERIZED PILLOW FILLING MACHINE - NEW MODEL: 003-PF WITH OPENING SECTION DIMENSIONS: 5000 X 5000 X 1400mm (16.4 FEET X 16.4 FEET X 55 INCHES) EQUIPMENT: FIBER OPENER 1 PCS; FAN 1 PCS; FILLING LOT 2 SET; PLC CONTROL SYSTEM 1 PCS VOLTAGE: AS PER CUSTOMER'S REQUEST CAPACITY: 150-180KG/H (300 TO 400 LBS/HR) FIBER OPENING RATE: MORE THAN 98% AND NOT BE DAMAGED WEIGHT: 690KG (1500 LBS) PLC (COMPUTER) CONTROL SYSTEM QUANTITY AVAILABLE: 1 Learn More

E-9990 COMPUTERIZED PILLOW FILLING MACHINEREFERENCE NUMBER: E-9990 COMPUTERIZED PILLOW FILLING MACHINE - NEW MODEL: 003-PF WITH OPENING SECTION DIMENSIONS: 5000 X 5000 X 1400mm (16.4 FEET X 16.4 FEET X 55 INCHES) EQUIPMENT: FIBER OPENER 1 PCS; FAN 1 PCS; FILLING LOT 2 SET; PLC CONTROL SYSTEM 1 PCS VOLTAGE: AS PER CUSTOMER'S REQUEST CAPACITY: 150-180KG/H (300 TO 400 LBS/HR) FIBER OPENING RATE: MORE THAN 98% AND NOT BE DAMAGED WEIGHT: 690KG (1500 LBS) PLC (COMPUTER) CONTROL SYSTEM QUANTITY AVAILABLE: 1 Learn More -

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More -

YY-3357 KHS FERRUM - FIPAL - ROBOPAC LINE FOR CANS (2015)YY-3357 KHS FERRUM - FIPAL - ROBOPAC LINE FOR CANS (2015) 1. YEAR: 2015 2. CATEGORY: COMPLETE FILLING LINES 3. MANUFACTURER: KHS 4. MODEL: FERRUM - FIPAL - ROBOPAC 5. AVAILABILITY: IMMEDIATELY QUANTITY: 1 Learn More

YY-3357 KHS FERRUM - FIPAL - ROBOPAC LINE FOR CANS (2015)YY-3357 KHS FERRUM - FIPAL - ROBOPAC LINE FOR CANS (2015) 1. YEAR: 2015 2. CATEGORY: COMPLETE FILLING LINES 3. MANUFACTURER: KHS 4. MODEL: FERRUM - FIPAL - ROBOPAC 5. AVAILABILITY: IMMEDIATELY QUANTITY: 1 Learn More -

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More -

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More