Search results for: 'For i'

-

YY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOURYY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOUR THE MACHINE IS COMPOSED OF MOTOR, HYDRAULIC SYSTEM, DRAG HOOK, PULL MOUTH, BODY, ETC. THE BASIC PRINCIPLE IS: THE MOTOR DRIVES THE HYDRAULIC SYSTEM AND HYDRAULIC CYLINDER, AND THE DRAG HOOK IS CONNECTED TO THE PULL ROD OF THE OIL CYLINDER. THE ACTION OF THE OIL PUMP AND OIL CYLINDER MAKES THE DRAG HOOK RECIPROCATE. QUANTITY: 1 Learn More

YY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOURYY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOUR THE MACHINE IS COMPOSED OF MOTOR, HYDRAULIC SYSTEM, DRAG HOOK, PULL MOUTH, BODY, ETC. THE BASIC PRINCIPLE IS: THE MOTOR DRIVES THE HYDRAULIC SYSTEM AND HYDRAULIC CYLINDER, AND THE DRAG HOOK IS CONNECTED TO THE PULL ROD OF THE OIL CYLINDER. THE ACTION OF THE OIL PUMP AND OIL CYLINDER MAKES THE DRAG HOOK RECIPROCATE. QUANTITY: 1 Learn More -

PICANOL AIR JET TERRY LOOMS, YEAR 1978 TO 2001, JACQUARDREFERENCE NUMBER: T-6926 PICANOL AIR JET TERRY LOOMS, YEAR 1978 TO 2001, JACQUARD ITEM 001 AIR JET JACQUARD TERRY LOOMS MOD GUNNE TERRY PLUS H 2600 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2001 6 COLORS 6 FEEDER IRO N6 PILE BEAM 1250 N 6 GROUND BEAM 1000 SEPARATE ROLLER FERBER MOD ES-64-36 YEAR 2001 DOUBLE JACQUARD STAUBLI CX 870 YEAR 2001 LOOM N1 1408 HOOKS LOOM N 4 2688 HOOKS QUANTITY: 2 ITEM 002 AIR JET JACQUARD TERRY LOOMS MOD PICANOL TERRY-6-J H 3400 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2003 6 COLORS 6 FEEDER IRO N9 PILE BEAM 1250 N9 GROUND BEAM 1000 SEPARATE ROLLER FERBER MOD ES-64-36 YEAR 2001 DOUBLE JACQUARD STAUBLI CX 870 YEAR 2003 LOOMS N 41-42-43 1664 HOOKS INSTALLED LOOM N 44 2216 HOOKS INSTALLED QUANTITY: 4 ITEM 003 AIR JET JACQUARD TERRY LOOMS MOD PICANOL TERRY-6-J H 2600+3400 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2004 6 COLORS 6 FEEDER IRO N2PILE BEAM 1250 N2GROUND BEAM 1000 H2600 N2PILE BEAM 1250 N2GROUND BEAM 1000 H3400 SEPARATE ROLLER FERBER MOD ES-64-36+ES63 YEAR 2001 DOUBLE JACQUARD STAUBLI CX 870 YEAR 2004 LOOM N45 2688 HOOKS LOOM N 46 1856 HOOKS QUANTITY: 2 ITEM 004 AIR JET JACQUARD TERRY LOOMS MOD PICANOL TERRY-6-J H 3600 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2007 6 COLORS 6 FEEDER IRO N6 PILE BEAM 1250 N6 GROUND BEAM 1000 SEPARATE ROLLER FERBER MOD ES-63+ES64 YEAR 2001 DOUBLE JACQUARD STAUBLI DX 80-F YEAR 2007 LOOM N47 1952 HOOKS LOOM N 48 2600 HOOKS QUANTITY: 2 ITEM 005 AIR JET LOOMS PICANOL MOD PICANOL OMNI-2-P H 3400 2 COL 6 CAMME FOR FLAT FABRIC DOBBY CAMS MOTION STAUBLI TYPE 1600 08-1995 2 FEEDER PICANOL 2231 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 1995 N12 GROUND BEAM 1000 QUANTITY: 2 ITEM 006 GROUP BLOWING AND DUST ASPIRATOR MAGITEX X JACQUARD STAUBLI 49 MT MAGITEX X PICANOL LOOMS 53 MT QUANTITY: 2 ITEM 007 SPECIAL FORK LIFT FOR BEAM FERBER MOD BZ-S MAX LOADING 2700 KG MAX WIDTH BEAM 3900mm MAX DIAMETER BEAM 1250mm SPECIAL FORK LIFT FOR BEAM STIPI MOD TE MAX LOADING 1500 KG ITEM 008 KNOTTER STAUBLI TOPMATIC MOD TPM 210-PC CART FOR KNOTTER H 3600 KNOTTER ZELWEGER USTER TYPE UMM ITEM 009 TUFTING LOOM FOR BATHMATS PICKERING YEAR 1978 REED WIDTH 960mm CREEL 280 BOBBIN 400/300mm DIAMETER JUMBO BOBBIN 30 X 27 X 24 LOOM FOR VELVET BATH CARPET G.T SUPPLIES ENGENEERING LTD GB REED WIDTH 800mm CREEL 420 POSITION 40/28 DIAMETER 2 GROUP BLOWING AND DUST ASPIRATOR MAGITEX X MATS LOOM 52X2 MT ITEM 010 AIR COMPRESSOR BOGE MOD SF150 AIR PRESSURE 8 BAR POWER 110+4KW AIR PRODUCTION 18.40 MT3 X MINUTE YEAR 2006 AIR COMPRESSOR BOGE MOD S 75 AIR PRESSURE 8 BAR POWER 110+4KW AIR PRODUCTION 9.10 MT3 X MINUTE YEAR 1996 Learn More

PICANOL AIR JET TERRY LOOMS, YEAR 1978 TO 2001, JACQUARDREFERENCE NUMBER: T-6926 PICANOL AIR JET TERRY LOOMS, YEAR 1978 TO 2001, JACQUARD ITEM 001 AIR JET JACQUARD TERRY LOOMS MOD GUNNE TERRY PLUS H 2600 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2001 6 COLORS 6 FEEDER IRO N6 PILE BEAM 1250 N 6 GROUND BEAM 1000 SEPARATE ROLLER FERBER MOD ES-64-36 YEAR 2001 DOUBLE JACQUARD STAUBLI CX 870 YEAR 2001 LOOM N1 1408 HOOKS LOOM N 4 2688 HOOKS QUANTITY: 2 ITEM 002 AIR JET JACQUARD TERRY LOOMS MOD PICANOL TERRY-6-J H 3400 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2003 6 COLORS 6 FEEDER IRO N9 PILE BEAM 1250 N9 GROUND BEAM 1000 SEPARATE ROLLER FERBER MOD ES-64-36 YEAR 2001 DOUBLE JACQUARD STAUBLI CX 870 YEAR 2003 LOOMS N 41-42-43 1664 HOOKS INSTALLED LOOM N 44 2216 HOOKS INSTALLED QUANTITY: 4 ITEM 003 AIR JET JACQUARD TERRY LOOMS MOD PICANOL TERRY-6-J H 2600+3400 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2004 6 COLORS 6 FEEDER IRO N2PILE BEAM 1250 N2GROUND BEAM 1000 H2600 N2PILE BEAM 1250 N2GROUND BEAM 1000 H3400 SEPARATE ROLLER FERBER MOD ES-64-36+ES63 YEAR 2001 DOUBLE JACQUARD STAUBLI CX 870 YEAR 2004 LOOM N45 2688 HOOKS LOOM N 46 1856 HOOKS QUANTITY: 2 ITEM 004 AIR JET JACQUARD TERRY LOOMS MOD PICANOL TERRY-6-J H 3600 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2007 6 COLORS 6 FEEDER IRO N6 PILE BEAM 1250 N6 GROUND BEAM 1000 SEPARATE ROLLER FERBER MOD ES-63+ES64 YEAR 2001 DOUBLE JACQUARD STAUBLI DX 80-F YEAR 2007 LOOM N47 1952 HOOKS LOOM N 48 2600 HOOKS QUANTITY: 2 ITEM 005 AIR JET LOOMS PICANOL MOD PICANOL OMNI-2-P H 3400 2 COL 6 CAMME FOR FLAT FABRIC DOBBY CAMS MOTION STAUBLI TYPE 1600 08-1995 2 FEEDER PICANOL 2231 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 1995 N12 GROUND BEAM 1000 QUANTITY: 2 ITEM 006 GROUP BLOWING AND DUST ASPIRATOR MAGITEX X JACQUARD STAUBLI 49 MT MAGITEX X PICANOL LOOMS 53 MT QUANTITY: 2 ITEM 007 SPECIAL FORK LIFT FOR BEAM FERBER MOD BZ-S MAX LOADING 2700 KG MAX WIDTH BEAM 3900mm MAX DIAMETER BEAM 1250mm SPECIAL FORK LIFT FOR BEAM STIPI MOD TE MAX LOADING 1500 KG ITEM 008 KNOTTER STAUBLI TOPMATIC MOD TPM 210-PC CART FOR KNOTTER H 3600 KNOTTER ZELWEGER USTER TYPE UMM ITEM 009 TUFTING LOOM FOR BATHMATS PICKERING YEAR 1978 REED WIDTH 960mm CREEL 280 BOBBIN 400/300mm DIAMETER JUMBO BOBBIN 30 X 27 X 24 LOOM FOR VELVET BATH CARPET G.T SUPPLIES ENGENEERING LTD GB REED WIDTH 800mm CREEL 420 POSITION 40/28 DIAMETER 2 GROUP BLOWING AND DUST ASPIRATOR MAGITEX X MATS LOOM 52X2 MT ITEM 010 AIR COMPRESSOR BOGE MOD SF150 AIR PRESSURE 8 BAR POWER 110+4KW AIR PRODUCTION 18.40 MT3 X MINUTE YEAR 2006 AIR COMPRESSOR BOGE MOD S 75 AIR PRESSURE 8 BAR POWER 110+4KW AIR PRODUCTION 9.10 MT3 X MINUTE YEAR 1996 Learn More -

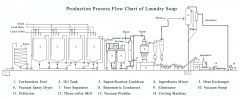

P-4421 LAUNDRY SOAP PRODUCTION LINECAPACITY 1000 to 1500 KILOGRAMS PER HOUR

P-4421 LAUNDRY SOAP PRODUCTION LINECAPACITY 1000 to 1500 KILOGRAMS PER HOURREFERENCE NUMBER: P-4421

VOLUME: 10m3SIZE:φ2800 x 3000, 20 m3POWER: 5.5 KILOWATTS PER SETLearn More -

M-1480 SLITTER REWINDER 1800mm WIDTH AND 1000mm DIAMETER-NEW MACHINE

M-1480 SLITTER REWINDER 1800mm WIDTH AND 1000mm DIAMETER-NEW MACHINEREFERENCE NUMBER: M-1480

SLITTER REWINDER 1800mm WIDTH AND 1000mm DIAMETER-NEW MACHINE

TECHNICAL CHARACTERISTICS:

UNWINDER

MAXIMUM WIDTH: 1800mm

MAXIMUM DIAMETER: 1100mm

MINIMUM WIDTH: 420mm

MAXIMUM WEIGHT: 300kgs

CORE ID: 3”

REWINDER:

MAXIMUM WIDTH: 1800mm

MAXIMUM DIAMETER: 1000mm

MINIMUM WIDTH: 100mm

MAXIMUM WEIGHT PER SHAFT: 300kgs

CORE ID: 3”

MATERIAL:

TYPE: 100% PP NONWOVEN

MINIMUM: 10gsm

MAXIMUM: 150gsm

TENSION:

MAXIMUM: 2 PLI

SPEED:

METERS PER MINUTE: 250

DESCRIPTION:

REWINDER MACHINE FOR NONWOVEN ROLLS: UP TO 1000 mm DIAMETER AT UNWINDER AND 1200 mm AT REWINDER.

THE WORKSTATION OFFERS EASY ACCESS TO THE TENSION CONTROL AREA AS WELL AS THE TRIMMING AREA; THIS WAY, ANY MODIFICATION ON THE MATERIAL MEASUREMENTS CAN BE DONE SAFELY.

THE WORKSTATION WILL DELIVER MODULES OF ROLLED MATERIAL WITH SPECIFIC DENSITY, AND SEPARATED FROM EACH OTHER IN ORDER TO KEEP OPERATION CONDITIONS WITHIN REQUIRED QUALITY CONTROLS.

UNWINDER WITH SHAFT:

THERE IS A CENTRAL UNWINDING SYSTEM SUPPORTED BY A 3” STEEL EXPANSION SHAFT.

THERE IS A TENSION CONTROL SYSTEM THAT WORKS THROUGH A PNEUMATIC DISK BRAKE WITH A REPLACEABLE PADS SYSTEM.

THE UNWINDER HAS A PIVOTABLE ROLLER SYSTEM WHEREBY TENSION MAY BE MODIFIED ON ONE END TO REDUCE TENSION DIFFERENCE ON MATERIAL IF NECESSARY.

THE SAFETY CHUCK HAS A MECHANICAL MOVEMENT SYSTEM FOR SHAFT INSERTION.

THE UNWINDER HAS AN ULTRASONIC OR LASER SENSOR FOR A REAL MEASURING OF ROLL DIAMETER. THIS INFORMATION WILL HELP TO KEEP A SPECIFIC TENSION ON MATERIAL DURING ALL THE PROCESS.

CUTTING:

THE LONGITUDINAL SHEAR CUT SYSTEM GUARANTEES CLEAN AND SAFE TRIMMING AT EVERY MODULE. THE CUTTING SYSTEM ADAPTED TO THE MAIN TRANSMISSION GUARANTEES AN OVER SPEED THAT MAY BE REGULATED ACCORDING TO THE MATERIAL DURING EVERY STAGE OF PROCESS. THE PNEUMATIC ACTIVATION KNIVES WILL ALLOW A FAST MODIFICATION OF THE CUTTING MEASUREMENTS.

THIS ROLLER IS LOCATED AT AN EASY ACCESS AREA FOR THE OPERATOR TO BE ABLE TO MAKE CHANGES ON THE CUTTING WIDTH SAFELY. THE COUNTER KNIVES ARE ASSEMBLED TO THE ROLLER BY 3 SETSCREWS THAT FIX THEIR POSITION ON THE ROLLER. THE COUNTERKNIVES HAVE TWO FACES, SO WHEN THE FIRST FACE HAS AN IMPORTANT WEAR, IT WILL BE REMOVED FROM THE ROLLER AND THE NEW FACE WILL BE PLACED INSTEAD. THIS WILL EXTEND THE LIFESPAN OF THIS IMPORTANT COMPONENT.

SHEAR CUT KNIVES: THERE IS AN ADJUSTMENT MECHANISM TO PLACE THEM ON THE COUNTER KNIFE AND TO ADJUST THE CUTTING LOAD ACCURATELY. THE COUNTER KNIVES ARE SUPPORTED TOWARDS THE ROLLER IN ORDER TO OBTAIN A CUTOFF. THE SPEED ON THIS SYSTEM IS AN OVER SPEED IN RELATION TO THAT OF THE MATERIAL, IN ORDER TO GENERATE A CLEAN CUT.

LONGITUDINAL SHEAR CUT: PNEUMATIC ACTIVATION.

COUNTER KNIVES ROLLER WITH 3 SUPPORT PLANES FOR THE COUNTER KNIVES; 120° DISPLACEMENT FROM EACH OTHER.

19 SLITTERS ARE INCLUDED.

REWINDER:

PERIPHERAL REWINDER FOR NONWOVEN. THIS SYSTEM HAS A COUPLE OF MAIN ROLLERS WHERE THE MATERIAL ROLL IS FORMED.

THIS SYSTEM HAS LINEAR GUIDES FOR COMPACTION THROUGH WICH A NIP IS OBTAINED ON THE MATERIAL. THE REWINDER WILL HAVE A TRANSMISSION BASED ON A VECTORIAL-TYPE MOTOR ADAPTED TO A CYCLOIDAL REDUCER. THE TRANSMISSION HAS A MECHANICAL TORQUE CONTROL SYSTEM TO CONTROL THE TORQUE DIFFERENTIAL BETWEEN MAIN ROLLS.

THIS SYSTEM WILL HAVE A 3” EXPANSION SHAFT WHERE THE CARDBOARD CORES WILL BE INSERTED AND THE MATERIAL ROLLS WILL BE FORMED.

FABRIC OPENING SYSTEM:

THIS SYSTEM IS BASED ON A VARIABLE CURVATURE SYSTEM BY A CENTER KNOB AND IT IS A BAR- TYPE SYSTEM. THIS KNOB IS THERE TO CONTROL THE CURVATURE OF THE BAR WHERE MATERIAL SLIDES THROUGH. THE SLIDING BAR IS MADE OUT OF AN ULTRA LOW FRICTION MATERIAL IN ORDER TO GENERATE A SMOOTH SLIDING OF MATERIAL WITHOUT ANY TENSION ADDED. THIS WILL REDUCE WRINKLES IN A SIGNIFICANT WAY.

AUTOMATIC TENSION SYSTEM:

THERE IS AN OPEN LOOP AUTOMATIC TENSION CONTROL SYSTEM WITH A SENSOR FOR DIAMETER MEASURING. BY THIS SYSTEM, A REAL VALUE OF DIAMETER IS OBTAINED AT THE REWINDER. PRESSURE OF PNEUMATIC BRAKE VARIES DURING PROCESS.

MANUAL POSITIONING (OPTIONAL):

THE MANUAL POSITIONING SYSTEM IS BASED ON THE POSITION CONTROL OF THE COUNTER KNIVES. THE MODULE IS POSITIONED AT A DESIRED CUTTING PARAMETER AND THE COUNTER KNIFE WILL PHYSICALLY COME ACROSS IT. THE REAL POSITION OF MODULE WILL BE SHOWN ON A SCREEN THAT OPERATOR WILL BE CONSTANTLY SUPERVISING. THIS SCREEN WILL SHOW THE REAL MEASUREMENTS OF THE CARRIAGE IN RELATION TO THE LAST ONE OR AS AN ABSOLUTE REFERENCE. OPERATOR WILL BE ABLE TO RESET THE MEASUREMENT ONCE THE COUNTER KNIFE IS REPLACED AND WILL REPEAT THIS PROCESS EVERY TIME A COUNTER KNIFE IS POSITIONED.

A DISPLAY WILL SHOW THE DESIRED POSITION IN MILLIMETERS OR INCHES.

THIS SYSTEM CAN SHOW MEASUREMENT IN AN EITHER ABSOLUTE OR INCREASING WAY.

POSITION TOLERANCE: +/- 0.30 mm.

THE POSITIONER IS INSTALLED ON A SUPPORT THAT WILL BE LOCATED ON THE REWINDER BENCHES. THEREFORE, THERE WILL BE AN EASY ACCESS TO SYSTEM AND AN EASY REPETITION OF POSITIONING PROCESS.

UNLOADING ROLL TABLE:

A HYDRAULIC PIVOTEABLE TABLE WILL HAVE AS MAIN FUNCTION THE UNLOADING OF FINISHED ROLLS THAT THEN WILL BE LOCATED ON FLOOR LEVEL. THIS SYSTEM WILL EJECT THE ROLL AND THEN IT WILL BE RECEIVED AT THE PIVOTING TABLE FOR AN EFFICIENT UNLOADING.

THE UNLOADING TABLE WILL ALSO WORK AS A PROTECTION FOR THE OPERATOR.

THIS EQUIPMENT WILL HAVE SECURITY CURTAINS AT FRONT TO KEEP OPERATOR FROM ENTERING THE REWINDING AREA. THERE WILL BE AN EMERGENCY STOP BUTTON OR WIRE WHERE OPERATOR WORKS AND WILL ALSO HAVE PHYSICAL PROTECTION WITH SECURITY SWITCHES AT CUTTING AREA.

CONTROL:

HMI CENTRAL CONTROL SYSTEM WITH TOUCH SCREEN TO PROGRAM THE OPERATION CYCLE AND ALL THE MATERIAL CHARACTERISTICS. OPERATOR WILL HAVE ACCESS TO ALL OPERATION PARAMETERS IN ORDER TO BE ABLE TO MAKE CHANGES ON THE EQUIPMENT OPERATION CONDITIONS, AND THEREFORE OBTAIN MATERIAL ROLLS WITH SPECIFIC DENSITIES.

TRANSMISSION: VECTORIAL MOTO REDUCER WITH 1000:1 TORQUE.

DIGITAL METER COUNTER WITH DISPLAY AND AUTOMATIC STOP AT DEFINED DISTANCE.

DOCUMENTS INCLUDED:

THE MACHINE WILL BE DELIVERED WITH THE FOLLOWING DOCUMENT:

OPERATION MANUAL

MAINTENANCE MANUAL

SAFETY MANUAL

ELECTRIC DIAGRAMS

CONTROL SYSTEM MANUAL

PLC BACKUP

REQUIREMENTS:

ELECTRIC 15 KW, 440 VAC, TRI PHASE.

PNEUMATIC 6 BAR - 60 LTS. / MIN.

DUCTS AND WIRING:

DUCTS AND WIRES RUNNING FROM UTILITIES SOURCES TO THE CONTROL PANEL AND FROM THE CONTROL PANEL TO THE MACHINE WILL BE AT CUSTOMER COSTS AND MUST BE DONE ACCORDING TO THE INSTRUCTIONS SHOWN IN OUR DIAGRAMS

SIEMENS PLC

Learn More -

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HRREFERENCE NUMBER: K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1

Learn More -

M-5244 TOYOTA JAT610 AIR JET LOOMS YEAR 1998 WIDTH 1900mm-2800mmREFERENCE NUMBER: M-5244 (1313JTBVXX12) L TOYOTA JAT610 AIR JET LOOMS YEAR 1998 WIDTH 1900mm-2800mm TOYOTA JAT610 AIR JET LOOMS, YEAR 1998 (60 LOOMS) X WIDTH 1900mm (12 LOOMS) X WIDTH 2800mm RUNNING CONDITION YEAR 1999 1 INVERTER FOR 36 LOOMS (2 INVERTERS FOR ALL 72 LOOMS) QUANTITY AVAILABLE: 27 LOOMS Learn More

M-5244 TOYOTA JAT610 AIR JET LOOMS YEAR 1998 WIDTH 1900mm-2800mmREFERENCE NUMBER: M-5244 (1313JTBVXX12) L TOYOTA JAT610 AIR JET LOOMS YEAR 1998 WIDTH 1900mm-2800mm TOYOTA JAT610 AIR JET LOOMS, YEAR 1998 (60 LOOMS) X WIDTH 1900mm (12 LOOMS) X WIDTH 2800mm RUNNING CONDITION YEAR 1999 1 INVERTER FOR 36 LOOMS (2 INVERTERS FOR ALL 72 LOOMS) QUANTITY AVAILABLE: 27 LOOMS Learn More -

M-3349 TOYOTA AIR JET LOOMSREFERENCE NUMBER: M-3349 (88013DYN7U)-D TOYOTA AIRJET LOOMS TOYOTA AIR JET LOOM QTY MODEL=JA2S-190TP-T610 TOTAL 60 LOOMS 60 STAUBLI POSITIVE TAPPET CAM MOPTION TYPE 1620 CAM BOX WITH 7 SHAFT 6 CAMS WITH 1 SPACER FOR EACH LOOM 60SETS 1 REPEAT GEAR FOR EACH LOOM 60SETS PROFILE REED SYSTEM REED SPACE 190 CM 60 LOWER BUILT ONE PIECE BOX TYPE SIDE FRAME FOR HIGH SPEED OPERATION 60 OIL BATH LUBRICATION FOR MAIN UNITS 60 TWO SIDES CRANK DRIVE BEATING WITH OIL BATH 60 HIGH TORQE INDUCTION MOTOR WITH SOLENOID BRAKE (4P-3PHASE,3.5KW) 60 MAIN CONTROL COMPUTER WITH 32 BYTES CPU 60 DISTRIBUTED CONTROL SYSTEM BY OPTICAL FIBER COMMUNICATION NETWORK 60 TOUCH SCREEN FUNCTION PANEL WITH MULTI- WINDOW DISPLAY 60 AUTOMATIC INITIAL CONDITION - (ICS) SYSTEM 60 AUTOMATIC FAULT ALRAM FUNCTION 60 WEEKLY EFFICIENCY GRAPH DISPLAY & DOWN TIME 60 CAUSE DISLPAY BEAM CLOTH ESTIMATOR 60 2 COLOUR MIXING DEVICE BY ELECTRIC DRUM POLE (EDP) 60 TAPERED SUB NOZZLE 60 LOW AIR PRESURE & HIGH PROPULSIVE MAIN NOZZLE 60 DIRECT DRIVE SOLENOID VALVE FOR MAIN & SUB NOZZLE 60 TWO INDEPENDENT SUB NOZZLE TANKS 60 TAPERED TUNNEL REED 60 AUTOMATIC TIMING CONTROLLER (ATC) 60 AUTOMATIC BRAKE SYSTEM (ABS) 60 TIMING CHEKER WITH GRAPH DISPLAY ON FUNCTION PANEL 60 CENTRALIZED REGULATOR 60 ELECTRONIC LET OFF MOTION BY DIGITAL AC SERVO MOTOR 60 AUTOMATIC LET OFF ADJUSTMENT 60 FELL FORWARD DEVICE FOR STOP MARK PREVENTION 60 POSITIVE EASING MOTION WITH TWIN BACK ROLLER 60 MECHANICAL TAKE UP MOTION BY CHANGE GEAR 60 ON LOOM TAKE UP MOTION FOR MAXIMUM -600MM CLOTH DIA 60 DOUBLE PRESS CLOTH ROLLS 60LOOM METAL SPRAYED SURFACE TAKE UP ROOLER 60 RING TAMPLE-3ROWS -24RING 60SET ROTARY LENO SELVEDGE AT L+R SIDE WITH ELECTRIC STOP MOTION 60SET DOUBLE FEELER FOR WEFT STOP MOTION -(REFLECTING TYPE ) 60 ELECTRIC WARP STOP MOTION BY SIX LINES CONTACT BAR 6 PER LOOM YARN BEAM SET WITH 1000 MM FLANGE & 178 MM BAREL DIA 90 CLOTH ROLLER 100 MM DIA 90 REED 60PIECE HEALD FRAMES 7 PER LOOM HEALD WIRE (331MML) C TYPE 6000PER LOOM DROPPER- (165-11-0.3) 6000PER LOOM QUANTITY: 60 TOYOTA AIR JET LOOM QTY MODEL=JA2S-280TP-T610 TOTAL 12 LOOM. 12 STAUBLI POSITIVE TAPPET CAM MOPTION 12SETS TYPE 1620 CAM BOX WITH 7 SHAFT 6 CAMS WITH 1 SPACER FOR EACH LOOM 12SETS 1 REPEAT GEAR FOR EACH LOOM 12SETS PROFILE REED SYSTEM REED SPACE 280 CM 12 LOWER BUILT ONE PIECE BOX TYPE SIDE FRAME FOR HIGH SPEED OPERATION 12 OIL BATH LUBRICATION FOR MAIN UNIT 12 TWO SIDES CRANK DRIVE BEATING WITH OIL BATH 12 HIGH TORQE INDUCTION MOTOR WITH SOLENOID 12 BRAKE (4P-3PHASE,3.5KW) MAIN CONTROL COMPUTER WITH 32 BYTES CPU 12 DISTRIBUTED CONTROL SYSTEM BY OPTICAL FIBER 12 COMMUNICATION NETWORK TOUCH SCREEN FUNCTION PANEL WITH MULTI- WINDOW DISPLAY 12 AUTOMATIC INITIAL CONDITION - (ICS) SYSTEM AUTOMATIC FAULT ALRAM FUNCTION 12 WEEKLY EFFICIENCY GRAPH DISPLAY & DOWN TIME 12 CAUSE DISLPAY BEAM CLOTH ESTIMATOR 12 2 COLOUR MIXING DEVICE BY ELECTRIC DRUM POLE (EDP) 12 TAPERED SUB NOZZLE 12 LOW AIR PRESURE & HIGH PROPULSIVE MAIN NOZZLE 12 DIRECT DRIVE SOLENIOD VALVE FOR MAIN & SUB NOZZLE 12 TWO INDEPENDENT SUB NOZZLE TANKS 12 TAPERED TUNNEL REED 12 AUTOMATIC TIMING CONTROL (ATC) 12 AUTOMATIC BRAKE SYSTEM (ABS) 12 TIMING CHEKER WITH GRAPH DISPLAY ON FUNCTION PANEL 12 CENTRALIZED REGULATOR 12 ELECTRONIC LET OFF MOTION BY DIGITAL AC SERVO MOTOR 12 AUTOMATIC LET OFF ADJUSTMENT 12 FELL FORWARD DEVICE FOR STOP MARK PREVENTION 12 POSITIVE EASING MOTION WITH TWIN BACK ROLLER 12 MECHANICAL TAKE UP MOTION BY CHANGE GEAR 12 ON LOOM TAKE UP MOTION FOR MAXIMUM -600MMCLOTH DIA 12 DOUBLE PRESS CLOTH ROLLS 12LOOM METAL SPRAYED SURFASE TAKE UP ROOLER 12 RING TAMPLE-3ROW -30RING 12SET OCCUPIED WITH TUCK IN DEVICE WITH COMPLETE ACCESSORIES DOUBLE FEELER FOR WEFT STOP MOTION -(REFLECTING TYPE ) ELECTRIC WARP STOP MOTION BY SIX LINES CONTACT BAR 6PER LOOM YARN BEAM SET WITH 1000 MM FLANGE & 178 MM BARREL DIA 18 CLOTH ROLLER 100 MM DIA 18 REED 12PIECE HEALD FRAMES 7 PER LOOM HEALD WIRE (331MML) C TYPE 8000PER LOOM DROPPER- (165-11-0.3) 8000PER LOOM QUANTITY AVAILABLE: 12 LOOMS 20 LOOMS HAVE GEAR FOR TUCK IN DEVICE, GEAR BOX AT LEFT SIDE 1 INVERTER FOR 36 LOOMS ( 2 INVERTERS FOR ALL 72) 2 ATLAS COPCO ZR-315 COMPRESORS AND DRYER MD-1000 AVAILALE AT ADDITIONAL COST Learn More

M-3349 TOYOTA AIR JET LOOMSREFERENCE NUMBER: M-3349 (88013DYN7U)-D TOYOTA AIRJET LOOMS TOYOTA AIR JET LOOM QTY MODEL=JA2S-190TP-T610 TOTAL 60 LOOMS 60 STAUBLI POSITIVE TAPPET CAM MOPTION TYPE 1620 CAM BOX WITH 7 SHAFT 6 CAMS WITH 1 SPACER FOR EACH LOOM 60SETS 1 REPEAT GEAR FOR EACH LOOM 60SETS PROFILE REED SYSTEM REED SPACE 190 CM 60 LOWER BUILT ONE PIECE BOX TYPE SIDE FRAME FOR HIGH SPEED OPERATION 60 OIL BATH LUBRICATION FOR MAIN UNITS 60 TWO SIDES CRANK DRIVE BEATING WITH OIL BATH 60 HIGH TORQE INDUCTION MOTOR WITH SOLENOID BRAKE (4P-3PHASE,3.5KW) 60 MAIN CONTROL COMPUTER WITH 32 BYTES CPU 60 DISTRIBUTED CONTROL SYSTEM BY OPTICAL FIBER COMMUNICATION NETWORK 60 TOUCH SCREEN FUNCTION PANEL WITH MULTI- WINDOW DISPLAY 60 AUTOMATIC INITIAL CONDITION - (ICS) SYSTEM 60 AUTOMATIC FAULT ALRAM FUNCTION 60 WEEKLY EFFICIENCY GRAPH DISPLAY & DOWN TIME 60 CAUSE DISLPAY BEAM CLOTH ESTIMATOR 60 2 COLOUR MIXING DEVICE BY ELECTRIC DRUM POLE (EDP) 60 TAPERED SUB NOZZLE 60 LOW AIR PRESURE & HIGH PROPULSIVE MAIN NOZZLE 60 DIRECT DRIVE SOLENOID VALVE FOR MAIN & SUB NOZZLE 60 TWO INDEPENDENT SUB NOZZLE TANKS 60 TAPERED TUNNEL REED 60 AUTOMATIC TIMING CONTROLLER (ATC) 60 AUTOMATIC BRAKE SYSTEM (ABS) 60 TIMING CHEKER WITH GRAPH DISPLAY ON FUNCTION PANEL 60 CENTRALIZED REGULATOR 60 ELECTRONIC LET OFF MOTION BY DIGITAL AC SERVO MOTOR 60 AUTOMATIC LET OFF ADJUSTMENT 60 FELL FORWARD DEVICE FOR STOP MARK PREVENTION 60 POSITIVE EASING MOTION WITH TWIN BACK ROLLER 60 MECHANICAL TAKE UP MOTION BY CHANGE GEAR 60 ON LOOM TAKE UP MOTION FOR MAXIMUM -600MM CLOTH DIA 60 DOUBLE PRESS CLOTH ROLLS 60LOOM METAL SPRAYED SURFACE TAKE UP ROOLER 60 RING TAMPLE-3ROWS -24RING 60SET ROTARY LENO SELVEDGE AT L+R SIDE WITH ELECTRIC STOP MOTION 60SET DOUBLE FEELER FOR WEFT STOP MOTION -(REFLECTING TYPE ) 60 ELECTRIC WARP STOP MOTION BY SIX LINES CONTACT BAR 6 PER LOOM YARN BEAM SET WITH 1000 MM FLANGE & 178 MM BAREL DIA 90 CLOTH ROLLER 100 MM DIA 90 REED 60PIECE HEALD FRAMES 7 PER LOOM HEALD WIRE (331MML) C TYPE 6000PER LOOM DROPPER- (165-11-0.3) 6000PER LOOM QUANTITY: 60 TOYOTA AIR JET LOOM QTY MODEL=JA2S-280TP-T610 TOTAL 12 LOOM. 12 STAUBLI POSITIVE TAPPET CAM MOPTION 12SETS TYPE 1620 CAM BOX WITH 7 SHAFT 6 CAMS WITH 1 SPACER FOR EACH LOOM 12SETS 1 REPEAT GEAR FOR EACH LOOM 12SETS PROFILE REED SYSTEM REED SPACE 280 CM 12 LOWER BUILT ONE PIECE BOX TYPE SIDE FRAME FOR HIGH SPEED OPERATION 12 OIL BATH LUBRICATION FOR MAIN UNIT 12 TWO SIDES CRANK DRIVE BEATING WITH OIL BATH 12 HIGH TORQE INDUCTION MOTOR WITH SOLENOID 12 BRAKE (4P-3PHASE,3.5KW) MAIN CONTROL COMPUTER WITH 32 BYTES CPU 12 DISTRIBUTED CONTROL SYSTEM BY OPTICAL FIBER 12 COMMUNICATION NETWORK TOUCH SCREEN FUNCTION PANEL WITH MULTI- WINDOW DISPLAY 12 AUTOMATIC INITIAL CONDITION - (ICS) SYSTEM AUTOMATIC FAULT ALRAM FUNCTION 12 WEEKLY EFFICIENCY GRAPH DISPLAY & DOWN TIME 12 CAUSE DISLPAY BEAM CLOTH ESTIMATOR 12 2 COLOUR MIXING DEVICE BY ELECTRIC DRUM POLE (EDP) 12 TAPERED SUB NOZZLE 12 LOW AIR PRESURE & HIGH PROPULSIVE MAIN NOZZLE 12 DIRECT DRIVE SOLENIOD VALVE FOR MAIN & SUB NOZZLE 12 TWO INDEPENDENT SUB NOZZLE TANKS 12 TAPERED TUNNEL REED 12 AUTOMATIC TIMING CONTROL (ATC) 12 AUTOMATIC BRAKE SYSTEM (ABS) 12 TIMING CHEKER WITH GRAPH DISPLAY ON FUNCTION PANEL 12 CENTRALIZED REGULATOR 12 ELECTRONIC LET OFF MOTION BY DIGITAL AC SERVO MOTOR 12 AUTOMATIC LET OFF ADJUSTMENT 12 FELL FORWARD DEVICE FOR STOP MARK PREVENTION 12 POSITIVE EASING MOTION WITH TWIN BACK ROLLER 12 MECHANICAL TAKE UP MOTION BY CHANGE GEAR 12 ON LOOM TAKE UP MOTION FOR MAXIMUM -600MMCLOTH DIA 12 DOUBLE PRESS CLOTH ROLLS 12LOOM METAL SPRAYED SURFASE TAKE UP ROOLER 12 RING TAMPLE-3ROW -30RING 12SET OCCUPIED WITH TUCK IN DEVICE WITH COMPLETE ACCESSORIES DOUBLE FEELER FOR WEFT STOP MOTION -(REFLECTING TYPE ) ELECTRIC WARP STOP MOTION BY SIX LINES CONTACT BAR 6PER LOOM YARN BEAM SET WITH 1000 MM FLANGE & 178 MM BARREL DIA 18 CLOTH ROLLER 100 MM DIA 18 REED 12PIECE HEALD FRAMES 7 PER LOOM HEALD WIRE (331MML) C TYPE 8000PER LOOM DROPPER- (165-11-0.3) 8000PER LOOM QUANTITY AVAILABLE: 12 LOOMS 20 LOOMS HAVE GEAR FOR TUCK IN DEVICE, GEAR BOX AT LEFT SIDE 1 INVERTER FOR 36 LOOMS ( 2 INVERTERS FOR ALL 72) 2 ATLAS COPCO ZR-315 COMPRESORS AND DRYER MD-1000 AVAILALE AT ADDITIONAL COST Learn More -

M-4432 SCHLAFHORST 338 WINDER YEAR 2001-2002 – 60 POSITIONS / 50 POSITIONSREFERENCE NUMBER: M-4432 (1010MNJWHH9) K SCHLAFHORST 338 WINDER YEAR 2001-2002 – 60 POSITIONS / 50 POSITIONS 2 SETS OF SCHALFHORST’S 338 WINDER A. 1 SET X 60 DRUMS MODEL : 338 (R SIDE) YEAR : 2001 NO. OF SPINDLE : 60 FEEDING : MAGAZINE MAGAZINE POCKET : 6 DRUM : STEEL MADE, 2.0 TURN, 6” TRAVERSE TAKE-UP SHAPE : 5°57 YARN CLEARER : USTER QUANTUM 1 (NO FOREIGN FIBER DETECTOR) SPLICER : PRISM DZ3 SUCTION TAIL END WITH OVERHEAD CLEANER WITHOUT WAXING DEVICE INDIVIDUAL SUCTION BLOWER (UPWARD) WITHOUT AUTO-DOFFER WITHOUT PACKAGE CONVEYOR POWER “ 380V50HZ B. 1 SET X 50 DRUMS MODEL : 338 (L SIDE) YEAR 2002 NO. OF SPINDLE : 50 FEEDING : MAGAZINE MAGAZINE POCKET : 6 DRUM : STEEL MADE, 2.5 TURN, 6” TRAVERSE TAKE-UP SHAPE : 5°57 YARN CLEARER : USTER QUANTUM 2 (NO FOREIGN FIBER DETECTOR) SPLICER : PRISM DZ3 SUCTION TAIL END WITH OVERHEAD CLEANER WITH WAXING DEVICE INDIVIDUAL SUCTION BLOWER (UPWARD) WITHOUT AUTO-DOFFER WITHOUT PACKAGE CONVEYOR POWER “ 380V50HZ QUANTITY AVAILABLE: 2 Learn More

M-4432 SCHLAFHORST 338 WINDER YEAR 2001-2002 – 60 POSITIONS / 50 POSITIONSREFERENCE NUMBER: M-4432 (1010MNJWHH9) K SCHLAFHORST 338 WINDER YEAR 2001-2002 – 60 POSITIONS / 50 POSITIONS 2 SETS OF SCHALFHORST’S 338 WINDER A. 1 SET X 60 DRUMS MODEL : 338 (R SIDE) YEAR : 2001 NO. OF SPINDLE : 60 FEEDING : MAGAZINE MAGAZINE POCKET : 6 DRUM : STEEL MADE, 2.0 TURN, 6” TRAVERSE TAKE-UP SHAPE : 5°57 YARN CLEARER : USTER QUANTUM 1 (NO FOREIGN FIBER DETECTOR) SPLICER : PRISM DZ3 SUCTION TAIL END WITH OVERHEAD CLEANER WITHOUT WAXING DEVICE INDIVIDUAL SUCTION BLOWER (UPWARD) WITHOUT AUTO-DOFFER WITHOUT PACKAGE CONVEYOR POWER “ 380V50HZ B. 1 SET X 50 DRUMS MODEL : 338 (L SIDE) YEAR 2002 NO. OF SPINDLE : 50 FEEDING : MAGAZINE MAGAZINE POCKET : 6 DRUM : STEEL MADE, 2.5 TURN, 6” TRAVERSE TAKE-UP SHAPE : 5°57 YARN CLEARER : USTER QUANTUM 2 (NO FOREIGN FIBER DETECTOR) SPLICER : PRISM DZ3 SUCTION TAIL END WITH OVERHEAD CLEANER WITH WAXING DEVICE INDIVIDUAL SUCTION BLOWER (UPWARD) WITHOUT AUTO-DOFFER WITHOUT PACKAGE CONVEYOR POWER “ 380V50HZ QUANTITY AVAILABLE: 2 Learn More -

TT-8624 TETRA PAK TBA/19 200 B BEVERAGE PRODUCTION MACHINETT-8624 TETRA PAK TBA/19 200 B BEVERAGE PRODUCTION MACHINE 1. MACHINE TYPE: BEVERAGE PRODUCTION MACHINE 2. BRAND: TETRA PAK 3. MODEL: TBA/19 200 B 4. CONDITION: EXCELLENT (USED) Learn More

TT-8624 TETRA PAK TBA/19 200 B BEVERAGE PRODUCTION MACHINETT-8624 TETRA PAK TBA/19 200 B BEVERAGE PRODUCTION MACHINE 1. MACHINE TYPE: BEVERAGE PRODUCTION MACHINE 2. BRAND: TETRA PAK 3. MODEL: TBA/19 200 B 4. CONDITION: EXCELLENT (USED) Learn More -

TT-8623 TETRA PAK® A3 FLEX 600V FILLING MACHINE 1000 EDGE 7000 BPH, YEAR 2006TT-8623 TETRA PAK® A3 FLEX 600V FILLING MACHINE 1000 EDGE 7000 BPH, YEAR 2006 1. TETRA PAK® A3 FLEX 600V FILLING MACHINE 2. YEAR OF CONSTRUCTION 2006 3. CONDITION USED 4. MACHINE TYPE: FILLING MACHINE 5. BRAND: TETRA PAK® 6. MODEL: A3 FLEX 600V 7. CONDITION: USED 8. OPERATING HOURS: 67,130 H Learn More

TT-8623 TETRA PAK® A3 FLEX 600V FILLING MACHINE 1000 EDGE 7000 BPH, YEAR 2006TT-8623 TETRA PAK® A3 FLEX 600V FILLING MACHINE 1000 EDGE 7000 BPH, YEAR 2006 1. TETRA PAK® A3 FLEX 600V FILLING MACHINE 2. YEAR OF CONSTRUCTION 2006 3. CONDITION USED 4. MACHINE TYPE: FILLING MACHINE 5. BRAND: TETRA PAK® 6. MODEL: A3 FLEX 600V 7. CONDITION: USED 8. OPERATING HOURS: 67,130 H Learn More