Search results for: 'equip'

- Related search terms

- equipme

- equipments

- equipments f

- equipments for su

- equip''

-

TT-8633 STX MAN DIESEL/HFO 18V32/40 GENSETS, 9.0 MW, 50/60 HzTT-8633 STX MAN DIESEL/HFO 18V32/40 GENSETS, 9.0 MW, 50/60 Hz 1. STX MAN DIESEL/HFO 18V32/40 GENSETS 2. GROSS ELECTRICAL OUTPUT APPROX. 9.0 MW 3. BRAND MAN DIESEL & TURBO, TYPE 18V32/40 - 4 STROKE, UNUSED EACH UNIT CONSISTS OF MOTOR, GENERATOR, RACK / BASE-FRAME QUANTITY: 20 UNITS Learn More

TT-8633 STX MAN DIESEL/HFO 18V32/40 GENSETS, 9.0 MW, 50/60 HzTT-8633 STX MAN DIESEL/HFO 18V32/40 GENSETS, 9.0 MW, 50/60 Hz 1. STX MAN DIESEL/HFO 18V32/40 GENSETS 2. GROSS ELECTRICAL OUTPUT APPROX. 9.0 MW 3. BRAND MAN DIESEL & TURBO, TYPE 18V32/40 - 4 STROKE, UNUSED EACH UNIT CONSISTS OF MOTOR, GENERATOR, RACK / BASE-FRAME QUANTITY: 20 UNITS Learn More -

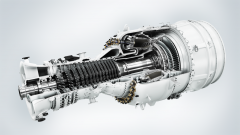

TT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MWTT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MW SIEMENS SST 400 YEAR 2011 TYPE: SST 400 CONDENSING STEAM TURBINE WITH FOUR BLEEDS AND ONE EXTRACTION TURBOSE OUTPUT: (AT GENERATOR TERMINALS) NORMAL 30 MW MAXIMAL 31.88 MW MINIMAL 4.5 MW QUANTITY: 4 Learn More

TT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MWTT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MW SIEMENS SST 400 YEAR 2011 TYPE: SST 400 CONDENSING STEAM TURBINE WITH FOUR BLEEDS AND ONE EXTRACTION TURBOSE OUTPUT: (AT GENERATOR TERMINALS) NORMAL 30 MW MAXIMAL 31.88 MW MINIMAL 4.5 MW QUANTITY: 4 Learn More -

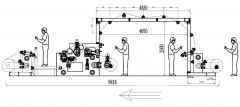

TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024 COATING LINE FROM BATH MAT PLANT LENGTH 97000mm WIDTH 7000mm ARTOS LATEX FOR BATHMATSB YEAR OF CONSTRUCTION: 2024 WORKING WIDTH: 1000mm TO 2600mm MAXIMUM SETTING WIDTH: 2750mm SPEED: 1.7 METERS TO 35 METERS PER MINUTE Learn More

TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024 COATING LINE FROM BATH MAT PLANT LENGTH 97000mm WIDTH 7000mm ARTOS LATEX FOR BATHMATSB YEAR OF CONSTRUCTION: 2024 WORKING WIDTH: 1000mm TO 2600mm MAXIMUM SETTING WIDTH: 2750mm SPEED: 1.7 METERS TO 35 METERS PER MINUTE Learn More -

TT-2363 LION AUTOMATIC BLOWER, NOZZLES 2, YEAR 2011TT-2363 LION AUTOMATIC BLOWER, NOZZLES 2, YEAR 2011 QUANTITY: 1 Learn More

TT-2363 LION AUTOMATIC BLOWER, NOZZLES 2, YEAR 2011TT-2363 LION AUTOMATIC BLOWER, NOZZLES 2, YEAR 2011 QUANTITY: 1 Learn More -

TT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 HzTT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 Hz GROSS EFFICIENCY 38.86.0% HEAT RATE9, 256 KJ/KWH UNUSED CONDITION: EXCELLENT (NEW SURPLUS) TURBINES STORED TO SIEMENS RECOMMENDATION. NOTE: THIS IS A PACKAGE DEAL AND REQUIRES BUYER TO PURCHASE ALL 3 UNITS. POI AND POF REQUIRED UPFRONT. QUANTITY: 3 Learn More

TT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 HzTT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 Hz GROSS EFFICIENCY 38.86.0% HEAT RATE9, 256 KJ/KWH UNUSED CONDITION: EXCELLENT (NEW SURPLUS) TURBINES STORED TO SIEMENS RECOMMENDATION. NOTE: THIS IS A PACKAGE DEAL AND REQUIRES BUYER TO PURCHASE ALL 3 UNITS. POI AND POF REQUIRED UPFRONT. QUANTITY: 3 Learn More -

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More -

TT-1043 UNIVERSAL TESTING MACHINE FOR TENSILE TEST, 30KNTT-1043 UNIVERSAL TESTING MACHINE FOR TENSILE TEST, 30KN KEY SPECIFICATIONS: MAX. CAPACITY: 10N, 20N, 50N, 100N, 200N, 500N, 1KN, 2KN, 5KN, 10KN, 20KN, 30KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTIO: 0.5mm TEST SPEED: 0.001-500mm/MIN, CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS WALKING SPACE: 1000mm (IT CAN BE CUSTOM-TAILOR ACCORDING TO THEIR REQUIREMENTS) FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W DIMENSIONS: 720 X 620 X 1400mm (W X D X H) WEIGHT: 150KG POWER SUPPLY: 220V 50/60Hz 10A STANDARDS: BS EN ISO 13934-1, 13934-2, 13937-2, 13937-3, 13937-4, 13935-1, 13935-2, BS 3320, 4303. ASTM D 434, 558, 2256, 2261, 2731, 3936, 4533, 4964, 5034, 5035, 5735. ISO 2062, 5082, 9073.4, 10321, 13919. ASTM882, ASTM638 STANDARD ACCESSORIES: ENGLISH OPERATION SOFTWARE 1PC CABLE CONNECT WITH PC 1PC LOAD CELL 1PC OPTION ACCESSORIES: DESKTOP COMPUTER 1PC QUANTITY: 1 Learn More

TT-1043 UNIVERSAL TESTING MACHINE FOR TENSILE TEST, 30KNTT-1043 UNIVERSAL TESTING MACHINE FOR TENSILE TEST, 30KN KEY SPECIFICATIONS: MAX. CAPACITY: 10N, 20N, 50N, 100N, 200N, 500N, 1KN, 2KN, 5KN, 10KN, 20KN, 30KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTIO: 0.5mm TEST SPEED: 0.001-500mm/MIN, CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS WALKING SPACE: 1000mm (IT CAN BE CUSTOM-TAILOR ACCORDING TO THEIR REQUIREMENTS) FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W DIMENSIONS: 720 X 620 X 1400mm (W X D X H) WEIGHT: 150KG POWER SUPPLY: 220V 50/60Hz 10A STANDARDS: BS EN ISO 13934-1, 13934-2, 13937-2, 13937-3, 13937-4, 13935-1, 13935-2, BS 3320, 4303. ASTM D 434, 558, 2256, 2261, 2731, 3936, 4533, 4964, 5034, 5035, 5735. ISO 2062, 5082, 9073.4, 10321, 13919. ASTM882, ASTM638 STANDARD ACCESSORIES: ENGLISH OPERATION SOFTWARE 1PC CABLE CONNECT WITH PC 1PC LOAD CELL 1PC OPTION ACCESSORIES: DESKTOP COMPUTER 1PC QUANTITY: 1 Learn More -

TT-6338 COMPLETE PULP MILL SOLD IN SECTIONS-PARTS, CAPACITY 350,000 TPYTT-6338 COMPLETE PULP MILL SOLD IN SECTIONS-PARTS, CAPACITY 350,000 TPY 1. IN GOOD WORKING CONDITION 2. STOPPED 2023 3. EQUIPMENT NOT AVAILABLE FOR LONG 4. COMPLETE PULP MILL. Learn More

TT-6338 COMPLETE PULP MILL SOLD IN SECTIONS-PARTS, CAPACITY 350,000 TPYTT-6338 COMPLETE PULP MILL SOLD IN SECTIONS-PARTS, CAPACITY 350,000 TPY 1. IN GOOD WORKING CONDITION 2. STOPPED 2023 3. EQUIPMENT NOT AVAILABLE FOR LONG 4. COMPLETE PULP MILL. Learn More -

YY-2409 SLOT DIE COATING MACHINE, MAXIMUM COATING WIDTH 1550mm (61 INCHES)YY-2409 SLOT DIE COATING MACHINE, MAXIMUM COATING WIDTH 1550mm (61 INCHES) APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, FOR COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. APPLICATION MATERIAL: PET, PVC, PAPER ETC. MACHINE FEATURES: 1. THIS MACHINE INCLUDES MICROCOMPUTER PLC, TOUCH SCREEN CONTROL, SIMPLE OPERATION AND HIGH AUTOMATION; 2. USING HIGH WEAR-RESISTANT ALLOY STEEL SLOT DIE, WITH COATING CONTROL ACCURACY AND GOOD SERVICE LIFE; 3. AN OVERALL COATING ADJUSTMENT BRACKET IS INCLUDED, AND THE REPEAT POSITIONING ACCURACY IS PRECISE; 4. AUTOMATICALLY TRACKS AND DISPLAYS AND STORES THE AMOUNT OF GLUE NEEDED, MAKING THE OPERATION AND USE CONVENIENT AND FAST; 5. THE FIRST UNWINDING IS EQUIPPED WITH A WEB GUIDING DEVICE, WITH A HIGH-PERFORMANCE INFRARED SENSOR AND ELECTRIC CONTROLLER TO ENSURE THE EVEN LET OFF OF THE MATERIAL ROLL; 6. THE HEATING TEMPERATURE IS ALL CENTRALLY CONTROLLED BY PLC; 7. THE AMOUNT OF GLUE SUPPLIED BY THE METERING PUMP FOR THE COATING WIDTH IS INPUT BY THE WORKER, AND THE AMOUNT OF GLUE SUPPLIED WILL BE AUTOMATICALLY CALCULATED AND SUPPLIED TO THE DIE SLOT. QUANTITY: 1 Learn More

YY-2409 SLOT DIE COATING MACHINE, MAXIMUM COATING WIDTH 1550mm (61 INCHES)YY-2409 SLOT DIE COATING MACHINE, MAXIMUM COATING WIDTH 1550mm (61 INCHES) APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, FOR COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. APPLICATION MATERIAL: PET, PVC, PAPER ETC. MACHINE FEATURES: 1. THIS MACHINE INCLUDES MICROCOMPUTER PLC, TOUCH SCREEN CONTROL, SIMPLE OPERATION AND HIGH AUTOMATION; 2. USING HIGH WEAR-RESISTANT ALLOY STEEL SLOT DIE, WITH COATING CONTROL ACCURACY AND GOOD SERVICE LIFE; 3. AN OVERALL COATING ADJUSTMENT BRACKET IS INCLUDED, AND THE REPEAT POSITIONING ACCURACY IS PRECISE; 4. AUTOMATICALLY TRACKS AND DISPLAYS AND STORES THE AMOUNT OF GLUE NEEDED, MAKING THE OPERATION AND USE CONVENIENT AND FAST; 5. THE FIRST UNWINDING IS EQUIPPED WITH A WEB GUIDING DEVICE, WITH A HIGH-PERFORMANCE INFRARED SENSOR AND ELECTRIC CONTROLLER TO ENSURE THE EVEN LET OFF OF THE MATERIAL ROLL; 6. THE HEATING TEMPERATURE IS ALL CENTRALLY CONTROLLED BY PLC; 7. THE AMOUNT OF GLUE SUPPLIED BY THE METERING PUMP FOR THE COATING WIDTH IS INPUT BY THE WORKER, AND THE AMOUNT OF GLUE SUPPLIED WILL BE AUTOMATICALLY CALCULATED AND SUPPLIED TO THE DIE SLOT. QUANTITY: 1 Learn More -

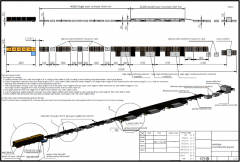

YY-1485 COMPLETE CONVEYORIZED TAPE EDGE LINE WITH DOUBLE CONVEYORS AND STACKING SYSTEMYY-1485 COMPLETE CONVEYORIZED TAPE EDGE LINE WITH DOUBLE CONVEYORS AND STACKING SYSTEM INCLUDES: 1 PALLET CONVEYOR ROLLER LINE 1 SINGLE-LAYER ASSEMBLY ROLLER LINE 1 DOUBLE-LAYER CONVEYOR ROLLER LINE 1 GRAVITY-FED ROLLER LINE 1 SINGLE-LAYER QUALITY INSPECTION CONVEYOR LINE PRESS MACHINE INLET AND OUTLET ROLLER LINE TOTAL 2 SECTIONS TOTAL ROLLER POWER HEAD ASSEMBLY PARTS: 52 SETS EACH FUNCTIONAL PART IS EQUIPPED WITH CORRESPONDING START SWITCH AND CONTROLLING POWER BOX, AND EQUIPPED WITH MICROCOMPUTER TO CONTROL THE PROCESSING Learn More

YY-1485 COMPLETE CONVEYORIZED TAPE EDGE LINE WITH DOUBLE CONVEYORS AND STACKING SYSTEMYY-1485 COMPLETE CONVEYORIZED TAPE EDGE LINE WITH DOUBLE CONVEYORS AND STACKING SYSTEM INCLUDES: 1 PALLET CONVEYOR ROLLER LINE 1 SINGLE-LAYER ASSEMBLY ROLLER LINE 1 DOUBLE-LAYER CONVEYOR ROLLER LINE 1 GRAVITY-FED ROLLER LINE 1 SINGLE-LAYER QUALITY INSPECTION CONVEYOR LINE PRESS MACHINE INLET AND OUTLET ROLLER LINE TOTAL 2 SECTIONS TOTAL ROLLER POWER HEAD ASSEMBLY PARTS: 52 SETS EACH FUNCTIONAL PART IS EQUIPPED WITH CORRESPONDING START SWITCH AND CONTROLLING POWER BOX, AND EQUIPPED WITH MICROCOMPUTER TO CONTROL THE PROCESSING Learn More