Search results for: 'Extruder line'

- Related search terms

- line

- line p

- EXTRUDER LA

- Line b

- EXTRUDER L'

-

TT-2671 DOLCI FILM EXTRUSION LINE, CAST FILM, WIDTH 2000mm, 7 LAYERS, YEAR 2012TT-2671 DOLCI FILM EXTRUSION LINE, CAST FILM, WIDTH 2000mm, 7 LAYERS, YEAR 2012 BRAND: DOLCI MODEL: UZ 4211 YEAR: 2012 QUANTITY: 1 Learn More

TT-2671 DOLCI FILM EXTRUSION LINE, CAST FILM, WIDTH 2000mm, 7 LAYERS, YEAR 2012TT-2671 DOLCI FILM EXTRUSION LINE, CAST FILM, WIDTH 2000mm, 7 LAYERS, YEAR 2012 BRAND: DOLCI MODEL: UZ 4211 YEAR: 2012 QUANTITY: 1 Learn More -

TT-2569 WELEX COMPLETE PELLETIZING LINE, 4.5 INCHES, CAPACITY 500 KG PER HOURTT-2569 WELEX COMPLETE PELLETIZING LINE, 4.5 INCHES, CAPACITY 500 KG PER HOUR EXTRUDERS AND EXTRUSION PLANTS TYPE SELLING BRAND WELEX CATEGORY EXTRUDERS AND EXTRUSION PLANTS CONDITION USED CAPACITY 500 KG PER HOUR DELIVERY TIME 1 WEEK Learn More

TT-2569 WELEX COMPLETE PELLETIZING LINE, 4.5 INCHES, CAPACITY 500 KG PER HOURTT-2569 WELEX COMPLETE PELLETIZING LINE, 4.5 INCHES, CAPACITY 500 KG PER HOUR EXTRUDERS AND EXTRUSION PLANTS TYPE SELLING BRAND WELEX CATEGORY EXTRUDERS AND EXTRUSION PLANTS CONDITION USED CAPACITY 500 KG PER HOUR DELIVERY TIME 1 WEEK Learn More -

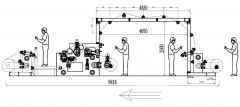

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More -

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More -

PP MELTBLOWN NONWOVEN FABRIC PRODUCTION LINE, 1600 mmREFERENCE NUMBER: A-2491 PP MELTBLOWN NONWOVEN FABRIC PRODUCTION LINE, 1600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 1600 mm MATERIAL MFI: 1000 TO 1600 PP CHIP MATERIAL PRODUCTION SPEED: 0 TO 50 M/min EXTRUDER DIAMETER IN mm: 90 mm EXTRUDER MOTOR IN KW: 55 KW PRODUCT WEIGHT RANGE: 10 TO 80 GSM FIBER FINENESS: 2 TO 5 mm ELECTROSTATIC ELECTRET: 200 KVA ROOTS BLOWER: 110 KW CENTRIFUGAL FAN: 75 KW MAX OUTPUT: UP TO 1500 KG/24 HOURS DIMENSION: 6000 X 3000 X 3000 mm WEIGHT: 8 TONS POWER (TOTAL KW): 400 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 45 HC PRODUCTION TIME: 30 DAYS Learn More

PP MELTBLOWN NONWOVEN FABRIC PRODUCTION LINE, 1600 mmREFERENCE NUMBER: A-2491 PP MELTBLOWN NONWOVEN FABRIC PRODUCTION LINE, 1600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 1600 mm MATERIAL MFI: 1000 TO 1600 PP CHIP MATERIAL PRODUCTION SPEED: 0 TO 50 M/min EXTRUDER DIAMETER IN mm: 90 mm EXTRUDER MOTOR IN KW: 55 KW PRODUCT WEIGHT RANGE: 10 TO 80 GSM FIBER FINENESS: 2 TO 5 mm ELECTROSTATIC ELECTRET: 200 KVA ROOTS BLOWER: 110 KW CENTRIFUGAL FAN: 75 KW MAX OUTPUT: UP TO 1500 KG/24 HOURS DIMENSION: 6000 X 3000 X 3000 mm WEIGHT: 8 TONS POWER (TOTAL KW): 400 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 45 HC PRODUCTION TIME: 30 DAYS Learn More -

M-1585 STAPLE FIBER LINE – 20 TO 25 TONS PER DAYREFERENCE NUMBER: M-1585 (66012THSGW5UF) STAPLE FIBER LINE – 20 TO 25 TONS PER DAY PRODUCT SPEC.: 1.4 ~ 20 DE. PET STAPLE FIBER SPINNING LINE CAPACITY: SPINNING: 20 T/D, DRAWING: 25 T/D CURRENTLY IN OPERATION SPINNING LINE DRAW LINE QUANTITY AVAILABLE: 1 Learn More

M-1585 STAPLE FIBER LINE – 20 TO 25 TONS PER DAYREFERENCE NUMBER: M-1585 (66012THSGW5UF) STAPLE FIBER LINE – 20 TO 25 TONS PER DAY PRODUCT SPEC.: 1.4 ~ 20 DE. PET STAPLE FIBER SPINNING LINE CAPACITY: SPINNING: 20 T/D, DRAWING: 25 T/D CURRENTLY IN OPERATION SPINNING LINE DRAW LINE QUANTITY AVAILABLE: 1 Learn More -

TT-7796 MUNCHY 100 RECYCLING MACHINE, YEAR 2008TT-7796 MUNCHY 100 RECYCLING MACHINE, YEAR 2008 1. BRAND: MUNCHY 2. MODEL: 100 3. YEAR: 2008 4. CATEGORY: RECYCLING MACHINES 5. CAPACITY: 110 KG/H 6. RECYCLED MATERIAL: LDPE, HDPE, PP QUANTITY: 1 Learn More

TT-7796 MUNCHY 100 RECYCLING MACHINE, YEAR 2008TT-7796 MUNCHY 100 RECYCLING MACHINE, YEAR 2008 1. BRAND: MUNCHY 2. MODEL: 100 3. YEAR: 2008 4. CATEGORY: RECYCLING MACHINES 5. CAPACITY: 110 KG/H 6. RECYCLED MATERIAL: LDPE, HDPE, PP QUANTITY: 1 Learn More -

TT-3642 BARMAG S5 EXTRUSION LINE WITH 6 WINDERS FOR BCF LINE, YEAR 2005TT-3642 BARMAG S5 EXTRUSION LINE WITH 6 WINDERS FOR BCF LINE, YEAR 2005 BARMAG S5 EXTRUSION LINE WITH 6 WINDERS FOR BCF LINE MODEL: S5 YEAR 2005 TYPE 15E10/30D Learn More

TT-3642 BARMAG S5 EXTRUSION LINE WITH 6 WINDERS FOR BCF LINE, YEAR 2005TT-3642 BARMAG S5 EXTRUSION LINE WITH 6 WINDERS FOR BCF LINE, YEAR 2005 BARMAG S5 EXTRUSION LINE WITH 6 WINDERS FOR BCF LINE MODEL: S5 YEAR 2005 TYPE 15E10/30D Learn More -

TT-3263 HERBOLD COMPLETE WASH LINE AND GRANULATION LINE, CONVERTING HDPE/PE BOTTLES TO 14mm FLAKES 2.5 TON PER HOURTT-3263 HERBOLD COMPLETE WASH LINE AND GRANULATION LINE, CONVERTING HDPE/PE BOTTLES TO 14mm FLAKES 2.5 TON PER HOUR TYPE SELLING BRAND HERBOLD CATEGORY SIZE REDUCTION / GRANULATORS / SHREDDERS CONDITION USED QUANTITY: 1 Learn More

TT-3263 HERBOLD COMPLETE WASH LINE AND GRANULATION LINE, CONVERTING HDPE/PE BOTTLES TO 14mm FLAKES 2.5 TON PER HOURTT-3263 HERBOLD COMPLETE WASH LINE AND GRANULATION LINE, CONVERTING HDPE/PE BOTTLES TO 14mm FLAKES 2.5 TON PER HOUR TYPE SELLING BRAND HERBOLD CATEGORY SIZE REDUCTION / GRANULATORS / SHREDDERS CONDITION USED QUANTITY: 1 Learn More -

TT-7643 EREMA EDGE TRIM PLASTIC RECYCLING LINE KAG 605, 66 TO 220 LBS PER HOURTT-7643 EREMA EDGE TRIM PLASTIC RECYCLING LINE KAG 605, 66 TO 220 LBS PER HOUR 1. EREMA EDGE TRIM PLASTIC RECYCLING LINE 2. TYPE KAG 605 3. CAPACITY OF 66 TO 220 POUNDS/HOUR (30-100 KGS/HOUR) QUANTITY: 1 Learn More

TT-7643 EREMA EDGE TRIM PLASTIC RECYCLING LINE KAG 605, 66 TO 220 LBS PER HOURTT-7643 EREMA EDGE TRIM PLASTIC RECYCLING LINE KAG 605, 66 TO 220 LBS PER HOUR 1. EREMA EDGE TRIM PLASTIC RECYCLING LINE 2. TYPE KAG 605 3. CAPACITY OF 66 TO 220 POUNDS/HOUR (30-100 KGS/HOUR) QUANTITY: 1 Learn More