Search results for: 'machine+de+fa'

- Related search terms

- machine+de+fabri

-

AUTOMATIC POCKET SPRING MACHINE – 60 SPRINGS/MINPS-HF AUTOMATIC POCKET SPRING MACHINE COMPACT DESIGN/ELECTRO-MECHANICAL CONVEYOR ARE CONTROLLED BY SERVO/ACCURATE MOTIONS INTELLIGENT SENSORS CAN CHECK MALFUNCTIONS ALL THE TIME/DISPLAY CORRESPONDING ALARM ON THE HIM DULY/ONE OPERATOR CAN RUN SEVERAL SETS OF PS-HF ALONE UNIQUE PATENTED SPRING CONVEYOR DESIGN INCREASES PRODUCTIVITY AND EFFICIENCY VERY OPERATOR USER-FRIENDLY NON-WOVEN JOINT DEVICE/SAVE TIME AND NON-WOVEN AUTOMATIC CUTTER FOR THE POCKET SPRINGS CAN BE SELECTED AS AN ADDITIONAL PART ULTRASONIC HORN IS MADE OF TITANIUM/DURABLE AND FIRM MOVABLE TEMPER FOR VARIABLE SPRING HEIGHTS LOW AND EASY MAINTENANCE, EASY TO OPERATE/SHORT TRAINING PERIOD SPARE PARTS ARE “OFF THE SHELF” SPRING TYPE: BARREL/CYLINDRICAL FABRIC MATERIAL: 65~90G/M2 FABRIC ROLL DIAMETER MAXIMUM 600mm POWER SUPPLY: 380V, 50/60HZ, 12KVA, INPUT FUSE 63A AIR CONSUMPTION: 30M3/H, 0.8 MPA PERFORMANCE: 60 SPRINGS/MINUTE WORKING TEMPERATURE: +5°C +45°C WEIGHT APPROXIMATELY 2260KG DORSAL SEAL TYPE (UNIT: mm) WIRE DIAMETER SPRING DIAMETER IN THE CENTER SPRING HEIGHT INSIDE THE NON-WOVEN PSHF-DS-01 Ø1.6~ Ø2.2 Ø55~ Ø70 80~140 PSHF-DS-02 Ø1.6~ Ø2.2 Ø55~ Ø70 120~180 PSHF-DS-03 Ø1.6~ Ø2.2 Ø60~ Ø75 80~140 PSHF-DS-04 Ø1.6~ Ø2.2 Ø60~ Ø75 120~180 PSHF-DS-05 Ø1.6~ Ø2.2 Ø60~ Ø75 140~200 PSHF-DS-T2 Ø1.3~ Ø1.6 Ø45~ Ø55 70~120 PSHF-DS-T2 Ø1.3~ Ø1.6 Ø45~ Ø55 120~180 BOTTOM SEAL TYPE (UNIT: mm) WIRE DIAMETER SPRING DIAMETER IN THE CENTER SPRING HEIGHT INSIDE THE NON-WOVEN PSHF-BS-01 Ø1.6~ Ø2.2 Ø45~ Ø60 120~180 PSHF-BS-01 Ø1.6~ Ø2.2 Ø45~ Ø60 140~180 PSHF-BS-01 Ø1.6~ Ø2.2 Ø55~ Ø70 120~180 PSHF-BS-01 Ø1.6~ Ø2.2 Ø55~ Ø70 140~120 PSHF-BS-01 Ø1.6~ Ø2.2 Ø55~ Ø70 160~220 PSHF-BS-01 SPECIAL Learn More

AUTOMATIC POCKET SPRING MACHINE – 60 SPRINGS/MINPS-HF AUTOMATIC POCKET SPRING MACHINE COMPACT DESIGN/ELECTRO-MECHANICAL CONVEYOR ARE CONTROLLED BY SERVO/ACCURATE MOTIONS INTELLIGENT SENSORS CAN CHECK MALFUNCTIONS ALL THE TIME/DISPLAY CORRESPONDING ALARM ON THE HIM DULY/ONE OPERATOR CAN RUN SEVERAL SETS OF PS-HF ALONE UNIQUE PATENTED SPRING CONVEYOR DESIGN INCREASES PRODUCTIVITY AND EFFICIENCY VERY OPERATOR USER-FRIENDLY NON-WOVEN JOINT DEVICE/SAVE TIME AND NON-WOVEN AUTOMATIC CUTTER FOR THE POCKET SPRINGS CAN BE SELECTED AS AN ADDITIONAL PART ULTRASONIC HORN IS MADE OF TITANIUM/DURABLE AND FIRM MOVABLE TEMPER FOR VARIABLE SPRING HEIGHTS LOW AND EASY MAINTENANCE, EASY TO OPERATE/SHORT TRAINING PERIOD SPARE PARTS ARE “OFF THE SHELF” SPRING TYPE: BARREL/CYLINDRICAL FABRIC MATERIAL: 65~90G/M2 FABRIC ROLL DIAMETER MAXIMUM 600mm POWER SUPPLY: 380V, 50/60HZ, 12KVA, INPUT FUSE 63A AIR CONSUMPTION: 30M3/H, 0.8 MPA PERFORMANCE: 60 SPRINGS/MINUTE WORKING TEMPERATURE: +5°C +45°C WEIGHT APPROXIMATELY 2260KG DORSAL SEAL TYPE (UNIT: mm) WIRE DIAMETER SPRING DIAMETER IN THE CENTER SPRING HEIGHT INSIDE THE NON-WOVEN PSHF-DS-01 Ø1.6~ Ø2.2 Ø55~ Ø70 80~140 PSHF-DS-02 Ø1.6~ Ø2.2 Ø55~ Ø70 120~180 PSHF-DS-03 Ø1.6~ Ø2.2 Ø60~ Ø75 80~140 PSHF-DS-04 Ø1.6~ Ø2.2 Ø60~ Ø75 120~180 PSHF-DS-05 Ø1.6~ Ø2.2 Ø60~ Ø75 140~200 PSHF-DS-T2 Ø1.3~ Ø1.6 Ø45~ Ø55 70~120 PSHF-DS-T2 Ø1.3~ Ø1.6 Ø45~ Ø55 120~180 BOTTOM SEAL TYPE (UNIT: mm) WIRE DIAMETER SPRING DIAMETER IN THE CENTER SPRING HEIGHT INSIDE THE NON-WOVEN PSHF-BS-01 Ø1.6~ Ø2.2 Ø45~ Ø60 120~180 PSHF-BS-01 Ø1.6~ Ø2.2 Ø45~ Ø60 140~180 PSHF-BS-01 Ø1.6~ Ø2.2 Ø55~ Ø70 120~180 PSHF-BS-01 Ø1.6~ Ø2.2 Ø55~ Ø70 140~120 PSHF-BS-01 Ø1.6~ Ø2.2 Ø55~ Ø70 160~220 PSHF-BS-01 SPECIAL Learn More -

T-9597 FABRIC BURSTING STRENGTH TESTERT-9597 FABRIC BURSTING STRENGTH TESTER KEY SPECIFICATION: RANGE: 2.00MPA TO 10.000MPA THE MIN. DIVISION VALUE: 0.001MPA TO 0.003MPA TEST AREA: 73mm2 (Φ30.5mm), 100mm2 (Φ35.7mm), 500mm2 (Φ79.8mm), 1000mm2 (Φ112.8mm) CAN BE OPTION THICKNESS OF RUBBER DIAPHRAGM: ≤2mm PRESSURE SPEED: 20ML/MIN - 600ML/MIN MAXIMUM EXPANSION HEIGHT: 75 ± 0.02mm TESTING UNITS: KPA, KGF/ CM2, ATM, MMHG, LB/IN2 FREE SHIFT TEST METHOD: CONSTANT RATE BURSTING CONSTANT EXPANSION CONSTANT PRESSURE CONSTANT TIME BURSTING OUTPUT: PRINTER, DISPLAY OUTPUT AND CAN BE CONNECTED TO THE COMPUTER POWER SUPPLY: AC 220V 50/60HZ 200W DIMENSIONS: 550 × 450 × 700mm NET WEIGHT: 125KG Learn More

T-9597 FABRIC BURSTING STRENGTH TESTERT-9597 FABRIC BURSTING STRENGTH TESTER KEY SPECIFICATION: RANGE: 2.00MPA TO 10.000MPA THE MIN. DIVISION VALUE: 0.001MPA TO 0.003MPA TEST AREA: 73mm2 (Φ30.5mm), 100mm2 (Φ35.7mm), 500mm2 (Φ79.8mm), 1000mm2 (Φ112.8mm) CAN BE OPTION THICKNESS OF RUBBER DIAPHRAGM: ≤2mm PRESSURE SPEED: 20ML/MIN - 600ML/MIN MAXIMUM EXPANSION HEIGHT: 75 ± 0.02mm TESTING UNITS: KPA, KGF/ CM2, ATM, MMHG, LB/IN2 FREE SHIFT TEST METHOD: CONSTANT RATE BURSTING CONSTANT EXPANSION CONSTANT PRESSURE CONSTANT TIME BURSTING OUTPUT: PRINTER, DISPLAY OUTPUT AND CAN BE CONNECTED TO THE COMPUTER POWER SUPPLY: AC 220V 50/60HZ 200W DIMENSIONS: 550 × 450 × 700mm NET WEIGHT: 125KG Learn More -

M-4618 CIBITEX SANFORIZING - COMPACTING AND SHRINKING LINE FOR WOVEN FABRIC IN OPEN WIDTHREFERENCE NUMBER: M-4618 (111152JYP10RX) D CIBITEX SANFORIZING - COMPACTING AND SHRINKING LINE FOR WOVEN FABRIC IN OPEN WIDTH YEAR: 1986, COMPLETELY OVERHAULED IN THE YEAR 2011 ROLLERS WIDTH: 2000MM WORKING WIDTH: 1800MM QUANTITY AVAILABLE: 1 Learn More

M-4618 CIBITEX SANFORIZING - COMPACTING AND SHRINKING LINE FOR WOVEN FABRIC IN OPEN WIDTHREFERENCE NUMBER: M-4618 (111152JYP10RX) D CIBITEX SANFORIZING - COMPACTING AND SHRINKING LINE FOR WOVEN FABRIC IN OPEN WIDTH YEAR: 1986, COMPLETELY OVERHAULED IN THE YEAR 2011 ROLLERS WIDTH: 2000MM WORKING WIDTH: 1800MM QUANTITY AVAILABLE: 1 Learn More -

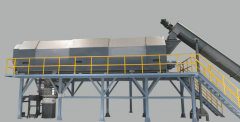

M-4566 THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm)REFERENCE NUMBER: M-4566 (1111225RSJ10U) L THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm) YEAR: 2005 TYPE: HM59-SD3 MATR: 404/04 ROLL FACE: 2600mm (102”) WORKING WIDTH: 2400mm (95”) VOLTAGE: 480/3/60 CONTROL VOLTAGE: 110/60 CONSISTING OF: CAROUSEL 3 POSITION LET-OFF, ENTRY ON ACCUMULATOR WITH HOT-WIRE SEAMING DEVICE, 8000 VOLT STATIC ELIMINATOR, PNEUMATICALLY OPERATED FABRIC HOLDING DEVICE FOR TENSION CONTROL, ACCUMULATOR WITH 8-ROLLS UP AND 9-ROLLS DOWN APPROX.. 80-YARD CAPACITY, COMPENSATING ARM ON EXIT SIDE. ROLLS ARE 4” DIA. X 102” FACE ALUMINUM, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. SECOND ACCUMULATOR WITH ROLL CRADLE FOR SECOND SUBSTRATE LET-OFF, ACCUMULATOR WITH 9-ROLLS UP AND 10 ROLLS DOWN, APPROX.. 54 YARD CAPACITY, ROLLS ARE 4’ DIA. X 102” FACE ALUMINUM, INCLUDES 8000 VOLT STATIC ELIMINATOR AND PNEUMATIC FABRIC HOLDING FOR TENSION, PENDULUM TYPE GUIDING DEVICE ON EXIT SIDE, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. OVERHEAD GANTRY WITH ACCESS STAIRS ON RIGHT SIDE OF FIRST ACCUMULATOR, EXTENDS OVER THE EXTRUDER WITH JIB MOUNTED FOR EASE IN REMOVING DIE FROM MACHINE, GUIDING/CENTERING DEVICE MOUNTED ONTO GANTRY FEEDING COATING HEAD. MP ENGINEERING EXTRUDER/APPLICATOR TYPE HM59-SD3, MATR. NO. 402/04, WITH 102” DIE, 98” RUBBER-BELT WITH PNEUMATIC CYLINDERS FOR BELT TENSION AND GUIDING, HEATED CYLINDER BACKING TO DIE, OPERATOR PLATFORM, CONTROLS MOUTNED IN DOOR AND OPERATOR TOUCH SCREEN PANEL. (NOTE: THESE ARE PRESENTLY MOUNTED ON PRODUCTION LINE AND WILL BE REMOVED AND PLACED BACK INTO/ONTO APPLICATOR. 480/3/60 COATEM SISTEMI C.R.L. IMBALLAGIO & HOT MELT EXTRUDER, S/N 50701, TYPE/MODEL CE-200, WITH DIGITAL MICROPROCESSOR AND INVERTER FOR SPEED VARIATION, DESIGNED TO WORK MAINLY WITH POLYESTER, POLYAMIDE AND POLYURETHANE BUT CAN ALSO EXTRUDE ABS, POLYTHENE, POLYPROPYLENE AND ADHESIVES LIKE EVA ADHESIVES. 480/3/60 CONAIR DRYER CD-300, PL-D-196-1, MODEL D03H4101310, S/N 9D0597, 480/3/60, AND HOPPER. THIRD ACCUMULATOR FOR BONDED PRODUCT WITH 6-ROLLS UP AND 7-ROLLS DOWN, APPROX…60-YARD CAPACITY, ROLLS ARE 6” DIA. X 102” FACE ALUMINUM, WITH DRAW-ROLL TENSION DEVICE MOUNTED ONTO EXIT, OVERHEAD CARRIER ROLLS AND FRAMEWORK DELIVERY TO ELECTRIC A-FRAME WINDER WITH 102” FACE LAY-ON ROLL, AND SEMI-AUTOMATIC BATCHER FOR INDIVIDUAL ROLLS, 2-ROLL SURFACE WINDING 102” FACE WIDTH, OVERHEAD CORE FEED, FABRIC CENTERING DEVICE, ELECTRIC SCISSOR CUT-OFF, KICK-OUT TO 2-ROLL BED, OPERATOR PLATFORM AND OPERATOR CONTROLS. ALL MACHINES PRODUCED BY MP CONFORMS TO EEC DIRECTORY 89/392 CEE (CE MARK) TECHNICAL FEATURES OF THE LINE, ACCORDING TO DWG 100-904/1C ROLLERS WIDTH 2600mm WORKING WIDTH 2400mm MAXIMUM DIAMTER OF THE ROLLS OF PU FOAM 1500mm MAXIMUM DIAMETER OF THE UNWOUND ROLLS OF FABRIC 600 ° 1500 MAXIMUM DIAMETER OF THE REWOUND ROLLS 500 ° 1500 (IN CASE YOU ARE REWINDING ROLLS OF FABRIC LAMINATED TO PU FOAM, THE MAXIMUM DIAMETER IS 1750mm) ADJUSTABLE MECHANIC SPEED: 5 TO 50 M/MIN MAIN POWER SUPPLY + NEUTRAL + EARTH 480+N+E/60 V/HZ VOLTAGE ON CONTROL PANELS 110/60 V/HZ INSTALLED POWER FOR MOTORS 22KW INSTALLED POWER FOR IR HEATER 14,25KW INSTALLED POWER TO HEAT THE SLOT-DIE 32KW INSTALLED POWER FOR THE THERMAL OIL HEATING UNIT FOR THE CALENDERING ROLLERS 32,2KW INSTALLED POWER FOR THE CHILLER 12,9KW A.C. MOTORS, DRIVER, ELECTRIC CABLES ARE ACCORDING TO CEI NORMS BACKGEAR ROLLERS, WITH PAINTED SURFACE OR ALUMINUM MADE WITH DIAMETER 100/120/150mm COMPRESSED AIR CONSUMPTION, AT 6 BAR 1500LT/H COOLING WATER CONSUMPTION (WATER MUST HAVE A TEMPERATURE NOT HIGHER THAN 10°C) 5500LT/H ADJUSTABLE TENSION ON THE REWOUND MATERIALS 5 A 35 KG. PAINTING GREEN RAL 6027 E BLUE MARINE RAL 5021 A.C. MOTORS CONTROL THE SPEED OF THE MACHINES, AND ARE AUTOMATICALLY SYNCHRONISED THROUGH ELECTRONIC DRIVES (INVERTER) AND PNEUMATIC DANCER UNITS (COMPENSTAORS) ESTRUDER: CAPACITY UP TO 200 KG/H (DEPENDING ON THE VISCOSITY OF THE ADHESIVE TO BE EXTRUDED) POWER OF THE MOTOR AND RESISTANCES: 90KW MAXIMUM MELTING TEMPERATURE: 220°C MATERIALS TO BE PROCESSED NONWOVENS 30:150 GR/M2 SYNTHETIC AND NATURAL FABRICS (EXCLUDING STRETCHY FABRICS) WITH WEIGHT 100:600 GR/M2 SCRIMS FOR BACKING FABRIC WITH WEIGHT 70:120 G/M2 MAXIMUM THICKNESS OF PU FOAM 15mm MINIMUM THICKNESS OF PU FOAM 2mm DENSITY OF PU FOAM 22/40 KG/M3 THERMOPLASTIC ADHESIVE TO BE COATED THERMOPLASTIC HOTMELTS (COPOLYAMMIDE, COPOLYESTER, EVA AND POLYURETHANE THERMOPLASTIC HOTMELT GRANULES) DATA REFERRING TO PRODUCTION THE PRODUCTION SPEED CAN CHANGE, DEPENDING ON THE KIND OF HOTMELTS, ON THEIR MELTING TEMPERATURE, ON THEIR VISCOSITY, AND ON THE GRAMS PER SQUARED METER TO BE COATED QUANTITY AVAILABLE: 1 Learn More

M-4566 THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm)REFERENCE NUMBER: M-4566 (1111225RSJ10U) L THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm) YEAR: 2005 TYPE: HM59-SD3 MATR: 404/04 ROLL FACE: 2600mm (102”) WORKING WIDTH: 2400mm (95”) VOLTAGE: 480/3/60 CONTROL VOLTAGE: 110/60 CONSISTING OF: CAROUSEL 3 POSITION LET-OFF, ENTRY ON ACCUMULATOR WITH HOT-WIRE SEAMING DEVICE, 8000 VOLT STATIC ELIMINATOR, PNEUMATICALLY OPERATED FABRIC HOLDING DEVICE FOR TENSION CONTROL, ACCUMULATOR WITH 8-ROLLS UP AND 9-ROLLS DOWN APPROX.. 80-YARD CAPACITY, COMPENSATING ARM ON EXIT SIDE. ROLLS ARE 4” DIA. X 102” FACE ALUMINUM, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. SECOND ACCUMULATOR WITH ROLL CRADLE FOR SECOND SUBSTRATE LET-OFF, ACCUMULATOR WITH 9-ROLLS UP AND 10 ROLLS DOWN, APPROX.. 54 YARD CAPACITY, ROLLS ARE 4’ DIA. X 102” FACE ALUMINUM, INCLUDES 8000 VOLT STATIC ELIMINATOR AND PNEUMATIC FABRIC HOLDING FOR TENSION, PENDULUM TYPE GUIDING DEVICE ON EXIT SIDE, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. OVERHEAD GANTRY WITH ACCESS STAIRS ON RIGHT SIDE OF FIRST ACCUMULATOR, EXTENDS OVER THE EXTRUDER WITH JIB MOUNTED FOR EASE IN REMOVING DIE FROM MACHINE, GUIDING/CENTERING DEVICE MOUNTED ONTO GANTRY FEEDING COATING HEAD. MP ENGINEERING EXTRUDER/APPLICATOR TYPE HM59-SD3, MATR. NO. 402/04, WITH 102” DIE, 98” RUBBER-BELT WITH PNEUMATIC CYLINDERS FOR BELT TENSION AND GUIDING, HEATED CYLINDER BACKING TO DIE, OPERATOR PLATFORM, CONTROLS MOUTNED IN DOOR AND OPERATOR TOUCH SCREEN PANEL. (NOTE: THESE ARE PRESENTLY MOUNTED ON PRODUCTION LINE AND WILL BE REMOVED AND PLACED BACK INTO/ONTO APPLICATOR. 480/3/60 COATEM SISTEMI C.R.L. IMBALLAGIO & HOT MELT EXTRUDER, S/N 50701, TYPE/MODEL CE-200, WITH DIGITAL MICROPROCESSOR AND INVERTER FOR SPEED VARIATION, DESIGNED TO WORK MAINLY WITH POLYESTER, POLYAMIDE AND POLYURETHANE BUT CAN ALSO EXTRUDE ABS, POLYTHENE, POLYPROPYLENE AND ADHESIVES LIKE EVA ADHESIVES. 480/3/60 CONAIR DRYER CD-300, PL-D-196-1, MODEL D03H4101310, S/N 9D0597, 480/3/60, AND HOPPER. THIRD ACCUMULATOR FOR BONDED PRODUCT WITH 6-ROLLS UP AND 7-ROLLS DOWN, APPROX…60-YARD CAPACITY, ROLLS ARE 6” DIA. X 102” FACE ALUMINUM, WITH DRAW-ROLL TENSION DEVICE MOUNTED ONTO EXIT, OVERHEAD CARRIER ROLLS AND FRAMEWORK DELIVERY TO ELECTRIC A-FRAME WINDER WITH 102” FACE LAY-ON ROLL, AND SEMI-AUTOMATIC BATCHER FOR INDIVIDUAL ROLLS, 2-ROLL SURFACE WINDING 102” FACE WIDTH, OVERHEAD CORE FEED, FABRIC CENTERING DEVICE, ELECTRIC SCISSOR CUT-OFF, KICK-OUT TO 2-ROLL BED, OPERATOR PLATFORM AND OPERATOR CONTROLS. ALL MACHINES PRODUCED BY MP CONFORMS TO EEC DIRECTORY 89/392 CEE (CE MARK) TECHNICAL FEATURES OF THE LINE, ACCORDING TO DWG 100-904/1C ROLLERS WIDTH 2600mm WORKING WIDTH 2400mm MAXIMUM DIAMTER OF THE ROLLS OF PU FOAM 1500mm MAXIMUM DIAMETER OF THE UNWOUND ROLLS OF FABRIC 600 ° 1500 MAXIMUM DIAMETER OF THE REWOUND ROLLS 500 ° 1500 (IN CASE YOU ARE REWINDING ROLLS OF FABRIC LAMINATED TO PU FOAM, THE MAXIMUM DIAMETER IS 1750mm) ADJUSTABLE MECHANIC SPEED: 5 TO 50 M/MIN MAIN POWER SUPPLY + NEUTRAL + EARTH 480+N+E/60 V/HZ VOLTAGE ON CONTROL PANELS 110/60 V/HZ INSTALLED POWER FOR MOTORS 22KW INSTALLED POWER FOR IR HEATER 14,25KW INSTALLED POWER TO HEAT THE SLOT-DIE 32KW INSTALLED POWER FOR THE THERMAL OIL HEATING UNIT FOR THE CALENDERING ROLLERS 32,2KW INSTALLED POWER FOR THE CHILLER 12,9KW A.C. MOTORS, DRIVER, ELECTRIC CABLES ARE ACCORDING TO CEI NORMS BACKGEAR ROLLERS, WITH PAINTED SURFACE OR ALUMINUM MADE WITH DIAMETER 100/120/150mm COMPRESSED AIR CONSUMPTION, AT 6 BAR 1500LT/H COOLING WATER CONSUMPTION (WATER MUST HAVE A TEMPERATURE NOT HIGHER THAN 10°C) 5500LT/H ADJUSTABLE TENSION ON THE REWOUND MATERIALS 5 A 35 KG. PAINTING GREEN RAL 6027 E BLUE MARINE RAL 5021 A.C. MOTORS CONTROL THE SPEED OF THE MACHINES, AND ARE AUTOMATICALLY SYNCHRONISED THROUGH ELECTRONIC DRIVES (INVERTER) AND PNEUMATIC DANCER UNITS (COMPENSTAORS) ESTRUDER: CAPACITY UP TO 200 KG/H (DEPENDING ON THE VISCOSITY OF THE ADHESIVE TO BE EXTRUDED) POWER OF THE MOTOR AND RESISTANCES: 90KW MAXIMUM MELTING TEMPERATURE: 220°C MATERIALS TO BE PROCESSED NONWOVENS 30:150 GR/M2 SYNTHETIC AND NATURAL FABRICS (EXCLUDING STRETCHY FABRICS) WITH WEIGHT 100:600 GR/M2 SCRIMS FOR BACKING FABRIC WITH WEIGHT 70:120 G/M2 MAXIMUM THICKNESS OF PU FOAM 15mm MINIMUM THICKNESS OF PU FOAM 2mm DENSITY OF PU FOAM 22/40 KG/M3 THERMOPLASTIC ADHESIVE TO BE COATED THERMOPLASTIC HOTMELTS (COPOLYAMMIDE, COPOLYESTER, EVA AND POLYURETHANE THERMOPLASTIC HOTMELT GRANULES) DATA REFERRING TO PRODUCTION THE PRODUCTION SPEED CAN CHANGE, DEPENDING ON THE KIND OF HOTMELTS, ON THEIR MELTING TEMPERATURE, ON THEIR VISCOSITY, AND ON THE GRAMS PER SQUARED METER TO BE COATED QUANTITY AVAILABLE: 1 Learn More -

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More -

K-9772 OSTHOFF-SENGE SINGEING MACHINE PK90 YEAR 1992 WIDTH 1800mmREFERENCE NUMBER: K-9772 OSTHOFF-SENGE SINGEING MACHINE PK90 YEAR 1992 WIDTH 1800mm SINGEING MACHINE OSTHOFF-SENGE 5600 MODEL PK90 YEAR OF CONSTRUCTION: 1992 ROLLERS WIDTH: 2000mm USEFUL WORKING WIDTH: 1800mm SPEED FROM 20 TO 120 METERS PER MINUTE QUANTITY AVAILABLE: 1 Learn More

K-9772 OSTHOFF-SENGE SINGEING MACHINE PK90 YEAR 1992 WIDTH 1800mmREFERENCE NUMBER: K-9772 OSTHOFF-SENGE SINGEING MACHINE PK90 YEAR 1992 WIDTH 1800mm SINGEING MACHINE OSTHOFF-SENGE 5600 MODEL PK90 YEAR OF CONSTRUCTION: 1992 ROLLERS WIDTH: 2000mm USEFUL WORKING WIDTH: 1800mm SPEED FROM 20 TO 120 METERS PER MINUTE QUANTITY AVAILABLE: 1 Learn More -

TT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KNTT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KN KEY SPECIFICATIONS: MAX. CAPACITY: 10N, 20N, 50N, 100N, 200N, 500N, 1KN, 2KN, 5KN,10KN,20KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.5mm TEST SPEED: 0.001-500mm/MIN OR 0.001-1000mm/MIN (OPTION), CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W DIMENSIONS: 720 X 620 X 1400mm (W X D X H) WEIGHT: 150KG POWER SUPPLY: 220V 50/60Hz 10A STANDARD ACCESSORIES: 1 SET OF GRIPS ENGLISH OPERATION SOFTWARE CABLE CONNECT WITH PC LOAD CELL OPTION ACCESSORIES: DESKTOP COMPUTER UNIVERSAL COMPRESSION TESTING MACHINE SOFTWARE FUNCTION: TEST & CONTROL SYSTEM IS DESIGNED FOR PC ELECTRONIC UNIVERSAL TESTING MACHINES, PC HYDRAULIC UNIVERSAL TESTING MACHINES AND PC COMPRESSION TESTERS. CAN CONDUCT TENSILE, COMPRESSION, BENDING, SHEARING, TEARING AND PEELING TEST; USE PC AND INTERFACE BOARD FOR DATA COLLECTION, PRESERVATION, PROCESSING AND PRINTING TEST RESULT; CAN CALCULATE MAX FORCE, YIELD STRENGTH, AVERAGE PEELING FORCE, MAX DEFORMATION, YIELD POINT, ELASTIC MODULUS AND OTHER PARAMETERS. CAN CONDUCT CURVE GRAPHICS PROCESSING, MULTI-SENSOR SUPPORT, VIDEO AND IMAGE INTERFACE, FLEXIBLE DATA PROCESSING, MS-ACCESS DATABASE SUPPORT, MAKING MORE POWERFUL FUNCTION OF SYSTEM. QUANTITY: 1 Learn More

TT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KNTT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KN KEY SPECIFICATIONS: MAX. CAPACITY: 10N, 20N, 50N, 100N, 200N, 500N, 1KN, 2KN, 5KN,10KN,20KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.5mm TEST SPEED: 0.001-500mm/MIN OR 0.001-1000mm/MIN (OPTION), CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W DIMENSIONS: 720 X 620 X 1400mm (W X D X H) WEIGHT: 150KG POWER SUPPLY: 220V 50/60Hz 10A STANDARD ACCESSORIES: 1 SET OF GRIPS ENGLISH OPERATION SOFTWARE CABLE CONNECT WITH PC LOAD CELL OPTION ACCESSORIES: DESKTOP COMPUTER UNIVERSAL COMPRESSION TESTING MACHINE SOFTWARE FUNCTION: TEST & CONTROL SYSTEM IS DESIGNED FOR PC ELECTRONIC UNIVERSAL TESTING MACHINES, PC HYDRAULIC UNIVERSAL TESTING MACHINES AND PC COMPRESSION TESTERS. CAN CONDUCT TENSILE, COMPRESSION, BENDING, SHEARING, TEARING AND PEELING TEST; USE PC AND INTERFACE BOARD FOR DATA COLLECTION, PRESERVATION, PROCESSING AND PRINTING TEST RESULT; CAN CALCULATE MAX FORCE, YIELD STRENGTH, AVERAGE PEELING FORCE, MAX DEFORMATION, YIELD POINT, ELASTIC MODULUS AND OTHER PARAMETERS. CAN CONDUCT CURVE GRAPHICS PROCESSING, MULTI-SENSOR SUPPORT, VIDEO AND IMAGE INTERFACE, FLEXIBLE DATA PROCESSING, MS-ACCESS DATABASE SUPPORT, MAKING MORE POWERFUL FUNCTION OF SYSTEM. QUANTITY: 1 Learn More -

TT-1042 UNIVERSAL TESTING MACHINE WITH PROTECTIVE COVERTT-1042 UNIVERSAL TESTING MACHINE WITH PROTECTIVE COVER UTM TESTING MACHINE KEY SPECIFICATIONS: MAX. CAPACITY: 30KN, 50KN, 100KN, 150KN,200KN,300KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.01mm TEST SPEED: 0.001-500mm/MIN, CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W POWER SUPPLY: 220V 50/60Hz 10A STANDARDS: BS EN ISO 13934-1, 13934-2, 13937-2, 13937-3, 13937-4, 13935-1, 13935-2, BS 3320, 4303. ASTM D 434, 558, 2256, 2261, 2731, 3936, 4533, 4964, 5034, 5035, 5735. ISO 2062, 5082, 9073.4, 10321, 13919. STANDARD ACCESSORIES: GRIPS ENGLISH OPERATION SOFTWARE CABLE CONNECT WITH PC OPTION ACCESSORIES: HP DESKTOP COMPUTER QUANTITY: 1 Learn More

TT-1042 UNIVERSAL TESTING MACHINE WITH PROTECTIVE COVERTT-1042 UNIVERSAL TESTING MACHINE WITH PROTECTIVE COVER UTM TESTING MACHINE KEY SPECIFICATIONS: MAX. CAPACITY: 30KN, 50KN, 100KN, 150KN,200KN,300KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.01mm TEST SPEED: 0.001-500mm/MIN, CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W POWER SUPPLY: 220V 50/60Hz 10A STANDARDS: BS EN ISO 13934-1, 13934-2, 13937-2, 13937-3, 13937-4, 13935-1, 13935-2, BS 3320, 4303. ASTM D 434, 558, 2256, 2261, 2731, 3936, 4533, 4964, 5034, 5035, 5735. ISO 2062, 5082, 9073.4, 10321, 13919. STANDARD ACCESSORIES: GRIPS ENGLISH OPERATION SOFTWARE CABLE CONNECT WITH PC OPTION ACCESSORIES: HP DESKTOP COMPUTER QUANTITY: 1 Learn More -

M-0180 AUTOMATIC VACUUM PILLOW MACHINE 001EREFERENCE NUMBER: M-0180 AUTOMATIC VACUUM PILLOW MACHINE 001E RAW MATERIAL & CASE FABRIC MATERIAL APPLICATION: FOR CONJUGATE HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm MICRO FIBER SHORTER THAN 100mm ELASTIC FIBER SHORTER THAN 100mm PILLOW FABRIC QUALITY: PERMEABLE FABRIC LENGTH: 13 METERS LONG QUANTITY AVAILABLE: 1 Learn More

M-0180 AUTOMATIC VACUUM PILLOW MACHINE 001EREFERENCE NUMBER: M-0180 AUTOMATIC VACUUM PILLOW MACHINE 001E RAW MATERIAL & CASE FABRIC MATERIAL APPLICATION: FOR CONJUGATE HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm MICRO FIBER SHORTER THAN 100mm ELASTIC FIBER SHORTER THAN 100mm PILLOW FABRIC QUALITY: PERMEABLE FABRIC LENGTH: 13 METERS LONG QUANTITY AVAILABLE: 1 Learn More -

Y-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mmYY-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mm WLS ROLLING & SCORING THE RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS: 2000 TO 3800 KG/HR. FEATURES: - CONDITION: REFURBISHED - MANUFACTURER: WLS - USAGE: CHEWING GUM FORMING LINE - CAPACITY: 2.000 KG/HR. - WORKING WIDTH: 460mm - PIECES’ DIMENSIONS: ACCORDING TO THE CUSTOMERS NEED Learn More

Y-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mmYY-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mm WLS ROLLING & SCORING THE RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS: 2000 TO 3800 KG/HR. FEATURES: - CONDITION: REFURBISHED - MANUFACTURER: WLS - USAGE: CHEWING GUM FORMING LINE - CAPACITY: 2.000 KG/HR. - WORKING WIDTH: 460mm - PIECES’ DIMENSIONS: ACCORDING TO THE CUSTOMERS NEED Learn More