Search results for: 'die cut'

- Related search terms

- Cutting ma

- cut f

- cutti'

- CUTTING S

- CUTTING+S'

-

L-2532 POLYETHYLENE FOAM PLANK PRODUCTION LINE MODEL 180 1000 TO 2000mm WIDTH 2 TO 18mm THICKNESS

L-2532 POLYETHYLENE FOAM PLANK PRODUCTION LINE MODEL 180 1000 TO 2000mm WIDTH 2 TO 18mm THICKNESSREFERENCE NUMBER: L-2532

Learn More

MODEL: 180

1000 TO 2000mm WIDTH -

C-4227 EREMA RM120TVE FILM/FIBER PELLETIZING LINE, EXTRUDER 120mm, YEAR 2000 - NEW

C-4227 EREMA RM120TVE FILM/FIBER PELLETIZING LINE, EXTRUDER 120mm, YEAR 2000 - NEWC-4227 EREMA RM120TVE FILM/FIBER PELLETIZING LINE, EXTRUDER 120mm, YEAR 2000 - NEW

EREMA PELLETIZING LINE NEW

MODEL: RM120TVE FILM/FIBER

YEAR: 2000

LINE CONSISTS OF THE FOLLOWING:

EREMA MODEL RM120TVE

120mm EXTRUDER WITH 36/1 L/D DOUBLE VENTED BARREL

EXTRUDER IS DRIVEN BY A 160KW AC MOTOR WITH INVERTER

DOUBLE VENT INCLUDES A STAINLESS STEEL DEKER VACUUM PUMP

APPROXIMATELY 50 CUBIC FOOT STAINLESS STEEL CUTTER/COMPACTOR MOUNTED AT FEED SECTION

AND FED BY A 35″ WIDE X 20′ LONG INCLINED BELT CONVEYOR

CUTTER COMPACTOR DRIVEN BY A 105 KW

480 VOLT AC MOTORQUANTITY: 1 LINE

Learn More -

R-8294 POLIN DROP DEPOSITOR WIRE-CUTTER BISCUIT MACHINE, YEAR 1995

R-8294 POLIN DROP DEPOSITOR WIRE-CUTTER BISCUIT MACHINE, YEAR 1995DROP DEPOSITOR WIRE-CUTTER

Learn More

MANUFACTURER: POLIN

MODEL: MD-390

YEAR: +- 1995

MANUAL: INCLUDED WIRE DIAGRAM

WEIGHT: 320 KG

DIMENSIONS: 600 X 660 X 800mm

TRAY SIZE: 400 TO460mm

ELECTRICAL: 380 VOLT 3 PHASE

NEUTRAL

EARTH

1.6 KW

NEW ELECTRONICS

NEW PLC

WITH TOUCH SCREEN

1X SET OF PLAIN NOZZLES

1X WIRE CUTTER + WIRE CUTTING DEVICE

1X DIE FOR SQUARE BISCUITS

QUANTITY: 1 -

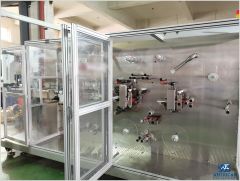

M-5138 SQUARE COTTON PAD PRODUCTION MACHINEREFERENCE NUMBER: M-5138 (12121745V11UX) L SQUARE COTTON PAD PRODUCTION MACHINE MODEL: XF SPEED: 1800 TO 3000 PCS/MINUTE PRODUCT SIZE: WIDTH: 40 TO 100mm, LENGTH 40 TO 100mm RAW MATERIAL SIZE: 1000mm, DIAMETER LESS THAN 1000mm POWER: 380V FREQUENCY: 50 HZ TOTAL POWER: 4.5KW DIMENSION: LENGTH: 2500mm, WIDTH: 1900mm, HEIGHT: 1600mm WEIGHT: 2500KG QUANTITY AVAILABLE: 1 Learn More

M-5138 SQUARE COTTON PAD PRODUCTION MACHINEREFERENCE NUMBER: M-5138 (12121745V11UX) L SQUARE COTTON PAD PRODUCTION MACHINE MODEL: XF SPEED: 1800 TO 3000 PCS/MINUTE PRODUCT SIZE: WIDTH: 40 TO 100mm, LENGTH 40 TO 100mm RAW MATERIAL SIZE: 1000mm, DIAMETER LESS THAN 1000mm POWER: 380V FREQUENCY: 50 HZ TOTAL POWER: 4.5KW DIMENSION: LENGTH: 2500mm, WIDTH: 1900mm, HEIGHT: 1600mm WEIGHT: 2500KG QUANTITY AVAILABLE: 1 Learn More -

J-4641 WOUND DRESSING MANUFACTURING AND PACKING LINE, WORKING WIDTH 100mmJ-4641 WOUND DRESSING MANUFACTURING AND PACKING LINE, WORKING WIDTH 100mm QUANTITY: 1 Learn More

J-4641 WOUND DRESSING MANUFACTURING AND PACKING LINE, WORKING WIDTH 100mmJ-4641 WOUND DRESSING MANUFACTURING AND PACKING LINE, WORKING WIDTH 100mm QUANTITY: 1 Learn More -

M-0630 SIMA PROMATECH EXTRUSION LINEREFERENCE NUMBER: M-0630 SIMA PROMATECH EXTRUSION LINE EXTRUSION LINE MADE BY SIMA/PROMATECH AND ESSENTIALLY CONSISTING OF: EXTRUDER 130mm DIAMETER AUTOSCREEN GEAR PUMP DIE 1700mm CHILL ROLL DIAMETER: 450 X 1800 AND AIR KNIFE CUTTING UNIT FIRST GODET, 3 ROLLS, DIAMETER 315 X 1650mm, PLUS 1 NIP ROLL STRETCHING OVEN 5000 X 1600 SECOND GODET, 6 ROLLS, DIAMETER 315 X 1650mm, PLUS 2 NIP ROLLS FIBRILLATOR UNIT ANNEALING GODET, 9 ROLLS + NIP ROLL CENTRAL CABINET HOT OIL EQUIPMENT FOR ANNEALING GODET WASTE SUCTION EQUIPMENT AS NEW QUANTITY AVAILABLE: 1 Learn More

M-0630 SIMA PROMATECH EXTRUSION LINEREFERENCE NUMBER: M-0630 SIMA PROMATECH EXTRUSION LINE EXTRUSION LINE MADE BY SIMA/PROMATECH AND ESSENTIALLY CONSISTING OF: EXTRUDER 130mm DIAMETER AUTOSCREEN GEAR PUMP DIE 1700mm CHILL ROLL DIAMETER: 450 X 1800 AND AIR KNIFE CUTTING UNIT FIRST GODET, 3 ROLLS, DIAMETER 315 X 1650mm, PLUS 1 NIP ROLL STRETCHING OVEN 5000 X 1600 SECOND GODET, 6 ROLLS, DIAMETER 315 X 1650mm, PLUS 2 NIP ROLLS FIBRILLATOR UNIT ANNEALING GODET, 9 ROLLS + NIP ROLL CENTRAL CABINET HOT OIL EQUIPMENT FOR ANNEALING GODET WASTE SUCTION EQUIPMENT AS NEW QUANTITY AVAILABLE: 1 Learn More -

TT-5555 EREMA INTAREMA 1714 TVEPLUS COMPLETE RECYCLING PLANT, YEAR 2017, 50HzTT-5555 EREMA INTAREMA 1714 TVEPLUS COMPLETE RECYCLING PLANT, YEAR 2017, 50Hz COMPLETE RECYCLING EREMA INTAREMA 1714 TVEPLUS YEAR 2017 AND WAS STARTED UP FOR THE FIRST TIME IN 2018 TYPE SELLING BRAND EREMA MODEL INTAREMA 1714 SINCE YEAR 2017 QUANTITY: 1 Learn More

TT-5555 EREMA INTAREMA 1714 TVEPLUS COMPLETE RECYCLING PLANT, YEAR 2017, 50HzTT-5555 EREMA INTAREMA 1714 TVEPLUS COMPLETE RECYCLING PLANT, YEAR 2017, 50Hz COMPLETE RECYCLING EREMA INTAREMA 1714 TVEPLUS YEAR 2017 AND WAS STARTED UP FOR THE FIRST TIME IN 2018 TYPE SELLING BRAND EREMA MODEL INTAREMA 1714 SINCE YEAR 2017 QUANTITY: 1 Learn More -

J-4678 AUTOMATIC HIGH SPEED COTTON PAD MACHINE (HOT MELT TYPE) -700 TO 1000 PIECES PER MINUTEJ-4678 AUTOMATIC HIGH SPEED COTTON PAD MACHINE (HOT MELT TYPE) -700 TO 1000 PIECES PER MINUTE AUTOMATIC MACHINE FROM RAW MATERIAL FEEDING TO FINISHED PRODUCTS. PRODUCT SHAPE CAN BE CUSTOMIZED ACCORDING TO CUSTOMER NEEDS. ONE MACHINE CAN BE USED FOR A VARIETY OF MOLDS. AUTOMATICALLY COLLECTS MATERIALS INTO ROLLS. PLC CONTROL CAN SET THE NUMBER OF EACH STACK. MACHINE INCLUDES 2 LAYERS TENSION CONTROLLER AND SERVO RECTIFYING CONTROLLER MATERIAL RACKS. MACHINE CAN BE SET TO STACK 100 PIECES PER STACK. QUANTITY: 1 Learn More

J-4678 AUTOMATIC HIGH SPEED COTTON PAD MACHINE (HOT MELT TYPE) -700 TO 1000 PIECES PER MINUTEJ-4678 AUTOMATIC HIGH SPEED COTTON PAD MACHINE (HOT MELT TYPE) -700 TO 1000 PIECES PER MINUTE AUTOMATIC MACHINE FROM RAW MATERIAL FEEDING TO FINISHED PRODUCTS. PRODUCT SHAPE CAN BE CUSTOMIZED ACCORDING TO CUSTOMER NEEDS. ONE MACHINE CAN BE USED FOR A VARIETY OF MOLDS. AUTOMATICALLY COLLECTS MATERIALS INTO ROLLS. PLC CONTROL CAN SET THE NUMBER OF EACH STACK. MACHINE INCLUDES 2 LAYERS TENSION CONTROLLER AND SERVO RECTIFYING CONTROLLER MATERIAL RACKS. MACHINE CAN BE SET TO STACK 100 PIECES PER STACK. QUANTITY: 1 Learn More -

M-4566 THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm)REFERENCE NUMBER: M-4566 (1111225RSJ10U) L THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm) YEAR: 2005 TYPE: HM59-SD3 MATR: 404/04 ROLL FACE: 2600mm (102”) WORKING WIDTH: 2400mm (95”) VOLTAGE: 480/3/60 CONTROL VOLTAGE: 110/60 CONSISTING OF: CAROUSEL 3 POSITION LET-OFF, ENTRY ON ACCUMULATOR WITH HOT-WIRE SEAMING DEVICE, 8000 VOLT STATIC ELIMINATOR, PNEUMATICALLY OPERATED FABRIC HOLDING DEVICE FOR TENSION CONTROL, ACCUMULATOR WITH 8-ROLLS UP AND 9-ROLLS DOWN APPROX.. 80-YARD CAPACITY, COMPENSATING ARM ON EXIT SIDE. ROLLS ARE 4” DIA. X 102” FACE ALUMINUM, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. SECOND ACCUMULATOR WITH ROLL CRADLE FOR SECOND SUBSTRATE LET-OFF, ACCUMULATOR WITH 9-ROLLS UP AND 10 ROLLS DOWN, APPROX.. 54 YARD CAPACITY, ROLLS ARE 4’ DIA. X 102” FACE ALUMINUM, INCLUDES 8000 VOLT STATIC ELIMINATOR AND PNEUMATIC FABRIC HOLDING FOR TENSION, PENDULUM TYPE GUIDING DEVICE ON EXIT SIDE, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. OVERHEAD GANTRY WITH ACCESS STAIRS ON RIGHT SIDE OF FIRST ACCUMULATOR, EXTENDS OVER THE EXTRUDER WITH JIB MOUNTED FOR EASE IN REMOVING DIE FROM MACHINE, GUIDING/CENTERING DEVICE MOUNTED ONTO GANTRY FEEDING COATING HEAD. MP ENGINEERING EXTRUDER/APPLICATOR TYPE HM59-SD3, MATR. NO. 402/04, WITH 102” DIE, 98” RUBBER-BELT WITH PNEUMATIC CYLINDERS FOR BELT TENSION AND GUIDING, HEATED CYLINDER BACKING TO DIE, OPERATOR PLATFORM, CONTROLS MOUTNED IN DOOR AND OPERATOR TOUCH SCREEN PANEL. (NOTE: THESE ARE PRESENTLY MOUNTED ON PRODUCTION LINE AND WILL BE REMOVED AND PLACED BACK INTO/ONTO APPLICATOR. 480/3/60 COATEM SISTEMI C.R.L. IMBALLAGIO & HOT MELT EXTRUDER, S/N 50701, TYPE/MODEL CE-200, WITH DIGITAL MICROPROCESSOR AND INVERTER FOR SPEED VARIATION, DESIGNED TO WORK MAINLY WITH POLYESTER, POLYAMIDE AND POLYURETHANE BUT CAN ALSO EXTRUDE ABS, POLYTHENE, POLYPROPYLENE AND ADHESIVES LIKE EVA ADHESIVES. 480/3/60 CONAIR DRYER CD-300, PL-D-196-1, MODEL D03H4101310, S/N 9D0597, 480/3/60, AND HOPPER. THIRD ACCUMULATOR FOR BONDED PRODUCT WITH 6-ROLLS UP AND 7-ROLLS DOWN, APPROX…60-YARD CAPACITY, ROLLS ARE 6” DIA. X 102” FACE ALUMINUM, WITH DRAW-ROLL TENSION DEVICE MOUNTED ONTO EXIT, OVERHEAD CARRIER ROLLS AND FRAMEWORK DELIVERY TO ELECTRIC A-FRAME WINDER WITH 102” FACE LAY-ON ROLL, AND SEMI-AUTOMATIC BATCHER FOR INDIVIDUAL ROLLS, 2-ROLL SURFACE WINDING 102” FACE WIDTH, OVERHEAD CORE FEED, FABRIC CENTERING DEVICE, ELECTRIC SCISSOR CUT-OFF, KICK-OUT TO 2-ROLL BED, OPERATOR PLATFORM AND OPERATOR CONTROLS. ALL MACHINES PRODUCED BY MP CONFORMS TO EEC DIRECTORY 89/392 CEE (CE MARK) TECHNICAL FEATURES OF THE LINE, ACCORDING TO DWG 100-904/1C ROLLERS WIDTH 2600mm WORKING WIDTH 2400mm MAXIMUM DIAMTER OF THE ROLLS OF PU FOAM 1500mm MAXIMUM DIAMETER OF THE UNWOUND ROLLS OF FABRIC 600 ° 1500 MAXIMUM DIAMETER OF THE REWOUND ROLLS 500 ° 1500 (IN CASE YOU ARE REWINDING ROLLS OF FABRIC LAMINATED TO PU FOAM, THE MAXIMUM DIAMETER IS 1750mm) ADJUSTABLE MECHANIC SPEED: 5 TO 50 M/MIN MAIN POWER SUPPLY + NEUTRAL + EARTH 480+N+E/60 V/HZ VOLTAGE ON CONTROL PANELS 110/60 V/HZ INSTALLED POWER FOR MOTORS 22KW INSTALLED POWER FOR IR HEATER 14,25KW INSTALLED POWER TO HEAT THE SLOT-DIE 32KW INSTALLED POWER FOR THE THERMAL OIL HEATING UNIT FOR THE CALENDERING ROLLERS 32,2KW INSTALLED POWER FOR THE CHILLER 12,9KW A.C. MOTORS, DRIVER, ELECTRIC CABLES ARE ACCORDING TO CEI NORMS BACKGEAR ROLLERS, WITH PAINTED SURFACE OR ALUMINUM MADE WITH DIAMETER 100/120/150mm COMPRESSED AIR CONSUMPTION, AT 6 BAR 1500LT/H COOLING WATER CONSUMPTION (WATER MUST HAVE A TEMPERATURE NOT HIGHER THAN 10°C) 5500LT/H ADJUSTABLE TENSION ON THE REWOUND MATERIALS 5 A 35 KG. PAINTING GREEN RAL 6027 E BLUE MARINE RAL 5021 A.C. MOTORS CONTROL THE SPEED OF THE MACHINES, AND ARE AUTOMATICALLY SYNCHRONISED THROUGH ELECTRONIC DRIVES (INVERTER) AND PNEUMATIC DANCER UNITS (COMPENSTAORS) ESTRUDER: CAPACITY UP TO 200 KG/H (DEPENDING ON THE VISCOSITY OF THE ADHESIVE TO BE EXTRUDED) POWER OF THE MOTOR AND RESISTANCES: 90KW MAXIMUM MELTING TEMPERATURE: 220°C MATERIALS TO BE PROCESSED NONWOVENS 30:150 GR/M2 SYNTHETIC AND NATURAL FABRICS (EXCLUDING STRETCHY FABRICS) WITH WEIGHT 100:600 GR/M2 SCRIMS FOR BACKING FABRIC WITH WEIGHT 70:120 G/M2 MAXIMUM THICKNESS OF PU FOAM 15mm MINIMUM THICKNESS OF PU FOAM 2mm DENSITY OF PU FOAM 22/40 KG/M3 THERMOPLASTIC ADHESIVE TO BE COATED THERMOPLASTIC HOTMELTS (COPOLYAMMIDE, COPOLYESTER, EVA AND POLYURETHANE THERMOPLASTIC HOTMELT GRANULES) DATA REFERRING TO PRODUCTION THE PRODUCTION SPEED CAN CHANGE, DEPENDING ON THE KIND OF HOTMELTS, ON THEIR MELTING TEMPERATURE, ON THEIR VISCOSITY, AND ON THE GRAMS PER SQUARED METER TO BE COATED QUANTITY AVAILABLE: 1 Learn More

M-4566 THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm)REFERENCE NUMBER: M-4566 (1111225RSJ10U) L THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm) YEAR: 2005 TYPE: HM59-SD3 MATR: 404/04 ROLL FACE: 2600mm (102”) WORKING WIDTH: 2400mm (95”) VOLTAGE: 480/3/60 CONTROL VOLTAGE: 110/60 CONSISTING OF: CAROUSEL 3 POSITION LET-OFF, ENTRY ON ACCUMULATOR WITH HOT-WIRE SEAMING DEVICE, 8000 VOLT STATIC ELIMINATOR, PNEUMATICALLY OPERATED FABRIC HOLDING DEVICE FOR TENSION CONTROL, ACCUMULATOR WITH 8-ROLLS UP AND 9-ROLLS DOWN APPROX.. 80-YARD CAPACITY, COMPENSATING ARM ON EXIT SIDE. ROLLS ARE 4” DIA. X 102” FACE ALUMINUM, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. SECOND ACCUMULATOR WITH ROLL CRADLE FOR SECOND SUBSTRATE LET-OFF, ACCUMULATOR WITH 9-ROLLS UP AND 10 ROLLS DOWN, APPROX.. 54 YARD CAPACITY, ROLLS ARE 4’ DIA. X 102” FACE ALUMINUM, INCLUDES 8000 VOLT STATIC ELIMINATOR AND PNEUMATIC FABRIC HOLDING FOR TENSION, PENDULUM TYPE GUIDING DEVICE ON EXIT SIDE, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. OVERHEAD GANTRY WITH ACCESS STAIRS ON RIGHT SIDE OF FIRST ACCUMULATOR, EXTENDS OVER THE EXTRUDER WITH JIB MOUNTED FOR EASE IN REMOVING DIE FROM MACHINE, GUIDING/CENTERING DEVICE MOUNTED ONTO GANTRY FEEDING COATING HEAD. MP ENGINEERING EXTRUDER/APPLICATOR TYPE HM59-SD3, MATR. NO. 402/04, WITH 102” DIE, 98” RUBBER-BELT WITH PNEUMATIC CYLINDERS FOR BELT TENSION AND GUIDING, HEATED CYLINDER BACKING TO DIE, OPERATOR PLATFORM, CONTROLS MOUTNED IN DOOR AND OPERATOR TOUCH SCREEN PANEL. (NOTE: THESE ARE PRESENTLY MOUNTED ON PRODUCTION LINE AND WILL BE REMOVED AND PLACED BACK INTO/ONTO APPLICATOR. 480/3/60 COATEM SISTEMI C.R.L. IMBALLAGIO & HOT MELT EXTRUDER, S/N 50701, TYPE/MODEL CE-200, WITH DIGITAL MICROPROCESSOR AND INVERTER FOR SPEED VARIATION, DESIGNED TO WORK MAINLY WITH POLYESTER, POLYAMIDE AND POLYURETHANE BUT CAN ALSO EXTRUDE ABS, POLYTHENE, POLYPROPYLENE AND ADHESIVES LIKE EVA ADHESIVES. 480/3/60 CONAIR DRYER CD-300, PL-D-196-1, MODEL D03H4101310, S/N 9D0597, 480/3/60, AND HOPPER. THIRD ACCUMULATOR FOR BONDED PRODUCT WITH 6-ROLLS UP AND 7-ROLLS DOWN, APPROX…60-YARD CAPACITY, ROLLS ARE 6” DIA. X 102” FACE ALUMINUM, WITH DRAW-ROLL TENSION DEVICE MOUNTED ONTO EXIT, OVERHEAD CARRIER ROLLS AND FRAMEWORK DELIVERY TO ELECTRIC A-FRAME WINDER WITH 102” FACE LAY-ON ROLL, AND SEMI-AUTOMATIC BATCHER FOR INDIVIDUAL ROLLS, 2-ROLL SURFACE WINDING 102” FACE WIDTH, OVERHEAD CORE FEED, FABRIC CENTERING DEVICE, ELECTRIC SCISSOR CUT-OFF, KICK-OUT TO 2-ROLL BED, OPERATOR PLATFORM AND OPERATOR CONTROLS. ALL MACHINES PRODUCED BY MP CONFORMS TO EEC DIRECTORY 89/392 CEE (CE MARK) TECHNICAL FEATURES OF THE LINE, ACCORDING TO DWG 100-904/1C ROLLERS WIDTH 2600mm WORKING WIDTH 2400mm MAXIMUM DIAMTER OF THE ROLLS OF PU FOAM 1500mm MAXIMUM DIAMETER OF THE UNWOUND ROLLS OF FABRIC 600 ° 1500 MAXIMUM DIAMETER OF THE REWOUND ROLLS 500 ° 1500 (IN CASE YOU ARE REWINDING ROLLS OF FABRIC LAMINATED TO PU FOAM, THE MAXIMUM DIAMETER IS 1750mm) ADJUSTABLE MECHANIC SPEED: 5 TO 50 M/MIN MAIN POWER SUPPLY + NEUTRAL + EARTH 480+N+E/60 V/HZ VOLTAGE ON CONTROL PANELS 110/60 V/HZ INSTALLED POWER FOR MOTORS 22KW INSTALLED POWER FOR IR HEATER 14,25KW INSTALLED POWER TO HEAT THE SLOT-DIE 32KW INSTALLED POWER FOR THE THERMAL OIL HEATING UNIT FOR THE CALENDERING ROLLERS 32,2KW INSTALLED POWER FOR THE CHILLER 12,9KW A.C. MOTORS, DRIVER, ELECTRIC CABLES ARE ACCORDING TO CEI NORMS BACKGEAR ROLLERS, WITH PAINTED SURFACE OR ALUMINUM MADE WITH DIAMETER 100/120/150mm COMPRESSED AIR CONSUMPTION, AT 6 BAR 1500LT/H COOLING WATER CONSUMPTION (WATER MUST HAVE A TEMPERATURE NOT HIGHER THAN 10°C) 5500LT/H ADJUSTABLE TENSION ON THE REWOUND MATERIALS 5 A 35 KG. PAINTING GREEN RAL 6027 E BLUE MARINE RAL 5021 A.C. MOTORS CONTROL THE SPEED OF THE MACHINES, AND ARE AUTOMATICALLY SYNCHRONISED THROUGH ELECTRONIC DRIVES (INVERTER) AND PNEUMATIC DANCER UNITS (COMPENSTAORS) ESTRUDER: CAPACITY UP TO 200 KG/H (DEPENDING ON THE VISCOSITY OF THE ADHESIVE TO BE EXTRUDED) POWER OF THE MOTOR AND RESISTANCES: 90KW MAXIMUM MELTING TEMPERATURE: 220°C MATERIALS TO BE PROCESSED NONWOVENS 30:150 GR/M2 SYNTHETIC AND NATURAL FABRICS (EXCLUDING STRETCHY FABRICS) WITH WEIGHT 100:600 GR/M2 SCRIMS FOR BACKING FABRIC WITH WEIGHT 70:120 G/M2 MAXIMUM THICKNESS OF PU FOAM 15mm MINIMUM THICKNESS OF PU FOAM 2mm DENSITY OF PU FOAM 22/40 KG/M3 THERMOPLASTIC ADHESIVE TO BE COATED THERMOPLASTIC HOTMELTS (COPOLYAMMIDE, COPOLYESTER, EVA AND POLYURETHANE THERMOPLASTIC HOTMELT GRANULES) DATA REFERRING TO PRODUCTION THE PRODUCTION SPEED CAN CHANGE, DEPENDING ON THE KIND OF HOTMELTS, ON THEIR MELTING TEMPERATURE, ON THEIR VISCOSITY, AND ON THE GRAMS PER SQUARED METER TO BE COATED QUANTITY AVAILABLE: 1 Learn More -

TT-3878 POLYSTAR REPRO-FLEX PLUS 165VS (6.5”) TWO-STAGE EXTRUSIONTT-3878 POLYSTAR REPRO-FLEX PLUS 165VS (6.5”) TWO-STAGE EXTRUSION POLYSTAR REPRO-FLEX PLUS 165VS (6.5”) TWO-STAGE EXTRUSION PELLETIZING SYSTEM W/MOST UPGRADE OPTIONS INCLUDING DUAL CONTROL PANELS, NIP ROLL FEEDER, CUTTER/COMPACTOR INVERTER, SIDEFEEDER, PE AND PP DIES, UPGRADED HORIZONTAL WATER RING PELLETIZER, SCREENER, CYCLONE SCALE. QUANTITY: 1 Learn More

TT-3878 POLYSTAR REPRO-FLEX PLUS 165VS (6.5”) TWO-STAGE EXTRUSIONTT-3878 POLYSTAR REPRO-FLEX PLUS 165VS (6.5”) TWO-STAGE EXTRUSION POLYSTAR REPRO-FLEX PLUS 165VS (6.5”) TWO-STAGE EXTRUSION PELLETIZING SYSTEM W/MOST UPGRADE OPTIONS INCLUDING DUAL CONTROL PANELS, NIP ROLL FEEDER, CUTTER/COMPACTOR INVERTER, SIDEFEEDER, PE AND PP DIES, UPGRADED HORIZONTAL WATER RING PELLETIZER, SCREENER, CYCLONE SCALE. QUANTITY: 1 Learn More