Search results for: 'pro 4 pro'

- Related search terms

- Productio

- product'[0]

- Process

- Process+o

- Production+capa'

-

M-0630 SIMA PROMATECH EXTRUSION LINEREFERENCE NUMBER: M-0630 SIMA PROMATECH EXTRUSION LINE EXTRUSION LINE MADE BY SIMA/PROMATECH AND ESSENTIALLY CONSISTING OF: EXTRUDER 130mm DIAMETER AUTOSCREEN GEAR PUMP DIE 1700mm CHILL ROLL DIAMETER: 450 X 1800 AND AIR KNIFE CUTTING UNIT FIRST GODET, 3 ROLLS, DIAMETER 315 X 1650mm, PLUS 1 NIP ROLL STRETCHING OVEN 5000 X 1600 SECOND GODET, 6 ROLLS, DIAMETER 315 X 1650mm, PLUS 2 NIP ROLLS FIBRILLATOR UNIT ANNEALING GODET, 9 ROLLS + NIP ROLL CENTRAL CABINET HOT OIL EQUIPMENT FOR ANNEALING GODET WASTE SUCTION EQUIPMENT AS NEW QUANTITY AVAILABLE: 1 Learn More

M-0630 SIMA PROMATECH EXTRUSION LINEREFERENCE NUMBER: M-0630 SIMA PROMATECH EXTRUSION LINE EXTRUSION LINE MADE BY SIMA/PROMATECH AND ESSENTIALLY CONSISTING OF: EXTRUDER 130mm DIAMETER AUTOSCREEN GEAR PUMP DIE 1700mm CHILL ROLL DIAMETER: 450 X 1800 AND AIR KNIFE CUTTING UNIT FIRST GODET, 3 ROLLS, DIAMETER 315 X 1650mm, PLUS 1 NIP ROLL STRETCHING OVEN 5000 X 1600 SECOND GODET, 6 ROLLS, DIAMETER 315 X 1650mm, PLUS 2 NIP ROLLS FIBRILLATOR UNIT ANNEALING GODET, 9 ROLLS + NIP ROLL CENTRAL CABINET HOT OIL EQUIPMENT FOR ANNEALING GODET WASTE SUCTION EQUIPMENT AS NEW QUANTITY AVAILABLE: 1 Learn More -

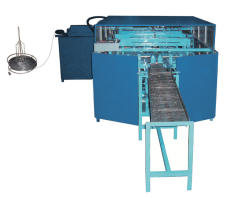

YY-2126 DOUBLE M-SPRING AUTOMATIC CNC GUARD SPRING MACHINE, PRODUCTIVITY 20 TO 25 PCS PER MINUTEYY-2126 DOUBLE M-SPRING AUTOMATIC CNC GUARD SPRING MACHINE, PRODUCTIVITY 20 TO 25 PCS PER MINUTE TECHNICAL PARAMETERS: WIRE GAUGE: 2.8 TO 4.00mm ARM LENGTH: 230 TO 330mm HEIGHT: 130 TO 200mm RING TURN: 1 TO 2 RING DIAMETER: 23 TO 40mm PRODUCTIVITY: 20 TO 25 PCS/MIN MOTOR POWER: 12KW POWER SUPPLY: 380V WEIGHT: 1500KG DOUBLE M EDGE GUARD IS OPTIONAL FOR CUSTOMER QUANTITY: 1 Learn More

YY-2126 DOUBLE M-SPRING AUTOMATIC CNC GUARD SPRING MACHINE, PRODUCTIVITY 20 TO 25 PCS PER MINUTEYY-2126 DOUBLE M-SPRING AUTOMATIC CNC GUARD SPRING MACHINE, PRODUCTIVITY 20 TO 25 PCS PER MINUTE TECHNICAL PARAMETERS: WIRE GAUGE: 2.8 TO 4.00mm ARM LENGTH: 230 TO 330mm HEIGHT: 130 TO 200mm RING TURN: 1 TO 2 RING DIAMETER: 23 TO 40mm PRODUCTIVITY: 20 TO 25 PCS/MIN MOTOR POWER: 12KW POWER SUPPLY: 380V WEIGHT: 1500KG DOUBLE M EDGE GUARD IS OPTIONAL FOR CUSTOMER QUANTITY: 1 Learn More -

P-5077 PROBAT L25 ROASTER 25 KILOS

P-5077 PROBAT L25 ROASTER 25 KILOSP-5077 PROBAT L25 ROASTER 25 KILOS

PROBAT 25 FOLLOWS YEARS OF TRADITION IN BUILDING REALLY TOUGH EASY TO REPAIR TYPE MACHINERY. THIS NEW MODEL IS EVEN MORE FRIENDLY AS IT HAS ELIMINATED ALL THE CHAINS AND BELTS OF YEARS GONE BY . . . AND HOW IS TOTALLY DIRECT DRIVE MOTORS - 4 OF THEM . . . ONE FOR EACH FUNCTION OF THE MACHINE. DON'T FORGET THAT THIS MACHINE IS TALL ENOUGH TO REQUIRE A LOADER AND THIS BASIC MODEL DOES NOT INCLUDE THE LOADER OR A DESTONER OR AN AFTERBURNER . . . AS ALL THESE ITEMS MUST BE ADDED TO THE BASIC MACHINE.

PROFILE EDITION: PLEASE NOTE THAT PROBAT IS OFFERING A PROFILE PACKAGE THAT CAN BE ADDED TO THIS MACHINE.

SPECIFICATIONS:

CAPACITY PER BATCH: 26–55 LBS (11.8–25 KG)

BATCHES PER HOUR: 4

CAPACITY PER HOUR: 220 LBS (100 KG)

NATURAL GAS OR PROPANE: 190,000 BTU / HR

INLET FITTING: ½ INCHES

VOLTAGE: 230 / 460 V

FREQUENCY: 60 HZ

PHASE: 3

MAX. LOAD: 40 / 20 AMPS

DIMENSIONS: 7 FEET 6 INCHES H X 3 FEET 6 INCHES W X 6 FEET D

WEIGHT: 2,500 LBSQUANTITY: 1

Learn More -

L-2176 PROFILE PLUS ROUGHNESS AND POROSITY MACHINE

L-2176 PROFILE PLUS ROUGHNESS AND POROSITY MACHINELIST NUMBER: L-2176

Learn More

PROFILE PLUS ROUGHNESS AND POROSITY MACHINE

WEIGHT: 37 KGS

HEIGHT: 660mm

DEPTH: 460mm

WIDTH: 267mm

QUANTITY: 1 -

M-0428 CATTLE SLAUGHTERING AND PROCESSING EQUIPMENT FOR 200 CATTLES PER DAYREFERENCE NUMBER: M-0428-SHORT VERSION CATTLE SLAUGHTERING AND PROCESSING EQUIPMENT FOR 200 CATTLES PER DAY 200 CATTLES PER DAY QUANTITY AVAILABLE: 1 Learn More

M-0428 CATTLE SLAUGHTERING AND PROCESSING EQUIPMENT FOR 200 CATTLES PER DAYREFERENCE NUMBER: M-0428-SHORT VERSION CATTLE SLAUGHTERING AND PROCESSING EQUIPMENT FOR 200 CATTLES PER DAY 200 CATTLES PER DAY QUANTITY AVAILABLE: 1 Learn More -

TT-7611 KOENIG & BAUER COMET - SC PRESS, YEAR 2010 – FOR PRODUCTION OF MAGAZINES, FLYERS, ETC.TT-7611 KOENIG & BAUER COMET - SC PRESS, YEAR 2010 – FOR PRODUCTION OF MAGAZINES, FLYERS, ETC. 1. KOENIG & BAUER COMET - SC PRESS 2. YEAR 2010 3. 32PP. CUT-OFF 578mm 4. KOENIG & BAUER COMET - SC WITH A HOT AIR DRYER FOR THE PRODUCTION OF MAGAZINES, FLYERS AND BOOK SIGNATURES (IT COMES WITH A KF3 SC SEMI COMMERCIAL VERSION). 5. THE PRESS WAS ONLY RUNNING LESS THAN 17,000 HOURS OF PRODUCTION QUANTITY: 1 Learn More

TT-7611 KOENIG & BAUER COMET - SC PRESS, YEAR 2010 – FOR PRODUCTION OF MAGAZINES, FLYERS, ETC.TT-7611 KOENIG & BAUER COMET - SC PRESS, YEAR 2010 – FOR PRODUCTION OF MAGAZINES, FLYERS, ETC. 1. KOENIG & BAUER COMET - SC PRESS 2. YEAR 2010 3. 32PP. CUT-OFF 578mm 4. KOENIG & BAUER COMET - SC WITH A HOT AIR DRYER FOR THE PRODUCTION OF MAGAZINES, FLYERS AND BOOK SIGNATURES (IT COMES WITH A KF3 SC SEMI COMMERCIAL VERSION). 5. THE PRESS WAS ONLY RUNNING LESS THAN 17,000 HOURS OF PRODUCTION QUANTITY: 1 Learn More -

TT-7525 SUCKER MULLER HACOBA DYEING, SIZING AND WARPING DENIM, WIDTH 1600mm TO 1800mm, YEAR 2003TT-7525 SUCKER MULLER HACOBA DYEING, SIZING AND WARPING DENIM, WIDTH 1600mm TO 1800mm, YEAR 2003 1. SUCKER MULLER HACOBA DYEING, SIZING AND WARPING DENIM 2. YEAR: 2003 3. BRAND: SUCKER MULLER HACOBA 4. DIRECT WARPER 5. 442 POSITIONS 6. 800 RPM 7. WIDTH 1600mm TO 1800mm 8. PLATE DIAMETER: 1400mm (55.1 IN) 9. CYLINDER DIAMETER: 456mm (17.95 IN) 10. MECHANISMS: ENTRY, EXIT Learn More

TT-7525 SUCKER MULLER HACOBA DYEING, SIZING AND WARPING DENIM, WIDTH 1600mm TO 1800mm, YEAR 2003TT-7525 SUCKER MULLER HACOBA DYEING, SIZING AND WARPING DENIM, WIDTH 1600mm TO 1800mm, YEAR 2003 1. SUCKER MULLER HACOBA DYEING, SIZING AND WARPING DENIM 2. YEAR: 2003 3. BRAND: SUCKER MULLER HACOBA 4. DIRECT WARPER 5. 442 POSITIONS 6. 800 RPM 7. WIDTH 1600mm TO 1800mm 8. PLATE DIAMETER: 1400mm (55.1 IN) 9. CYLINDER DIAMETER: 456mm (17.95 IN) 10. MECHANISMS: ENTRY, EXIT Learn More -

TT-7524 SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE, WIDTH 2000mm, YEAR 2003TT-7524 SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE, WIDTH 2000mm, YEAR 2003 1. SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE 2. YEAR: 2003 3. BRAND: SUCKER MULLER HACOBA Learn More

TT-7524 SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE, WIDTH 2000mm, YEAR 2003TT-7524 SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE, WIDTH 2000mm, YEAR 2003 1. SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE 2. YEAR: 2003 3. BRAND: SUCKER MULLER HACOBA Learn More -

INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNITREFERENCE NUMBER: A-2472 INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT MACHINE HAS A HIGH PRODUCTION CAPACITY. IT ALSO ENABLES EASY MONITORING AND MANAGEMENT OF ALL PARAMETERS THAT ARE EFFECTIVE IN THE PRODUCTION OF NANOFIBERS. FOR THE COMMERCIAL PRODUCTION, REPEATABLE PRODUCTION OF MATERIALS IN UNIFORM AND SPECIFIC STANDARDS HAS THE HIGHEST IMPORTANCE. MACHINE IS EQUIPPED WITH 132 ELECTROSPINNING NEEDLES AND A HOMOGENIZATION SYSTEM, ALLOWING THE SURFACE TO BE UNIFORMLY AND CONTINUOUSLY AT A WIDTH OF 1 METER. BECAUSE OF ITS ADVANCED AUTOMATION SYSTEM AND THE AIR CONDITIONING EQUIPMENT, IT ENABLES CONTINUOUS PRODUCTION AT THE HIGHEST SET QUALITY EVEN UNDER CHANGING ENVIRONMENTAL CONDITIONS. SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATIC PAINTED SHEET METAL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX. 600 KGS DIMENSIONS: 3650 x 1950 X 1940 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: IN THE SPINNERET 0-(+)60 KV VOLTAGE PRECISION: 0.1 KV MAXIMUM CURRENT: 3 MA PUMP SYSTEM FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML CONTINUES FEEDING PUMP SYSTEM FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 33 PCS NUMBER OF FEEDING PIPE SETS: 4 PCS NUMBER OF NOZZLES: 132 PCS SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: STANDARD NOZZLE: 0.8 mm (DIFFERENT DIAMETERS CAN BE USED) MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 3 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 25 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 150 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 50 mm TO 350 mm DISTANCE ADJUSTMENT PRECISION: 1 mm COLLECTOR ROLL TO ROLL COLLECTOR FIBER DEPOSITION WIDTH: 1000 mm SUBSTRATE WINDING SPEED: MAX. 0,1 M/ min TO MIN. 10 M/ min COATING HOMOGENEITY SYSTEM: X-AXIS STROKE OF COATING HOMOGENEITY SYSTEM: 30 mm TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm/SEC UNIQUE USER INTERFACE 12” TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 Hz @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 5000 X 3000 mm Learn More

INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNITREFERENCE NUMBER: A-2472 INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT MACHINE HAS A HIGH PRODUCTION CAPACITY. IT ALSO ENABLES EASY MONITORING AND MANAGEMENT OF ALL PARAMETERS THAT ARE EFFECTIVE IN THE PRODUCTION OF NANOFIBERS. FOR THE COMMERCIAL PRODUCTION, REPEATABLE PRODUCTION OF MATERIALS IN UNIFORM AND SPECIFIC STANDARDS HAS THE HIGHEST IMPORTANCE. MACHINE IS EQUIPPED WITH 132 ELECTROSPINNING NEEDLES AND A HOMOGENIZATION SYSTEM, ALLOWING THE SURFACE TO BE UNIFORMLY AND CONTINUOUSLY AT A WIDTH OF 1 METER. BECAUSE OF ITS ADVANCED AUTOMATION SYSTEM AND THE AIR CONDITIONING EQUIPMENT, IT ENABLES CONTINUOUS PRODUCTION AT THE HIGHEST SET QUALITY EVEN UNDER CHANGING ENVIRONMENTAL CONDITIONS. SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATIC PAINTED SHEET METAL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX. 600 KGS DIMENSIONS: 3650 x 1950 X 1940 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: IN THE SPINNERET 0-(+)60 KV VOLTAGE PRECISION: 0.1 KV MAXIMUM CURRENT: 3 MA PUMP SYSTEM FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML CONTINUES FEEDING PUMP SYSTEM FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 33 PCS NUMBER OF FEEDING PIPE SETS: 4 PCS NUMBER OF NOZZLES: 132 PCS SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: STANDARD NOZZLE: 0.8 mm (DIFFERENT DIAMETERS CAN BE USED) MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 3 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 25 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 150 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 50 mm TO 350 mm DISTANCE ADJUSTMENT PRECISION: 1 mm COLLECTOR ROLL TO ROLL COLLECTOR FIBER DEPOSITION WIDTH: 1000 mm SUBSTRATE WINDING SPEED: MAX. 0,1 M/ min TO MIN. 10 M/ min COATING HOMOGENEITY SYSTEM: X-AXIS STROKE OF COATING HOMOGENEITY SYSTEM: 30 mm TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm/SEC UNIQUE USER INTERFACE 12” TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 Hz @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 5000 X 3000 mm Learn More -

TT-6483 BELL & HOWELL GUNTHER EP-4000 LARGE FORMAT MAILING SYSTEM, 10 X 13, YEAR 2017TT-6483 BELL & HOWELL GUNTHER EP-4000 LARGE FORMAT MAILING SYSTEM, 10 X 13, YEAR 2017 1. BELL & HOWELL GUNTHER EP-4000 LARGE FORMAT MAILING SYSTEM 2. YEAR 2017 3. 10 X 13 SCANNING INPUT ONE FEEDER HAS A SCANNER FOR MATCHING STITCHER ASSEMBLY LOW COUNTS, 4. THIS SYSTEM WAS ACQUIRED PRIOR TO COVID 19 AND HAS NEVER BEEN RE-INSTALLED QUANTITY: 1 Learn More

TT-6483 BELL & HOWELL GUNTHER EP-4000 LARGE FORMAT MAILING SYSTEM, 10 X 13, YEAR 2017TT-6483 BELL & HOWELL GUNTHER EP-4000 LARGE FORMAT MAILING SYSTEM, 10 X 13, YEAR 2017 1. BELL & HOWELL GUNTHER EP-4000 LARGE FORMAT MAILING SYSTEM 2. YEAR 2017 3. 10 X 13 SCANNING INPUT ONE FEEDER HAS A SCANNER FOR MATCHING STITCHER ASSEMBLY LOW COUNTS, 4. THIS SYSTEM WAS ACQUIRED PRIOR TO COVID 19 AND HAS NEVER BEEN RE-INSTALLED QUANTITY: 1 Learn More