Search results for: 'Electric d''

- Related search terms

- Electric di

- Electrical

- electric d'[0]

- electric can

- electric''

-

TT-2350 GARDNER DENVER OIL DRILLING RIG, 1000HPTT-2350 GARDNER DENVER OIL DRILLING RIG, 1000HP ONE SINGLE MACHINE DRAWWORKS GARDNER DENVER 800M SINGLE DRUM WITH 1 3/8” GROOVING RATED FOR 1000 INPUT HORSEPOWER, WITH TWO ENGINE COMPOUND. POWERED BY (2) CAR C-18 ACERT, EPA TEIR 3 ENGINES WITH 195-100 OWI TORQUE CONVERTER. HYDROMATIC BRAKE. QUANTITY: 1 Learn More

TT-2350 GARDNER DENVER OIL DRILLING RIG, 1000HPTT-2350 GARDNER DENVER OIL DRILLING RIG, 1000HP ONE SINGLE MACHINE DRAWWORKS GARDNER DENVER 800M SINGLE DRUM WITH 1 3/8” GROOVING RATED FOR 1000 INPUT HORSEPOWER, WITH TWO ENGINE COMPOUND. POWERED BY (2) CAR C-18 ACERT, EPA TEIR 3 ENGINES WITH 195-100 OWI TORQUE CONVERTER. HYDROMATIC BRAKE. QUANTITY: 1 Learn More -

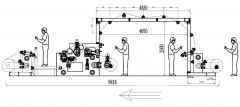

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More -

AA-1120 BASE SHOP COFFEE ROASTERAA-1120 –SALE BASE SHOP COFFEE ROASTER TECHNICAL SPECIFICATIONS: GREEN COFFEE BATCH CAPACITY (MAX): 1.2KG BATCH CAPACITY (MINIMUM ADVISED): 0.5KG CAPACITY PER HOUR: 4KG OPERATION CONTROL TYPE: MANUAL AIRFLOW CONTROL (DAMPER): MANUAL ROASTING TIME: 12 TO 15MIN TEMPERATURE SENSORS: 2 (BEAN AND EXHAUST AIR TEMPERATURE) COOLING TIME: 3MIN TYPE OF COOLING: AIR AMBIENT SAFETY DEVICE: YES OPERATION TYPE BURNER: MANUAL FUEL TYPE: NATURAL GAS(LNG)/PROPANE GAS(LPG) BURNER POWER LPG (G30): LPG 7 TO 23.885KW - BTU/H BURNER POWER LNG (G20): LNG 12 TO 40.945KW - BTU/H INLET PRESSURE LNG: 20MBAR INLET PRESSURE LPG: 37MBAR POWER: 2200W VOLTAGE: 220V/60HZ EXHAUST CHIMNEY (ROASTER CYCLONE): 100mm EXHAUST CHIMNEY (COOLER): 80mm ROASTER FAN MOTOR: 0.33HP COOLER FAN MOTOR: 0.33HP DRUM GEARBOX: 0.17HP COOLER GEARBOX: 170/374HP DIMENSIONS (L X W X H): 1465X940X1180mm NET WEIGHT (ROASTER + CYCLONE): 170KG SHIPPING BOX (L X W X H): 1560X1150X1410mm SHIPPING WEIGHT: 410KG Learn More

AA-1120 BASE SHOP COFFEE ROASTERAA-1120 –SALE BASE SHOP COFFEE ROASTER TECHNICAL SPECIFICATIONS: GREEN COFFEE BATCH CAPACITY (MAX): 1.2KG BATCH CAPACITY (MINIMUM ADVISED): 0.5KG CAPACITY PER HOUR: 4KG OPERATION CONTROL TYPE: MANUAL AIRFLOW CONTROL (DAMPER): MANUAL ROASTING TIME: 12 TO 15MIN TEMPERATURE SENSORS: 2 (BEAN AND EXHAUST AIR TEMPERATURE) COOLING TIME: 3MIN TYPE OF COOLING: AIR AMBIENT SAFETY DEVICE: YES OPERATION TYPE BURNER: MANUAL FUEL TYPE: NATURAL GAS(LNG)/PROPANE GAS(LPG) BURNER POWER LPG (G30): LPG 7 TO 23.885KW - BTU/H BURNER POWER LNG (G20): LNG 12 TO 40.945KW - BTU/H INLET PRESSURE LNG: 20MBAR INLET PRESSURE LPG: 37MBAR POWER: 2200W VOLTAGE: 220V/60HZ EXHAUST CHIMNEY (ROASTER CYCLONE): 100mm EXHAUST CHIMNEY (COOLER): 80mm ROASTER FAN MOTOR: 0.33HP COOLER FAN MOTOR: 0.33HP DRUM GEARBOX: 0.17HP COOLER GEARBOX: 170/374HP DIMENSIONS (L X W X H): 1465X940X1180mm NET WEIGHT (ROASTER + CYCLONE): 170KG SHIPPING BOX (L X W X H): 1560X1150X1410mm SHIPPING WEIGHT: 410KG Learn More -

P-4421 LAUNDRY SOAP PRODUCTION LINECAPACITY 1000 to 1500 KILOGRAMS PER HOUR

P-4421 LAUNDRY SOAP PRODUCTION LINECAPACITY 1000 to 1500 KILOGRAMS PER HOURREFERENCE NUMBER: P-4421

VOLUME: 10m3SIZE:φ2800 x 3000, 20 m3POWER: 5.5 KILOWATTS PER SETLearn More -

C-4085 GREENVILLE CONTINUOS INDIGO & SULPHUR AND MERCERIZING DYEING LINE, YEAR RECONDITIONED 2004

C-4085 GREENVILLE CONTINUOS INDIGO & SULPHUR AND MERCERIZING DYEING LINE, YEAR RECONDITIONED 2004REFERENCE NUMBER: C-4085

GREENVILLE CONTINUOS INDIGO & SULPHUR AND MERCERIZING DYEING LINE, YEAR RECONDITIONED 2004

GREENVILLE CONTINUOS INDIGO & SULPHUR AND MERCERIZING DYEING LINE

IN 20 ROPES

YEAR RECONDITIONED: 2004

AND THEN IT STOPPED ON 2009

STILL ON MILL FLOOR

A-BALL WARPING MACHINES:

OFFER 001

RED-CHATWOOD BALL WARPER

MODEL: WC 480

YEAR: 1991

MAX. DIAMETER: 1200mm

TRAVERSE MAX.1200mm

MAX. WEIGHT: 816 KGS

ELECTRONIC CONTROL

2 ROLLERS WITH SENSOR

FOR AUTOMATIC REGULATION

AND CONSTANT AND PERIPHERIC WINDING SPEED

AND TENSION YARN FROM CREEL

QUANTITY: 1

OFFER 002

REED-CHATWOOD V CREEL

MODEL: LVC/A

YEAR: 1991

WITH ELECTRONIC TENSION REGULATION

504 POSITIONS WORKING

504 POSITIONS STORAGE

GAUGE 340mm X 340mm

80-WOOD LOG

QUANTITY: 2

OFFER 003

INDIGO & SULPHUR AND MERCERIZING ROPES DYEING LINE:

YEAR: 1972

YEAR RECONDITIONED: 2004

GREENVILLE

ROPES RANGE 20 ROPES

THIS ROPE RANGE HAS THE FLEXIBILITY TO PRODUCE 11 DIFFERENT DYEING PROCESS

QUANTITY: 1

COMPLETE OF:

OFFER 004

CREEL FOR 20 BALLS WARP POSITIONS

QUANTITY: 1

OFFER 005

ROPES YARN INTRODUCTION

AND DRAGGING CALENDER

QUANTITY: 1

OFFER 006

TANK1 - SODAING, IMBIBITION AND PURGING TANK

WITH LIQUID CIRCULATION

AND FILTERING GROUP

WITH SQEEZING PADDER FOR 10000 KGS

IN UPPER POSITION

QUANTITY: 1

OFFER 007

STEAMER

WITH VERTICAL PASSAGES OF FABRIC BY 6 UPPER

AND UNDER 5 CYLINDERS

CAP.L.M.40

QUANTITY: 1

OFFER 008

TANK2- FIXING, WASHING, INDIGO DYEING TANK

WITH SQEEZING PADDER FOR 10000 KGS FOR EACH TANK

QUANTITY: 1

OFFER 009

8 LONGITUDINAL FINNED CYLINDERS FOR OXIDIZATION OF INDIGO-DYED YARNS

FABRIC CAPACITY 28 LINEAR METERS

QUANTITY: 1 SET

OFFER 010

TANK3 - NEUTRALIZATION, WASHING AND INDIGO DYEING

WITH SQEEZING PADDER 10000 KGS

IRON AISI 316 FOR EACH TANK

QUANTITY: 1

OFFER 011

8 LONGITUDINAL FINNED CYLINDERS FOR OXIDIZATION OF INDIGO-DYED YARNS

FABRIC CAPACITY 28 LINEAR METERS

QUANTITY: 1 SET

OFFER 012

TANK4-TANK5

WASHING AND INDIGO DYEING TANK

WITH SQEEZING PADDER 10000 KGS FOR EACH TANK

QUANTITY: 2

OFFER 013

8 LONGITUDINAL FINNED CYLINDERS FOR OXIDIZATION OF INDIGO-DYED YARNS

FABRIC CAPACITY 28 LINEAR METERS

QUANTITY: 1 SET

OFFER 014

TANK6-TANK7 - WASHING AND INDIGO DYEING

BLACK SULPHUR DYEING

WITH SQEEZING PADDER 10000 KGS

FOR EACH TANK

QUANTITY: 2

OFFER 015

8 LONGITUDINAL FINNED CYLINDERS FOR OXIDIZATION OF INDIGO-DYED YARNS

QUANTITY: 1 SET

OFFER 016

TANK8 - INDIGO SPECIAL COLORS DYEING

BLACK SULPHUR DYEING TANK

WITH LIQUID CIRCOLATION

AND FILTERING GROUP

WITH SQEEZING PADDER 10000 KGS FOR EACH TANK

QUANTITY: 1

OFFER 017

8 LONGITUDINAL FINNED CYLINDERS FOR OXIDIZATION OF INDIGO-DYED YARNS

FABRIC CAPACITY 28 LINEAR METERS

IN UPPER POSITION

QUANTITY: 1 SET

OFFER 018

STEAMER

WITH VERTICAL PASSAGES OF FABRIC BY 6 UPPER

AND UNDER 5 CYLINDERS

CAP.L.M.40

QUANTITY: 1

OFFER 019

INDIGO CIRCULATION TANK

COMPLETED WITH FILTERS, HEATING COILS AND

AUTOMATIC DOSER FOR HYDROSULPHITE CAPACIOUS FOR 200 LT.S

WITH DOSING PUMP FOR AUTOMATIC SODA DOSING

ELECTRONIC EQUIPMENT FOR CONTROL OF PH

AND REDOX PARAMETERS

QUANTITY: 1

OFFER 020

TANK9-TANK10 - INDIGO DYEING

BLACK SULPHUR DYEING

WITH SQEEZING PADDER 10000 KGS

FOR EACH TANK

QUANTITY: 2

OFFER 021

8 LONGITUDINAL FINNED CYLINDERS FOR OXIDIZATION OF INDIGO-DYED YARNS

QUANTITY: 1 SET

OFFER 022

TANK11-TANK12-TANK13 - HOT WASHING (AND/ OR INDIGO DYEING)

TANK WITH SQEEZING PADDER 10000 KGS

WITH INOX STEEL HOOD AND ASPIRATION FAN

ALL INSIDE AND OUTSIDE TANKS AND CYLINDERS ARE IN INOX IRON

ALL THE TANKS ARE THERMOREGULATED

EACH TANK IS COMANDED BY MOTOR POWER INVERTER

QUANTITY: 3

OFFER 023

RAMALLUMIN DRYING CYLINDERS

YEAR: 1972

YEAR RECONDITIONED: 2002

PART OF TEFLONED CYLINDERS

ALL CYLINDERS STEAM HEATING THERMOREGULATED EXIT

20 COILER SYSTEM FOR CANS

DIAMETER: 1200mm X H.800mm

FOR DYEING ROPES

PANEL ELECTRONIC COMPUTERIZED

AND ELECTRIC POWER FOR ALL FUNCTIONS OF THE LINE

ELECTRONIC CONTROL OF THE TENSION OF THE YARN

WITH ELONGATIONS IN %

BETWEEN THE DIFFERENT POINT

MOISTURE CONTROL

QUANTITY: 36

OFFER 024

CANS STORAGE

DIAMETER: 1200mm X H.800mm

INCLUDING-CABIES-PIPING

QUANTITY: 60

OFFER 025

INOX IRON CONTROL PANEL FOR THE DYEING PROCESS

QUANTITY: 1

OFFER 026

INOX IRON CONTROL PANEL FOR THE SPEED REGULATION

QUANTITY: 1

OFFER 027

INOX IRON CONTROL PANEL FOR THE COLORS KITCHEN

COLORS AUTOMATIC ELECTRONIC KITCHEN

QUANTITY: 1

OFFER 028

COMPOSED WITH:

CAPACIOUS FOR DARK INDIGO SALVAGE FOR 3500 LTS EACH

QUANTITY: 6

OFFER 029

CAPACIOUS FOR DARK INDIGO SALVAGE FOR 10000 LTS EACH

ALL THE CAPACIOUSES ARE IN INOX IRON

AND ARE PROVIDED WITH THE ELECTRIC AGITATOR

PART OF THEM ARE THERMOREGULATED

QUANTITY: 6

OFFER 030

DIRECT WARPER MACHINES FOR REBEAMING:

REED-CHATWOOD CHAIN BEAMERS DIRECT WARPERS

MODEL: SBB

YEAR: 1991

MAX. SPEED 410 M/MIN

BEAM FLANGE

DIAMETER: 1000mm

BEAM MAX. WEIGHT: 907 KGS

FOR REBEAMING FROM CANS

WITH ROPES DYEING

TO REED-CHATWOOD CHAIN BEAMERS

WITH AUTOMATIC ELECTRONIC PREFEEDER ACCUMULATOR

WITH 2 POSITIVE ROLLERS

FOR ELECTRONIOC CONTROL OF CONSTANT TENSION

AND PERIPHERIC SPEED ROPES

QUANTITY: 1

OFFER 031

NUOVA FORMIA CHAIN BEAMERS DIRECT WARPERS

YEAR: 1987

MAX. SPEED: 410 M/MIN

BEAM FLANGE DIAMETER: 1000mm

BEAM MAX. WEIGHT: 907 KGS

FOR REBEAMING FROM CANS

WITH ROPES DYEING

TO NUOVA FORMIA CHAIN BEAMERS

WITH AUTOMATIC ELECTRONIC

PREFEEDER ACCUMULATOR

WITH 2 POSITIVE ROLLERS

FOR ELECTRONIOC

CONTROL OF CONSTANT TENSION

AND PERIPHERIC SPEED ROPES

QUANTITY: 5

OFFER 032

WARP BEAMS FLANGE DIAMETER: 1000mm

INSIDE DISTANCE FLANGE TO FLANGE: 1600mm

FOR EXIT CHAIN BEAMERS AND FEEDING CREEL ROTAL

SIZING MACHINE

SPARE PARTS EXISTING IN THE COMPANY

QUANTITY: 100

OFFER 033

SIZING MACHINE

ROTAL SIZING MACHINE

YEAR: 1990

QUANTITY: 1

COMPOSED WITH:

OFFER 034

FEEDING CREEL FOR 16 POSITIONS FOR BEAMS FLANGE

DIAMETER: 1000mm X INSIDE

DISTANCE FLANGE TO FLANGE 1600mm

QUANTITY: 1

OFFER 035

SIZE TANK WITH DOUBLE GROUP OF DOUBLE SQEEZING

3 CYLINDERS EACH SET GROUP

HIGH PRESSURE TYPE

YEAR: 1999

COMPLETE

QUANTITY: 2

OFFER 036

DRYER-GROUP MODEL

OF 16 DRYING INOX CYLINDERS

DIAMETER: 800mm

PART OF THEM TEFLONED

WITH SIDE COVERINGS AND ASPIRATOR

QUANTITY: 1

OFFER 037

AUTOMATIC BEAMING MACHINE FOR BEAMS

WIDTH: 2600mm

FOR FLANGE DIAMETER: 1200mm

COMPLETED WITH ELECTRONIC CONTROLS, ETC

QUANTITY: 1

OFFER 038

SIZING KITCHEN

COMPOSED OF INOX

1 TANK FOR SIZE PREPARATION

CAPACITY: 1000LTS

AND CAPACIOUS FOR COOKING AUTOCLAVE OF 1000 LTS

AND OF 2 STORAGE RESERVE SIZING CAPACIOUS FOR 1500 LTS

COMPLETED WITH ELECTRIC PANEL

WITH THERMOREGULATION, ETC

QUANTITY: 1

QUANTITY: 1 LINE

Learn More -

V-0046 SHRINK PACKING MACHINEREFERENCE NUMBER: V-0046 AUTOMATIC ROLL SHRINK PACKING MACHINE MODEL ARPM-240I QUANTITY AVAILABLE: 1 Learn More

V-0046 SHRINK PACKING MACHINEREFERENCE NUMBER: V-0046 AUTOMATIC ROLL SHRINK PACKING MACHINE MODEL ARPM-240I QUANTITY AVAILABLE: 1 Learn More -

K-9326 BABCOCK WIDE TENTER FRAME 144" (3657mm)REFERENCE NUMBER: K-9326 BABCOCK WIDE TENTER FRAME 144" (3657mm) QUANTITY AVAILABLE: 1 Learn More

K-9326 BABCOCK WIDE TENTER FRAME 144" (3657mm)REFERENCE NUMBER: K-9326 BABCOCK WIDE TENTER FRAME 144" (3657mm) QUANTITY AVAILABLE: 1 Learn More -

M-1976 BABCOCK FRAME 144" WIDE-3600mmREFERENCE NUMBER: M-1976 (770395POK6RM) BABCOCK FRAME 144" WIDE-3600mm QUANTITY AVAILABLE: 1 Learn More

M-1976 BABCOCK FRAME 144" WIDE-3600mmREFERENCE NUMBER: M-1976 (770395POK6RM) BABCOCK FRAME 144" WIDE-3600mm QUANTITY AVAILABLE: 1 Learn More -

TT-6376 THIBEAU DOUBLE DOFFER CA6 CARDING MACHINE WITH VAT6 ORIGINAL THIBEAU FEEDER, 2500mmTT-6376 THIBEAU DOUBLE DOFFER CA6 CARDING MACHINE WITH VAT6 ORIGINAL THIBEAU FEEDER, 2500mm 1. THIBEAU DOUBLE DOFFER CA6 CARDING MACHINE 2. 2500mm 3. WITH VAT6 ORIGINAL THIBEAU FEEDER 4. THE MACHINE WAS DISMANTLED BY US IN FRANCE IN AUGUST 2024 5. AND IS IN QUITE GOOD SHAPE. 6. IT NEEDS A NEW ELECTRICAL CONTROL TO TREAT IT AS FULLY PROFESSIONAL SOLUTION. 7. ORIGINAL YEAR: 1986. 8. WELL MAINTAINED. Learn More

TT-6376 THIBEAU DOUBLE DOFFER CA6 CARDING MACHINE WITH VAT6 ORIGINAL THIBEAU FEEDER, 2500mmTT-6376 THIBEAU DOUBLE DOFFER CA6 CARDING MACHINE WITH VAT6 ORIGINAL THIBEAU FEEDER, 2500mm 1. THIBEAU DOUBLE DOFFER CA6 CARDING MACHINE 2. 2500mm 3. WITH VAT6 ORIGINAL THIBEAU FEEDER 4. THE MACHINE WAS DISMANTLED BY US IN FRANCE IN AUGUST 2024 5. AND IS IN QUITE GOOD SHAPE. 6. IT NEEDS A NEW ELECTRICAL CONTROL TO TREAT IT AS FULLY PROFESSIONAL SOLUTION. 7. ORIGINAL YEAR: 1986. 8. WELL MAINTAINED. Learn More -

TT-4911 DILO DI-LOUR 25 MACHINE, WORKING WIDTH 2500mm, YEAR 1987TT-4911 DILO DI-LOUR 25 MACHINE, WORKING WIDTH 2500mm, YEAR 1987 DILO DI-LOUR 25 MACHINE RECENTLY RECONDITIONED AND UPGRADED WITH A NEW ELECTRICAL CONTROLS SYSTEM WORKING WIDTH 2500mm YEAR BUILT 1987 WE RECONDITIONED AND UPGRADED IN AUGUST 2021 MAXIMUM DAYLIGHT: 12.5” (WITHOUT SAFETY GUARDING ON INLET) NEEDLE BOARDS: 2 NEEDLE BOARDS AND 1 DUMMY BOARD NEEDLE POPULATION: 8000 NEEDLES PER METER MAIN MOTOR: 34.5 KW (460 V); 30 KW (400 V) ESTIMATED NUMBER OF BRUSHES: 1640 BRUSH BRISTLE HEIGHT: 20mm MAXIMUM ECCENTRIC RPM: 980 MAXIMUM BRUSH CONVEYOR SPEED: 5.6 METERS PER MINUTE MAXIMUM DRAW-OFF ROLLER SPEED: 6 METERS PER MINUTE QUANTITY: 1 Learn More

TT-4911 DILO DI-LOUR 25 MACHINE, WORKING WIDTH 2500mm, YEAR 1987TT-4911 DILO DI-LOUR 25 MACHINE, WORKING WIDTH 2500mm, YEAR 1987 DILO DI-LOUR 25 MACHINE RECENTLY RECONDITIONED AND UPGRADED WITH A NEW ELECTRICAL CONTROLS SYSTEM WORKING WIDTH 2500mm YEAR BUILT 1987 WE RECONDITIONED AND UPGRADED IN AUGUST 2021 MAXIMUM DAYLIGHT: 12.5” (WITHOUT SAFETY GUARDING ON INLET) NEEDLE BOARDS: 2 NEEDLE BOARDS AND 1 DUMMY BOARD NEEDLE POPULATION: 8000 NEEDLES PER METER MAIN MOTOR: 34.5 KW (460 V); 30 KW (400 V) ESTIMATED NUMBER OF BRUSHES: 1640 BRUSH BRISTLE HEIGHT: 20mm MAXIMUM ECCENTRIC RPM: 980 MAXIMUM BRUSH CONVEYOR SPEED: 5.6 METERS PER MINUTE MAXIMUM DRAW-OFF ROLLER SPEED: 6 METERS PER MINUTE QUANTITY: 1 Learn More