Search results for: 'Parts'

- Related search terms

- parts for T

- parts for Te

- parts for c

- parts for c-

- parts for c-2

-

T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003 78” X 54” BRUNO FH 250-T YEAR: 2003 QUANTITY: 1 Learn More

T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003 78” X 54” BRUNO FH 250-T YEAR: 2003 QUANTITY: 1 Learn More -

T-9275 ZIMMER CHROMOJET PILE FABRIC DIGITAL PRINTER, WORKING WIDTH 2000mm, YEAR 2001T-9275 ZIMMER CHROMOJET PILE FABRIC DIGITAL PRINTER, WORKING WIDTH 2000mm, YEAR 2001 ELECTRICAL SUPPLY: 3 PHASE 380-440V, 50Hz SPARE PARTS: ALL RELATED SPARE PARTS AND ACCESSORIES AVAILABLE IN THE FACTORY (IF ANY). MANUALS: ALL MANUALS AVAILABLE IN THE FACTORY (IF ANY). QUANTITY: 1 Learn More

T-9275 ZIMMER CHROMOJET PILE FABRIC DIGITAL PRINTER, WORKING WIDTH 2000mm, YEAR 2001T-9275 ZIMMER CHROMOJET PILE FABRIC DIGITAL PRINTER, WORKING WIDTH 2000mm, YEAR 2001 ELECTRICAL SUPPLY: 3 PHASE 380-440V, 50Hz SPARE PARTS: ALL RELATED SPARE PARTS AND ACCESSORIES AVAILABLE IN THE FACTORY (IF ANY). MANUALS: ALL MANUALS AVAILABLE IN THE FACTORY (IF ANY). QUANTITY: 1 Learn More -

T-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACKT-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACK WET WIPES MACHINE CAPACITY: 5 TO 30 PIECES PER PACK DRIVE MODE: AUTOMATIC FOLDING: 300 TO 400 PIECES PER MINUTE (STABLE SPEED) PACKAGING: 40 BAGS PER MINUTE (STABLE SPEED) MACHINE SIZE (L X W X H): 5000mm X 1200mm X 2100mm QUANTITY: 1 Learn More

T-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACKT-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACK WET WIPES MACHINE CAPACITY: 5 TO 30 PIECES PER PACK DRIVE MODE: AUTOMATIC FOLDING: 300 TO 400 PIECES PER MINUTE (STABLE SPEED) PACKAGING: 40 BAGS PER MINUTE (STABLE SPEED) MACHINE SIZE (L X W X H): 5000mm X 1200mm X 2100mm QUANTITY: 1 Learn More -

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More -

T-7125 CARDING WILLOW, WORKING WIDTH 1500mmT-7125 CARDING WILLOW, WORKING WIDTH 1500mm TYPE OF FIBRES: ALPACA OR WOOL WILLOW CARDING IS EQUIPPED WITH MECHANICAL AND ELECTRICAL DRIVES CAPACITY: UP TO 1500 KGS/HOUR WORKING WIDTH: 1500mm QUANTITY: 1 Learn More

T-7125 CARDING WILLOW, WORKING WIDTH 1500mmT-7125 CARDING WILLOW, WORKING WIDTH 1500mm TYPE OF FIBRES: ALPACA OR WOOL WILLOW CARDING IS EQUIPPED WITH MECHANICAL AND ELECTRICAL DRIVES CAPACITY: UP TO 1500 KGS/HOUR WORKING WIDTH: 1500mm QUANTITY: 1 Learn More -

J-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mmJ-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mm PP FIBRILLATED YARN EXTRUDER LINE MODEL: NOVASTAR-120 EXTRUSION LINE FOR PRODUCTION OF PP FIBRILLATED YARN RAW MATERIAL: PP GRANULE FINISHED PRODUCTS: NON-TWISTED TAPE YARN, FIBRILLATED YARN FOR TWINE RANGE OF PRODUCT: 10,000 TO 30,000 DENIER 10000 DENIER APPROXIMATELY 17 TO 19 YARN 16000 DENIER APPROXIMATELY 11 TO 12 YARN 22000 DENIER APPROXIMATELY 8 TO 9 YARN 28000 DENIER APPROXIMATELY 6 TO 7 YARN 32000 DENIER APPROXIMATELY 5 TO 6 YARN EXTRUSION THROUGHPUT: 300 KG PER HOUR EXTRUSION CAPACITY: 180 TO 250 KG PER HOUR (PRODUCT CAPACITY DEPEND ON FILAMENT SIZE) EXTRUDER SCREW DIAMETER: Ø 120mm T-DIE WIDTH: 1300mm TAKE-OFF ROLLER WIDTH: 1200mm TAKE-OFF LINE SPEED: 160 METERS PER MINUTE (MAXIMUM) OPERATION SIDE: RIGHT TO LEFT, OR LEFT TO RIGHT Learn More

J-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mmJ-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mm PP FIBRILLATED YARN EXTRUDER LINE MODEL: NOVASTAR-120 EXTRUSION LINE FOR PRODUCTION OF PP FIBRILLATED YARN RAW MATERIAL: PP GRANULE FINISHED PRODUCTS: NON-TWISTED TAPE YARN, FIBRILLATED YARN FOR TWINE RANGE OF PRODUCT: 10,000 TO 30,000 DENIER 10000 DENIER APPROXIMATELY 17 TO 19 YARN 16000 DENIER APPROXIMATELY 11 TO 12 YARN 22000 DENIER APPROXIMATELY 8 TO 9 YARN 28000 DENIER APPROXIMATELY 6 TO 7 YARN 32000 DENIER APPROXIMATELY 5 TO 6 YARN EXTRUSION THROUGHPUT: 300 KG PER HOUR EXTRUSION CAPACITY: 180 TO 250 KG PER HOUR (PRODUCT CAPACITY DEPEND ON FILAMENT SIZE) EXTRUDER SCREW DIAMETER: Ø 120mm T-DIE WIDTH: 1300mm TAKE-OFF ROLLER WIDTH: 1200mm TAKE-OFF LINE SPEED: 160 METERS PER MINUTE (MAXIMUM) OPERATION SIDE: RIGHT TO LEFT, OR LEFT TO RIGHT Learn More -

A-2573 TUBE FILLING SEALING MACHINE 2 KWA-2573 TUBE FILLING SEALING MACHINE 2 KW SPECIFICATIONS: SEALING TYPE: HEATING (PLASTIC), FOLDING (ALUMINUM) MAX POWER: 2 KW (PLASTIC), 3.3 KW (ALUMINUM) VOLTAGE: 220 VOLTZ AND 50/60 Hz PRODUCTIVITY: 30 TO 80 PCS/Min FILLING VOLUME: 5 TO 200 ML (CHANGE PUMP) TUBE DIAMETER: 10 TO 50 mm (CHANGE MOLDS) TUBE LENGTH: 210 mm (THE MAX.) FILLING ACCURACY: ≤±1% CONTROL: PLC CONTROL SYSTEM DISPLAY: TOUCH SCREEN DISPLAY FEATURE: NO TUBE NO FILLING DIMENSION (L X W X H): 1500 X 1100 X 1900 mm WEIGHT: ABOUT 850 KG Learn More

A-2573 TUBE FILLING SEALING MACHINE 2 KWA-2573 TUBE FILLING SEALING MACHINE 2 KW SPECIFICATIONS: SEALING TYPE: HEATING (PLASTIC), FOLDING (ALUMINUM) MAX POWER: 2 KW (PLASTIC), 3.3 KW (ALUMINUM) VOLTAGE: 220 VOLTZ AND 50/60 Hz PRODUCTIVITY: 30 TO 80 PCS/Min FILLING VOLUME: 5 TO 200 ML (CHANGE PUMP) TUBE DIAMETER: 10 TO 50 mm (CHANGE MOLDS) TUBE LENGTH: 210 mm (THE MAX.) FILLING ACCURACY: ≤±1% CONTROL: PLC CONTROL SYSTEM DISPLAY: TOUCH SCREEN DISPLAY FEATURE: NO TUBE NO FILLING DIMENSION (L X W X H): 1500 X 1100 X 1900 mm WEIGHT: ABOUT 850 KG Learn More -

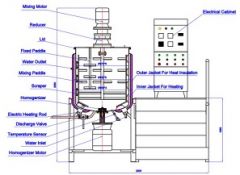

Z-1564 500 L LIQUID WASHING HOMOGENIZER MIXERSZ-1564 500 L LIQUID WASHING HOMOGENIZER MIXERS MAIN STRUCTURE: MIXING POT, ELECTRIC CONTROL SYSTEM, OPERATION PLATFORM ESTIMATED PRODUCTION TIME AND CAPACITY FOR REF • MIXING + HOMOGENIZER + HEATING • REMARK: 2 TO 2.5 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 1500 IT’S TO 2000 DAY. • MIXING + HOMOGENIZER • REMARK: 2 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 2000 IT’S DAY. • MIXING ONLY • REMARK: 1 TO 1.5 HOURS PER BATCH, IF 8 HOURS DAY, 2500 IT’S TO 4000 DAY. QUANTITY: 1 Learn More

Z-1564 500 L LIQUID WASHING HOMOGENIZER MIXERSZ-1564 500 L LIQUID WASHING HOMOGENIZER MIXERS MAIN STRUCTURE: MIXING POT, ELECTRIC CONTROL SYSTEM, OPERATION PLATFORM ESTIMATED PRODUCTION TIME AND CAPACITY FOR REF • MIXING + HOMOGENIZER + HEATING • REMARK: 2 TO 2.5 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 1500 IT’S TO 2000 DAY. • MIXING + HOMOGENIZER • REMARK: 2 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 2000 IT’S DAY. • MIXING ONLY • REMARK: 1 TO 1.5 HOURS PER BATCH, IF 8 HOURS DAY, 2500 IT’S TO 4000 DAY. QUANTITY: 1 Learn More -

DORNIER PTS4/S RAPIER LOOM SETUP TO WEAVE, WIDTH 1900mm, YEAR 2016REFERENCE NUMBER: T-6980 DORNIER PTS4/S RAPIER LOOM SETUP TO WEAVE, WIDTH 1900mm, YEAR 2016 DORNIER PTS4/S RAPIER LOOM SETUP TO WEAVE WIDTH 1900mm FLAT CARBON FIBER YARN YEAR 2016 (INCORPORATING ISUMI WEFT FEEDER AND TEXKIMP COMPOSITE 960 END CREEL) BRIEF TECHNICAL INFORMATION: MAKE AND TYPE: DORNIER PTS 4/S WEFT INSERTION: RAPIER RAPIER: FIXED / POSITIVE WEFT COLORS: 4 (ONLY 1 BEING USED) ECS SELECTORS: 4 WEFT FEED: ISUMI NO TWIST SINGLE FLAT YARN FEEDER MODEL WF-510 WARP FEED: 960 END TEXKIMP COMPOSITE CREEL TYPE CF-F SELVEDGE TYPE: CATCH SELVEDGE CUTTER LHS AND RHS PREINSTALLED SELVEDGE WASTE BIN: 1 DOBBY MODEL & TYPE: STAUBLI S3020 E3 INSTALLED LEVERS: 12 INSTALLED UNDERMOTIONS: 12 FRAMES SUPPLIED: 12 LOOM TAKE-UP: ELECTRICAL LOOM LET-OFF: ELECTRICAL CLOTH ROLLERS: 2 X AIR BARS FOR WINDING ONTO CARDBOARD TUBE HEALD WIRES: AS ON LOOMS CONTROL PANEL: 15 INCHES TOUCHSCREEN PANEL ERGOWEAVE SPARE PARTS & MANUALS: ALL RELATED SPARE PARTS AVAILABLE IN THE FACTORY ELECTRICAL SUPPLY: 3 PHASE 380-415V, 50Hz QUANTITY: 1 Learn More

DORNIER PTS4/S RAPIER LOOM SETUP TO WEAVE, WIDTH 1900mm, YEAR 2016REFERENCE NUMBER: T-6980 DORNIER PTS4/S RAPIER LOOM SETUP TO WEAVE, WIDTH 1900mm, YEAR 2016 DORNIER PTS4/S RAPIER LOOM SETUP TO WEAVE WIDTH 1900mm FLAT CARBON FIBER YARN YEAR 2016 (INCORPORATING ISUMI WEFT FEEDER AND TEXKIMP COMPOSITE 960 END CREEL) BRIEF TECHNICAL INFORMATION: MAKE AND TYPE: DORNIER PTS 4/S WEFT INSERTION: RAPIER RAPIER: FIXED / POSITIVE WEFT COLORS: 4 (ONLY 1 BEING USED) ECS SELECTORS: 4 WEFT FEED: ISUMI NO TWIST SINGLE FLAT YARN FEEDER MODEL WF-510 WARP FEED: 960 END TEXKIMP COMPOSITE CREEL TYPE CF-F SELVEDGE TYPE: CATCH SELVEDGE CUTTER LHS AND RHS PREINSTALLED SELVEDGE WASTE BIN: 1 DOBBY MODEL & TYPE: STAUBLI S3020 E3 INSTALLED LEVERS: 12 INSTALLED UNDERMOTIONS: 12 FRAMES SUPPLIED: 12 LOOM TAKE-UP: ELECTRICAL LOOM LET-OFF: ELECTRICAL CLOTH ROLLERS: 2 X AIR BARS FOR WINDING ONTO CARDBOARD TUBE HEALD WIRES: AS ON LOOMS CONTROL PANEL: 15 INCHES TOUCHSCREEN PANEL ERGOWEAVE SPARE PARTS & MANUALS: ALL RELATED SPARE PARTS AVAILABLE IN THE FACTORY ELECTRICAL SUPPLY: 3 PHASE 380-415V, 50Hz QUANTITY: 1 Learn More -

A-2534 PACKAGING FILM BLOWN MACHINE1. THE EFFICIENCY IS OBVIOUS BY INCORPORATING FREQUENCY CONVERSION CONTROL. 2. THE ELECTRICAL PARTS ARE ALL MADE OF INTERNATIONAL PARTS. Learn More

A-2534 PACKAGING FILM BLOWN MACHINE1. THE EFFICIENCY IS OBVIOUS BY INCORPORATING FREQUENCY CONVERSION CONTROL. 2. THE ELECTRICAL PARTS ARE ALL MADE OF INTERNATIONAL PARTS. Learn More