Search results for: 'Contact a'

- Related search terms

- Contact i

- Contact in e

- Contact++in

- Contact i'

- Contact++i'

-

R-1390 OSTHOFF SINGEING/CORINO ENTRY & EXIT/PAREX & DESIZING RANGE, WORKING WIDTH 2000mm, YEAR 1995 - RECONDITIONED 2015

R-1390 OSTHOFF SINGEING/CORINO ENTRY & EXIT/PAREX & DESIZING RANGE, WORKING WIDTH 2000mm, YEAR 1995 - RECONDITIONED 2015REFERENCE NUMBER: R-1390

OSTHOFF SINGEING/CORINO ENTRY & EXIT/PAREX & DESIZING RANGE, WORKING WIDTH 2000mm, YEAR 1995 - RECONDITIONED 2015

DETAILS:

BRAND:OSTHOFF

WORKING WIDTH: 2000mm

YEAR: 1995

FULLY RECONDITIONED IN YEAR: 2015COMPRISING OF:

ITEM 001

CORINO DE- BATCH- J BOX & BRUSH

WORKING WIDTH: 2000mm

QUANTITY: 1ITEM 002

OSTHOFF SINGEING MACHINE

TYPE: PK 90

MAXIMUM FABRIC WIDTH: 2000mm

MAXIMUM FLAME WIDTH: 2200mm

QUANTITY: 1ITEM 003

GAS BURNERS WITH AUTO IGNITION ELECTRODES

WORKING WIDTH: 2000mm

QUANTITY: 2ITEM 004

PAREX DESIZING WITH 2 BOWL PADDER

QUANTITY: 1ITEM 005

Learn More

ONE PAREX OPEN WIDTH DESIZING - WASHING TANK

WORKING WIDTH: 2000mm

QUANTITY: 1 -

P-5043 PROBAT (P5) ROASTER 5 KILOS YEAR 2009

P-5043 PROBAT (P5) ROASTER 5 KILOS YEAR 2009P-5043 PROBAT (P5) ROASTER 5 KILOS YEAR 2009

PROBAT

MODEL: P5

ROASTER

YEAR: 2009

5 KILOS

NICE FULL CONTROL PANEL MOUNTED ON LEFT SIDE

AVERAGE 33 POUNDS PER HOUR. MAXIMUM 10 POUNDS PER BATCH

PROBAT HAS RETURNED TO THEIR CLASSIC, NOSTALGIC DESIGN CONTACT COMPONENTS MADE OF HIGH-QUALITY CAST IRON

SIMULTANEOUS ROASTING AND COOLING HAS JUST BEEN ADDED WITH SUCTION FOR COOLING AND ROASTING EXHAUST AIR

SEPARATE MOTORS FOR DRUM DRIVE, COOLING SIEVE STIRRING ARM AS WELL AS ROASTER AND COOLER FANS – NO MORE BELTS AND CHAINS, A GREAT IMPROVEMENT.

SIMPLIFIED CLEANING BY REMOVABLE LATERAL WALLS

SEPARATE ROASTING CYCLONE FOR AN EFFECTIVE CHAFF ASPIRATION WHICH CAN BE LOCATED IN DIFFERENT LOCATIONS AS NEEDED

CLEAR OPERATION WITH DIGITAL TIME AND TEMPERATURE DISPLAY

EMERGENCY DISCHARGE IN CASE OF POWER OUTAGE USING SUPPLIED CRANK. ADAPTER MAKES POSSIBLE THE USE OF A CORDLESS SCREWDRIVER

OPTIONAL (PROBATONE 5 / PROBATONE 12): PS NASED CONTROL SYSTEM WITH VISUALISATION OF PRODUCT TEMPERATURE CURVE AND RECIPE MEMORYQUANTITY: 1

Learn More -

R-1391 OSTHOFF SINGEING RANGE, WORKING WIDTH 1800mm, YEAR 1983 TO 1993

R-1391 OSTHOFF SINGEING RANGE, WORKING WIDTH 1800mm, YEAR 1983 TO 1993R-1391 OSTHOFF SINGEING , WORKING WIDTH 1800mm, YEAR 1983 TO 1993

OSTHOFF SINGEING RANGE

WORKING WIDTH: 1800mm

YEAR: 1983 TO 1993

PRE TENSION DRIVEN ENTRY WITH J BOX SCRAY

WITH DOUBLE BRUSHING UNIT

E+L KF20 WITH CENTRALISING GUIDERS

OSTHOFF SINGE TYPE U80 WITH 2 GAS BURNERS

E+L DOGAL GUIDER COMPLETE

WITH CONOSCREEN ROTORY MICROFILTERING

YEAR: 2005

NUOVA - RUDECO EXTRACTION DUST SYSTEM

YEAR: 2000

SIEMENS PLC CONTORLES FITTED IN YEAR: 2000

OXIDIZATION SECTION 10 METER CLOTH CONTENT

KUSTER DESIZING WITH 2 DESIZE TANKS AND 2 PADDERS

2 CHEMICAL MIXING TANKS

TAKE OFF BY CONTACT BATCHERQUANTITY: 1

Learn More -

P-5090 JOPER CAST IRON ROASTER 60 KILOS

P-5090 JOPER CAST IRON ROASTER 60 KILOSP-5090 JOPER CAST IRON ROASTER 60 KILOS

ONE BAG ROASTING – WORLDWIDE FAVORITE SINCE MOST OF THE COFFEE BAGS IN THE WORLD ARE 60 KILO. NOW THIS IS NOT AN EXCUSE TO AVOID SILO MANAGEMENT OF THE COFFEE BEANS - AS COFFEE STORED IN SILOS ENJOY A UNIVERSAL MOISTURE CONTENT WHERE LEAVING IT IN BAGS WILL GIVE YOU MOISTURE ALL OVER THE PLACE - SO THINK SILOS AS PART OF YOUR PLANT. NOW TO THE ACTUAL ROASTER BEING A VERY RUGGED CAST IRON ROASTING FRAME AND ROASTING DRUM CONTACT-CLEARANCES WITH THAT SOLID FRAME MAKING IT JUST PLAIN SOLID AND DOES NOT MOVE UNDER LONG OR EXTENDED USE. DOUBLE WALL DRUM MEANS THAT THE HEAT IS ALL DESIGNED TO GO THROUGH THE CENTER OF THE ROASTING CHAMBER, NOT "ONTO" THE DRUM EXTERIOR. TOTAL TRUE CONVECTION. NOT ONLY IS THIS THE SAME STYLE FROM THE OLD GOTHOT & BARTH ROASTER DAYS. . . BUT EVEN BETTER AS THE SHAFT DESIGN SO THAT BEARINGS ARE EXTERNALLY MOUNTED AND ADDITIONALLY ARE AIR COOLED FOR LONG LIFE AND TROUBLE-FREE CONTROL. EVEN THE SIDE PANELS OR PRODUCT FLIGHTS HAVE A LONGER CURVE POSITIONING THAT ALLOWS FOR MORE PRODUCT FLOW INTO THE HOT AIR STREAM, RESULTING IN A SLIGHTLY MORE RAPID ROAST WITH MORE EVEN BEAN INTERIOR AND EXPANSION THAT FRANKLY LEADS THE INDUSTRY.

ALL THIS COMMENTARY ABOVE MEANS THIS ROASTER SIMPLY IS MORE QUIET THAN ANYTHING ON THE MARKET. PERIOD. THERMAL INSULATION WITH HIGHEST QUALITY OF FIBER FOR LOW GAS CONSUMPTION; DIGITAL TEMPERATURE CONTROL. CYCLONE IS SEPARATE. THE COOLER, BEING TOTALLY SEPARATE ALSO HAS THE LARGEST AIR COLLECTION AREA OF ANY ROASTER MADE ALLOWING FOR TOTAL AMBIENT COOL COFFEE IN LESS THAN THREE MINUTES. ADD TO THIS PACKAGE A LOADER OR YOUR CHOICE OF DESTONERS AND EVEN YOUR CHOICE OF CONTROL METHODS. . . SEE BELOW FOR DETAILS. SPECIAL NOTE - THE MORE AUTOMATIC VERSIONS OF THIS ROASTER MEANS THAT EVERYTHING IS TOTALLY DIFFERENT FROM THE BURNER TO THE MOTORS USED TO CONTROL EACH FUNCTION - AS THEY ARE ALL SPEED CONTROLLED - SO THERE IS A HUGE DIFFERENCE BETWEEN THE "MANUAL" METHOD AND THE AUTOMATIC AND PROFILE OPERATED MACHINE.

SPACE PLANNING AND DRAWINGS - WE ARE HAPPY TO DRAW THIS INTO YOUR DRAWINGS, SO THAT YOU CAN SEE SPECIFICALLY JUST WHERE AND HOW THIS WILL FUNCTION WITHIN YOUR PLANT. PLEASE SEND YOUR DRAWINGS FOR A DETAIL STUDY.

BUILT TO UL295 STANDARDS.

QUANTITY: 1

Learn More -

P-5079 COMMERCIAL JOPER CAST IRON CRM-30 ROASTER 30 KILOS

P-5079 COMMERCIAL JOPER CAST IRON CRM-30 ROASTER 30 KILOSP-5079 COMMERCIAL JOPER CAST IRON CRM-30 ROASTER 30 KILOS

WHAT WE HAVE HERE IS A VERY RUGGED CAST IRON ROASTING FRAME AND ROASTING CONTACT CLEARANCES WITH THE MACHINE - JUST PLAIN SOLID AND DOES NOT MOVE UNDER LONG OR EXTENDED USE. DOUBLE WALL DRUM MEANS THAT THE HEAT IS ALL DESIGNED TO GO THROUGH THE CENTER OF THE ROASTING CHAMBER, NOT "ONTO" THE DRUM EXTERIOR. TOTAL TRUE CONVECTION. NOT ONLY IS THIS THE SAME STYLE FROM THE OLD GOTHOT & BARTH ROASTER DAYS. . . BUT EVEN BETTER AS THE SHAFT DESIGN SO THAT BEARINGS ARE EXTERNALLY MOUNTED AND ADDITIONALLY ARE AIR COOLED FOR LONG LIFE AND TROUBLE-FREE CONTROL. EVEN THE SIDE PANELS OR PRODUCT FLIGHTS HAVE A LONGER CURVE POSITIONING MORE PRODUCT FLOW INTO THE HOT AIR STREAM, RESULTING IN A SLIGHTLY MORE RAPID ROAST WITH MORE EVEN BEAN INTERIOR AND EXPANSION THAT FRANKLY LEADS THE INDUSTRY.

ALL THIS COMMENTARY ABOVE MEANS THIS ROASTER SIMPLY IS MORE QUIET THAN ANYTHING ON THE MARKET. PERIOD. THERMAL INSULATION WITH HIGHEST QUALITY OF FIBER FOR LOW GAS CONSUMPTION; DIGITAL TEMPERATURE CONTROL. CYCLONE IS SEPARATE. THE COOLER, BEING TOTALLY SEPARATE ALSO HAS THE LARGEST AIR COLLECTION AREA OF ANY ROASTER MADE ALLOWING FOR TOTAL AMBIENT COOL COFFEE IN LESS THAN THREE MINUTES. ADD TO THIS PACKAGE A LOADER OR YOUR CHOICE OF DESTONERS AND EVEN YOUR CHOICE OF CONTROL METHODS.

DATA INFORMATION:

BATCH CAPACITY: 30 KG / 66 LBS

CONTROL DESIGN: MANUAL

CAPACITY PER HOUR: 120 KG / 265 LBS

ROASTING TIME: 12-18 MIN (4 BATCHES AN HOUR)

EXHAUST AIR TREATMENT: OPTIONAL

COOLING CYCLONE: OPTIONAL

PRE-COOLING WITH WATER IN DRUM: OPTIONAL

COOLING TIME: 3-4 MIN

TYPE OF COOLING: AIR AMBIENT

SAFETY DEVICE: YES

BURNER POWER: 110 KW / 375000 BTU

BURNERS MANUFACTURER: RIELLO

OPERATION TYPE BURNER: BS2D-2 STAGE

FUEL TYPE: PROPANE/NAUTRAL GAS/DIESEL

SIDE OF OPERATION: LEFT

POWER REQUIREMENTS: 20 AMP

VOLTAGE/FREQUENCY/PHASES: 400+N-230 V / 50-60 HZ / 3 PH

9 AMP. . . 3 PHASE 50/60 HZ PREFERRED, YOUR CHOICE OF 220/440 - SINGLE PHASE AVAILABLE AT SPECIAL REQUEST

(NOTE ON 3 PHASE. . . NOT ONLY IS IT LESS EXPENSIVE TO OPERATE, BUT IT RUNS MORE QUIETLY THAN SINGLE PHASE WHENEVER OR WHEREVER IT IS USED. KEEP THIS IN MIND FOR ANY MACHINERY.)

Ø EXHAUST CHIMNEY (ROASTER CYCLONE): 250MM / 9,8 INCH

Ø EXHAUST CHIMNEY (COOLER): 250MM / 9,8 INCH

Ø HOPPER ROAST CHIMNEY: 150MM / 5,9 INCH

ROASTER WEIGHT WITH CYCLONE: 1050 KG / 2310 LBS

COOLER WEIGHT: 300 KG / 660 LBS

ROASTER FAN MOTOR: 1, 5 HP

COOLER FAN: 4 HP

DRUM GEARBOX: 1 HP

COOLER GEARBOX: 0, 75 HP

BUILT TO UL295 STANDARDS.QUANTITY: 1

Learn More -

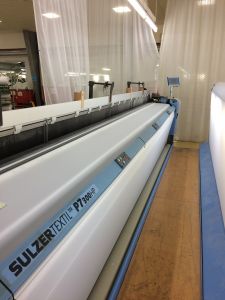

M-4243 K PICANOL OMNI YEAR 1998 WIDTH 1900mm -DENIM LOOMS - CAM BOX

M-4243 K PICANOL OMNI YEAR 1998 WIDTH 1900mm -DENIM LOOMS - CAM BOXREFERENCE NUMBER: M-4243

PICANOL OMNI YEAR 1998 WIDTH 1900mm -DENIM LOOMS - CAM BOX

PICANOL OMNI

YEAR 1988

WIDTH 1900mm

DENIM LOOMS

(2) PICANOL 2231 FEEDERS PER MACHINE

(4) HARNESS FRAMES PER MACHINE

(6) CONTACT BARS WITH DROPPERS PER MACHINE

1 BEAM PER MACHINE

LET OFF: ELECTRONIC

TAKE UP: ELECTRONIC

POSITIVE CAM BOX: 1620 B WITH (6) LEVERS AND (6) HARNESS FRAME DRIVE

QUANTITY: 75

Learn More -

V-1041 AIRLAY- FELT LINE 2400mmINDEX 1. Technical specification pag.2 2. Line composition pag.3 3. Machines description pag.4 4. Total price of the turn-key plant pag.25 5. Sale terms pag.26 6. Payment terms pag.28 7. General selling terms and conditions pag.29 Learn More

V-1041 AIRLAY- FELT LINE 2400mmINDEX 1. Technical specification pag.2 2. Line composition pag.3 3. Machines description pag.4 4. Total price of the turn-key plant pag.25 5. Sale terms pag.26 6. Payment terms pag.28 7. General selling terms and conditions pag.29 Learn More -

M-2042 WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGSREFERENCE NUMBER: M-2042 (770IDFGXX6) WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGS GAS FIRED BATCH OVEN MANUFACTURER: WISCONSIN OVEN STILL ASSEMBLED TODAY OVEN WILL BE USED FOR TEMPERING STEEL SPRING ASSEMBLIES WITH A LOADING OF APPROXIMATELY 50 ASSEMBLIES WEIGHING APPROXIMATELY 40 POUNDS, IN THE OVEN AT A TIME THE SIZE IS BASED ON APPROXIMATELY 4 TO 5 CYCLES PER HOUR PROVIDING THE LOADING AND UNLOADING IS ACCOMPLISHED PROMPTLY THE HEATING RATE IS BASED ON A HEATING CYCLE OF APPROXIMATELY 12 MINUTES PER CYCLE THE OVEN WILL INCLUDE, BUT NOT BE LIMITED TO, THE DEISNG FEATURES OUTLINED IN OUR SPECIFICATIONS LISTED BELOW FURTHER MODIFICATIONS AND DESIGN CHANGES MAY BE INCORPORATED AT THE FINAL ENGINEERING STAGES TO PRODUCE THE BEST EQUIPMENT POSSIBLE QUANTITY AVAILABLE: 1 Learn More

M-2042 WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGSREFERENCE NUMBER: M-2042 (770IDFGXX6) WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGS GAS FIRED BATCH OVEN MANUFACTURER: WISCONSIN OVEN STILL ASSEMBLED TODAY OVEN WILL BE USED FOR TEMPERING STEEL SPRING ASSEMBLIES WITH A LOADING OF APPROXIMATELY 50 ASSEMBLIES WEIGHING APPROXIMATELY 40 POUNDS, IN THE OVEN AT A TIME THE SIZE IS BASED ON APPROXIMATELY 4 TO 5 CYCLES PER HOUR PROVIDING THE LOADING AND UNLOADING IS ACCOMPLISHED PROMPTLY THE HEATING RATE IS BASED ON A HEATING CYCLE OF APPROXIMATELY 12 MINUTES PER CYCLE THE OVEN WILL INCLUDE, BUT NOT BE LIMITED TO, THE DEISNG FEATURES OUTLINED IN OUR SPECIFICATIONS LISTED BELOW FURTHER MODIFICATIONS AND DESIGN CHANGES MAY BE INCORPORATED AT THE FINAL ENGINEERING STAGES TO PRODUCE THE BEST EQUIPMENT POSSIBLE QUANTITY AVAILABLE: 1 Learn More -

V-0046 SHRINK PACKING MACHINEREFERENCE NUMBER: V-0046 AUTOMATIC ROLL SHRINK PACKING MACHINE MODEL ARPM-240I QUANTITY AVAILABLE: 1 Learn More

V-0046 SHRINK PACKING MACHINEREFERENCE NUMBER: V-0046 AUTOMATIC ROLL SHRINK PACKING MACHINE MODEL ARPM-240I QUANTITY AVAILABLE: 1 Learn More