Search results for: 'two f'

- Related search terms

- two

- two fo

- two for o

- Two for one t

- Two for one tw

-

YY-1499 AUTOMATIC BAR TACKING SEWING MACHINEYY-1499 AUTOMATIC BAR TACKING SEWING MACHINE DIFFERENT PATTERNS CAN BE DESIGNED WITH THE SOFTWARE. FAST WORKING SPEED, 5 SECONDS TO FINISH ONE TACKING. Learn More

YY-1499 AUTOMATIC BAR TACKING SEWING MACHINEYY-1499 AUTOMATIC BAR TACKING SEWING MACHINE DIFFERENT PATTERNS CAN BE DESIGNED WITH THE SOFTWARE. FAST WORKING SPEED, 5 SECONDS TO FINISH ONE TACKING. Learn More -

SEMI INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT - 18 NOZZLESREFERENCE NUMBER: A-2474 SEMI INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT - 18 NOZZLES MACHINE IS A COMPACT CONTINUOUS NANOFIBER PRODUCTION MACHINE. ITS MAJOR ADVANTAGE IS SCALABILITY, AS IT’S SUITABLE FOR BOTH PRODUCTION LINE AS WELL AS R&D PROJECTS. IT FUNCTIONS WITH 18 NOZZLES ENABLING HIGH PRODUCTIVITY FOR MASS PRODUCTION OF NANOFIBERS, HOWEVER IT CAN ALSO FUNCTION WITH SINGLE NOZZLE THEREFORE ENABLES WORKING ON SMALL-SCALE R&D PROJECTS. ITS UNIQUE DESIGN ENABLES PRODUCTION OF NANOFIBERS AND COMPOSITES, IT ACCOMMODATES TWO SYRINGE PUMPS AND TWO HIGH VOLTAGE POWER SUPPLIERS, MAKING IT POSSIBLE TO WORK SIMULTANEOUSLY WITH UP TO TWO DIFFERENT POLYMERS, INDEPENDENTLY CONTROLLABLE SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATIC PAINTED SHEET METAL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX. 350 KGS DIMENSIONS: 1585 X 1550 X 1950 mm HIGH VOLTAGE POWER SUPPLY NUMBER OF HV GENERATORS: 2 UNITS (1 FOR EACH SOLUTION FEEDING ROD) VOLTAGE RANGE: 0 TO 40 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.125 MA HIGH PRECISION MICRO PUMP NUMBER OF PUMPS: 2 UNITS FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML AVAILABLE SYRINGES: ALL TYPES ARE AVAILABLE FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 9 PCS NUMBER OF FEEDING PIPE SETS: 2 PCS NUMBER OF NOZZLES: 18 PCS SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: 0.8 mm MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 2 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 8 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 18 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 30 TO 280 mm DISTANCE ADJUSTMENT PRECISION: 1 mm COLLECTOR ROLL TO ROLL COLLECTOR FIBER DEPOSITION WIDTH: 300 mm SUBSTRATE WINDING SPEED: 0,01 M/MIN TO 1 M/min REPETITIVE WINDING MODE (OPTIONAL) COATING HOMOGENEITY SYSTEM: X-AXIS REPETITIVE MOTION STROKE OF COATING HOMOGENEITY SYSTEM: 10 MM TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm/SEC UNIQUE USER INTERFACE 9" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 2000 X 2000 mm Learn More

SEMI INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT - 18 NOZZLESREFERENCE NUMBER: A-2474 SEMI INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT - 18 NOZZLES MACHINE IS A COMPACT CONTINUOUS NANOFIBER PRODUCTION MACHINE. ITS MAJOR ADVANTAGE IS SCALABILITY, AS IT’S SUITABLE FOR BOTH PRODUCTION LINE AS WELL AS R&D PROJECTS. IT FUNCTIONS WITH 18 NOZZLES ENABLING HIGH PRODUCTIVITY FOR MASS PRODUCTION OF NANOFIBERS, HOWEVER IT CAN ALSO FUNCTION WITH SINGLE NOZZLE THEREFORE ENABLES WORKING ON SMALL-SCALE R&D PROJECTS. ITS UNIQUE DESIGN ENABLES PRODUCTION OF NANOFIBERS AND COMPOSITES, IT ACCOMMODATES TWO SYRINGE PUMPS AND TWO HIGH VOLTAGE POWER SUPPLIERS, MAKING IT POSSIBLE TO WORK SIMULTANEOUSLY WITH UP TO TWO DIFFERENT POLYMERS, INDEPENDENTLY CONTROLLABLE SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATIC PAINTED SHEET METAL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX. 350 KGS DIMENSIONS: 1585 X 1550 X 1950 mm HIGH VOLTAGE POWER SUPPLY NUMBER OF HV GENERATORS: 2 UNITS (1 FOR EACH SOLUTION FEEDING ROD) VOLTAGE RANGE: 0 TO 40 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.125 MA HIGH PRECISION MICRO PUMP NUMBER OF PUMPS: 2 UNITS FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML AVAILABLE SYRINGES: ALL TYPES ARE AVAILABLE FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 9 PCS NUMBER OF FEEDING PIPE SETS: 2 PCS NUMBER OF NOZZLES: 18 PCS SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: 0.8 mm MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 2 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 8 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 18 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 30 TO 280 mm DISTANCE ADJUSTMENT PRECISION: 1 mm COLLECTOR ROLL TO ROLL COLLECTOR FIBER DEPOSITION WIDTH: 300 mm SUBSTRATE WINDING SPEED: 0,01 M/MIN TO 1 M/min REPETITIVE WINDING MODE (OPTIONAL) COATING HOMOGENEITY SYSTEM: X-AXIS REPETITIVE MOTION STROKE OF COATING HOMOGENEITY SYSTEM: 10 MM TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm/SEC UNIQUE USER INTERFACE 9" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 2000 X 2000 mm Learn More -

FULLY AUTOMATIC MASK MACHINEREFERENCE NUMBER: P-8845 FULLY AUTOMATIC MASK MACHINE THIS EQUIPMENT IS A FULL-AUTOMATIC ONE-TIME PLANE MASK FORMING MACHINE, WHICH IS USED FOR THE FORMING OF ONE-TIME RECTANGULAR EAR HANGING THREE DRAWER MASKS. ONE MAIN MACHINE IS EQUIPPED WITH TWO EAR BELT SPOT WELDING MACHINES (ONE FOR TWO). THE DRIVING MOTOR IS SERVO MOTOR, SO IT HAS THE ADVANTAGES OF HIGH RELIABILITY, EASY OPERATION, ACCURATE TRANSMISSION, STABLE CONTROL, ADJUSTABLE SPEED, LOW COST AND CONVENIENT MAINTENANCE, ESPECIALLY SUITABLE FOR THE PRODUCTION OF HIGH-QUALITY MASKS. SPECIFICATIONS TEMPERATURE: 10 TO 350, HUMIDITY 5 TO 35%, NO FLAMMABILITY AND NONCORROSIVE GAS VOLTAGE: 220V POWER FREQUENCY: 50Hz PER 60Hz TOTAL POWER OF EQUIPMENT: 8.5KW ULTRASONIC FREQUENCY: 5 TO 20KHz MAX FEEDING WITH OVERALL DIMENSION OF EQUIPMENT: 6100 x 3300 x 1800 MACHINE WEIGHT: 2 TONS PRODUCTION EFFICIENCY: 80 TO 120 TABLETS PER MIN (EACH WORKING STATION 60 PCS PER MIN, AS WE HAVE TWO WORKING STATION). OPERATOR: 1 PERSON QUANTITY: 1 Learn More

FULLY AUTOMATIC MASK MACHINEREFERENCE NUMBER: P-8845 FULLY AUTOMATIC MASK MACHINE THIS EQUIPMENT IS A FULL-AUTOMATIC ONE-TIME PLANE MASK FORMING MACHINE, WHICH IS USED FOR THE FORMING OF ONE-TIME RECTANGULAR EAR HANGING THREE DRAWER MASKS. ONE MAIN MACHINE IS EQUIPPED WITH TWO EAR BELT SPOT WELDING MACHINES (ONE FOR TWO). THE DRIVING MOTOR IS SERVO MOTOR, SO IT HAS THE ADVANTAGES OF HIGH RELIABILITY, EASY OPERATION, ACCURATE TRANSMISSION, STABLE CONTROL, ADJUSTABLE SPEED, LOW COST AND CONVENIENT MAINTENANCE, ESPECIALLY SUITABLE FOR THE PRODUCTION OF HIGH-QUALITY MASKS. SPECIFICATIONS TEMPERATURE: 10 TO 350, HUMIDITY 5 TO 35%, NO FLAMMABILITY AND NONCORROSIVE GAS VOLTAGE: 220V POWER FREQUENCY: 50Hz PER 60Hz TOTAL POWER OF EQUIPMENT: 8.5KW ULTRASONIC FREQUENCY: 5 TO 20KHz MAX FEEDING WITH OVERALL DIMENSION OF EQUIPMENT: 6100 x 3300 x 1800 MACHINE WEIGHT: 2 TONS PRODUCTION EFFICIENCY: 80 TO 120 TABLETS PER MIN (EACH WORKING STATION 60 PCS PER MIN, AS WE HAVE TWO WORKING STATION). OPERATOR: 1 PERSON QUANTITY: 1 Learn More -

L-6069 EASTMAN STATIC TABLE CUTTING MACHINE MODEL M9000, 20’ X 72’, YEAR 2009

L-6069 EASTMAN STATIC TABLE CUTTING MACHINE MODEL M9000, 20’ X 72’, YEAR 2009REFERENCE NUMBER: L-6069

EASTMAN STATIC TABLE CUTTING MACHINE MODEL M9000, 20’ X 72’, YEAR 2009

STATIC TABLE CUTTING MACHINE

MAKE: EASTMAN

MODEL: M9000

20 FEET LONG X 72 FEET WIDE

PURCHASED IN YEAR 2009

220 VOLT, 1 PHASE

QUANTITY: 1

Learn More -

F-1428 FEATHER FILLING MACHINE MODEL SR-2

F-1428 FEATHER FILLING MACHINE MODEL SR-2REFERENCE NUMBER: F-1428

FEATHER FILLING MACHINE MODEL SR-2

PRODUCT FEATURES

• FULLY ENCLOSED DESIGN TO KEEP SURROUNDINGS CLEAN AND TO SAVE MATERIAL

• AUTOMATIC WEIGHING WITH ACCURATE LOAD CELL TO ENSURE PRODUCTION QUALITY

• FILLING TIME IS 2 TO 5 SECONDS

• NICE DESIGN SUITABLE FOR ALL KINDS OF FABRIC

• CE CERTIFICATE

• ITEM NO.: SR-2

• DIMENSION: APPROX. 11000 x 2500 x 3000MM

• VOLTAGE: 200/380415V 50/60HZ 3PHASE

• POWER: 13KW

• FILLING RANGE: 2 TO 100 G, DEPENDING ON THE MATERIAL

• ACCURACY: ±1G

• AIR PRESSURE: 0.5-0.8MPA

• THERE ARE 4 WEIGHING SYSTEMS AND ONE WORKING TABLE FOR DOWN FEATHER

• IT IS MAINLY USED TO MAKE DOWN FEATHER QUILT

• IT INCLUDES TWO AUTOMATIC FILLING TABLES, THE WORKING TABLE INCLUDES PNEUMATIC CLAMPING DEVICE FOR TWO FILLING PIPES, COMPOUND SHOE CLAMPING DEVICE, RING CLAMPING DEVICE AIR SUCTION, COMPRESSED AIR RING INJECTOR

• THE FEATHER DOWN FILLING USES VACUUM METHOD STYLE FUNCTION THAT HELPS TO KEEP THE MATERIAL SOFT, ELASTIC AND HAND FEELING AND AVOIDS THE FEATHER BEING DAMAGED DURING THE FILLING PROCEDURE

• WEIGHING ACCURACY CAN BE CONTROLLED WITHIN 1 GRAM WHICH CAN BE ADJUSTED BY SINGLE SET OR SINGLE PIECE ACCORDING TO DIFFERENT REQUIREMENT OF DIFFERENT PRODUCTS.

THIS HELPS QUALITY CONTROLLING AND AVOIDS MATERIAL WASTE ALSO

• SIMPLE OPERATION THAT SAVES LABOR COST AND THE WHOLE SET CAN BE HANDLED BY ONE OPERATOR.

• WORKING SURROUNDINGS ARE KEPT CLEAN BECAUSE ALL FILLING MATERIALS ARE KEPT INSIDE OF THE HOPPER

• ADVANCED TECHNOLOGY LEVEL; THE WHOLE SET IS CONTROLLED BY PLC SYSTEM WITH AN ENGLISH OPERATION MENU WHEREIN 100 RECIPES CAN BE SET UP, EACH RECIPE CAN BE SET UP WITH ABOUT 80 SETS OF WEIGHT VALUE WHICH IS SUITABLE FOR VERY COMPLICATED PRODUCT DESIGN WITHIN ONE PIECE

• HIGH WORKING CAPACITY; THE AVERAGE MATERIAL MEASURING TIME IS 4 TO 6 SECONDS. THE FILLING TIME CAN BE ADJUSTED AS DESIRED SO THAT TWO FILLERS CAN BE HANDLED BY ONLY ONE OPERATOR.

• WITH OUR PROFESSIONAL R&D GROUP WE CAN DESIGN THE INDIVIDUAL FILLINGS ACCORDING TO YOUR REQUIREMENTS

EQUIPMENT INCLUDED:

• MATERIAL HOPPER: DIA.1700 x 2500 1PCS

• WEIGHING SYSTEM: 800 x 1000 x 1200MM 2PCS

• PLC CONTROL SYSTEM & CONTROL PANEL: 1 SETS

• MATERIAL CHANGING HOPPER: 1200 x 1200 x 2500MM 1PCS

• AIR HOPPER: 1200 x 1200 x 2500MM 1PCS

• MATERIAL FEEDER: 1200 x 1200 x 1200MM 1PCS

• BLOWER: 4PCS

• PIPE: 1SET

• AUTOMATIC WORKING TABLE: 2SETS

• ENGLISH EDITION ARTICLE AND VIDEO FOR OPERATION DESCRIPTION

Learn More -

K-3889 LABORATORY TWO FOR ONE TWISTER

K-3889 LABORATORY TWO FOR ONE TWISTERREFERENCE NUMBER: K-3889

LABORATORY TWO FOR ONE TWISTER

MACHINE: X-A5 TWO-FOR –ONE

NAME:LABORATORY TWISTER

MODEL: HFX-A5

BASIC FUNCTION:THROUGH TWO-FOR-ONE TWISTING SPINDLES, THE MACHINE IS USED TO TWIST SINGLE YARNS INTO STRINGS

TECHNIQUE DATA:

CONTROL MODE: TOUCH SCREEN+ PLC

SPINDLE NUMNER: 1

TWISTING DEGREE: ABOUT 50-2000 TIMES/METER

OUTPUT: ABOUT 0.25KG TO 1KG

OUTPUT SPEED: 80M/MIN

ROTATION SPEED OF SPINDLE: 8000RPM

DRUM SIZE: Φ82mm×170mm

BOBBIN SIZE: Φ42mm×170mm

TOTAL POWER: 360W

VOLTAGE: 220/3×380V AC 50/60Hz

MACHINE DIMENSIONS: 800mm×600mm×1700mm

Learn More -

F-1432 FEATHER FILLING MACHINE MODEL EF-6

F-1432 FEATHER FILLING MACHINE MODEL EF-6REFERENCE NUMBER: F-1432

FEATHER FILLING MACHINE MODEL SR-6

PRODUCT FEATURES

• FULLY ENCLOSED DESIGN TO KEEP SURROUNDINGS CLEAN AND TO SAVE MATERIAL

• AUTOMATIC WEIGHING WITH ACCURATE LOAD CELL TO ENSURE PRODUCTION QUALITY

• FILLING TIME IS 2 TO 5 SECONDS

• NICE DESIGN SUITABLE FOR ALL KINDS OF FABRIC

• CE CERTIFICATE

• ITEM NO.: SR-6

• DIMENSION: APPROX. 6400×2500×3000MM

• VOLTAGE: 200/380415V 50/60HZ 3PHASE

• POWER: 11KW

• FILLING RANGE: 2-2000 G, DEPENDING ON THE MATERIAL

• ACCURACY: ±10G

• AIR PRESSURE: 0.5-0.8MPA

• THERE ARE 4 WEIGHING SYSTEMS AND ONE WORKING TABLE FOR THE DOWN FEATHER FILLING LINE

• IT IS MAINLY USED TO MAKE DOWN FEATHER QUILT

• IT INCLUDES TWO AUTOMATIC FILLING TABLES, THE WORKING TABLE INCLUDES PNEUMATIC CLAMPING DEVICE FOR TWO FILLING PIPES, COMPOUND SHOE CLAMPING DEVICE, RING CLAMPING DEVICE AIR SUCTION, COMPRESSED AIR RING INJECTOR

• THE FEATHER DOWN FILLING USES VACUUM METHOD STYLE HELPS KEEP THE ORIGINAL MATERIAL SOFT, ELASTIC AND HAND TACT AND AVOIDS THE FEATHER BEING DAMAGED DURING THE FILLING PROCEDURE

• THE ACCURACY CAN BE CONTROLLED WITHIN 10 GRAMS (WEIGHING RANGE:2000 GRAMS), WHICH CAN BE ADJUSTED BY SINGLE SET OR SINGLE PIECE ACCORDING TO THE REQUIREMENTS OF DIFFERENT PRODUCTS. IT HELPS QUALITY CONTROLLING AND AVOIDS MATERIAL WASTE

• SIMPLE OPERATION THAT SAVES LABOR COST; THE WHOLE MACHINE CAN BE HANDLED BY ONLY ONE OPERATOR.

• KEEPS CLEAN OF THE SURROUNDING ENVIRONMENT BECAUSE ALL THE FILLING MATERIALS ARE KEPT INSIDE OF THE HOPPER

• THE WHOLE MACHINE IS CONTROLLED BY PLC SYSTEM WITH AN ENGLISH OPERATION MENU WHEREIN 100 RECIPES CAN BE SET UP IN ADVANCE TO THE CONTROL SYSTEM. EACH RECIPE CAN BE SET UP TO ABOUT 80 SETS OF WEIGHT VALUE WHICH IS SUITABLE FOR VERY COMPLICATED PRODUCT DESIGN WITHIN ONE PIECE

• THE AVERAGE MATERIAL MEASURING TIME IS 4 TO 6 SECONDS. THE FILLING TIME CAN BE ADJUSTED AS DESIRED SO THAT TWO FILLERS CAN BE HANDLED BY ONE OPERATOR.

• OUR PROFESSIONAL R&D GROUP CAN DESIGN THE INDIVIDUAL FILLINGS ACCORDING TO YOUR REQUIREMENTS

EQUIPMENT INCLUDED:

• FEEDING SYSTEM: 2400 x 1500 x 3300MM 1PCS

• WEIGHING SYSTEM: 800 x 1000 x 1200MM 2PCS

• PLC CONTROL SYSTEM & CONTROL PANEL: 1 SETS

• BLOWER: 4PCS

• PIPE: 1SET

• AUTOMATIC WORKING TABLE: 2SETS

• ENGLISH EDITION ARTICLE AND VIDEO FOR OPERATION DESCRIPTION

Learn More -

C-4013 VILLARS AG SCATTER- COATING AND LAMINATING MACHINE, WORKING WIDTH 1000mm, YEAR 1994

C-4013 VILLARS AG SCATTER- COATING AND LAMINATING MACHINE, WORKING WIDTH 1000mm, YEAR 1994C-4013 VILLARS AG SCATTER- COATING AND LAMINATING MACHINE, WORKING WIDTH 1000mm, YEAR 1994

MAKE: VILLARS AG

YEAR: 1994

WORKING WIDTH: 1000mm

WORKING SPEED: 0 TO 10 M/MIN

ELECTRICAL POWER: 3 X 400 VOLT + PN + PE, 50 HZ

POWER: 140 KW

WEIGHT: 8637 KGSQUANTITY: 1

Learn More -

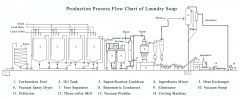

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HRREFERENCE NUMBER: K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1

Learn More -

K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HRREFERENCE NUMBER: K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1 Learn More

K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HRREFERENCE NUMBER: K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1 Learn More