Search results for: 'automatic+V'''

-

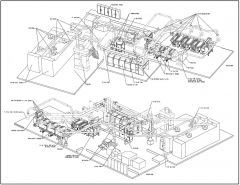

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINEREFERENCE NUMBER: M-7873

CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

AUTOMATIC LINE

FOR CHOCOLATE CEREAL AND GRANOLA BARS

AUTOMATIC COMBINATION BETWEEN THE FREEZING, FORMING, AND PRESSING ROLLERS, AND THE SLITTING TECHNOLOGY.

THIS PRODUCING LINE IS A MULTI-FUNCTION LINE WHICH CONSISTS OF KITCHEN EQUIPMENTS, FORMING AND SHEETING SYSTEM, NUTS SPRINKLING SYSTEM, FORMING AND PRESSING ROLLER, REFRIGERATION SYSTEM, COOLING TUNNEL, CANDY BAR SLITTING, CUTTING AND CONVEYING SYSTEM, AND CHOCOLATE ENROBING MACHINE, ETC.

THIS LINE TAKES THE PLACE OF THE TRADITIONAL, MANUAL WORKSHOP PRODUCTION WITH FULL AUTOMATIC MACHINERY PRODUCTION. THIS LINE WILL BE IDEAL FOR THE CANDY BAR LEISURE FOOD INDUSTRY, WITH MODERN AND LARGE QUANTITY PRODUCTION.

Learn More -

M-6423 AUTOMATIC YOGURT CUP FILLING AND SEALING MACHINE – ROTARY TYPE – OUTPUT 800 TO 1,000 CUPS PER HOUR

M-6423 AUTOMATIC YOGURT CUP FILLING AND SEALING MACHINE – ROTARY TYPE – OUTPUT 800 TO 1,000 CUPS PER HOURREFERENCE NUMBER: M-6423

AUTOMATIC YOGURT CUP FILLING AND SEALING MACHINE – ROTARY TYPE – OUTPUT 800 TO 1,000 CUPS PER HOURAUTOMATIC CUP FILLING AND SEALING MACHINE – FILLING YOGURT

ROTARY TYPE

DIAMETER: 9.5 CM

OUTPUT: 800 TO 1,000 CUPS PER HOUR

ROLL FILMQUANTITY: 1

Learn More -

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More -

TT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATORTT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATOR QUANTITY: 10 Learn More

TT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATORTT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATOR QUANTITY: 10 Learn More -

V-2195 FULLY AUTOMATIC SINGLE SHAFT BALONEY SLITTER, WORKING WIDTH 1850mmV-2195 FULLY AUTOMATIC SINGLE SHAFT BALONEY SLITTER, WORKING WIDTH 1850mm APPLICATIONS: SUITABLE FOR VARIOUS TAPE SUCH AS PVC, MASKING, DOUBLE SIDE, OPP PACKAGING AND FOAM TAPES, ETC. QUANTITY: 1 MACHINE NOTE: BLADE SIZE IS PER CUSTOMER REQUIREMENTS Learn More

V-2195 FULLY AUTOMATIC SINGLE SHAFT BALONEY SLITTER, WORKING WIDTH 1850mmV-2195 FULLY AUTOMATIC SINGLE SHAFT BALONEY SLITTER, WORKING WIDTH 1850mm APPLICATIONS: SUITABLE FOR VARIOUS TAPE SUCH AS PVC, MASKING, DOUBLE SIDE, OPP PACKAGING AND FOAM TAPES, ETC. QUANTITY: 1 MACHINE NOTE: BLADE SIZE IS PER CUSTOMER REQUIREMENTS Learn More -

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOURREFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

REFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

Learn More -

TT-3916 MARGASA TEARING LINE, WORKING WIDTH 2000mm, 5 DRUMS, YEAR 2010 COMPLETE PLANT WITH MIXING ROOMS AND FILTRATION, ALL PIPING INCLUDED. WITH AUTEFA AUTOMATIC BALE PRESSTT-3916 MARGASA TEARING LINE, WORKING WIDTH 2000mm, 5 DRUMS, YEAR 2010 COMPLETE PLANT WITH MIXING ROOMS AND FILTRATION, ALL PIPING INCLUDED. WITH AUTEFA AUTOMATIC BALE PRESS QUANTITY: 1 Learn More

TT-3916 MARGASA TEARING LINE, WORKING WIDTH 2000mm, 5 DRUMS, YEAR 2010 COMPLETE PLANT WITH MIXING ROOMS AND FILTRATION, ALL PIPING INCLUDED. WITH AUTEFA AUTOMATIC BALE PRESSTT-3916 MARGASA TEARING LINE, WORKING WIDTH 2000mm, 5 DRUMS, YEAR 2010 COMPLETE PLANT WITH MIXING ROOMS AND FILTRATION, ALL PIPING INCLUDED. WITH AUTEFA AUTOMATIC BALE PRESS QUANTITY: 1 Learn More -

YY-1366 (USERS MANUAL) BAG CLOSING MACHINE HEAD, INSTRUCTION MANUALYY-1366 BAG CLOSING MACHINE HEAD, INSTRUCTION MANUAL FOR OPENRATOR SAFETY: - THIS MANUAL BOOK CONTAINS INSTRUCTIONS AND PRECAUTIONS FOR USING THE BAG CLOSING MACHINE HEAD. BE SURE TO READ AND UNDERSTAND THE MANUAL BOOK BEFORE USING THE MACHINES. - KEEP THIS MANUAL BOOK NEAR THE SEWING MACHINE FOR REFERENCE. BE SURE TO ATTACH THIS MANUAL BOOK TO THE MACHINE WHEN LENDING OR TRANSFER IT TO ANOTHER PERSON OR COMPANY. - PLEASE CONTACT THIS MANUAL BOOK FROM US IF IT LOST. - THE CONTENTS OF THIS MANUAL BOOK ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE FOR IMPROVEMENT AND SAFETY PURPOSE. Learn More

YY-1366 (USERS MANUAL) BAG CLOSING MACHINE HEAD, INSTRUCTION MANUALYY-1366 BAG CLOSING MACHINE HEAD, INSTRUCTION MANUAL FOR OPENRATOR SAFETY: - THIS MANUAL BOOK CONTAINS INSTRUCTIONS AND PRECAUTIONS FOR USING THE BAG CLOSING MACHINE HEAD. BE SURE TO READ AND UNDERSTAND THE MANUAL BOOK BEFORE USING THE MACHINES. - KEEP THIS MANUAL BOOK NEAR THE SEWING MACHINE FOR REFERENCE. BE SURE TO ATTACH THIS MANUAL BOOK TO THE MACHINE WHEN LENDING OR TRANSFER IT TO ANOTHER PERSON OR COMPANY. - PLEASE CONTACT THIS MANUAL BOOK FROM US IF IT LOST. - THE CONTENTS OF THIS MANUAL BOOK ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE FOR IMPROVEMENT AND SAFETY PURPOSE. Learn More -

TT-3204 SINGLE SHAFT AUTO CUTTING MACHINE, WORKING WIDTH 1500mm (BALONEY SLITTER, SUITABLE FOR FILMS)TT-3204 SINGLE SHAFT AUTO CUTTING MACHINE, WORKING WIDTH 1500mm (BALONEY SLITTER, SUITABLE FOR FILMS) SLITTER REWINDER MAX SLITTING WIDTH: 1600mm (CAN BE CUSTOMIZED FROM 800mm TO 3000mm) MINI SLITTING WIDTH: 10mm UNWINDING DIAMETER: 600mm REWINDING DIAMETER: 300mm AUTOMATIC CUTTING MACHINE FOR FILM ROLLS: AFTER YOU SET THE PARAMETER IT WOULD CUT THE FILM ROLLS TO SMALL WIDTH ROLLS AUTOMATICALY WORKING WIDTH: 1500mm LARGE ROLL MATERIAL DIAMETER MAX: 350mm NO PROBLEM FOR THIS MACHINE TO SLIT YOUR PVC FILM MATERIAL Learn More

TT-3204 SINGLE SHAFT AUTO CUTTING MACHINE, WORKING WIDTH 1500mm (BALONEY SLITTER, SUITABLE FOR FILMS)TT-3204 SINGLE SHAFT AUTO CUTTING MACHINE, WORKING WIDTH 1500mm (BALONEY SLITTER, SUITABLE FOR FILMS) SLITTER REWINDER MAX SLITTING WIDTH: 1600mm (CAN BE CUSTOMIZED FROM 800mm TO 3000mm) MINI SLITTING WIDTH: 10mm UNWINDING DIAMETER: 600mm REWINDING DIAMETER: 300mm AUTOMATIC CUTTING MACHINE FOR FILM ROLLS: AFTER YOU SET THE PARAMETER IT WOULD CUT THE FILM ROLLS TO SMALL WIDTH ROLLS AUTOMATICALY WORKING WIDTH: 1500mm LARGE ROLL MATERIAL DIAMETER MAX: 350mm NO PROBLEM FOR THIS MACHINE TO SLIT YOUR PVC FILM MATERIAL Learn More -

YY-2332 AUTOMATIC HOT MELT TANK FILLING SYSTEM (ATFS)YY-2332 AUTOMATIC HOT MELT TANK FILLING SYSTEM (ATFS) AUTOMATICALLY REPLENISHES ADHESIVE TO THE DESIRED LEVEL IN HOT MELT EQUIPMENT. PRODUCT DETAILS: - AUTOMATIC "ON DEMAND" FILLING OF THE HOT MELT UNIT. - REMOVES AN OPERATOR FROM THE HOT MELT SUPPLY UNIT AREA. - NOZZLE PLUGGING AND SYSTEM CONTAMINATION IS VIRTUALLY ELIMINATED. - LESS THERMAL SHOCK TO THE HOT MELT SYSTEM. QUANTITY: 1 Learn More

YY-2332 AUTOMATIC HOT MELT TANK FILLING SYSTEM (ATFS)YY-2332 AUTOMATIC HOT MELT TANK FILLING SYSTEM (ATFS) AUTOMATICALLY REPLENISHES ADHESIVE TO THE DESIRED LEVEL IN HOT MELT EQUIPMENT. PRODUCT DETAILS: - AUTOMATIC "ON DEMAND" FILLING OF THE HOT MELT UNIT. - REMOVES AN OPERATOR FROM THE HOT MELT SUPPLY UNIT AREA. - NOZZLE PLUGGING AND SYSTEM CONTAMINATION IS VIRTUALLY ELIMINATED. - LESS THERMAL SHOCK TO THE HOT MELT SYSTEM. QUANTITY: 1 Learn More