Search results for: 'automatic+test'

-

T-8028 HIGH SPEED SOFT WINDING MACHINET-8028 HIGH SPEED SOFT WINDING MACHINE SIZE: 2050 X 750 X 1500mm SINGLE-SIDE CONFIGURATION: 6 SPINDLES/SET WEIGHT: 150KG QUANTITY: 1 SET (6 SPINDLES) Learn More

T-8028 HIGH SPEED SOFT WINDING MACHINET-8028 HIGH SPEED SOFT WINDING MACHINE SIZE: 2050 X 750 X 1500mm SINGLE-SIDE CONFIGURATION: 6 SPINDLES/SET WEIGHT: 150KG QUANTITY: 1 SET (6 SPINDLES) Learn More -

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More -

1000 L STABILITY CHAMBERREFERENCE NUMBER: A-2492 1000 L STABILITY CHAMBER SPECIFICATIONS: INNER CHAMBER SIZE: 1 X 1 X 1 mm EXTERNAL DIMENSION: 1.2 X 1.97 X 2.17 mm TEMPERATURE RANGE: 70 TO 180°C HUMIDITY RANGE: 10% TO 98% RH, WHEN THE TEMPERATURE IS ABOVE 60°C, THE HUMIDITY CAN ACHIEVE 10% RH TEMPERATURE & HUMIDITY FLUCTUATION: ±0.2℃, ±0.5% RH INDICATION RESOLUTION: 0.01℃, 0.1% RH TEMPERATURE & HUMIDITY UNIFORMITY: ±2℃, ±3% RH (TESTED WITH THE EMPTY CHAMBER, 30 MINUTES AFTER STABILIZATION) HEAT UP AND COOL DOWN TIME: HEATING RATE: AVERAGE 3 ℃/MINUTES; COOLING RATE: AVERAGE 1 ℃/MINUTE (UNLOADED TEST) MATERIAL: INNER CHAMBER: SUS#304 STAINLESS STEEL EXTERIOR STRUCTURE: STAINLESS STEEL PLATE + POWDER COATED INSULATION: GLASS WOOL & PUF PERSPIRATION RESISTANT: K STYLE TUBE ACCESSORIES • TEMPERATURE RESISTANT SILICONE GASKET: 1 PC • CABLE PORT:1 PC; OD: 100 mm • WINDOW LIGHT: 1 PC • MULTIPANE VIEW WINDOW: 1 PC • LOADING SHELVES: 2 PCS REFRIGERATION & HEATING SYSTEM • ORIGINAL IMPORTED HIGH EFFICIENCY COMPRESSOR • AIR COOLING CONDENSER • FIN – TUBE HEATER • ORIGINAL IMPORTED SOLENOID VALVES • INNER SPIRAL K – TYPE REFRIGERANT COPPER TUBE • U – TYPE FINNED ELECTRO - THERMAL TUBE • HEATING & COOLING SYSTEMS SEPARATED • SINGLE STAGE REFRIGERATING SYSTEM HUMIDIFYING & DEHUMIDIFYING SYSTEM • ELECTRIC & BYTE TYPE HUMIDIFYING SYSTEM • STAINLESS STEEL HUMIDIFYING BARREL WITH VIEW WINDOW FOR WATER LEVEL • ADP DEHUMIDIFYING WAY • OVER – TEMPERATURE AND OVERFLOW PROTECTION UNITS • HUMIDIFYING & DEHUMIDIFYING SYSTEMS SEPARATED CIRCLING & DRAIN SYSTEM • CENTRIFUGAL FAN & IMPORTED MOTOR • REVERSE UNIFLOW (AIR FLOW DIRECTION) • FLOW – THROWS WIND • DRAIN SYSTEM USES SWIRL TYPE OUTLET AND U – TRAP DEPOSITION UNIT PROGRAMABLE MICRO COMPUTER LCD TOUCH CONTROLLER • PROGRAMMABLE TOUCH CONTROLLER, USER - FRIENDLY, STABLE AND EASY USE • PROGRAMS: 99 SEGMENTS PER PROGRAM, 120 PROGRAMS, 120 CYCLING PER PROGRAM • PID & SSR CONTROL WAY, STABLE AND EASY USE • HAVE SLOP CONTROL FUNCTION FOR HEATING & COOLING, LINKED PTNS CAN BE EXECUTED • PID AUTOMATIC CALCULATION • MICRO COMPUTER MULTI FUNCTION CONTROLLER, MAIN COMPONENTS ’DATA AUTOMATICALLY OUTPUT INCLUDING COMPRESSORS, SOLENOIDS, HEATING UNITS, ETC • ERRORS OF MAIN COMPONENTS APPEAR ON THE LCD PANEL • THE BRIGHTNESS OF THE LCD PANEL CAN BE ADJUSTED • TIME SEQUENCE CONTROL INTERFACE RELAYS HAVE 3 GROUPS WHICH MANAGE THE OUTPUT OF OUTSIDE LOGIC UNITS INCLUDING SIGNAL, MECHANICAL AND POWER, ETC • PROGRAMS AUTO – SAVE FUNCTION IF POWER CUT OFF SUDDENLY • HAVE HOLD & ADV BUTTONS INPROGRAMS • AUTOMATICALLY SET THE HIGH & LOW TEMPERATURE LIMITS AFTER PROGRAMS SET • PASSWORD SET FUNCTION • SD CARD SLOT, 2 GB SD CARD, RS232 OR ETHERNET (RJ45) OPERATING ENVIRONMENT • AMBIENT TEMPERATURE: +25℃ (2) RH ≤85% PROTECTION • ELECTRICITY LEAK PROTECTION • LIGHTNING STRIKE PROTECTION, ZRN LIGHTNING ARRESTER INSIDE THE CONTROLLER • SENSOR DATES TRANSFERRED INSIDE THE MICRO COMPUTER • TEMP. SENSORS TO OPEN CIRCUIT OR SHORT CIRCUIT (+ - OVER) • THE FIRST LEVEL OVER TEMPERATURE PROTECTION • ERROR DETECTED UNITS • THE SECOND LEVEL OVER TEMPERATURE PROTECTION TO ELECTRONIC OVER - TEMP PROTECTION UNIT • THE THIRD LEVEL OVER - TEMPERATURE PROTECTION • COMPRESSOR PROTECTION TO REFRIGERANTS PRESSURE PROTECTION & OVERLOAD PROTECTION. • EXTENDED PROTECTION UNIT TO TWO SUPPLETIVE PORTS • ERROR PROTECTION TO POWER CUT OFF, ERROR REPORTS SHOWN IN LCD PANEL AND AUDIBLE ALARM STARTS • DYNAMIC HIGH AND LOW TEMPERATURE PROTECTION • AMBIENT TEMPERATURE PROTECTION TO THE INNER CHAMBER AND SPECIMENS AUTOMATICALLY RETURN BACK TO AMBIENT TEMPERATURE AFTER THE OPERATION STOP SAFETY PROTECTION • NON-FUSE PROTECTION SWITCH • OVERHEAT ALARM PROTECTION • COMPRESSOR OVERLOAD PROTECTION • PHASE SEQUENCE PROTECTION • MOTOR OVER TO CURRENT PROTECTION Learn More

1000 L STABILITY CHAMBERREFERENCE NUMBER: A-2492 1000 L STABILITY CHAMBER SPECIFICATIONS: INNER CHAMBER SIZE: 1 X 1 X 1 mm EXTERNAL DIMENSION: 1.2 X 1.97 X 2.17 mm TEMPERATURE RANGE: 70 TO 180°C HUMIDITY RANGE: 10% TO 98% RH, WHEN THE TEMPERATURE IS ABOVE 60°C, THE HUMIDITY CAN ACHIEVE 10% RH TEMPERATURE & HUMIDITY FLUCTUATION: ±0.2℃, ±0.5% RH INDICATION RESOLUTION: 0.01℃, 0.1% RH TEMPERATURE & HUMIDITY UNIFORMITY: ±2℃, ±3% RH (TESTED WITH THE EMPTY CHAMBER, 30 MINUTES AFTER STABILIZATION) HEAT UP AND COOL DOWN TIME: HEATING RATE: AVERAGE 3 ℃/MINUTES; COOLING RATE: AVERAGE 1 ℃/MINUTE (UNLOADED TEST) MATERIAL: INNER CHAMBER: SUS#304 STAINLESS STEEL EXTERIOR STRUCTURE: STAINLESS STEEL PLATE + POWDER COATED INSULATION: GLASS WOOL & PUF PERSPIRATION RESISTANT: K STYLE TUBE ACCESSORIES • TEMPERATURE RESISTANT SILICONE GASKET: 1 PC • CABLE PORT:1 PC; OD: 100 mm • WINDOW LIGHT: 1 PC • MULTIPANE VIEW WINDOW: 1 PC • LOADING SHELVES: 2 PCS REFRIGERATION & HEATING SYSTEM • ORIGINAL IMPORTED HIGH EFFICIENCY COMPRESSOR • AIR COOLING CONDENSER • FIN – TUBE HEATER • ORIGINAL IMPORTED SOLENOID VALVES • INNER SPIRAL K – TYPE REFRIGERANT COPPER TUBE • U – TYPE FINNED ELECTRO - THERMAL TUBE • HEATING & COOLING SYSTEMS SEPARATED • SINGLE STAGE REFRIGERATING SYSTEM HUMIDIFYING & DEHUMIDIFYING SYSTEM • ELECTRIC & BYTE TYPE HUMIDIFYING SYSTEM • STAINLESS STEEL HUMIDIFYING BARREL WITH VIEW WINDOW FOR WATER LEVEL • ADP DEHUMIDIFYING WAY • OVER – TEMPERATURE AND OVERFLOW PROTECTION UNITS • HUMIDIFYING & DEHUMIDIFYING SYSTEMS SEPARATED CIRCLING & DRAIN SYSTEM • CENTRIFUGAL FAN & IMPORTED MOTOR • REVERSE UNIFLOW (AIR FLOW DIRECTION) • FLOW – THROWS WIND • DRAIN SYSTEM USES SWIRL TYPE OUTLET AND U – TRAP DEPOSITION UNIT PROGRAMABLE MICRO COMPUTER LCD TOUCH CONTROLLER • PROGRAMMABLE TOUCH CONTROLLER, USER - FRIENDLY, STABLE AND EASY USE • PROGRAMS: 99 SEGMENTS PER PROGRAM, 120 PROGRAMS, 120 CYCLING PER PROGRAM • PID & SSR CONTROL WAY, STABLE AND EASY USE • HAVE SLOP CONTROL FUNCTION FOR HEATING & COOLING, LINKED PTNS CAN BE EXECUTED • PID AUTOMATIC CALCULATION • MICRO COMPUTER MULTI FUNCTION CONTROLLER, MAIN COMPONENTS ’DATA AUTOMATICALLY OUTPUT INCLUDING COMPRESSORS, SOLENOIDS, HEATING UNITS, ETC • ERRORS OF MAIN COMPONENTS APPEAR ON THE LCD PANEL • THE BRIGHTNESS OF THE LCD PANEL CAN BE ADJUSTED • TIME SEQUENCE CONTROL INTERFACE RELAYS HAVE 3 GROUPS WHICH MANAGE THE OUTPUT OF OUTSIDE LOGIC UNITS INCLUDING SIGNAL, MECHANICAL AND POWER, ETC • PROGRAMS AUTO – SAVE FUNCTION IF POWER CUT OFF SUDDENLY • HAVE HOLD & ADV BUTTONS INPROGRAMS • AUTOMATICALLY SET THE HIGH & LOW TEMPERATURE LIMITS AFTER PROGRAMS SET • PASSWORD SET FUNCTION • SD CARD SLOT, 2 GB SD CARD, RS232 OR ETHERNET (RJ45) OPERATING ENVIRONMENT • AMBIENT TEMPERATURE: +25℃ (2) RH ≤85% PROTECTION • ELECTRICITY LEAK PROTECTION • LIGHTNING STRIKE PROTECTION, ZRN LIGHTNING ARRESTER INSIDE THE CONTROLLER • SENSOR DATES TRANSFERRED INSIDE THE MICRO COMPUTER • TEMP. SENSORS TO OPEN CIRCUIT OR SHORT CIRCUIT (+ - OVER) • THE FIRST LEVEL OVER TEMPERATURE PROTECTION • ERROR DETECTED UNITS • THE SECOND LEVEL OVER TEMPERATURE PROTECTION TO ELECTRONIC OVER - TEMP PROTECTION UNIT • THE THIRD LEVEL OVER - TEMPERATURE PROTECTION • COMPRESSOR PROTECTION TO REFRIGERANTS PRESSURE PROTECTION & OVERLOAD PROTECTION. • EXTENDED PROTECTION UNIT TO TWO SUPPLETIVE PORTS • ERROR PROTECTION TO POWER CUT OFF, ERROR REPORTS SHOWN IN LCD PANEL AND AUDIBLE ALARM STARTS • DYNAMIC HIGH AND LOW TEMPERATURE PROTECTION • AMBIENT TEMPERATURE PROTECTION TO THE INNER CHAMBER AND SPECIMENS AUTOMATICALLY RETURN BACK TO AMBIENT TEMPERATURE AFTER THE OPERATION STOP SAFETY PROTECTION • NON-FUSE PROTECTION SWITCH • OVERHEAT ALARM PROTECTION • COMPRESSOR OVERLOAD PROTECTION • PHASE SEQUENCE PROTECTION • MOTOR OVER TO CURRENT PROTECTION Learn More -

P-4421 LAUNDRY SOAP PRODUCTION LINECAPACITY 1000 to 1500 KILOGRAMS PER HOUR

P-4421 LAUNDRY SOAP PRODUCTION LINECAPACITY 1000 to 1500 KILOGRAMS PER HOURREFERENCE NUMBER: P-4421

VOLUME: 10m3SIZE:φ2800 x 3000, 20 m3POWER: 5.5 KILOWATTS PER SETLearn More -

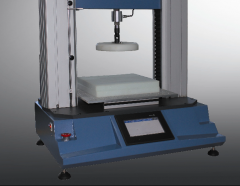

L-2031 FOAM IFD TESTER

L-2031 FOAM IFD TESTERREFERENCE NUMBER: L-2031

Learn More

DIMENSIONS (W*D*H): 720 X580 X850mm

QUANTITY: 1 -

M-5819 USTER HVI-900 TESTER YEAR 1994

M-5819 USTER HVI-900 TESTER YEAR 1994M-5819 USTER HVI-900 TESTER YEAR 1994

MAKE: USTER

MODEL: HVI

YEAR: 1994 (APPROXIMATELY)

USTER HVI900 SUITABLE FOR MEASUREMENT OF RAW COTTON FIBER

SEMI AUTOMATIC SAMPLE TESTING

LENGTH & STRENGTH: LENGTH MODULE USED FOR MEASUREMENT OF LENGTH PARAMETERS SUCH AS UHML, ML, UNIFORMITY & SFI ETC. AND STRENGTH MODULE FOR BUNDLE STRENGTH IN GRAM/TEX AND ELONGATION IN %

MIX MODULE: MEASUREMENT OF MICRONAIRE

COLOR MODULE: COLOR MODULE MEASURES REFLECTANCE (RD) AND BRIGHTNESS (+B) AND COLOR GRADE FOR COTTON CLASSING

DOS OPERATING PLATFORM WITH DISPLAY & PRINTER

SYSTEM WAS CALIBRATED AND CHECKED USING USDA CALIBRATION SAMPLESQUANTITY: 1

Learn More -

S-1197 LAUNDRY SOAP PRODUCTION LINE, CAPACITY 1000 TO 1500 KG/HR

S-1197 LAUNDRY SOAP PRODUCTION LINE, CAPACITY 1000 TO 1500 KG/HRS-1197 LAUNDRY SOAP PRODUCTION LINE, CAPACITY 1000 TO 1500 KG/HR

LAUNDRY SOAP PRODUCTION LINE

CAPACITY: 1000 TO 1500 KG/HR

I. PROJECT INSTRUCTION

THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES, VACUUM EXTRUDING AND THEN CUTTING INTO SOAPS.

THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT.

PLEASE NOTICE THAT:

IT IS A TURN-KEY PROJECT. THE PROFESSIONAL TEAM PROVIDE YOU ALL MACHINES AND ACCESSORIES, THE WHOLE PROCESS OF PRODUCTION, FORMULA, LAYOUT DESIGN, MACHINES INSTALLATION, PRODUCTS TRIAL ETC. ALL SOLUTION ACCORDING TO YOUR REQUIREMENTS.

THE QUOTATION INCLUDES ALL EXCEPT: BOILER, WORKSHOP BUILDING, HEAT INSULATING MATERIAL, WIRES, PACKING MACHINE, AND CONSUMABLE MATERIALS FOR INSTALLING (WELDING ROD, CRANE, ELECTRIC WELDER, ETC.).1. PRODUCTION REQUIREMENTS:

A. STEAM BOILER: 2 MT/HR.

B. WORKSHOP AREA: LARGER THAN 300 M². (L: 35M, W: 7M, H: 7M)

C. POWER: 130 KW, 380 V, 50 HZ.

D. WATER: CIRCULATING WATER FOR VACUUM DRYING SYSTEM: 40 M3; PRODUCTION WATER.

E. CAPACITY: 1000 TO 1500 KG/HR, 8 TO 12 TON/DAY (8 HR/DAY). OIL CONSUMTION: 5 TO 8 TON/DAY.

F. WORKER: 10 TO 12 WORKERS.

2. MATERIAL AND CONSUMING FOR PRODUCING SOAP:

OIL OR FAT OF PLANT OR ANIMAL (PALM OIL, COCONUT OIL, TALLOW OIL, ETC.), CAUSTIC SODA (NAOH), SODIUM-CHLORIDE (NACL), SODIUM SILICATE, FRAGRANCE, PIGMENT, ETC.

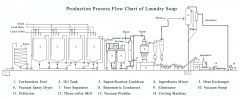

3. PRODUCTION PROCESS:

MIX AND MELT OIL --> SAPONIFICATION --> ADD OTHER INGREDIENTS --> VACUUM DRYING --> SOAP NOODLE --> GRINDING --> VACUUM EXTRUDING --> CUTTING.III. SPECIFICATIONS AND QUOTATION OF EQUIPMENT

1. CARBURETION WORKSHOP:

MIX KINDS OF OIL TOGETHER ON THE BASIS OF THE FORMULA. DEPOSIT AND TAKE OUT THE UNSAPONIFIABLES.ITEM 001

CARBURETION POOL

MIX KINDS OF OIL TOGETHER ON THE BASIS OF THE FORMULA.

VOLUME: 10 M3.

FIELD WORK

QUANTITY: 1ITEM 002

STORAGE TANK FOR REFINE OIL

SIZE: Φ2000X2600, 8.2 M3;

FEATURE: WITH COILER INSIDE.

QUANTITY: 1ITEM 003

WATER PUMP, OIL PUMP, CAUSTIC SODA PUMP

POWER: 1.5 KW/SET.

QUANTITY: 4ITEM 004

SEAMLESS TUBE

(Φ76X3.5) (Φ57X3.5), ETC.

QUANTITY: SEVERALITEM 005

VALVE

Φ65, Φ40, ETC.

QUANTITY: SEVERALITEM 006

FLANGE, SCREW, ELBOW, GASKET.

QUANTITY: SEVERAL2. OIL AND FAT SAPONIFICATION WORKSHOP:

OIL AND ALKALI DO REACTIONS IN THE SAPONIFICATION CAULDRONS. IT IS A GOOD COMBINATION OF FOUR SAPONIFICATION CAULDRONS, WATER CIRCULATES FROM NO. 1 CAULDRON TO NO. 4, IT SAVES WATER, NAOH AND NACL AT THE MOST.ITEM 007

SAPONIFICATION CAULDRON

SAPONIFICATION BETWEEN OIL AND NAOH, LASTING ABOUT 40 TO 60 HRS. SUFFICIENT REACTION. SAVE WATER.

SIZE: Φ2800 X 3000, 20 M3

AUXILIARY FACILITIES: LIQUID CAUSTIC SODA POOL.2 M3

FIELD WORK

QUANTITY: 4ITEM 008

HIGH TEMPERATURE AND HIGH PRESSURE SOAP PUMP

POWER: 5.5 KW/SET

QUANTITY: 3ITEM 009

SEAMLESS TUBE

(Φ76X3.5)(Φ57X3.5), ETC.

QUANTITY: SEVERALITEM 010

VALVE

Φ76, Φ48, ETC.

QUANTITY: SEVERALITEM 011

FLANGE, SCREW, ELBOW, GASKET.

QUANTITY: 13. SOAP VACUUM DRYING SYSTEM:

TO MAKE SOAP MATERIALS FLASH DRY AND COOL INSTANTLY. TO CONTROL THE FATTY ACID CONTENT FROM 50% TO 80%. TO IMPROVE THE QUALITY OF SOAP MATERIALS.ITEM 012

INGREDIENTS MIXTURE TANK

PUT ESSENCE, PIGMENT IN THE LIQUID SOAP. HEATING AND MIXING

SIZE: 1.8 M3, Φ1200X1500

FEATURE: WITH PIPE LINER, HEATING AND MIXING

POWER: 4 KW/SET.

QUANTITY: 2ITEM 013

HEAT EXCHANGER

HEAT THE LIQUID SOAP RAPIDLY

SIZE: Φ325 X 4000

QUANTITY: 1ITEM 014

VACUUM SPRAY DRYER

THE VACUUM DRYER MAKES THE SOAP FLAKES THINNER AND EVENER, AND COOLS THEM DOWN MORE QUICKLY, TO IMPROVE THE QUALITY OF SOAP NOODLES.

ADOPT HARD TOOTH SURFACE GEAR REDUCER AND THE OIL PUMP INSIDE LUBRICATES AUTOMATICALLY AND MAKES A LONG LIFESPAN. THE THICKNESS OF BARREL IS 14 MM, THE INNER WALL IS PROCESSED BY VERTICAL LATHE TO ACHIEVE THE COAXIALITY AND SMOOTH SURFACE. THE SHAFT IS MADE BY A Φ108 X 14mm SEAMLESS TUBE. THE NOZZLE (Φ10mm) IN THE SHAFT SPRAYS SOAP MATERIALS, AND THE THREE BLADES SCRAPE THEM DOWN, AND THE SOAP MATERIALS DRY OUT FAST AND UNIFORM. THE WHOLE SET OF VACUUM SYSTEM CAN MAKE SOAPS WITH FATTY ACID CONTENT FROM 55% TO 80%.

1. TYPE: XSD-1000

2. CAPACITY: 1000 TO 1500 KG/HR

3. BARREL DIAMETER: Φ 1200mm

4. MOUTH DIAMETER: 10mm

5. SPEED: 13 R/MIN

6. POWER: 3 KW

7. DIMENSION: Φ 1600 X 4500mm

8. WEIGHT: 3200 KGS

QUANTITY: 1ITEM 015

FINE SEPARATORS

SEPARATE THE SOAP POWDER FROM THE WATER WHEN VACUUM DRYING

QUANTITY: 2ITEM 016

BAROMETRIC CONDENSER

CONDENSE WATER FROM THE SOAP

QUANTITY: 1ITEM 017

ELIMINATOR

DRAW OFF WATER

QUANTITY: 1ITEM 018

PELLETIZER

IT IS USED TO PRESS THE VACUUM-DRIED SOAP MATERIALS INTO SOAP NOODLES. LONG DOUBLE SCREWS TURN INWARD TO DRIVE SOAP MATERIALS TO EXTRUDE SOAP NOODLES THROUGH PORE PLATES.

1. TYPE: XSN-1000

2. CAPACITY: 1000 TO 1500 KG/HR

3. SCREW DIAMETER: Φ 230mm X 2

4. POWER: 15 KW

5. DIMENSION: 3100 X 1200 X 1550mm

6. WEIGHT: 3000 KGS

QUANTITY: 1ITEM 019

STAGE VACUUM PUMP

KEEP THE VACUUM SYSTEM IN VACUUM STATE

POWER: 15 KW

QUANTITY: 1ITEM 020

BUFFER TANK OF VACUUM PUMP

PROTECT THE VACUUM PUMP FROM STEAM WATER

SIZE: Φ600 X1200

QUANTITY: 1ITEM 021

SOAP PUMP, WATER PUMP

SOAP PUMP: SPECIAL CONSTRUCTURE, DRAW LIQUID SOAP FROM INGREDIENTS MIXURE TANK TO HEAT EXCHANGER. POWER: 7.5 KW

WATER PUMP: FOR WATER CIRCULATING. POWER: 5.5 KW

QUANTITY: 2ITEM 022

SEAMLESS TUBE AND VALVE

Φ76 Φ48, ECT.

QUANTITY: SEVERALITEM 023

FLANGE, SCREW, ELBOW, ETC.

QUANTITY: SEVERAL4. FINISHING LINE:

MILL SOAP NOODLES TWICE, VACUUM EXTRUDING SOAP BAR, CUT SOAP CAKES, AT THE SAME TIME STAMP LOGO ON SOAP CAKES.ITEM 024

THREE-ROLL GRINDING MILL

THREE-ROLL GRINDING MILL IS USED TO GRIND, PRESS THE MATERIAL TO INCREASE ITS DENSITY AND QUALITY.

1. ROLL DIAMETER: Φ260

2. ROLL LENGTH: 780mm

3. MOTOR POWER: 7.5KW

4. ROLL SPEED RATIO: 1:3:9

5. DIMENSION: 1500 X 1200 X 1000mm

6. WEIGHT: 2400 KGS

QUANTITY: 2ITEM 025

VACUUM PLODDER

VACUUM PLODDER IS USED TO GRIND, REFINE AND PRESS SOAP MATERIAL INTO SOAP BAR. THE ABOVE AND BELOW SCREWS AND TWO ORIFICE PLATES PRESS AND REFINE THE SOAP MATERIAL AND MAKE THE SOAP BAR TIGHT AND THE SURFACE BRIGHT.

THE MOTOR AND THE REDUCER ARE SEPARATED, FOR LONG LIFE-SPAN AND MAINTENANCE. THE BELOW SCREW’ SPEED IS ADJUSTABLE TO REGULATE THE PRODUCTION CAPACITY. THE VACUUM CHAMBER HAS A VISION GLASS TO WATCH THE INNER, THE VACUUM METER TESTS THE VACUUM DEGREE. THE HEATER INSIDE THE OUTLET ADOPT AUTOMATIC TEMPERATURE CONTROL SYSTEM. THE JACKETS OF THE ABOVE AND BELOW BARRELS ARE CONNECTED TO A CIRCULATING WATER SOURCE.

1. TYPE: XS-1000

2. CAPACITY: 1000 TO 1500 KG/HR

3. DIAMETER OF SCREW: Φ230mm

4. SPEED: TOP 15; BOTTOM: 12 TO 18

5. POWER: TOP: 11 KW; BOTTOM: 15 KW

6. DIMENSION: 4350 × 1200 × 2630mm

7. WEIGHT: 4500 KGS

QUANTITY: 1ITEM 026

ELECTRONIC

CUTTING MACHINE

SOAP ELECTRONIC CUTTING MACHINE IS USED TO CUT SOAPS INTO CAKES AND STAMP PATTERNS ON THE SOAP. ADOPT DELTA SERVO MOTOR AND CONVERTER, VOLTAGE STABILIZER AND PRECISION PURIFIED AC VOLTAGE STABILIZER, TO PROTECT MOTOR AND ELECTRICAL COMPONENTS AND TO KEEP HIGH ACCURACY.

THE MOULD WHEELS RUN BY THE MOVING OF SOAP BAR FROM VACUUM PLODDER. BECAUSE OF THE ELECTRONIC TRACKING SYSTEM, IT CAN CUT SOAP BARS WITH ANY SIZES AND WEIGHT AFTER SETTING THE COMPUTER.

THE CHARACTERS AND THE SHAPE OF SOAP IS CLEAR AND NEAT

THE SIZE AND PATTERN ARE DESIGNED ACCORDING TO CUSTOMERS’ REQUIREMENTS

1. SIZE AND WEIGHT: ADJUSTED BY CUSTOMER’S REQUIREMENTS

2. POWER: 2 KW, 380 V, 50 HZ

3. CAPACITY: IN STEP OF VACUUM PLODDER

4. MOULD: WITH ONE SET

5. DIMENSION: 1000 × 400 × 1200mm

6. WEIGHT: 100 KGS

WOODEN CASE

QUANTITY: 1ITEM 027

CONVEYORS

APPEARANCE IS GOOD AND OPERATION IS STABLE, NON-NOISE AND ANTI-DUST

MOTOR: 1.1 TO 1.5 KW/PCS

QUANTITY: 4ITEM 028

VACUUM PUMP

FOR VACUUM PLODDER

POWER: 2.35 KW

QUANTITY: 15. OTHERS

ITEM 029

EQUIPMENT SUPPORT, OPERATING PLATFORM, LADDER, ETC.

USED IN CARBURATION POOL, SAPONIFICATION CAULDRONS, AND VACUUM SYSTEM

QUANTITY: 1ITEM 030

DISTRIBUTION BOX

CONTROL MACHINES, BIG BRAND ELECTRICAL COMPONENTS

WOODEN CASE

QUANTITY: 46. ADDITIONAL MACHINES AND SPARE PARTS

ITEM 031

ELECTRICAL CABLES

ALL WIRES FROM EACH MACHINE TO THE FOUR DISTRIBUTION BOXES. THE MAIN WIRE FROM THE FOUR DISTRIBUTION BOXES TO THE MAIN DISTRIBUTION BOX AND SLEEVES ARE NOT INCLUDED

QUANTITY: 1ITEM 032

HEAT INSULATING MATERIAL

ABOUT 450 M3, INCLUDING GALVANIZED SHEET 450 M3. GLASS WOOL CLOTH, NAILS

QUANTITY: 1ITEM 033

WELDING ROD

ABOUT 50 BOXES, 1 TON.

QUANTITY: 1ITEM 034

STEAM BOILER

MATERIAL: DIESEL OIL.

RATED POWER: 2000 KG/H

RATED PRESSURE: 1.25 MPA

RATED STEAM TEMPERATURE: 194 ℃

THE QUOTATION IS FOR ONE WHOLE SET OF BOILER, INCLUDING THE STEAM BOILER, WATER TREATMENT EQUIPMENTS, WATER BOXES, OIL BOXES, PUMPS, AND SOME SPARE PARTS

THE QUOTATION INCLUDES SALARY OF BOILER ENGINEER'S INSTALLATING AND TESTING

THE AIR TICKET AND ACCOMMODATION ARE NOT INCLUDED

LOADED BY A 40 'GP CONTAINER

QUANTITY: 1QUANTITY: 1 PLANT

Learn More -

K-0713 RIETER COTTON COMBING PLANT 2002REFERENCE NUMBER: K- 0713 RIETER COTTON COMBING PLANT 2002 1 X RIETER UNILAP MODEL: E32 5 X RIETER HIGH SPEED COMBING MACHINES MODEL: E62 YEAR: 2002 8 X COMBING HEADS/POSITIONS PER MACHINE COILER (CAN) SIZE: 24" X 48" AUTOMATIC CAN CHANGER INDIVIDUAL SUCTION WITH 6 TROLLIES FOR SPOOLS INCLUDING LAP TRANSPORT TROLLEYS AND SPOOLS EXCELLENT CONDITION STILL ERECTED ON MILLS FLOOR AND CONNECTED TO POWER TEST RUN WITHOUT MATERIAL IS POSSIBLE QUANTITY AVAILABLE: 1 Learn More

K-0713 RIETER COTTON COMBING PLANT 2002REFERENCE NUMBER: K- 0713 RIETER COTTON COMBING PLANT 2002 1 X RIETER UNILAP MODEL: E32 5 X RIETER HIGH SPEED COMBING MACHINES MODEL: E62 YEAR: 2002 8 X COMBING HEADS/POSITIONS PER MACHINE COILER (CAN) SIZE: 24" X 48" AUTOMATIC CAN CHANGER INDIVIDUAL SUCTION WITH 6 TROLLIES FOR SPOOLS INCLUDING LAP TRANSPORT TROLLEYS AND SPOOLS EXCELLENT CONDITION STILL ERECTED ON MILLS FLOOR AND CONNECTED TO POWER TEST RUN WITHOUT MATERIAL IS POSSIBLE QUANTITY AVAILABLE: 1 Learn More -

P-1813 BRAZZOLI H.T. SATURNO LUFT HTF DYEING MACHINE YEAR 2002 400KGREFERENCE NUMBER: P-1813 BRAZZOLI H.T. SATURNO LUFT HTF DYEING MACHINE YEAR 2002 400KG BRAZZOLI MODEL: H.T. DYEING MACHINE TYPE: SATURNO LUFT HTF FOR TERRY TOWEL FABRICS YEAR: 2002 CAPACITY: 400 KILOGRAMS EACH MACHINE TEHSE MACHINES CAN ALSO BE OPERATED COUPLED TO DYE ONE LOT OF 800 KILOGRAMS SUPPLIED WITH MAIN MOTOR AND PUMP AUTOMATIC VALVES FOR STEAM AND WATER FUNCTIONS ADD TANK + DOSING PUMP ELECTRICAL PANEL WITH MICROPROCESSOR CONTROLS TEST RUN POSSIBLE, SINCE THE UNITS ARE STILL FULLY CONNECTED TO THE ELECTRICITY, STEAM, WATER, ETC QUANTITY AVAILABLE: 2 Learn More

P-1813 BRAZZOLI H.T. SATURNO LUFT HTF DYEING MACHINE YEAR 2002 400KGREFERENCE NUMBER: P-1813 BRAZZOLI H.T. SATURNO LUFT HTF DYEING MACHINE YEAR 2002 400KG BRAZZOLI MODEL: H.T. DYEING MACHINE TYPE: SATURNO LUFT HTF FOR TERRY TOWEL FABRICS YEAR: 2002 CAPACITY: 400 KILOGRAMS EACH MACHINE TEHSE MACHINES CAN ALSO BE OPERATED COUPLED TO DYE ONE LOT OF 800 KILOGRAMS SUPPLIED WITH MAIN MOTOR AND PUMP AUTOMATIC VALVES FOR STEAM AND WATER FUNCTIONS ADD TANK + DOSING PUMP ELECTRICAL PANEL WITH MICROPROCESSOR CONTROLS TEST RUN POSSIBLE, SINCE THE UNITS ARE STILL FULLY CONNECTED TO THE ELECTRICITY, STEAM, WATER, ETC QUANTITY AVAILABLE: 2 Learn More -

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HRREFERENCE NUMBER: K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1

Learn More